Escolar Documentos

Profissional Documentos

Cultura Documentos

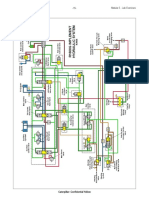

015 VA1 BSWS 00100 GE M3 PID 0040 Legend and Symbols

Enviado por

Scribd_delDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

015 VA1 BSWS 00100 GE M3 PID 0040 Legend and Symbols

Enviado por

Scribd_delDireitos autorais:

Formatos disponíveis

NC

LO

LC

FO

FC

FL

FI

ISA

GF0F1F2F3FN

A1A2ANA3

GF0F1F2F3FNA1ANA3

ISA ISA

LS HH HIGH HIGH

H HIGH (MAX)

L LOW (MAX)

LL LOW LOW

SIGNAL SENT TO DCS OR

SIGNAL RECEIVED FROM DCS

VALVES, EQUIPMENT, PIPING SPECIALTIES

AND INLINE INSTRUMENTS

NOMINAL DIAMETER

PIPE SPECIFICATION

INSULATION

PIPE RUN

OPERATING TEMP. AND PRESS.

DESIGN TEMP. AND PRESS.

FLOW RATE

* NOTE: FLAG POINTS IN

DIRECTION OF FLOW

GF0F1F2F3FN

GF0F1F2F3FN

A1A2ANA3

A1A2ANA3

ISA CODE

LOCALLY MOUNTED

INDICATOR OR CONTROL

SIGNAL TO OR FROM OTHER

CONTROL SYSTEM (EG PLC)

PROCESS CODE

LOCATION CODE

OFFLINE INSTRUMENTS

GF0F1F2F3FNA1ANA3 LOCATION CODE

PROCESS CODE

PROCESS CODE

LEVEL ALARMS FOR SWITCHES

DN 100-AAABCZS-N

FR

GF0F1F2F3FN

A1A2ANA3

GF0F1F2F3FNA1ANA3

GF0F1F2F3FN

A1A2ANA3

GF0F1F2F3FNA1ANA3

999kPa(g) 99C

999kPa(g) 99C

999 kg/h

PIPING & INSTRUMENTATION DIAGRAM

LEGEND SHEET (SYMBOLS, CODES & DESIGNATORS)

VA1-BSWS-00100-GE-M3-PID-0040

A FIRST SUBMISSION ZHM ASG CSP 19.01.10

12 = 125 POUND CLASS

15 = 150 POUND CLASS

17 = 200 POUND CLASS

30 = 300 POUND CLASS

60 = 600 POUND CLASS

90 = 900 POUND CLASS

150 = 1500 POUND CLASS

250 = 2500 POUND CLASS

450 = 4500 POUND CLASS

"S" IS PLACED AT THE END OF ANY LINE

SPECIFICATION THAT IS NO LONGER A

STANDARD BUT HAS BECOME PROJECT

SPECIFIC.

A = CARBON STEEL

B = CARBON STEEL (LOW TEMP. & PRESS.)

C = ALLOY

D = STAINLESS STEEL

E = CAST IRON

F = DUCTILE IRON

G = GALVANIZED CARBON STEEL STEEL

H = POLYPROPYLENE LINED CARBON STEEL

J = NON-METAL (HDPE, PVC, ETC.)

K = CONCRETE/ STEEL

M = COPPER

Q = TUBING

NONE = B31.1

4 = NFPA

5 = AWWA

6 = PLUMBING

9 = B31.3

AAA B

C

S

PIPE SPECIFICATION

F1F2F3 A1A2

Z

SEQUENTIAL NUMBER

VALVES, DAMPERS, ETC.

MIXERS, AGITATORS

COMPRESSOR UNITS, FANS, BLOWERS

PUMP UNITS

CLEANING, DRYING, FILTERING, SEPARATING EQUIPMENT

VESSELS, STORAGE TANKS

JET PUMPS, EJECTORS, INJECTORS

FLOW RESTRICTORS, LIMITERS, ORIFICES

PIPING

SILENCERS

FLOW MEASUREMENT

LEVEL MEASUREMENT

PRESSURE MEASUREMENT

QUALITY VARIABLES (ANALYSIS, MATERIAL PROPERTIES)

001 - 099

501 - 599

901 - 999

001 - 099

101 - 199

201 - 299

301 - 399

401 - 499

501 - 599

601 - 699

701 - 799

801 - 899

901 - 999

001 - 099

101 - 199

401 - 499

501 - 599

601 - 699

ABOVE GROUND LARGE BORE PIPING

ABOVE GROUND SMALL BORE PIPING

UNDERGROUND PIPING

AA

AM

AN

AP

AT

BB

BN

BP

BR

BS

CF

CL

CP

CQ

ACTUATED CONTROL VALVES

SELF-REGULATING VALVES

MOTOR OPERATED ON-OFF VALVES

PISTON OPERATED ON-OFF VALVES

SOLENOID OPERATED VALVES

MANUAL OPERATED VALVES

SAFETY AND RELIEF VALVES

CHECK VALVES

VENT AND DRAIN VALVES

INSTRUMENT ROOT VALVES

TRANSMITTERS

SWITCHES

LOCAL TEST POINTS

LOCAL INDICATOR

PRIMARY ELEMENT

PIPING

VALVES

INSTRUMENT / CONTROL

EQUIPMENT UNIT CODE ( )

EQUIPMENT UNIT CODE ( )

FUNCTION KEY ( )

PROCESS RELATED CODE:

LOCATION CODE:

A1:

R ROOM

S FIRE AREA

A2 IS NOT USED

AN

PROCESS RELATED CODE:

LOCATION CODE:

ROOM NUMBER:

STARTING WEST TO EAST

AND THEN SOUTH TO NORTH

PRIMARY ELEMENT, ANALYSIS

PRIMARY ELEMENT, FLOW

INDICATOR, FLOW

INDICATING TRANSMITTER, FLOW

GAUGE GLASS, LEVEL

INDICATING TRANSMITTER, LEVEL

SWITCH, LEVEL

INDICATOR, PRESSURE DIFF.

TRANSMITTER, PRESSURE DIFF.

INDICATOR, PRESSURE

SWITCH, PRESSURE

AE

FE

FI

FIT

LG

LIT

LS

PDI

PDT

PI

PS

ISA DESIGNATOR

DISTANCE, LENGTH, POSITION CG

QUALITY VARIABLES (ANALYSIS, MATERIAL PROPERTIES) FQ

GAC

GAD

GAF

GBB

GBK

GBN

GBS

GCB

GCF

GCK

GCN

GCP

GCR

GHD

GHF

GHH

GME

GNB

GNC

GND

GNK

QFG

PIPING AND CHANNEL SYSTEM

STORAGE SYSTEM

PUMP SYSTEM

FILTERING, MECHANICAL CLEANING SYSTEM

PIPING SYSTEM, TEMPORARY STORAGE SYSTEM, PUMP SYSTEM FOR MAIN FLUID

CHEMICAL SUPPLY SYSTEM

SLUDGE THICKENING SYSTEM

FILTERING, MECHANICAL CLEANING SYSTEM

ION EXCHANGE, REVERSE OSMOSIS SYSTEM

PIPING SYSTEM, TEMPORARY STORAGE SYSTEM, PUMP SYSTEM FOR MAIN FLUID

CHEMICAL SUPPLY SYSTEM

REGENERATION, FLUSHING EQUIPMENT

FLUSHING WATER AND RESIDUE REMOVAL SYSTEM

SERVICE WATER DISTRIBUTION - FIRE PROTECTION

SERVICE WATER DISTRIBUTION - WATER & WASTEWATER AREA

DEMINERALIZED WATER DISTRIBUTION SYSTEM

PROCESS DRAINS COLLECTION AND DRAINAGE

FILTERING, MECHANICAL CLEANING SYSTEM

AERATION, GAS INJECTION SYSTEM

PRECIPITATION SYSTEM

PIPING SYSTEM, TEMPORARY STORAGE SYSTEM,

GENERAL CONTROL AIR SUPPLY, WATER AND WASTEWATER

(G) WATER SUPPLY AND DISPOSAL

(GC) TREATMENT SYSTEM (DEMINERALIZATION)

(GH) DISTRIBUTION SYSTEMS (NOT DRINKING WATER)

(GK) POTABLE WATER SUPPLY

GKF POTABLE WATER DISTRIBUTION

(GN) PROCESS DRAIN TREATMENT

INSULATION

AC

AS

HC

PF

PP

N

ACOUSTIC CONTROL

ANTI - SWEAT

HEAT CONSERVATION

FREEZE PROTECTION

PERSONNEL PROTECTION

NONE

F1F2F3 FUNCTION KEY ( )

PUMP SYSTEM FOR MAIN FLUID

GBL

GBP

GBQ

STORAGE SYSTEM OUTSIDE FLUID TREATMENT SYSTEM

REGENERATION, FLUSHING EQUIPMENT

INJECTION SYSTEM FOR MAIN FLUID

(GD) TREATMENT SYSTEM (DISTRICT HEATING WATER)

GBD

GDK

FILTERING, MECHANICAL CLEANING SYSTEM

PIPING SYSTEM, TEMPORARY STORAGE SYSTEM, PUMP SYSTEM FOR MAIN FLUID

GNN

GNP

GNR

CHEMICALS SUPPLY SYSTEM

REGENERATION, FLUSHING EQUIPMENT

FLUSHING WATER AND RESIDUES REMOVAL SYSTEM INCL.

NEUTRALIZATION

GNQ INJECTION SYSTEM FOR MAIN FLUID

GCC AERATION, GAS INJECTION SYSTEM

GCL STORAGE SYSTEM OUTSIDE FLUID TREATMENT SYSTEM

SWITCH, POSITION/DIMENSION ZS

B SECOND SUBMISSION ZHM ASG CSP 23.04.10

AIT

PDS

(GA) RAW WATER SUPPLY

(GB) TREATMENT SYSTEM (CARBONATE HARDNESS REMOVAL)

SWITCH, PRESSURE DIFF.

INDICATING TRANSMITTER, ANALYSIS

ZHM

ASG

CSP

01.07.10

C N.T.S

01.07.10

01.07.10

VUNG ANG 1 THERMAL POWER PLANT 2 x 600MW

01/v0PP - LlLAVA/01-2009/vA1

120110/LILAMA-BOUSTEAD SALCON

FICHTNER GmbH & Co. KG

THIRD SUBMISSION ZHM ASG CSP 01.07.10

FOR APPROVAL

C

Você também pode gostar

- B Dep Piping and Instrument Diagram AppendixDocumento69 páginasB Dep Piping and Instrument Diagram AppendixAKSHEYMEHTA87% (15)

- China Tariffs ListDocumento28 páginasChina Tariffs ListBrett LoGiurato100% (17)

- Water Network Development: Standard DrawingsDocumento40 páginasWater Network Development: Standard Drawingsabdul jackil100% (1)

- Water Pipe SizingDocumento40 páginasWater Pipe SizingAfzal Khan100% (2)

- Serv1852 02 TXT2 PDFDocumento24 páginasServ1852 02 TXT2 PDFابو احمد100% (13)

- Cryogenic LNG LPG Type Product Group 800Documento16 páginasCryogenic LNG LPG Type Product Group 800Thiên KhánhAinda não há avaliações

- Pump Training Slides Slides 1 - 20Documento20 páginasPump Training Slides Slides 1 - 20Jegede OluwaseunAinda não há avaliações

- NSRP Refinery Plant Environmental Impact AssessmentDocumento115 páginasNSRP Refinery Plant Environmental Impact AssessmentScribd_del88% (8)

- Centrifugal Pump Sizing, Selection and Design Practices (Hay)Documento77 páginasCentrifugal Pump Sizing, Selection and Design Practices (Hay)Scribd_del75% (8)

- AP-1055B ASPHALT PAVER 8BM Diagrama Hidraulico PDFDocumento2 páginasAP-1055B ASPHALT PAVER 8BM Diagrama Hidraulico PDFchakroune100% (1)

- HES Bid Set Plumbing DrawingsDocumento18 páginasHES Bid Set Plumbing DrawingsTeukuJoharAinda não há avaliações

- Cryogel Pipe Install ManualDocumento35 páginasCryogel Pipe Install ManualDiego CarrascalAinda não há avaliações

- SERVA Pumps C-Pumps 052918p en Screen 0711Documento50 páginasSERVA Pumps C-Pumps 052918p en Screen 0711Ilham Nugroho100% (2)

- Va1 Dec 00100 I M1D Pid 0001 PDFDocumento2 páginasVa1 Dec 00100 I M1D Pid 0001 PDFAnonymous JtYvKt5XEAinda não há avaliações

- AC-036484-001 WN Flanges and Blind FlangesDocumento1 páginaAC-036484-001 WN Flanges and Blind Flangesnarutothunderjet216Ainda não há avaliações

- 57326274Documento7 páginas57326274Inkanata SacAinda não há avaliações

- ABO Ball ValveDocumento6 páginasABO Ball ValveSunil BajpaiAinda não há avaliações

- Gas Vessel PecoDocumento16 páginasGas Vessel PecopsycopaulAinda não há avaliações

- Filtration in HydrotreatingDocumento2 páginasFiltration in Hydrotreatingck196548400% (1)

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocumento20 páginasBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelAinda não há avaliações

- Environment Baseline SURVEY Report For Nghi Son Refinery Petrochemical ComplexDocumento159 páginasEnvironment Baseline SURVEY Report For Nghi Son Refinery Petrochemical ComplexScribd_delAinda não há avaliações

- Standard Hook-Up Wires & Cables For ElectronicsDocumento124 páginasStandard Hook-Up Wires & Cables For ElectronicsdlstoneAinda não há avaliações

- SY215C 9 Excavator PDF Valve Throttle (Revisi) PDFDocumento93 páginasSY215C 9 Excavator PDF Valve Throttle (Revisi) PDFSohibul AminAinda não há avaliações

- Coalescer PallDocumento16 páginasCoalescer PallJeEJyZaAinda não há avaliações

- ControlvalvesDocumento166 páginasControlvalvesboby730Ainda não há avaliações

- 503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFDocumento8 páginas503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFsvnaik14Ainda não há avaliações

- Bunner ControlDocumento19 páginasBunner ControlHai NguyenAinda não há avaliações

- Gas Filter Separators 4Documento8 páginasGas Filter Separators 4Anonymous bHh1L1Ainda não há avaliações

- Flowmeter Piping RequirementsDocumento4 páginasFlowmeter Piping RequirementsYoke ShuAinda não há avaliações

- Stainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Documento5 páginasStainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Utada HikaruAinda não há avaliações

- 06215E04Documento140 páginas06215E04Glad BlazAinda não há avaliações

- PP Aaa PP1 123Documento20 páginasPP Aaa PP1 123Rabah AmidiAinda não há avaliações

- High-Pressure Load-Sensing Control Block of Sandwich Plate DesignDocumento20 páginasHigh-Pressure Load-Sensing Control Block of Sandwich Plate Designeaglego00100% (1)

- Gen PNG STD 001 - 02Documento40 páginasGen PNG STD 001 - 02Jose C. MelendezAinda não há avaliações

- Pohokura DeckDocumento54 páginasPohokura DeckLynn BishopAinda não há avaliações

- Diesel Catalytic CrackingDocumento28 páginasDiesel Catalytic CrackingAdyAinda não há avaliações

- P & I Diagram: Koncept Learning CenterDocumento21 páginasP & I Diagram: Koncept Learning CenterIsaAl-rasyidAinda não há avaliações

- WKS G 8Documento23 páginasWKS G 8debu1985Ainda não há avaliações

- Civil and Structural Underground System, Site Finishing & Miscellaneous Construction StandardsDocumento63 páginasCivil and Structural Underground System, Site Finishing & Miscellaneous Construction StandardsKoshi DragonAinda não há avaliações

- Chapter 3 Warehouse LayoutsDocumento15 páginasChapter 3 Warehouse LayoutsSasank Sai100% (1)

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocumento1 página4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFshawonscribdAinda não há avaliações

- Mech STD Details IndexDocumento3 páginasMech STD Details IndexMarc AnmellaAinda não há avaliações

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Documento10 páginasDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182Ainda não há avaliações

- GSWC STANDARD DRAWINGS 2016 (Final Version) - Part 2Documento104 páginasGSWC STANDARD DRAWINGS 2016 (Final Version) - Part 2Hussein MohamedAinda não há avaliações

- JCSD Standards Manual 2011 - Sect6Documento111 páginasJCSD Standards Manual 2011 - Sect6cipele12Ainda não há avaliações

- Cone Design ToolDocumento1 páginaCone Design ToolPramod KumarAinda não há avaliações

- Distorsion Prevent by Pre Setting Pre Bending Use of RestraintDocumento4 páginasDistorsion Prevent by Pre Setting Pre Bending Use of RestraintMathew RodriguezAinda não há avaliações

- Seprasol Plus: Liquid/Gas CoalescersDocumento4 páginasSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiAinda não há avaliações

- Professional Resume FormatDocumento3 páginasProfessional Resume FormatsankalpadixitAinda não há avaliações

- Chiyoda Malaysia Sdn. BHD.: Anuj Maifeng Winms Anuj Maifeng WinmsDocumento4 páginasChiyoda Malaysia Sdn. BHD.: Anuj Maifeng Winms Anuj Maifeng WinmsmeeAinda não há avaliações

- NGL1 V1 Sec 4Documento218 páginasNGL1 V1 Sec 4varatharajan g rAinda não há avaliações

- Air ComprDocumento118 páginasAir ComprMoaaz KhanAinda não há avaliações

- Standard Drawings 1Documento12 páginasStandard Drawings 1api-3698996Ainda não há avaliações

- Bombas Centrífugas GeralDocumento125 páginasBombas Centrífugas GeralJonatasAinda não há avaliações

- Safety Valve Technical DetailsDocumento5 páginasSafety Valve Technical DetailsvineethvskkdAinda não há avaliações

- Indirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhDocumento6 páginasIndirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhMuhammad AhsanAinda não há avaliações

- Especificaciones de Construcción de Trabajo para La Gestión de Las Actividades de SoldaduraDocumento14 páginasEspecificaciones de Construcción de Trabajo para La Gestión de Las Actividades de SoldaduraMartin Morales RodriguezAinda não há avaliações

- PP Aaa PP1 117Documento15 páginasPP Aaa PP1 117Rabah AmidiAinda não há avaliações

- Dezurik Awwa Butterfly Valves Baw Technical 43 - 00 - 2 PDFDocumento24 páginasDezurik Awwa Butterfly Valves Baw Technical 43 - 00 - 2 PDFANILAinda não há avaliações

- 6 SS Direct Fired Air HeaterDocumento1 página6 SS Direct Fired Air HeaterYhony Gamarra VargasAinda não há avaliações

- Nicole Balani Almachar: ObjectiveDocumento2 páginasNicole Balani Almachar: ObjectiveMichael Silva100% (1)

- UnderHung Scaffold ChecklistDocumento2 páginasUnderHung Scaffold Checklistomar santosAinda não há avaliações

- Conical StrainerDocumento2 páginasConical StrainernguyennhatbaoAinda não há avaliações

- P & I Diagram: Koncept Learning CenterDocumento8 páginasP & I Diagram: Koncept Learning CenterediabcAinda não há avaliações

- Quick-Opening Closures SurveyDocumento13 páginasQuick-Opening Closures SurveyAjmi HmidaAinda não há avaliações

- PP Aaa PP1 145Documento13 páginasPP Aaa PP1 145Rabah AmidiAinda não há avaliações

- Flare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out Flare GuidelinesDocumento7 páginasFlare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out Flare GuidelinesRebekah SchmidtAinda não há avaliações

- Cold Pipe Shoe - Weight&DimensionDocumento1 páginaCold Pipe Shoe - Weight&DimensionB GirishAinda não há avaliações

- Exxon Mobile Colour - Code For PaintingDocumento1 páginaExxon Mobile Colour - Code For PaintingellamellamAinda não há avaliações

- Gilman Boiler Control Expo06Documento41 páginasGilman Boiler Control Expo06Tapiwa MuzondoAinda não há avaliações

- Thermal Power Plant - General Technical RequirementsDocumento59 páginasThermal Power Plant - General Technical RequirementsScribd_delAinda não há avaliações

- Commissioning Manual - M456 Package. - UnofficialDocumento71 páginasCommissioning Manual - M456 Package. - Unofficialphuocduy86Ainda não há avaliações

- Water Lifting Devices - Section 0 - CONTENTSDocumento17 páginasWater Lifting Devices - Section 0 - CONTENTSScribd_delAinda não há avaliações

- NSRP Overview (From WWW - Idemitsu.com)Documento2 páginasNSRP Overview (From WWW - Idemitsu.com)Scribd_delAinda não há avaliações

- 2009.oct.26 - VA1 - QA-QC Flow Chart Official)Documento2 páginas2009.oct.26 - VA1 - QA-QC Flow Chart Official)Scribd_delAinda não há avaliações

- To Zen General CatalogueDocumento18 páginasTo Zen General CatalogueReza TambaAinda não há avaliações

- Valves: "Hose Bibb"Documento3 páginasValves: "Hose Bibb"queeneequeeneeAinda não há avaliações

- Sect. 1 Technical Data PC7 2106A1350Documento8 páginasSect. 1 Technical Data PC7 2106A1350Alexis MikeAinda não há avaliações

- Atlas Copco Drilling Solutions: Part List Model: Dm50/Lp S/N: US009240Documento790 páginasAtlas Copco Drilling Solutions: Part List Model: Dm50/Lp S/N: US009240Nasrul arul100% (1)

- R K Bansal-A Textbook of Fluid Mechanics and Hydraulic Machines - by EasyEngineering - Net-1101-1125Documento25 páginasR K Bansal-A Textbook of Fluid Mechanics and Hydraulic Machines - by EasyEngineering - Net-1101-1125Shanawas Abdul RazakAinda não há avaliações

- File For Parts Bricks Lining Machine and UT PumopDocumento7 páginasFile For Parts Bricks Lining Machine and UT Pumopranjan shiveshAinda não há avaliações

- Pro PDF p27Documento1 páginaPro PDF p27Андрей НавAinda não há avaliações

- Hydraulics Part List March2013 Rexroth LineDocumento5 páginasHydraulics Part List March2013 Rexroth LineDaniela SouzaAinda não há avaliações

- Matering Dispensing Valve BrochureDocumento8 páginasMatering Dispensing Valve BrochureThomas HaböckAinda não há avaliações

- HIDRAULICADocumento1 páginaHIDRAULICAcesarAinda não há avaliações

- Mitsubishi Electric PUHY-P YKB-A1 Service Parts EngDocumento25 páginasMitsubishi Electric PUHY-P YKB-A1 Service Parts EngBranko VeskovicAinda não há avaliações

- DSFFDFSDDocumento2 páginasDSFFDFSDSanjay MehtaAinda não há avaliações

- Jet Pumps & BoostersDocumento24 páginasJet Pumps & BoosterscihuyAinda não há avaliações

- Utilities Pugeda Quiz 5Documento4 páginasUtilities Pugeda Quiz 5klikbayt0.1Ainda não há avaliações

- HSV5 TBDocumento15 páginasHSV5 TBSaad AttarAinda não há avaliações

- Espring Service PartsDocumento4 páginasEspring Service PartstsoukerAinda não há avaliações

- Concentrate Control System: Operating, Maintenance, and Filling ManualDocumento24 páginasConcentrate Control System: Operating, Maintenance, and Filling ManualSadegh AhmadiAinda não há avaliações

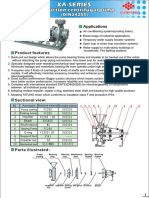

- Evergush Xa en 50hzDocumento15 páginasEvergush Xa en 50hzFikry HarzanAinda não há avaliações

- 4c-Iso Certificate PDFDocumento2 páginas4c-Iso Certificate PDFashish kumar pandeyAinda não há avaliações

- Slide Valve SV and SV1 Series (U)Documento9 páginasSlide Valve SV and SV1 Series (U)Enis LoureiroAinda não há avaliações

- BoQ MEP Club House KosongDocumento53 páginasBoQ MEP Club House KosongkelikAinda não há avaliações