Escolar Documentos

Profissional Documentos

Cultura Documentos

Hex BoltNut 325US

Enviado por

api-3712612Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hex BoltNut 325US

Enviado por

api-3712612Direitos autorais:

Formatos disponíveis

Hexagon Bolt and Nut Sizes ¤

Determine the maximum IMPORTANT

torque according to the bolt The hexagon sizes shown in the

(nut) size and grade. Always tables below should be used as a

consult the manufacturer’s guide only. Individual sizes should be

instructions or engineering recommen- checked before specifying any equipment.

dations when making bolted

connections.

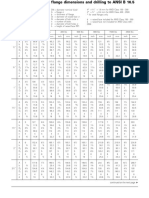

Metric Sizes Imperial Sizes

S J S J

D D

Hexagon Thread Hexagon Hexagon Thread Hexagon

Size Size Size Size Size Size

S D J S D J

(mm) (mm) (mm) (inch) (inch) (inch)

17 M 10 8 11/16 5/8 1/2

19 M 12 10 11/4 3/4 5/8

22 M 14 12 17/16 7/8 3/4

24 M 16 14 15/8 1 3/4

27 M 18 14 113/16 11/8 7/8

30 M 20 17 2 11/4 7/8

32 M 22 17 3

2 /16 13/8 1

36 M 24 19 23/8 11/2 1

41 M 27 19 29/16 15/8 -

46 M 30 22 23/4 13/4 11/4

50 M 33 24 215/16 17/8 13/8

55 M 36 27 3 2 11/2

60 M 39 27 (30) 31/8 2 15/8

65 M 42 32 33/8 21/4 13/4

70 M 45 - 31/2 21/4 13/4

75 M 48 36 33/4 21/2 13/4

80 M 52 36 37/8 21/2 17/8

85 M 56 41 41/8 23/4 2

90 M 60 46 41/4 23/4 2

95 M 64 46 45/8 3 21/4

100 M 68 50 5 31/4 21/4

105 M 72 55

110 M 76 60

Use only Heavy-duty Impact

115 M 80 65 Sockets for power driven

120 M 85 70 torquing equipment,

130 M 90 70 (75) according to ISO 2725 and

135 M 95 - ISO 1174; DIN 3129 and DIN 3121 or

145 M 100 85 ASME-B107.2/1995.

150 M 105 -

155 M 110 -

165 M 115 -

170 M 120 -

180 M 125 -

185 M 130 -

200 M 140 -

210 M 150 -

228

Você também pode gostar

- Dimensions For Nuts: Din/Iso Din/IsoDocumento1 páginaDimensions For Nuts: Din/Iso Din/IsoAlexandre Caciano dos SantosAinda não há avaliações

- Everest Tools Socket Price ListDocumento18 páginasEverest Tools Socket Price ListinderAinda não há avaliações

- Pipe TableDocumento25 páginasPipe TableMarde Vinson OpamenAinda não há avaliações

- En 13121-3 Bridas Pn10Documento1 páginaEn 13121-3 Bridas Pn10Ricardo BustamanteAinda não há avaliações

- Din Flange Din 2627: (Dimensions in MM.)Documento12 páginasDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönAinda não há avaliações

- Inch and Metric Hex Bolt and Socket Cap Screw Tool Size Chart Northwest FastenerDocumento1 páginaInch and Metric Hex Bolt and Socket Cap Screw Tool Size Chart Northwest FastenerPankaj MauryaAinda não há avaliações

- SAE FlangesDocumento12 páginasSAE Flangesra5tr@Ainda não há avaliações

- Brochure Reamers Type DDocumento2 páginasBrochure Reamers Type DPatrizio MassaroAinda não há avaliações

- جدول روابط تخصصی فصل 5Documento27 páginasجدول روابط تخصصی فصل 5mehdi rezaeiAinda não há avaliações

- Reference Card PDFDocumento2 páginasReference Card PDFroshan mungurAinda não há avaliações

- Tuercas MariposaDocumento1 páginaTuercas MariposaarrancatetasAinda não há avaliações

- Mss SP 97 DimensionsDocumento9 páginasMss SP 97 DimensionsMichał KlebanAinda não há avaliações

- Stainless steel fittings guideDocumento7 páginasStainless steel fittings guideKoya ThangalAinda não há avaliações

- PLASTIC BEARING UNITS FOR SUPPORT AND GUIDANCEDocumento8 páginasPLASTIC BEARING UNITS FOR SUPPORT AND GUIDANCEAlex MathewAinda não há avaliações

- KG Web Products ENGDocumento7 páginasKG Web Products ENGocean blueAinda não há avaliações

- 10.flange Bolts, STD TeesDocumento7 páginas10.flange Bolts, STD TeesNIRMAL SINGHAinda não há avaliações

- 7698 enDocumento1 página7698 enl_aguilar_mAinda não há avaliações

- RTJ Flange Dimensions Guide for Classes 150-2500Documento25 páginasRTJ Flange Dimensions Guide for Classes 150-2500SaekhuAinda não há avaliações

- Tap & Die Set-Hss: in Metal Cases DIN StandardsDocumento3 páginasTap & Die Set-Hss: in Metal Cases DIN StandardsnateAinda não há avaliações

- Plain Bearing Shells Type GDocumento8 páginasPlain Bearing Shells Type GAlex SeguidaAinda não há avaliações

- 3mas Afg M M (3000-6000 Psi)Documento1 página3mas Afg M M (3000-6000 Psi)Velibor KaranovicAinda não há avaliações

- Pipetable - ENDocumento20 páginasPipetable - ENMircea Dan StanciuAinda não há avaliações

- RR Items ReportsDocumento54 páginasRR Items ReportsShaikh AdilAinda não há avaliações

- Econ Ball Valves, Carbon Steel, Full Bore DIN PN 500 - 100, Blow-Out Proof StemDocumento1 páginaEcon Ball Valves, Carbon Steel, Full Bore DIN PN 500 - 100, Blow-Out Proof StemChristianGuerreroAinda não há avaliações

- 113 PDFDocumento1 página113 PDFChristianGuerreroAinda não há avaliações

- Hot Rolled Round Steel BarsDocumento20 páginasHot Rolled Round Steel BarsNomoAinda não há avaliações

- Codigo Rosca Unf Tubo LDocumento4 páginasCodigo Rosca Unf Tubo LEric RegaladoAinda não há avaliações

- ISO 7089 (Washer)Documento1 páginaISO 7089 (Washer)anks_raAinda não há avaliações

- Brida 150 LBDocumento1 páginaBrida 150 LBIngenieria BaldarragoAinda não há avaliações

- V Belts Standard DimenionsDocumento2 páginasV Belts Standard DimenionsAbu BakarAinda não há avaliações

- Identificación de RoscasDocumento7 páginasIdentificación de RoscasEduAinda não há avaliações

- Hexagon Nut DrillingDocumento1 páginaHexagon Nut DrillingMeravigliorso76Ainda não há avaliações

- Wire Rope Cutting ChartDocumento8 páginasWire Rope Cutting ChartAkash SharmaAinda não há avaliações

- T 69 UDocumento1 páginaT 69 URenny DevassyAinda não há avaliações

- Pages From Operation 78ed 176eedv400 - eDocumento8 páginasPages From Operation 78ed 176eedv400 - eNaresh KumarAinda não há avaliações

- SL MILLIARD 1 Sept 2021Documento1 páginaSL MILLIARD 1 Sept 2021Farah SilviramAinda não há avaliações

- TDC British Standard Pipe ThreadsDocumento1 páginaTDC British Standard Pipe ThreadsvmuthubharathAinda não há avaliações

- Hreaded Ccessories: FIG. 38 Forged Steel ClevisDocumento1 páginaHreaded Ccessories: FIG. 38 Forged Steel Clevisabhishek yadavAinda não há avaliações

- C 3 ShaferDocumento1 páginaC 3 ShaferSebastin DrignyAinda não há avaliações

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs MSS SP97 PDFDocumento3 páginasDimensions of Sockolets Pressure Class 3000 and 6000 Lbs MSS SP97 PDFmarkoredsAinda não há avaliações

- B16.5 Size ListDocumento3 páginasB16.5 Size ListSue EpicAinda não há avaliações

- Nut Tightening TorquesDocumento1 páginaNut Tightening TorquesHendra MonoAinda não há avaliações

- Conveyor Chains | DIN 8167 / M Series Specs & Weight TablesDocumento3 páginasConveyor Chains | DIN 8167 / M Series Specs & Weight TablesMaiquel Eduardo ErnAinda não há avaliações

- Rfs Hydraulic Sae FlangesDocumento10 páginasRfs Hydraulic Sae Flangeskeerthiphotography1992Ainda não há avaliações

- Bolt Stud Dimensions For FlangesDocumento1 páginaBolt Stud Dimensions For FlangesMULAYAM SINGH YADAVAinda não há avaliações

- Ryco Hose Ends CatalogsDocumento55 páginasRyco Hose Ends Catalogsjob saputraAinda não há avaliações

- UCP 213 Y UCP 215 - FYHcat3300 PDFDocumento1 páginaUCP 213 Y UCP 215 - FYHcat3300 PDFFranz Alex Fernandez CeronAinda não há avaliações

- Rexnord 2 Bolt Pillow BlockDocumento30 páginasRexnord 2 Bolt Pillow BlockAnonymous qfrYnT7LAQAinda não há avaliações

- IDENTIFY HYDRAULIC FITTINGSDocumento1 páginaIDENTIFY HYDRAULIC FITTINGShelderfgmAinda não há avaliações

- AsturFluid S.LDocumento1 páginaAsturFluid S.LvasotermiAinda não há avaliações

- Stainless Steel Weld Neck Flange Technical Data Sheet: TypeDocumento5 páginasStainless Steel Weld Neck Flange Technical Data Sheet: TypeÁngela GarzónAinda não há avaliações

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Documento8 páginasInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)ranjitkumar1977Ainda não há avaliações

- Cutting Tips and Specs for Victor Series 3 Acetylene TorchDocumento3 páginasCutting Tips and Specs for Victor Series 3 Acetylene TorchcarlosAinda não há avaliações

- FT Brida SW 150 LBSDocumento1 páginaFT Brida SW 150 LBSFernando CarreñoAinda não há avaliações

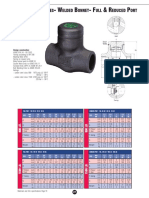

- C V - W B - F & R P: Heck Alves Elded Onnet ULL Educed ORTDocumento1 páginaC V - W B - F & R P: Heck Alves Elded Onnet ULL Educed ORTMostafizur RahmanAinda não há avaliações

- Fusion Series 322 Threaded Ball ValveDocumento2 páginasFusion Series 322 Threaded Ball ValveOceanexAinda não há avaliações

- Manuli: M22512 Jic Female 74º Cone Seat (Thrust-Wire Nut)Documento1 páginaManuli: M22512 Jic Female 74º Cone Seat (Thrust-Wire Nut)Rogger TonoliAinda não há avaliações

- Package QuantityDocumento3 páginasPackage QuantitymirosekAinda não há avaliações

- Margeau Chapeau: A New Perspective on Classic Knit HatsNo EverandMargeau Chapeau: A New Perspective on Classic Knit HatsNota: 3.5 de 5 estrelas3.5/5 (6)

- Y StrainrDocumento2 páginasY Strainrapi-3712612Ainda não há avaliações

- Seamless Pipe FittingsDocumento3 páginasSeamless Pipe Fittingsapi-3712612Ainda não há avaliações

- Pipe FittingsDocumento5 páginasPipe Fittingsapi-3712612Ainda não há avaliações

- Bolt Sizes and DimensionsDocumento1 páginaBolt Sizes and DimensionsgilbnyAinda não há avaliações

- Clear Y StrainersDocumento2 páginasClear Y Strainersapi-3712612100% (1)

- FastenersDocumento17 páginasFastenersapi-3712612Ainda não há avaliações

- Bolt Size ConversionDocumento3 páginasBolt Size Conversionapi-3712612100% (3)

- Norm Ex ValvesDocumento6 páginasNorm Ex Valvesapi-3712612Ainda não há avaliações

- Butterfly Valve Assemblies Tech SheetDocumento16 páginasButterfly Valve Assemblies Tech Sheetapi-3712612Ainda não há avaliações

- MillimetersDocumento1 páginaMillimetersapi-3712612Ainda não há avaliações

- Red Bag StandardsDocumento7 páginasRed Bag Standardsapi-3712612Ainda não há avaliações

- Approximate Weight.24.01.08Documento14 páginasApproximate Weight.24.01.08api-3712612Ainda não há avaliações

- Approximate Weight.24.01Documento14 páginasApproximate Weight.24.01api-3712612Ainda não há avaliações

- Excavation Safety GuideDocumento62 páginasExcavation Safety Guideallen 5222100% (1)

- 01 - Introduction To Aircraft DrawingDocumento33 páginas01 - Introduction To Aircraft Drawing14Muhammad Abdur RakhmanAinda não há avaliações

- Espectrómetro FT-IR Nicolet Is 10Documento1 páginaEspectrómetro FT-IR Nicolet Is 10Adriano BludegardAinda não há avaliações

- New Consultant List 20177 For Cea Website 10.02.2016Documento4 páginasNew Consultant List 20177 For Cea Website 10.02.2016hxian.y9333Ainda não há avaliações

- Customer service records for auto repairsDocumento30 páginasCustomer service records for auto repairsAsad LaghariAinda não há avaliações

- TBR Wipro LeanDocumento8 páginasTBR Wipro LeanAnonymous fVnV07HAinda não há avaliações

- SeminarDocumento4 páginasSeminarmukulAinda não há avaliações

- Static Electricity and Charge AccumulationDocumento75 páginasStatic Electricity and Charge AccumulationArjav DesaiAinda não há avaliações

- Mosquito RepellentDocumento6 páginasMosquito RepellentJai MurugeshAinda não há avaliações

- SailPointCustomConnectors PDFDocumento17 páginasSailPointCustomConnectors PDFprudhvi reddy0% (1)

- Residual Life Assessment and Failure of The BoilerDocumento21 páginasResidual Life Assessment and Failure of The BoilernagasureshAinda não há avaliações

- IBM-Tandy Guide for Secret Weapons of the LuftwaffeDocumento41 páginasIBM-Tandy Guide for Secret Weapons of the Luftwaffetestinghb100% (1)

- Cathode Ray Oscilloscope (Cro)Documento2 páginasCathode Ray Oscilloscope (Cro)jesunathan44@yahoo.comAinda não há avaliações

- Chapter 5-The Memory SystemDocumento80 páginasChapter 5-The Memory Systemjsanandkumar22Ainda não há avaliações

- SATIP-H-100-01 Rev 8Documento4 páginasSATIP-H-100-01 Rev 8SajjadPervaiz100% (2)

- Static Analysis of VMC Spindle For Maximum Cutting Force: Mahesh M. Ghadage Prof. Anurag V. KarandeDocumento5 páginasStatic Analysis of VMC Spindle For Maximum Cutting Force: Mahesh M. Ghadage Prof. Anurag V. Karandefujy fujyAinda não há avaliações

- DTH Drilling MachineDocumento8 páginasDTH Drilling MachineREL PromoAinda não há avaliações

- Geotech Final ReportDocumento38 páginasGeotech Final Reportapi-320590292Ainda não há avaliações

- Seismic Analysis of A Valley-Fill Heap Leach PadDocumento17 páginasSeismic Analysis of A Valley-Fill Heap Leach PadMARCOS ABRAHAM ALEJANDRO BALDOCEDA HUAYASAinda não há avaliações

- Pilot Operated Safety Relief ValvesDocumento6 páginasPilot Operated Safety Relief ValvesfabioAinda não há avaliações

- Nitotile Fix PRO - High performance tile adhesiveDocumento2 páginasNitotile Fix PRO - High performance tile adhesivetalatzahoorAinda não há avaliações

- Norma Astm A234 WPBDocumento6 páginasNorma Astm A234 WPBJuan Carlos CastroAinda não há avaliações

- Household Electricity End-Use ConsumptionDocumento22 páginasHousehold Electricity End-Use ConsumptionEva ViskadourakiAinda não há avaliações

- Thermocouple & PRT Cable Selection GuideDocumento15 páginasThermocouple & PRT Cable Selection Guidetees220510Ainda não há avaliações

- Mine Design and SchedulingDocumento10 páginasMine Design and SchedulingLeandro FagundesAinda não há avaliações

- 90ma012 - CarrierDocumento32 páginas90ma012 - Carrierrafaelpaiva871531Ainda não há avaliações

- Ktu Laca Solved Question PaperDocumento22 páginasKtu Laca Solved Question PaperSofiyaAinda não há avaliações

- RtosDocumento78 páginasRtossekinAinda não há avaliações

- Atlas of Furniture DesignDocumento2 páginasAtlas of Furniture DesignDeepanjan Kumar0% (4)