Escolar Documentos

Profissional Documentos

Cultura Documentos

ISO/IEC 17025 Requirements for Calibration Laboratories

Enviado por

Ali ZafarDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ISO/IEC 17025 Requirements for Calibration Laboratories

Enviado por

Ali ZafarDireitos autorais:

Formatos disponíveis

Requirements on Implementation of ISO/IEC 17025 for Calibration Laboratory

1. Introduction 1.1. 1.2. This document is an integral part of KAN laboratory accreditation system based on the ISO/IEC 17025 : 2005 This document provides requirements on the specific interpretation to the technical requirements of ISO/IEC 17025 : 2005, those shall be met by KAN accredited calibration laboratory and used by KAN assessor to assess competence of calibration laboratories KAN has provided general interpretation of ISO/IEC 17025: 2005 in the KAN Guide on the Interpretation of ISO/IEC 17025: 2005) KAN accreditted laboratories shall meet ISO/IEC 17025: 2005 requirements, and if applicable KAN Guide on the Interpretation of ISO/IEC 17025: 2005 shall be used as a reference to implement ISO/IEC 17025: 2005 in the laboratory Implementation of ISO/IEC 17025: 2005 in the calibration laboratories need specific interpretation, especially for implementation of its technical requirements. This document provides that specific interpretations to improve harmonization, effectivness and efficiency of calibration laboratorys management system

1.3. 1.4.

1.5.

2. Scope of Accreditation 2.1. An applicant calibration laboratory shall fill Accreditation Application Checklist (FPA 03.02b) and Proposed scope of Accreditation Form (Annex of FPA 03.01b for calibration laboratory), which includes, calibration or measurement fields, type of item to be calibrated, measurement range, best measurement capabilty, as well as method and/or specification used by the laboratory to provide its calibration services Calibration laboratory accreditation is not restricted only to high level of accuracy. Accreditation may be granted to the lower accuracy level, provided with larger BMC, as appropriate with the uncertainty of measurement achieved by the laboratory in more or less routine calibrations. Classification of the scope of KAN accreditation for calibration laboratories is shown in Annex A of this documents

2.2.

2.3.

3. Personnel 3.1. .Laboratories shall equipped with appropriately competence personnel to cover all calibration included in its accreditation scopes and of sufficient number to cover volume of calibration works. Personnel responsible for technical operation of the laboratory shall have adequate knowledge on the calibration principles (including evaluation of measurement uncertainty) and having skill to make critical evaluation of calibration results) Competence of laboratory personnel shall be objectively assessed based on their ability to apply their knowledge in the scope of activities they responsible for, Education, training

3.2.

Translated from Indonesian Version ed. 12_05

and experiences record of personnel in the specific field of calibration may support their competence. However those records may not enough to meet competency requirements if objective evidence to apply their knowledge is not provided. 3.3. 3.4. Laboratory shall establish scope of competency of each laboratorys technical personnel, including authority and responsibility to execute calibration work in its accreditation scope. When, more than one personnel are authorized to execute similar calibration work of equivalence accuracy, laboratory shall provide objective evidence shows their ability to achieve an equal accuracy level. If there is no objective evidence showing an equal competency level of technical personnel, laboratory shall document the accuracy level that may be achieved by individual laboratory personnel.

4. Accomodation and Environmental Conditions 4.1. 4.2. Accommodation and environmental conditions needed by the calibration laboratories will depend on the type of calibration and/or measurement and BMC claimed in its scope. Accommodation and environmental conditions shall be monitored and controlled in such way that function and accuracy of all standards and equipment used by the laboratory is assured. Attention may be given to temperature, temperature gradient, relative humidity, vibration, dust, cleanliness, electromagetic disturbance, interferences, lighting and other factors affecting validity of calibration results. Limits of environmental condition shall be established by the laboratory based on requirements of standards, methods, specification, operating conditions of standards and equipment, and/or other existing information including experimental data showing the effect of environmental condition to the achieved measurement uncertainty. Laboratory shall be able to provide an evidence that the established limits is achieved in day-to-day operation. When on-site calibration is included in management system of the laboratory, it shall equipped with a mobile or portable environmental monitoring system needed to monitor an environmental paramater that may be affect the on-site work. When environmental condition significantly affect validity of calibration results in such way that contributes significantly to measurement uncertainty, that condition shall be monitored and recorded continuously. When correction caused by environmental conditions is applied to calibration results, those original and corrected measurement data shall be recorded.

4.3.

4.4.

4.5.

4.6.

5. Measurement Uncertainty 5.1. Procedure for evaluation of measurement uncertainty shall be based on KAN Guide on the Evaluation and Expression of Uncertainty and/or other equivalent documents based on the ISO Guide to the Expression of Uncertainty in Measurement. Calibration laboratory shall have documented procedure for the evaluation of uncertainty covering important stages in the evaluation of measurement uncertainty and the estimate of contribution summarizing in the uncertainty budget. (guidance is given in the Annex C of this document.

5.2.

Translated from Indonesian Version ed. 12_05

6. Best Measurement Capability (BMC) 6.1. Best measurement Capability is simply defined as smallest uncertainty that the laboratory can achieve in more or less routine calibration of nearly ideal devices that can be calibrated aginst laboratorys calibration system, which is stated as expanded uncertainty at 95% in the scope of accreditation. Best Measurement Capability should be routinely achieved by the laboratory when calibrates unit under test having equivalent characteristic with those used as the basis of their claimed BMC In the framework of KAN calibration laboratory accreditation system, the claimed BMC shall be supported by an appropriate uncertainty budget and experimental evidence showing that the laboratory is capable to achieve their BMCs

6.2.

6.3.

7. Measurement Standards and Measuring Equipments 7.1. All measurement standards and equipments including ancilliary equipments used by the laboratory shall meet requirements of the calibration method claimed by the laboratory and shall support their claimed BMC 7.2. Measurement standards and/or measuring instruments shall be only used by as the reference standards when the laboratory has procedures needed to verified their accuracy, including their long term variability. If applicable, laboratory shall have a documented procedure for the verification of their measurement standards and/or measuring instruments Note: procedures and records of the verification of standards accuracy may be integrated with the internal quality control system of the laboratory Laboratory shall have a list of all measurement standards, measuring equipments, including any ancilliary equipment needed for all calibration in its scope, as well as establishing the functions as a reference standards, working standards, comparators, calibration media, ancilliary equipement (e.g measuring instruments for environmental condition, etc) Laboratory shall establih acceptance criteria of each measurement standards and equipments and shall ensure that all of them meet that established acceptance criteria. Record of verification againts acceptance criteria shall be documented. Calibration of measurement standards and equipments is not the only responsibility of calibration laboratory, to ensure their compliance with the established acceptance criteria, the laboratory shall appropriately choose, install, maintain, check, operate and store them. When measurement standards and measuring equipments those significantly affect the calibration results is used outside of laboratorys permanent facility (including when they are sent for calibration), the laboratory shall appropriately checks their performance immediately before and after sent them out of permanent facility to ensure that their performance is not significantly changed as such affect their ability to achieve the claimed BMC. All measurement standards and measuring equipment shall be labelled, coded or otherwise identified to indicate their calibration status, i.e. the date of last calibration and

7.3. 7.4.

7.5.

7.6.

7.7.

7.8.

Translated from Indonesian Version ed. 12_05

the next calibration date. Any limitation of calibration or restriction of use shall be clearly indicated on the equipment. 7.9. When neither labelling nor coding is practicable, or is not considered essential for control purposes, other procedures shall be established to ensure conformance to these requirements Access to adjustable devices on measurement standards and measuring equipment, which are fixed at the time of calibration, shall be sealed or otherwise safeguarded to prevent tampering by unauthorised personnel. Seals shall be designed so that tampering will destroy them. NOTE: This requirement does not apply to adjustable devices that are intended to be set by the user without needing external references. 8. Measurement Traceability 8.1. All quantitative measuring equipments and measurement standards having significant effect to calibration results shall be calibrated before used by the laboratory. 8.2. Measuring equipments and measurement standards shall be calibrated with an appropriate interval based on its stability, its intended use, environment, and frequency of use. Calibration interval for each equipments and standards shall provide confidence that specification limits defined by the laboratory is not breached between its subsequent calibrations. Calibration interval should not exceed maximum recommended interval in the Annex B of this document. Laboratory may establish longer calibration interval if objective evidence provided that extension of calibration interval will not affect its capability to achieve claimed BMC Extension of calibration interval shall only be done based on the evaluation of at least 3 (three) subsequent calibration certificates, or based on IQC records having more than 50 (fifty) QC periodic measurements. Laboratory shall established shorter calibration interval If evaluation on previous calibration certificates and/or IQC records show that drift or instability of standards and equipments between periodic calibration are not support its claimed BMC Change of calibration interval shall be an integral part of laboratorys quality management system and a planned action based on provision of objective evidence that is not adversely affect laboratory performance. Change of calibration interval will affect an estimate compensation for drift or stability of standards and equipments those may affect BMC granted in its scope of accreditation. Calibration laboratories shall fulfill KAN Policy on Traceability of Measurement

7.10.

8.3.

8.4. 8.5. 8.6.

8.7.

8.8.

8.9. 8.10.

9. Computerized Calibration System 9.1. The equipment shall be satisfactory for its intended purpose. The adequacy of the equipment will be determined by the accuracy and speed of making the reading

Translated from Indonesian Version ed. 12_05

9.2.

The system shall be satisfactory calibrated. If the measuring equipment cannot be isolated from the data processing system, the system as a whole shall be calibrated either statically or dynamically. If the measuring equipment can be isolated from the data processing system, the equipment can be calibrated in the conventional manner and a separate verification of the data processing system can be undertaken. The data processing system shall allow for the detection of errors in data input and the monitoring of the progress of the calibration. data processing system shall maintain the original integrity of the measured data. The limiting factor on the precision of the numbers which the data processing system can handle must be taken into account. The system shall be capable of being checked for error-free operation with respect to data capture, data processing and freedom from sources of external interference. This check shall be determined by manual check or by a set of artefact data, etc

9.3. 9.4. . 9.5.

10. Assuring Quality of Calibration Results 10.1. Laboratory shall implement internal quality control system and have external quality control program through participation in relevant proficiency testing activites. The type of Proficiency Testing Programme those may be accepted within KAN accreditation system for calibration laboratory are proficiency testing schemes in accordance with ISO Guide 43, bilateral proficiency testing, and/or other interlaboratory comparisons program designed for other purposes. 10.2. Laboratorys internal quality control system shall be designed in such way that short term and long term random variability and bias of the measurement system, measurement standards, and all relevant resources will be monitored continuously to assure validity of calibration results Quality control data may be analyzed using a relevant control chart, or other statistical analysis based on measurement data from calibration of reference standards, calibration of working standards and supporting equipment, intermediate check, calibration of customer items or other sources of data as relevant with type and volume of laboratory acitivities Degree of rigour of laboratorys quality control system will depend on their claimend BMC. Smaller claimed BMC will need more rigorous quality control, while larger claimed BMC may need the only simple quality control system To implement quality control programme, laboratory may refer to KAN Guide on Measurement Assurance Applicant laboratory shall, at least participates 1 (one) proficiency testing programme for 1 (one) of calibration fields covered in the proposed scope of accreditation. Calibration laboratory shall establish a program for its participation in proficiency testing to ensure that each calibration field is verified by 1 (one) proficiency testing activities per 4 (four) years.

10.3.

10.4.

10.5. 10.6. 10.7.

Translated from Indonesian Version ed. 12_05

10.8.

Accredited calibration laboratories were obliged to participate in Proficiency Testing Activities and/or Measurement Audit conducted by KAN for their relevant scope of accreditation Laboratory may arrange a bilateral calibration proficiency testing and/or other interlaboratory comparison programmes with the other accredited calibration laboratories having similar scope of accreditation and submit the results of those program to KAN secretariat as an evidence for their participation in proficiency testing programmes

10.9.

10.10. In case of bilateral interlaboratory comparison, laboratory should chose the other laboratory that has been participated in national/regional/international interlaboratory comparison programmes and having smaller BMC than their own claimed BMC 10.11. Laboratory shall follow-up any outliers results in proficiency testing in accordance with KAN Policy on Proficiency Testing Activity -----000000-----

Translated from Indonesian Version ed. 12_05

ANNEX A Classification of Accreditation Scope for Calibration Laboratory

Calibration fields 1. Temperature

Instruments to be calibrated 1.1 Liquid-in glass thermomter 1.2. Temperature sensor with display unit : 1.2.1 thermocouple sensor with display unit 1.2.2 resistance thermometer sensor with display unit 1.3. Temperature Indicator (without sensor) : 1.3.1 for thermocouple sensor 1.3.2 for Resistance thermometer sensor 1.4. Resistance thermometer sensor 1.5. Themocouple sensor 1.5.1 T type 1.5.2 J - type 1.5.3 E type 1.5.4 K type 1.5.5 S and R - type 1.5.6 B - type

1. Temperature (contd)

1.6. Radiation thermometer 1.6.1 Infrared photodetector 1.6.2 Visible-light photodetector 1.7. Optical pyrometer 1 diminishing filament pyrometer 1.8. Hygrometer, hygrograph 1.9. Thermohygrometer, Thermohygrograph 1.10. Temperature enclosure 1.10.1 Oven 1.10.2 Furnace 1.10.3 Bath 1.10.4 Incubator 1.10.5 Refrigerator 1.11. Humidity Chamber

2. Mass

2.1 Conventional Mass (mass standards, weights)

Translated from Indonesian Version ed. 12_05

Calibration fields

Instruments to be calibrated 2.2 Balances 1.2.1 1.2.2 1.2.3 1.2.4 Electronic Balance Mechanical Balance Equal Arm Balance Batching Plant

3. Volumetric

3.1 Volumetric proving measures 3.2 Volumetric glassware (buret / pipet / labu ukur / etc) 4.1 4.2 Dead Weight Tester (DWT Pressure Balance) Pressure Test Gauge (used for calibration for pressure gauge) 4.3 Pressure Gauge 4.4 Electromechanical manometer (indicated pressure transducer, pressure transmitter, digital manometer) 4.5. Vacuum gauge (gauge or absolute indication) 4.6 Barometer 5.1 5.2 5.3 5.4 5.5 5.6 5.7 Load cell Tension force testing machines Compression force tersting machines Universal force testing machine Hydraulic Jack Force gauge / proving ring Impact Testing Machine

4. Pressure

5. Force

6. Torque 7. Hardness 8. Flow 9. Length

6.1 Torque meter 7.1 Hardness testing machines 8.1 Flowmeter

9.1 Length standards 9.1.1 Gauge blok / end gauge / slip gauge 9.1.2 Step gauge - Vernier caliper cheker, inside checker, chek master. 9.2 Micrometer 9.2.1 Outside micrometer 9.2.2 Inside micrometer 9.2.3 Micrometer head 9.2.4 3-point inside micrometer 9.2.5 Depth micrometer 9.2.6 indicating micrometer 9.2.7 Mikrometer roda gigi

Translated from Indonesian Version ed. 12_05

Calibration fields

Instruments to be calibrated 9.3 Calliper 9.3.1 Vernier caliper 9.3.2 Height gauge 9.3.3 Depth caliper 9.4 Dial Gauge 9.4.1 Dial indicator 9.4.2 Mechanic dial comparator 9.4.3 Electronic dial comparator 9.4.4 Dial Test indikator 9.4.5 Linear scale / LVDT 9.4.6 Bore gauge 9.5 Gauges 9.5.1 Feeler gauge 9.5.2 Pin gauge 9.5.3 Straight edge 9.5.4 Plug gauge 9.5.5 Ring gauge 9.6 Angle measuring devices 9.6.1 Bevel Protactor 9.6.2 Waterpass / Spirit level / bubble / clinometer 9.6.3 Theodolite 9.6.4 Telescope 9.6.5 Square 9.6.6 Sine bar 9.7 Meeasuring Machine 9.7.1 Profile projector 9.7.2 Roughness meter 9.7.3 Coordinate Measuring Machine 9.7.4 Microskop 9.7.5 Roundnessmeter 9.7.7 Dial gauge tester 9.7.8 Digital mu checker

9. Length (Contd)

9.8.Miscellaneous 9.8.1Thickness gauge 9.8.2 Surface plate 9.8.3 Height master 9.8.4 Electronic distance meter 9.8.5 Walking measurer 9.8.6 Planimeter 9.8.7 Tape measure 9.8.8 Steel ruler 9.8.9 V-blok

Translated from Indonesian Version ed. 12_05

Calibration fields 10. Electrical

Instruments to be calibrated 10.1 . Current 10.1.1 10.1.2 10.1.3 10.1.4 AC/DC Current source AC/DC Ampere meter AC/DC current recorder Current transducer

10.2. Voltage 10.2.1 10.2.2 10.2.3 10.2.4 10.2.5 AC/DC AC/DC AC/DC AC/DC AC/DC Voltage source Voltmeter voltage recorder voltage devider) voltage transducer

10.3. Resistance 10.3.1 10.3.2 10.3.3 10.3.4 10.3.5 10.3.6 Resistor Decade resistor Hammond resistor Current shunt Ohmmeter Resistance bridge

10.4. Capacitance 10.4.1 10.4.2 10.4.3 10.4.4 Capasitor Decade capacitor Capacitance bridge Capacitance meter

10.5. Inductance 10.5.1 lnductor 10.5.2 Decade capacitor 10.5.3 Inductance bridge 10.5.4 Inductance meter 10.6. Electric Power and Phase 10.6.1 10.6.2 10.6.3 10.6.4 11. Time and Frequency 11.1 Time 11.1.1 Stopwatch 11.1.2 Tirner Power meter Cos meter Energy meter Power transducer

Translated from Indonesian Version ed. 12_05

10

Calibration fields

Instruments to be calibrated 11.2. Frequency 11.2.1 Frequency standard 11.2.1.1 Rubidium frequency standard 11.2.1.2 X'tal frequency standard 11.2.2 Counter 11.2.2.1 Frequency counter 11.2.2.2 Frequency meter 11.2.2.3 Microwave frequency counter 11.2.2.4 Universal time counter 11.2.3 Frequency converter 11.2.4 Down converter 11.2.5 RPM converter 11.2.5.1 Optical 11.2.5.2 Electromagnetic 11.2.5.3 Mechanical 11.3. AF & RF signal 11.3.1 AF signal 11.3.1.1 AF oscillator 11.3.1.2 Function generator 11.3.1.3 Pulse generator 11.3.2 RF Signal 11.3.2.1 Synthesized signal generator 11.3.2.2 Synthesized sweeper 11.3.2.3 AM / FM signal generator 11.4. RF Power & Attenuation 11.4.1 11.4.2 11.4.3 11.4.4 RF Power meter RF attenuator Power divider / coupler RF Amplifier

Translated from Indonesian Version ed. 12_05

11

Calibration fields

Instruments to be calibrated 11.5 AF / RF Analyzer 11.5.1 Analyzer 11.5.1.1 Distortion analyzer / distortion meter 11.5.1.2 Modulation analyzer / modulation meter 11.5.1.3 Spectrum analyzer 11.5.1,4 Impedance analyzer 11.5.1.5 Audio analyzer 11.5.1.6 Network analyzer 11.5.2 Osiloskop 11.5.2.1 Oscilloscope 11.5.2.2 Digitizing oscilloscope 11.5.2.3 Storage oscilloscope 11.5.2.4 Plug-in-type oscilloscope 11.5.3 Measuring receiver / signal analyzer 11.5.4 Other measuring equipment

12. Accoustics and Vibration

12.1 Accoustics 12. 1.1 Sound level meter 12. 1.2 Microphone 12.2 Vibration 12.2.1 Accelerometer 12.2.2 Displacement 12.2.3 Vibratiometer / Vibrometer

13. Analytical Instruments

13.1 Spectro-photometry 13.1.1 UV - Vis Spectrophotometer 13.2 Chemical testing Instruments 13.2.1 PH meter 13.2.2 Viscometer

14. Optical

14.1 Optical Power Meter 14.2 Optical Time Domain Reflectometer 14.3 Optical Light Source 14.4 Optical Attenuator

Translated from Indonesian Version ed. 12_05

12

Appendix B Recommended Calibration Interval The following table sets out nominal maximum periods between successive calibrations for a number of reference standards and measuring instruments. It must be stressed that these periods are generally considered to be the maximum appropriate in each case providing that the other criteria as specified below are met: That the equipment is of good quality and proven adequate stability, and That the laboratory has both the equipment capability and staff expertise to perform adequate intermediate checks, and That if any suspicion or indication of overloading or mishandling arises the equipment will be checked immediately and thereafter at fairly frequent intervals until it can be shown that stability has not been impaired. Where the above criteria cannot be met appropriately, shorter intervals shall be specified.

The list of standards and measuring instruments is by no means exhaustive, and will be updated periodically. No 1 Type of instruments Calibration bath and Furnace Maximum calibration intervals Temperature Initial spatial and temporal surveys should be carried out Check temperature distribution at one temperature every five years 2 Thermocouple Rare metal, reference for use below 10000 C Rare metal,reference for use above 10000C Rare metal, working standard Base metal, working standard 100 hours use or three years 10 hours use or three years 100 hours use or three years Calibration interval to suit particular application

Thermometer:

Translated from Indonesian Version ed. 12_05

13

No

Type of instruments Liquid in glass (reference thermometer)

Maximum calibration intervals Check ice point or other suitable reference point each time of use or at interval of one to two months, whichever is the sooner until the secular change is less than half the uncertainty of calibration. Then check every six months. Recalibrate every five years when reference point changes by five or more scale divisions Compare working thermometer with reference thermometer at two points in the working range every six months. Recalibrate every five years or when a change of five or more scale division is noted Check ice point before use or at least every six months Recalibrate every five years or when ice point change by more than the equivalent of five times the uncertainty of calibration Check thermometer ice point every six months. Calibrate thermometers every five years or when ice point changes by more than five scale divisions 1 year 100 hours use or five years 1 year

Liquid in glass (working thermometer)

Resistance temperature thermometer

Psychrometers

5 6 7

Pyrometers Strip lamps Hygrometer

Mass and Related Quantities 1 Mass standards Reference standards Working standards 2 Balances Electronic, mechanic 1 year With monthly single point check at full scale Mass comparator 3 Dead Weight Tester (Pressure Balance) Accuracy < 0.01% Accuracy > 0.01% 4 Pressure Test Gauge for calibrating pressure gauge 3 years, with spin-rate examination anually 5 years, with spin-rate examination anually 1 year Repeatability check every 6 months 3 years 1 year

Manometer :

Translated from Indonesian Version ed. 12_05

14

No

Type of instruments Reference std (liquid) Working std (liquid) Electronic

Maximum calibration intervals 10 years, with checking the cleanliness of the fluid every 36 months 5 years, with checking the cleanliness of fluid every 36 months 1 year Initial, with one point check using transfer instrument every 5 years 1 year 2 years 4 years than 8 years subsequent 1 years

Barometer: Fortin Aneroid

8 9

Load Cell Torque: Standard beam and masses Transducer

10

Force Testing Machine: Dead Weight Elastic Dynamometer Hydraulic, Pneumatic 5 year 2 year 2 year 5 years Check against reference hydrometer or in newly prepared solutions of known density every 1 year Check against reference hydrometer or in newly prepared solutions of known density every 6 months 2 years then 5 years subsequent initial Initial, with visual check for wear and damage every 6 months Length, Angle and Dimensional

11

Hydrometer: Reference Working - glass

Working - metal

12 13 14

Density Bottles Volumetric Glassware Orifice Plates

Gauge Block: Reference standard Working standard 3 years 1 year 4 years 2 years 3 years

Angle Gauge: Reference standard Working standard

Comparator

Translated from Indonesian Version ed. 12_05

15

No 4

Type of instruments Height setting micrometer and Riser Blocks Setting rings and plugs: Reference standard Working standard

Maximum calibration intervals 3 years with annual performance checks

3 years 1 year 6 years 5 years 2 years 2 years 6 years 1 years 3 years

6 7 8 9 10 11

Autocollimator Dividing Head and Rotary Tables Callipers Dial Gauges Alignment Telescopes Surface plates: Cast iron Granite

12

Measuring Machine (Other than CMC): Precision scale Geometric Test Micrometer Heads 10 years 5 years 3 years Three years 1 year, with performance check before use 5 years, with annual zero, one point check (against gauge block) and condition of anvil 4 years 2 years 4 years 5 years 3 years 5 years 4 years 5 years 4 years 5 years 4 years, with annnual microscopic inspection Initial, with annual microscopic inspection 3 years

13 14 15 16

Optical flats/parallels Linear transducer Micrometers Length bar: Reference Working

17 18 19 20 21 22 23 24 25

Precision Level Precision Linear scale Micrometer setting gauge Optical projectors Pitch Diameter reference disc Precision Polygon Rollers and Balls Roundness standard Roughness standards: Metal Glass

26

Screw check for ring gauge

Translated from Indonesian Version ed. 12_05

16

No 27 28 29 30 31 32

Type of instruments Screw pitch reference standard Screw thread measurement cylinder and vee pieces Setting cylinder Sine bars, centres and tables Squareness testers Squares: Try squares Block squares Steel / cast iron Straight Edges Granites

Maximum calibration intervals 3 years Initial, with annual visual inspection 3 years 3 years 3 years 2 years 4 years 3 years 4 years Initial, wiht check at maximum length every 2 to 5 months dpending on use and accuracy required Initial, wiht check at maximum length every 2 to 5 months dpending on use and accuracy required Electrical

33

Tape measures, Rules: Tape measures

Steel rules

1 2 3 4 5 6 7 8 9

Electronic standard cells Digital meters Analog meters Resistors Capacitor Standard cell, Weston AC-DC Transfer standards Bridges Potentiometer

1 year 1 year, compare every sixth month 2 years, compare every sixth months 3 years, compare anually 3 years, compare anually 2 years, compare at least sixt monthly 2 years, compare immediately after calibration 3 years (full calibration), check against laboratory standard anually 3 years, compare anually

Time and Frequency 1 2 3 4 Signal Generator Attenuator RF Power Meter Stop watches, clock 1 year 3 years (frequency response) resistance check anually where appropriate 1 year 1 year

Translated from Indonesian Version ed. 12_05

17

No 1 2 3 4

Type of instruments Luminous intensity lamps Luminous flux lamps Illuminance (lux) meter Luminance meter

Maximum calibration intervals Photometry 1 year 1 year 1 year 1 year Radiometry

1 2 3 4 5

Spectral irradiance lamps UV irradiance meters Laser/optical power meter Fibre optic power meter Laser wavelength (fiber optic)

100 hours burning time or three years, whichever is earlier 6 months (heavy usage) 1 year (light usage) 1 year 1 year 1 year

Spectrophotometry 1 2 3 Wavelength standard filters Transmittance standard filters Reflectance standards 1 year 1 year 1 year

Translated from Indonesian Version ed. 12_05

18

ANNEX C (Indonesian Only) Guide on writing procedure for the evaluation of Uncertainty in Measurement for Calibration Laboratories Evaluasi ketidakpastian pengukuran merupakan bagian dari kegiatan kalibrasi atau pengukuran. Sebagaimana halnya dengan metode kalibrasi/pengujian yang harus diuraikan dalam dokumen instruksi kerja, begitu pula metode atau prosedur evaluasi ketidakpastian harus diuraikan dalam suatu dokumen instruksi kerja evaluasi ketidakpastian pengukuran. Instruksi kerja tersebut harus dibuat agar jelas dan mudah dipahami, sehingga dapat diterapkan tanpa keraguan oleh operator kalibrasi dan dapat diverifikasi oleh asesor dengan mudah. Untuk dapat membuat instruksi kerja yang efektif itulah perlu diperhatikan beberapa langkah yang diuraikan dalam pedoman ini. Untuk memudahkan verifikasi instruksi kerja, sebaiknya instruksi kerja tersebut disajikan dengan format yang terdiri atas: 1) mathematical model 2) uncertainty equation, 3) description of uncertainty sources, and 4) uncertainty budget table. Komponen-komponen ini akan diuraikan dalam bagian berikut: Model Matematis Model matematis menyatakan hubungan matematis antara measurand (besaran yang diukur) dengan besaran-besaran yang mempengaruhi. Jika suatu besaran dianggap mempengaruhi hasil pengukuran, maka variabel yang melambangkan besaran tersebut harus ada dalam model matematis. Sebaliknya, jika suatu besaran dianggap tidak berpengaruh, maka tidak perlu ada variabel yang mewakilinya dalam model matematis. Model matematis dapat dimodifikasi dengan penyederhanaan atau pendekatan yang logis untuk mempermudah evaluasinya. Persamaan Ketidakpastian Persamaan ketidakpastian pada dasarnya adalah elaborasi dari rumus ketidakpastian baku gabungan (ISO GUM): uc2 = (ci2ui2) = c12u12 + c22u22 + c32u32 + [1] Untuk setiap variabel xi dalam model matematis, akan ada komponen ketidakpastian baku ui dan koefisien sensitivitas ci. Perlu diperhatikan bahwa nilai (atau rumus) koefisien sensitivitas sangat bergantung pada bentuk persamaan dalam model matematis, karena itulah penentuan model matematis harus tepat dan jelas. Deskripsi Sumber-Sumber Ketidakpastian Persamaan ketidakpastian akan mempunyai dua macam komponen: komponen ketidakpastian (ui) dan komponen konstanta (ci). Kedua macam komponen ini nilainya harus ditentukan; baik dengan diestimasi maupun diturunkan dari data lain. Untuk itu perlu ada uraian yang jelas mengenai cara menentukan nilai-nilai ini. Uraian ini meliputi: cara menentukan atau mengestimasi ketidakpastian terentang (expanded uncertainty) setiap sumber ketidakpastian; jenis distribusi dan faktor pembagi yang sesuai;

penentuan nilai konstanta yang menjadi faktor dalam koefisien sensitivitas Tanpa adanya suatu uraian yang jelas, budget ketidakpastian menjadi sulit diverifikasi, bahkan bisa dikatakan meaningless (tidak berarti).

Translated from Indonesian Version ed. 12_05

19

Tabel Anggaran Ketidakpastian Tabel budget ketidakpastian berisi nilai-nilai ketidakpastian dari tiap-tiap sumber ketidakpastian beserta variabel-variabel lainnya (faktor pembagi, koefisien sensitivitas, derajat kebebasan). Budget ketidakpastian dibuat dalam format yang sedemikian rupa untuk memudahkan penghitungan ketidakpastian baku tiap-tiap sumber, ketidakpastian baku gabungan, derajat kebebasan efektif dan faktor cakupan (jika diperlukan) serta nilai ketidakpastian terentang (expanded uncertainty). Bentuk ini sangat sesuai untuk digunakan dalam program spreadsheet sehingga penghitungan secara otomatis dapat dilakukan dengan mudah. Catantan: Notasi Ketidakpastian Baku dan Ketidakpastian Bentangan To avoid misunderstanding, notation for the standard uncertainty and expanded uncertainty shall be considered: standard uncertainty is stated as u (non-capital letter) expanded uncertainty is stated as U (capital letter) standard uncertainty of variable Xi is stated as u(Xi).

Formula Baku dan Konsep Dasar Rumus-rumus baku serta konsep-konsep dasar dari ISO GUM tidak perlu dicantumkan lagi dalam instruksi kerja, karena diasumsikan bahwa pengguna instruksi kerja sudah memahami konsepkonsep dasar ISO GUM. Rumus-rumus yang bisa dianggap baku misalnya rumus rerata, simpangan baku, ketidakpastian gabungan, derajat kebebasan efektif (rumus WelchSatterthwaite). Example : Kalibrasi Gauge Block dengan Metode Pembandingan Mekanik Model matematis Model dasar yang meliputi besaran-besaran yang utama atau dominan diturunkan sebagai berikut: L = Ls + d dengan: [2] L = panjang balok tes Ls = panjang balok acuan d = penunjukan komparator Untuk memperhitungkan pengaruh besaran-besaran lain yang berpengaruh, model tersebut dielaborasi menjadi sebagai berikut: L(1 + ) = Ls(1 + ss) + d + Ldrift dengan: [3] = koefisien muai panjang balok tes = suhu balok tes s = koefisien muai panjang balok acuan s = suhu balok acuan Ldrift = perubahan panjang balok acuan akibat drift Dengan manipulasi matematis [ISO GUM H.1], persamaan [3] dapat disederhanakan untuk mempermudah evaluasi ketidakpastian, menjadi seperti berikut: L = Ls + Ls(s + s) + d + Ldrift dengan: [4] = selisih antara koefisien muai panjang balok tes dan balok acuan = selisih antara suhu balok tes dan balok acuan Persamaan [4] selanjutnya akan dipakai sebagai model matematis untuk kalibrasi gauge block dengan metode perbandingan.

Translated from Indonesian Version ed. 12_05

20

Persamaan ketidakpastian Setelah menurunkan koefisien sensitivitas untuk tiap-tiap komponen ketidakpastian, maka persamaan ketidakpastian untuk kalibrasi gauge block dengan metode perbandingan dapat diturunkan dari Persamaan [4] sebagai berikut: u2(L) = u2(Ls) + (s + s)2u2(Ls) + Ls2s2u2() + Ls2s2u2() + Ls22u2(s) + Ls22u2(s) + u2(d) + u2(Ldrift) [5] Karena dan masing-masing mempunyai nilai taksiran nol, maka Persamaan [5] dapat dipersingkat menjadi u2(L) = u2(Ls) + Ls2s2u2() + Ls2s2u2() + u2(d) + u2(Ldrift) [6] Persamaan [6] merupakan persamaan ketidakpastian kalibrasi gauge block metode perbandingan. Deskripsi Sumber-Sumber Ketidakpastian Persamaan [6] mempunyai beberapa input ketidakpastian yaitu u(Ls), u(), u(), u(d), u(Ldrift); serta beberapa konstanta yaitu Ls, s, s. Tiap-tiap input ketidakpastian mempunyai sumber-sumber ketidakpastian yang diuraikan dalam tabel berikut, berikut cara mengevaluasi nilai dan distribusinya. Tabel 1. Deskripsi Sumber-Sumber Ketidakpastian Input/ Deskripsi variabel u(Ls) Ketidakpastian nilai balok acuan u(d) Ketidakpastian penunjukan atau pembacaan komparator u(Ldrift) Ketidakpastian drift balok acuan u() Sumber Penentuan nilai ketidakpastian ketidakpastian terentang dan pembaginya 1. Kalibrasi balok 1. Dari sertifikat kalibrasi, dibagi k acuan 1. Daya baca 1. Setengah dari resolusi komparator, 2. Repeatability dibagi 3 3. Kalibrasi komparator 2. Simpangan baku, dibagi n 3. Dari sertifikat kalibrasi, dibagi k 1. Estimasi nilai drift 1. Nilai maximum permissible secular change (ISO3650) (dianggap sebaran persegi), dibagi 3 * kecuali ada acuan lain Ketidakpastian 1. Estimasi nilai selisih 1. Jika kedua balok dari bahan yang sama, selisih koefisien sepersepuluh dari nilai nominal (mis. muai kedua = 11,5e-6 C1 untuk baja) (dianggap balok sebaran persegi), dibagi 3 Ketidakpastian 1. Estimasi nilai selisih 1. Jika kedua balok telah dikondisikan selisih suhu cukup lama dalam suhu lab, 0,05 C kedua balok (dianggap sebaran persegi), dibagi 3

u()

The values of constants used in the uncertainty equation may be evaluated as follows: Tabel 2. Deskripsi Konstanta yang Digunakan Konstanta Deskripsi Ls Panjang balok acuan s s Koefisien muai balok acuan Deviasi suhu balok acuan Penentuan nilai konstanta Untuk tiap rentang ukur, ambil nilai yang terbesar (mis. untuk rentang 0~1 mm, maka L = 1 mm atau 1000 m) Estimasi berdasarkan bahan balok, atau informasi dari pembuat. Mis. untuk baja, = 11,5 e-6 C-1 Selisih antara suhu balok acuan dengan 20 C. Mis. jika suhu = 20,1 C, maka s = 0,1 C.

Translated from Indonesian Version ed. 12_05

21

Tabel Anggaran Ketidakpastian

Uncertainty sources Unit Distribution Symbol Expanded Cov.erage uncertainty Factor (U) (k) Degrees of freedom (vi) Standard. Uncertainty (ui) Sensitivity Coefficiients (ci) ci.ui (ci.ui)2 (ci.ui)4/vi

1 Reference block value 2 Readability of instrument 3 Repeatability of measurement 4 Instrument correction 5 Reference block drift 6 Difference between and s 7 Temperature gradient between blocks

m m m m m /C

Normal Rect Rect Normal Rect Rect

u(Ls) u(d1) u(d2) u(d3) u(Ldrift) u()

Rect

u()

Sums Combined uncert, uc Eff. Deg of freedom, veff Cov. Factor for 95% CL Expanded uncertainty, U95

===end of document===

Translated from Indonesian Version ed. 12_05

22

Você também pode gostar

- RLK+01 KAN+requirement+for+Calibration+Laboratory+ (EN)Documento25 páginasRLK+01 KAN+requirement+for+Calibration+Laboratory+ (EN)glardoniAinda não há avaliações

- RLK 01 - KAN Requirement For Calibration LaboratoryDocumento30 páginasRLK 01 - KAN Requirement For Calibration Laboratorysandeep100% (1)

- Improving Calibration and Measurement Capability (CMC) of Psychrometer CalibrationDocumento7 páginasImproving Calibration and Measurement Capability (CMC) of Psychrometer CalibrationMiguel Angel Pacahuala CristobalAinda não há avaliações

- As 2853 1986 Enclosures Temperature Controlled Performance Testing and Grading PDFDocumento5 páginasAs 2853 1986 Enclosures Temperature Controlled Performance Testing and Grading PDFIndra AditamaAinda não há avaliações

- KAN K-02.01 Uncertainty in CalibrationDocumento6 páginasKAN K-02.01 Uncertainty in CalibrationsujudAinda não há avaliações

- SASSCO Intermediate Check InstructionDocumento4 páginasSASSCO Intermediate Check InstructionStudent ForeignAinda não há avaliações

- Calibrate Electronic Hygrometers Accurately Under 40 CharactersDocumento1 páginaCalibrate Electronic Hygrometers Accurately Under 40 CharactersAdhitya PT. SIGAinda não há avaliações

- Kalibrasi EnclosurDocumento20 páginasKalibrasi Enclosurmuslim1583Ainda não há avaliações

- Ketertelusuran Dan Uncertainty 090717Documento35 páginasKetertelusuran Dan Uncertainty 090717Anonymous OpRuX6V100% (1)

- E925 09 2014Documento7 páginasE925 09 2014Indra Aditama100% (1)

- RDocumento5 páginasRRangga K NegaraAinda não há avaliações

- Optical CalibrationDocumento6 páginasOptical CalibrationTekos7Ainda não há avaliações

- KAN Pd-01.03 Rev 1. Guide On The Evaluation and ExpressionDocumento29 páginasKAN Pd-01.03 Rev 1. Guide On The Evaluation and ExpressionMulia IslamiyahAinda não há avaliações

- Ifcc CCLM Symposium Ed Randell Six SigmaDocumento32 páginasIfcc CCLM Symposium Ed Randell Six SigmaWimbaWidagdhoAinda não há avaliações

- Calibration of BalancesDocumento7 páginasCalibration of BalancesebbasinghAinda não há avaliações

- Astm e 77-07 PDFDocumento14 páginasAstm e 77-07 PDFDewa LanggengAinda não há avaliações

- Kan Pd-01.03 Guide On The Evaluation and ExpressionDocumento30 páginasKan Pd-01.03 Guide On The Evaluation and ExpressionHaizelAinda não há avaliações

- P 06 - KAN Policy On Proficiency Testing (En)Documento8 páginasP 06 - KAN Policy On Proficiency Testing (En)Sutarwanto Siswo MulyonoAinda não há avaliações

- As - 2853Documento13 páginasAs - 2853jepri purwantoAinda não há avaliações

- Calibration Laboratory NotesDocumento18 páginasCalibration Laboratory NotesBusani NdlovuAinda não há avaliações

- G133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Documento9 páginasG133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Alberto Garcia100% (1)

- E 1965 - 98 - Rte5njutotgDocumento16 páginasE 1965 - 98 - Rte5njutotgPrakash MakadiaAinda não há avaliações

- Checklist For ISO 17043Documento26 páginasChecklist For ISO 17043mujahidin100% (1)

- G-20-Interpretation and Guidance On The Estimation of Uncertainty of Measurement in Testing (EN)Documento17 páginasG-20-Interpretation and Guidance On The Estimation of Uncertainty of Measurement in Testing (EN)Ahmad HidayatAinda não há avaliações

- Form Q-15 Icc-Es Nonaccredited Laboratory Assessment ChecklistDocumento5 páginasForm Q-15 Icc-Es Nonaccredited Laboratory Assessment ChecklistShaun HolderAinda não há avaliações

- Measurement UncertaintyDocumento10 páginasMeasurement UncertaintyRoyal BimhahAinda não há avaliações

- Cal Water BathDocumento6 páginasCal Water Bathmuzammil21_adAinda não há avaliações

- Calibrating Balances MLS Technical Guide 25Documento9 páginasCalibrating Balances MLS Technical Guide 25iptAinda não há avaliações

- E1965-98 2016.scnv0049Documento18 páginasE1965-98 2016.scnv0049Robert LegaultAinda não há avaliações

- TR 47-03 TR 47-03 - South African National Accreditation SystemDocumento11 páginasTR 47-03 TR 47-03 - South African National Accreditation Systemviethuong96Ainda não há avaliações

- Ba Tho 5000toce Full Calibration Sop en 58130094bDocumento38 páginasBa Tho 5000toce Full Calibration Sop en 58130094bعبدالعزيز بدرAinda não há avaliações

- Calibrate Metal Tapes Using Standard Tape MethodDocumento12 páginasCalibrate Metal Tapes Using Standard Tape Methodhaharamesh100% (1)

- ISO/IEC 17043 Conformity Assessment Requirements for Proficiency TestingDocumento18 páginasISO/IEC 17043 Conformity Assessment Requirements for Proficiency TestingMukhamad Muslim HabibieAinda não há avaliações

- GLP Iso-Iec 17025Documento4 páginasGLP Iso-Iec 17025umavenkataAinda não há avaliações

- Prosedur KalibrasiDocumento23 páginasProsedur KalibrasiAgus Be PeAinda não há avaliações

- Handbook of Weighting Applications PDFDocumento32 páginasHandbook of Weighting Applications PDFiptAinda não há avaliações

- AS 2853-1986 - Enclousure - Temperature Controlled - Perfomance Testing and Grading PDFDocumento15 páginasAS 2853-1986 - Enclousure - Temperature Controlled - Perfomance Testing and Grading PDFDini AprianiAinda não há avaliações

- BS en 12823-1-2014Documento20 páginasBS en 12823-1-2014Abdullah FouadAinda não há avaliações

- PH Sensor Calibration ProcedureDocumento2 páginasPH Sensor Calibration ProcedureRajuAinda não há avaliações

- Annex 4 Qualification of IR SpectrophotometersDocumento12 páginasAnnex 4 Qualification of IR SpectrophotometersAbhilash NarayananAinda não há avaliações

- Iso 7218 1996 Amd 1 2001 en FR PDFDocumento6 páginasIso 7218 1996 Amd 1 2001 en FR PDFWisnu PengenjadHi RapperAinda não há avaliações

- Calibrating Piston PippetesDocumento7 páginasCalibrating Piston PippetesluigimasterAinda não há avaliações

- NABL 181 Provides Guidance for PT ProvidersDocumento29 páginasNABL 181 Provides Guidance for PT Providerszilangamba_s453550% (2)

- pH Meter SOPDocumento6 páginaspH Meter SOPChristian JosephAinda não há avaliações

- Nata - Verificacion de BalalnzasDocumento9 páginasNata - Verificacion de BalalnzasDiego TobrAinda não há avaliações

- Reagents and Chrom Columns USP 36 PDFDocumento97 páginasReagents and Chrom Columns USP 36 PDFRitesh NarkhedeAinda não há avaliações

- 008 ISO 10421998 Laboratory Glassware One Mark VolumDocumento2 páginas008 ISO 10421998 Laboratory Glassware One Mark VolumAriAinda não há avaliações

- Calibrating ultrasonic flowmeters independently of pipesDocumento18 páginasCalibrating ultrasonic flowmeters independently of pipesMARIANAinda não há avaliações

- E 1812 Standard Practice For Optimization of Flame Atomic Absorption Spectrometric EquipmentDocumento2 páginasE 1812 Standard Practice For Optimization of Flame Atomic Absorption Spectrometric EquipmentBryan Mesala Rhodas GarciaAinda não há avaliações

- Optimization, Calibration, and Validation of Atomic Absorption Spectrometry For Metal Analysis of Petroleum Products and LubricantsDocumento9 páginasOptimization, Calibration, and Validation of Atomic Absorption Spectrometry For Metal Analysis of Petroleum Products and LubricantscamiloAinda não há avaliações

- The New ISO Guide 80 Guidance For The In-House PreDocumento7 páginasThe New ISO Guide 80 Guidance For The In-House PreVidal Flores CopaAinda não há avaliações

- No 1 Method ValidationDocumento2 páginasNo 1 Method ValidationdanaciortanAinda não há avaliações

- Cleaning and disinfection of food factories: a practical guideNo EverandCleaning and disinfection of food factories: a practical guideAinda não há avaliações

- Requirements for ISO 17025 Calibration Lab ImplementationDocumento22 páginasRequirements for ISO 17025 Calibration Lab ImplementationNurul RochmawatiAinda não há avaliações

- ISO/IEC 17025 Calibration Lab RequirementsDocumento25 páginasISO/IEC 17025 Calibration Lab Requirementsyosia adiAinda não há avaliações

- Hoklas SC002Documento54 páginasHoklas SC002Aqueous CarlosAinda não há avaliações

- SustainabilityAssessment System - AM PDFDocumento35 páginasSustainabilityAssessment System - AM PDFAli ZafarAinda não há avaliações

- Eurolab Handbook Iso Iec 17025 2017Documento32 páginasEurolab Handbook Iso Iec 17025 2017Ali ZafarAinda não há avaliações

- ISO/IEC 17025:2017 Tutorial for UKAS StaffDocumento74 páginasISO/IEC 17025:2017 Tutorial for UKAS StaffAli Zafar100% (1)

- The Foundations of the Process ApproachDocumento34 páginasThe Foundations of the Process ApproachAli ZafarAinda não há avaliações

- Root Cause AnalysisDocumento62 páginasRoot Cause AnalysisLintang Sekar KinanthiAinda não há avaliações

- Nebosh International Diploma Examiners Report Jan 2011 - Unit IaDocumento15 páginasNebosh International Diploma Examiners Report Jan 2011 - Unit IaJack Ebiyabo Sled LawsonAinda não há avaliações

- Victoria Compliance Framework HandbookDocumento22 páginasVictoria Compliance Framework HandbookAli ZafarAinda não há avaliações

- RCA Mini Guide PDFDocumento15 páginasRCA Mini Guide PDFIldzamar Haifa WardhaniAinda não há avaliações

- The Ideology of Pakistan Javid Iqbal 1959 - 000026Documento98 páginasThe Ideology of Pakistan Javid Iqbal 1959 - 000026Ali Zafar100% (1)

- NEBOSH Idip July 2012 Unit IA Exam PaperDocumento12 páginasNEBOSH Idip July 2012 Unit IA Exam PaperNaeem Iqbal33% (3)

- Examiner Reports January 2009 Unit IADocumento13 páginasExaminer Reports January 2009 Unit IAElavarasan RamalingamAinda não há avaliações

- Diploma Unit A Revision Cards PDFDocumento72 páginasDiploma Unit A Revision Cards PDFAli Zafar100% (1)

- National Fire Guide Nov 14 Spec V242201634116Documento67 páginasNational Fire Guide Nov 14 Spec V242201634116Ali ZafarAinda não há avaliações

- Unit Ia Exam SuccessDocumento82 páginasUnit Ia Exam SuccessAli Zafar100% (8)

- NQA ISO 14001 2015 Transition GuidanceDocumento6 páginasNQA ISO 14001 2015 Transition GuidancePedroAinda não há avaliações

- Annex SL Excerpt - 2015 6th Edition - Hls and Guidance Only PDFDocumento23 páginasAnnex SL Excerpt - 2015 6th Edition - Hls and Guidance Only PDFalexmardukAinda não há avaliações

- Maturity AssessmentDocumento228 páginasMaturity AssessmentAli ZafarAinda não há avaliações

- Communication, Participation & Consultation ProceduresDocumento12 páginasCommunication, Participation & Consultation ProceduresAli ZafarAinda não há avaliações

- COOP Risk Assessment Vulnerability AnalysisDocumento8 páginasCOOP Risk Assessment Vulnerability AnalysisAli ZafarAinda não há avaliações

- Costain BBS ProgrammeDocumento55 páginasCostain BBS ProgrammeAli ZafarAinda não há avaliações

- ISO 9001 Auditor Training Q&ADocumento10 páginasISO 9001 Auditor Training Q&AAli Zafar71% (7)

- F13 SiteDailyLogDocumento5 páginasF13 SiteDailyLogAli ZafarAinda não há avaliações

- Evolution of a Process Flow Diagram for Farming OperationsDocumento18 páginasEvolution of a Process Flow Diagram for Farming OperationsAli ZafarAinda não há avaliações

- Costain BBS ProgrammeDocumento55 páginasCostain BBS ProgrammeAli ZafarAinda não há avaliações

- Hazop Training GuideDocumento9 páginasHazop Training GuideAdyBorsosAinda não há avaliações

- Crisis Management Manual: SampleDocumento53 páginasCrisis Management Manual: SampleloveasoneAinda não há avaliações

- FIRE HYDRANT DESIGN CRITERIADocumento85 páginasFIRE HYDRANT DESIGN CRITERIAhareeshrp_87515719350% (2)

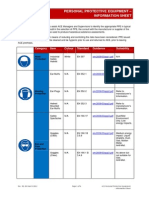

- ACE Personal Protective Equipment Information SheetDocumento4 páginasACE Personal Protective Equipment Information SheetAli ZafarAinda não há avaliações

- Aspect-Impact Assessments Significance Ranking Total Rank A B C D E F Impact Direct/Indir Ect Condition N/A/EDocumento1 páginaAspect-Impact Assessments Significance Ranking Total Rank A B C D E F Impact Direct/Indir Ect Condition N/A/EAli ZafarAinda não há avaliações

- Communication Plan for HSSE DepartmentDocumento1 páginaCommunication Plan for HSSE DepartmentAli ZafarAinda não há avaliações

- GWP - Unicef - Guidance Note Risk Assessments For Wash PDFDocumento56 páginasGWP - Unicef - Guidance Note Risk Assessments For Wash PDFyomifAinda não há avaliações

- Di OutlineDocumento81 páginasDi OutlineRobert E. BrannAinda não há avaliações

- New Text DocumentDocumento8 páginasNew Text DocumentDhaniAinda não há avaliações

- Silvianita - LK 0.1 Modul 2 English For Personal CommunicationDocumento3 páginasSilvianita - LK 0.1 Modul 2 English For Personal CommunicationSilvianita RetnaningtyasAinda não há avaliações

- Discuss in Details With Appropriate Examples What Factors Could Lead To Sympatric and Allopatric SpeciationDocumento5 páginasDiscuss in Details With Appropriate Examples What Factors Could Lead To Sympatric and Allopatric SpeciationKhairul ShahmiAinda não há avaliações

- Acute Care Handbook For Physical Therapists 5Th Edition Full ChapterDocumento41 páginasAcute Care Handbook For Physical Therapists 5Th Edition Full Chaptergloria.goodwin463100% (20)

- Literature - Part I: Group InterventionsDocumento14 páginasLiterature - Part I: Group InterventionsDanielAinda não há avaliações

- Skellig - Chapters 16-20 QuestionsDocumento1 páginaSkellig - Chapters 16-20 Questionselishasantos0% (1)

- Andy Landers - Freeze Zone OffenseDocumento6 páginasAndy Landers - Freeze Zone OffenseWinston Brown100% (1)

- Intro To Flight (Modelling) PDFDocumento62 páginasIntro To Flight (Modelling) PDFVinoth NagarajAinda não há avaliações

- Aiatsoymeo2016t06 SolutionDocumento29 páginasAiatsoymeo2016t06 Solutionsanthosh7kumar-24Ainda não há avaliações

- Banking & Finance Awareness 2016 (Jan-Nov) by AffairsCloudDocumento167 páginasBanking & Finance Awareness 2016 (Jan-Nov) by AffairsCloudkaushikyAinda não há avaliações

- Prayer BuddyDocumento42 páginasPrayer BuddyJoribelle AranteAinda não há avaliações

- CHEST 6. Chest Trauma 2022 YismawDocumento61 páginasCHEST 6. Chest Trauma 2022 YismawrobelAinda não há avaliações

- Test Unit 3Documento2 páginasTest Unit 3RAMONA SECUAinda não há avaliações

- A Cautionary Tale of Psychoanalysis and SchizophreniaDocumento30 páginasA Cautionary Tale of Psychoanalysis and SchizophreniaJona JoyAinda não há avaliações

- S The Big Five Personality TestDocumento4 páginasS The Big Five Personality TestXiaomi MIX 3Ainda não há avaliações

- Ehlers-Danlos Syndromes (EDS) : Fiona Li Pharm D Candidate University of Saint Joseph School of PharmacyDocumento22 páginasEhlers-Danlos Syndromes (EDS) : Fiona Li Pharm D Candidate University of Saint Joseph School of PharmacyDiogo CapellaAinda não há avaliações

- Module 2 - Content and Contextual Analysis of Selected Primary andDocumento41 páginasModule 2 - Content and Contextual Analysis of Selected Primary andAngelica CaldeoAinda não há avaliações

- General Ledger Journal Import ProcessDocumento13 páginasGeneral Ledger Journal Import ProcessMadhavi SinghAinda não há avaliações

- Chap 4 eDocumento22 páginasChap 4 eHira AmeenAinda não há avaliações

- Thin Layer Chromatograph1Documento25 páginasThin Layer Chromatograph12581974Ainda não há avaliações

- SDLC - Agile ModelDocumento3 páginasSDLC - Agile ModelMuhammad AkramAinda não há avaliações

- Phantom Susan KayDocumento379 páginasPhantom Susan Kaytheeyeofthemoon100% (9)

- Bob Jones - Science 4Documento254 páginasBob Jones - Science 4kage_urufu100% (4)

- Nitrate Reduction in Sulfate Reducing BacteriaDocumento10 páginasNitrate Reduction in Sulfate Reducing BacteriaCatalinaManjarresAinda não há avaliações

- Umair Mazher ThesisDocumento44 páginasUmair Mazher Thesisumair_mazherAinda não há avaliações

- Kurukshetra English August '17Documento60 páginasKurukshetra English August '17amit2688Ainda não há avaliações

- Shear Explains Shear Cracks 45 DegDocumento15 páginasShear Explains Shear Cracks 45 DegHieu Huy NguyenAinda não há avaliações

- Source: Sonia S. Daquila. The Seeds of RevolutionDocumento6 páginasSource: Sonia S. Daquila. The Seeds of RevolutionJulliena BakersAinda não há avaliações