Escolar Documentos

Profissional Documentos

Cultura Documentos

FANUC Robotics SYSTEM R-J3 Controller S-430i Series Mechanical Unit Maintenance Manual MARM3S43009801E REV. B

Enviado por

Eric Pops LinkDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

FANUC Robotics SYSTEM R-J3 Controller S-430i Series Mechanical Unit Maintenance Manual MARM3S43009801E REV. B

Enviado por

Eric Pops LinkDireitos autorais:

Formatos disponíveis

FANUC Robotics SYSTEM R-J3 Controller S-430i Series Mechanical Unit Maintenance ...

Page 1 of 4

FANUC Robotics SYSTEM R-J3 Controller S-430i Series Mechanical Unit Maintenance Manual MARM3S43009801E REV. B

B-80935EN/02

Back to Main | Table of Contents | Previous Section | Next Section

3.1REPLACING GREASE OF THE DRIVE MECHANISM

Replace the wrist grease of the reducers of J1, J2, and J3 axes, and the J4-axis gear box, every three years or 20,000 hours by using the following procedures. Table 3.1 Grease for 3-year periodical replatement

Supply position J1-axis reducer J2-axis reducer

Grease name

Quantity 4100 cc (3600g)

1650 cc (1450g) Kyodo yushi J3-axis reducer 1600 cc (1400g) Moly white Re no.00 J4-axis gear box (Spec.: A98L-0040-0119) 2000 cc (1800g) Wrist 1 4000 cc (3500g) Wrist 2 400 cc (350g)

1) Replacing procedure of grease to the reducer and the gear box 1 Turn off the power. 2 Remove the grease outlet plug or seal bolt. Also remove the grease nipple for J1axis. 3 Apply new grease from the grease inlet until it comes out from the grease outlet. 4 Remount the plug or seal bolt at the grease outlet. (For mounting the seal bolt, coil a new seal tape.) NOTE

If greasing is performed incorrectly, the internal pressure of the grease bath may suddenly increase, possibly causing damage to the seal, which would in turn lead to grease leakage and abnormal operation. When performing greasing, therefore, observe the following cautions. 1 Before starting to grease, open the grease outlet (remove the plug or bolt from the grease outlet). 2 Supply grease slowly without applying excessive force, using a manual pump. 3 Whenever possible, avoid using a compressed-air pump, powered by the factory air supply. If the use of a compressed air pump is unavoidable, restrict the maximum greasing rate to 15 cc/s and the air pressure to 75 kgf/cm2.

file:///C:/Engineering/ROBOT/Handling%20&%20Pallet%20Tool%205.50/content/80935... 2/16/2012

FANUC Robotics SYSTEM R-J3 Controller S-430i Series Mechanical Unit Maintenance ... Page 2 of 4

4 Use grease only of the specified type. Grease of a type other than that specified may damage the reducer or lead to other problems. 5 After greasing, confirm that no grease is leaking from the grease outlet and that the grease bath is not pressurized, then close the grease outlet. 6 To prevent accidents caused by slipping, completely remove any excess grease from the floor or robot.

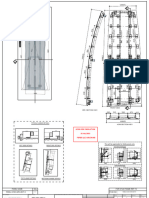

Fig. 3.1 (a) Replacing grease of J1/J2-axis reducer

file:///C:/Engineering/ROBOT/Handling%20&%20Pallet%20Tool%205.50/content/80935... 2/16/2012

FANUC Robotics SYSTEM R-J3 Controller S-430i Series Mechanical Unit Maintenance ... Page 3 of 4

Fig. 3.1 (b) Replacing grease of J3-axis reducer and J4-axis gear box

Fig. 3.1 (c) Replacing grease of wrist

Back to top

Posture at greasing

When replacing or supplying grease, position the robot as the zero degree posture. Back to Main | Table of Contents | Previous Section | Next Section

file:///C:/Engineering/ROBOT/Handling%20&%20Pallet%20Tool%205.50/content/80935... 2/16/2012

FANUC Robotics SYSTEM R-J3 Controller S-430i Series Mechanical Unit Maintenance ... Page 4 of 4

Copyright 1999 by FANUC Robotics North America, Inc.

file:///C:/Engineering/ROBOT/Handling%20&%20Pallet%20Tool%205.50/content/80935... 2/16/2012

Você também pode gostar

- Dokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFDocumento4 páginasDokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFMabrouk GuezatiAinda não há avaliações

- Dokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFDocumento4 páginasDokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFMabrouk GuezatiAinda não há avaliações

- M-900iA600 Mechanical Unit Parts Manual (B-82176EN - 01) PDFDocumento95 páginasM-900iA600 Mechanical Unit Parts Manual (B-82176EN - 01) PDFfrederic190pAinda não há avaliações

- FANUC SYSTEM R-J3iB Controller ArcTool Setup and Operations ManualDocumento194 páginasFANUC SYSTEM R-J3iB Controller ArcTool Setup and Operations Manualtsmith350% (1)

- Fanuc R-2000iA Series PDFDocumento4 páginasFanuc R-2000iA Series PDFAntonio RodriguezAinda não há avaliações

- Ipendant Customization Manual Ver.7.70 (MAROC77CG01101E Rev.Documento222 páginasIpendant Customization Manual Ver.7.70 (MAROC77CG01101E Rev.Manuel Gutierrez100% (1)

- R-J2 Controller - Maintenance Manual B-80525E - 04 PDFDocumento608 páginasR-J2 Controller - Maintenance Manual B-80525E - 04 PDFAdam ZiobrowskiAinda não há avaliações

- Fanuc Roboguide - V6.Xx User Manual (en-JP)Documento132 páginasFanuc Roboguide - V6.Xx User Manual (en-JP)Ioana Apucaloaei100% (2)

- RJ Controller Maintenance ManualDocumento435 páginasRJ Controller Maintenance ManualKien Nguyen TrungAinda não há avaliações

- R J2 RemasteringDocumento16 páginasR J2 RemasteringGerritAinda não há avaliações

- FANUC R-J3iB - Maintenance Manual For Europe - B-81465EN-1-02Documento345 páginasFANUC R-J3iB - Maintenance Manual For Europe - B-81465EN-1-02sierrapr92% (12)

- Software Instalation R-J2Documento213 páginasSoftware Instalation R-J2Marcelo Fiod HasmanAinda não há avaliações

- FANUC Robotics SYSTEM R-J3 (RIA) A-Size, B-Size and Paint Controller Connection and Maintenance Manual Section IV PDFDocumento103 páginasFANUC Robotics SYSTEM R-J3 (RIA) A-Size, B-Size and Paint Controller Connection and Maintenance Manual Section IV PDFMayank PatelAinda não há avaliações

- M410 RJ3Documento4 páginasM410 RJ3Ali Hernandez100% (1)

- VisionR 30iaDocumento14 páginasVisionR 30iaNahum Alamilla100% (3)

- BookDocumento212 páginasBookVelez100% (1)

- LRMate200iC Maintenance Manual (B-82585EN02)Documento196 páginasLRMate200iC Maintenance Manual (B-82585EN02)sierraprAinda não há avaliações

- Fanuc Robotics System 1Documento35 páginasFanuc Robotics System 1Kevin KellyAinda não há avaliações

- S-420i Mechanical Unit Maintenance (B-80505EN - 06)Documento212 páginasS-420i Mechanical Unit Maintenance (B-80505EN - 06)Damian Dusiński100% (4)

- IRVision Operation Manual V8.10Pxx V8.20Pxx (B-83304EN 03) (Output Measurement)Documento4 páginasIRVision Operation Manual V8.10Pxx V8.20Pxx (B-83304EN 03) (Output Measurement)Marin ZagarAinda não há avaliações

- Software Options FANUCDocumento12 páginasSoftware Options FANUCIvanMakarovAinda não há avaliações

- FANUC IO Products PDFDocumento4 páginasFANUC IO Products PDFtom100% (1)

- Fanuc Modbus CommunicationDocumento10 páginasFanuc Modbus Communicationfenix5114Ainda não há avaliações

- S 420i Mechanical Unit Maintenance B 80505en 06 PDFDocumento212 páginasS 420i Mechanical Unit Maintenance B 80505en 06 PDFAdam ZiobrowskiAinda não há avaliações

- Grease Alternative For FANUC Robots Hardware Engineering BulletinDocumento3 páginasGrease Alternative For FANUC Robots Hardware Engineering BulletinshareavAinda não há avaliações

- R30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFDocumento219 páginasR30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFdenix49Ainda não há avaliações

- Powerwave ManagerDocumento128 páginasPowerwave ManagerJackson Dias RochaAinda não há avaliações

- Setting Up A Password System On Fanuc Robots (R-30iB V8.30P)Documento7 páginasSetting Up A Password System On Fanuc Robots (R-30iB V8.30P)Amine AbassiAinda não há avaliações

- Force Sensor Operation Manual (B-81154EN 03)Documento227 páginasForce Sensor Operation Manual (B-81154EN 03)Neda Elena Andreea100% (3)

- 2 Axis Positioner ManualDocumento76 páginas2 Axis Positioner Manualgerco12Ainda não há avaliações

- R-J2 Controller For Europe - Maintenance Manual B-80525E-1 - 03 PDFDocumento510 páginasR-J2 Controller For Europe - Maintenance Manual B-80525E-1 - 03 PDFAdam ZiobrowskiAinda não há avaliações

- Fanuc R-J Controller Series Electrical Connection and Maintenance Manual PDFDocumento436 páginasFanuc R-J Controller Series Electrical Connection and Maintenance Manual PDFEly100% (1)

- Tarjeta IO EA Robot FanucDocumento3 páginasTarjeta IO EA Robot FanucDracoRodriguezAinda não há avaliações

- FANUC Software OlpcPRODocumento2 páginasFANUC Software OlpcPROJavierJBVAinda não há avaliações

- MANTENIMIENTO ELECTRICO ROBOTS CONTROLADOR RJ3iB ESP PDFDocumento170 páginasMANTENIMIENTO ELECTRICO ROBOTS CONTROLADOR RJ3iB ESP PDFViri Hernandez MarquezAinda não há avaliações

- FANUCDocumento66 páginasFANUCSara Santos67% (3)

- R-J2 Mate Controller - B81315Documento181 páginasR-J2 Mate Controller - B81315Marek Grysko100% (1)

- FANUC Educational Cell Exercises PDFDocumento240 páginasFANUC Educational Cell Exercises PDFjorgemoody100% (2)

- 30ia DCS Cartesian Position Limit Avoidance and RecoveryDocumento8 páginas30ia DCS Cartesian Position Limit Avoidance and RecoveryJorge ValdezAinda não há avaliações

- Paint Mate 200ia Series - 27Documento4 páginasPaint Mate 200ia Series - 27countzeroaslAinda não há avaliações

- Application Equipment ManualDocumento545 páginasApplication Equipment Manualgguadian21Ainda não há avaliações

- FANUC Series: Operator'S ManualDocumento104 páginasFANUC Series: Operator'S ManualZied RaouakAinda não há avaliações

- R-30iB Visual Linetracking Operator Manual (B-83304EN-4 01)Documento180 páginasR-30iB Visual Linetracking Operator Manual (B-83304EN-4 01)uriahp76Ainda não há avaliações

- R-J3iC Robot Link User ManualDocumento88 páginasR-J3iC Robot Link User ManualSebautomatisme0% (1)

- 2nd Generation Henrob Controller: Operation and Maintenance Manual For Henrob Self-Pierce Riveting SystemDocumento152 páginas2nd Generation Henrob Controller: Operation and Maintenance Manual For Henrob Self-Pierce Riveting SystemAlejandro PuenteAinda não há avaliações

- R-30iAMate LRHandlingTool UOP AssignmentsDocumento9 páginasR-30iAMate LRHandlingTool UOP Assignmentsdenix49100% (1)

- Operator'S Manual: Fanuc Devicenet BoardDocumento124 páginasOperator'S Manual: Fanuc Devicenet BoardDiego Amador100% (1)

- Fanuc I/O Unit-Model A: Connection and Maintenance ManualDocumento246 páginasFanuc I/O Unit-Model A: Connection and Maintenance Manualcamgz32Ainda não há avaliações

- A - Inhaltsverzeichnis - R30IB Rev 9Documento17 páginasA - Inhaltsverzeichnis - R30IB Rev 9Quí Lâm NguyễnAinda não há avaliações

- Fanuc Training Guide 2009 IBDocumento56 páginasFanuc Training Guide 2009 IBEdgardo Aguillon100% (1)

- 78 Dt400e DT250E ManualDocumento18 páginas78 Dt400e DT250E Manualdisgustipate0% (1)

- Helical Gearbox InstallationDocumento8 páginasHelical Gearbox InstallationKUNALJAYAinda não há avaliações

- Lubrication PDFDocumento22 páginasLubrication PDFAndrey GladyshevAinda não há avaliações

- Mt700C/800C Series Tracked Tractors Secondary Steering Valve Rework - Rp6396 MandatoryDocumento4 páginasMt700C/800C Series Tracked Tractors Secondary Steering Valve Rework - Rp6396 MandatoryMessi EmetievAinda não há avaliações

- Yamaha DS7 (72) RD250 (73) R5C (72) RD350Documento113 páginasYamaha DS7 (72) RD250 (73) R5C (72) RD350Igor Majksner100% (5)

- 2AZ FE LubricationDocumento22 páginas2AZ FE LubricationLuks Fernandez100% (2)

- C9 Service Letter Injector ReplaceDocumento6 páginasC9 Service Letter Injector Replaceharikrishnanpd3327Ainda não há avaliações

- Timing Chain - 2003 Toyota Camry Sedan l4-2Documento10 páginasTiming Chain - 2003 Toyota Camry Sedan l4-2ftafedeAinda não há avaliações

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Ainda não há avaliações

- Ensunchadora AH-114 - SignodeDocumento4 páginasEnsunchadora AH-114 - SignodeTanSoloUnMinutoAinda não há avaliações

- NOV Profab Daily Meeting - Kakinada Project STP For KG DWN-98/2 Kakinada FPSO Week-40Documento28 páginasNOV Profab Daily Meeting - Kakinada Project STP For KG DWN-98/2 Kakinada FPSO Week-40Rendra Maha Putra JfAinda não há avaliações

- FM-II Week 4Documento22 páginasFM-II Week 4khizeraftab1018Ainda não há avaliações

- BB831 Xa03xen E1 PDFDocumento62 páginasBB831 Xa03xen E1 PDFDaniel RamirezAinda não há avaliações

- Launching Girder PDFDocumento26 páginasLaunching Girder PDFparamarthasom19740% (1)

- Agitator Manual PDFDocumento76 páginasAgitator Manual PDFJoan Camilo PovedaAinda não há avaliações

- Operating Principles of Narkomed Anaesthesia Systems - DrägerDocumento189 páginasOperating Principles of Narkomed Anaesthesia Systems - DrägerSergio MontesAinda não há avaliações

- Press Tool MCQDocumento6 páginasPress Tool MCQMahesh Dalavi90% (10)

- Lección 3 - To Be Interrogativo - His and HerDocumento2 páginasLección 3 - To Be Interrogativo - His and Herjosedth robayoAinda não há avaliações

- Split Unit AC Lab ReportDocumento6 páginasSplit Unit AC Lab ReportusmanAinda não há avaliações

- Steam Traps Wiki Seminar2Documento7 páginasSteam Traps Wiki Seminar2Ram KumaarAinda não há avaliações

- Axial and Radial Flow Turbines Solved Problems RagazaDocumento4 páginasAxial and Radial Flow Turbines Solved Problems RagazaAnonymous 1VhXp1Ainda não há avaliações

- Rule of Thumb For Duct SystemsDocumento1 páginaRule of Thumb For Duct SystemsImtiaz AhmedAinda não há avaliações

- Blair Multi-Rope Double-Drum Winder For South Deep Gold Mines (South Africa)Documento4 páginasBlair Multi-Rope Double-Drum Winder For South Deep Gold Mines (South Africa)Freddie FosterAinda não há avaliações

- Rsmli CH03 GRC Bot 9Documento1 páginaRsmli CH03 GRC Bot 9Muhammad BilalAinda não há avaliações

- Wire Rope Common Terms: Hand Laid & Spliced SlingsDocumento2 páginasWire Rope Common Terms: Hand Laid & Spliced SlingsseawizeAinda não há avaliações

- Product List Onetouch PDFDocumento5 páginasProduct List Onetouch PDFGouse BujjiAinda não há avaliações

- Emergency Stop Valve PDFDocumento4 páginasEmergency Stop Valve PDFMauricio GarciaAinda não há avaliações

- Mechanical BeltsDocumento9 páginasMechanical BeltstorresgiovanniAinda não há avaliações

- Pcs Fca140 Leaflet Interactiveonline enDocumento4 páginasPcs Fca140 Leaflet Interactiveonline enLyonelAinda não há avaliações

- Socket - EM-DUO 120/15 - 5600461: Key Commercial DataDocumento4 páginasSocket - EM-DUO 120/15 - 5600461: Key Commercial DataJavier CuzcoAinda não há avaliações

- Purchase Department Sample Data-VDocumento8 páginasPurchase Department Sample Data-VBhuvnesh BatraAinda não há avaliações

- 0702 Pnuematic Component Symbols - ASCO PDFDocumento2 páginas0702 Pnuematic Component Symbols - ASCO PDFShilpa Kamath100% (1)

- United States Patent: (73) Assignee: Cameron International Corporation, 535856. A. 1323 E. ST AlDocumento12 páginasUnited States Patent: (73) Assignee: Cameron International Corporation, 535856. A. 1323 E. ST AlErin GokAinda não há avaliações

- List Hasil Interview KaryawanDocumento1 páginaList Hasil Interview KaryawanTeguh DwiyantoAinda não há avaliações

- CWT CWTF CWTF-MV: Illustrated Parts CatalogDocumento41 páginasCWT CWTF CWTF-MV: Illustrated Parts CatalogAndres NovaAinda não há avaliações

- Swedmaq PDFDocumento92 páginasSwedmaq PDFAlejandroAinda não há avaliações

- Partes de Un Martillo - (rh35hp - Manual) - 2015Documento17 páginasPartes de Un Martillo - (rh35hp - Manual) - 2015jhonaAinda não há avaliações

- Schedule of Footing Schedule of Columns: A B C D EF G HDocumento1 páginaSchedule of Footing Schedule of Columns: A B C D EF G HSimantaSonowalAinda não há avaliações

- Hydril 533Documento4 páginasHydril 533Fernando OlaveoAinda não há avaliações