Escolar Documentos

Profissional Documentos

Cultura Documentos

Victoria Chemicals PLC Case Analysis

Enviado por

Lesika Q. MintzDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Victoria Chemicals PLC Case Analysis

Enviado por

Lesika Q. MintzDireitos autorais:

Formatos disponíveis

VICTORIA CHEMICALS PLC (A): THE MERSEYSIDE PROJECT

Capital Budgeting Case Analysis

DeQuincy Adamson Donald Harrell Lekisha McKinley Taylor Wolfe

Finance 5387 Spring 2012

VICTORIA CHEMICALS: CASE BACKGROUND Victoria Chemicals was a major competitor in the chemical industry worldwide. The company was the leading producer of polypropylene, a polymer that is used in a variety of products including carpet fibers, packaging, and automobile parts. Polypropylene was essentially priced as a commodity. In order to meet demand, Victoria Chemicals produced and manufactured polypropylene at two plants, the Merseyside Works plant in Liverpool, England, and the Rotterdam facility in Rotterdam, Holland. The plants were built in 1967 and are identical in scale and design. Additionally, managers of both plants reported to James Fawn, the executive vice president and manager of the Intermediate Chemicals Group (ICG). The production of polypropylene pellets begins at Merseyside with propylene, a refined gas received in tank cars known as propylene. The production process consisted of two stages: In the first stage, the gas form of polypropylene was combined with a solvent in a pressurized vessel and then concentrated and collected in a centrifuge. Next, the polypropylene was mixed with stabilizers, modifiers, fillers, and pigments in order to create the final product, a plastic pellet, which is shipped to the customer. The company positioned itself as a supplier to customers in Europe and the Middle East. In addition to small producers, seven major competitors manufactured polypropylene in Victoria Chemicals market region. Their plants operated at various cost levels. Primary competitors CBTG A.G. and Hosche A.G. were able to produce higher annual output at lower costs per ton. Table 1 on the following page presents a comparison of plant sizes and indexed costs.

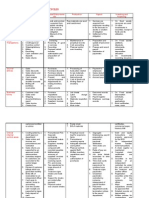

Table 1: Comparison on the Seven Largest Polypropylene Plants in Europe

Plant Plant Location Year Plant Built Annual Output (in metric tons)

CBTG A.G. Victoria Chemicals Victoria Chemicals Hosche A.G. Montecassino SpA Saone-Poulet S.A. Vaysol S.A. Next 10 Largest Plants Saabrun Liverpool Rotterdam Hamburg Genoa Marseille Antwerp 1981 1967 1967 1977 1961 1972 1976 350,000 250,000 250,000 300,000 120,000 175,000 220,000 450,000

Product Cost per ton (indexed to lowcost producer)

1.00 1.09 1.09 1.02 1.11 1.07 1.06 1.19

Plant Name

VICTORIA CHEMICALS: ISSUES/PROBLEMS In 2007, Victoria Chemicals experienced a significant drop in its financial performance from 2006. The company was under pressure to improve its performance as its earnings had fallen 38% from 250 pence per share to 180 pence per share in a year. In addition, Victoria Chemicals saw the accumulation of its common shares by a well-known corporate raider named Sir David Benjamin. The entrance of a corporate raider may have shown that the firms assets appeared to be under valued. This corporate raider could gather a large voting right, change the management, and ultimately increase share value and get a big return on his investment. The decline in the companys value was due in large part to its current production process and the condition of its facilities: The method of producing the polypropylene at the Merseyside Works plant was obsolete compared to new technology with its competitors, and required more labor than the process used by its competitors. As well, the previous manager of the plant had enhanced operating results by minimizing capital expenditures to cover only necessary

maintenance over the past five years; routine maintenance had been delayed to the point that it was now imperative for it to no longer be deferred in order to renew the production line. Another issue that Victoria Chemicals faces is that its product is a commodity. They do not compete with a differentiated product; as such, to remain competitive and gain market share, they need to maintain competitive prices while increasing profits through lowering their costs. Because both their plants are older and use a semi continuous production process, Victoria Chemicals requires more labor than its competitors in newer, more efficient plants. Compared to its competitors, Victoria Chemicals incurs high costs of production mainly due to higher dependence on labor. Montecassino is the only other firm among the top 7 whose costs are higher than that of Victoria Chemicals, but it is an older plant (built in 1961) and produces a lower volume compared to Victoria Chemicals. Therefore, Victoria Chemicals faces issues not only with lower revenues but with higher costs as well. Given these factors, Merseyside Works plant manager Lucy Morris thought it an ideal time to seek funding from corporate headquarters for a modernization program for the Merseyside Works. Morris felt this move would help improve the companys financial situation and help them remain a major competitor in the worldwide chemical industry. VICTORIA CHEMICALS: THE PROPOSED PROJECT Morris and her controller, Frank Greystock, proposed a project to overhaul the entire polymerization line at a cost of GBP 12 million. The proposed project would be to renovate and rationalize the polypropylene production line at the Merseyside plant in order to make up for deferred maintenance and to exploit opportunities to achieve increased production efficiency. Morris revealed the areas of opportunity in which the project covered: No longer defer maintenance on essential tools and equipment required in the production process. Correct the plant design on ways that would save energy and improve the process flow by: o Relocating and modernizing the tank-car unloading areas, which would enable the process flow to be streamlined. o Refurbishing the polymerization tank to achieve higher pressures and thus greater throughput.

o Renovating the compounding plant to increase extrusion throughput and obtain energy savings. The benefits of this project were increased efficiencies in terms of: Reduced energy consumption, which was assumed to equal 1.25% of sales in the first year and .75% in years 6-10. Increased gross margin of up to 12.5%. Increased manufacturing output. Currently, Victoria Chemicals was producing 250,000 tons of polypropylene pellets a year at a price of GBP675 per ton. The project would also result in seven percent (7%) greater manufacturing throughput; however, the entire line would need to be shut down for 45 days in the first year for construction. Based on the current annual 250,000 ton production figure, Victoria Chemicals would experience roughly a 13% decrease in production for that year upon implementing the project. The 13% figure was determined using the following equation where 1.5 (months) equals 45 days in which the plant would be shut down for construction: ( )

The tax rate required in the capital-expenditure analysis was 30%. Greystock also speculated that any new assets acquired would depreciate in 15 years. In addition, he predicted that in the first year the company would incur GBP500, 000 in engineering costs due to the renovation. VICTORIA CHEMICALS: CONCERNS WITH THE PROPOSED PROJECT Even though the project seemed to have promising returns, there were some issues or concerns that were associated with the project. Renovating the Merseyside plant would require it to shut down for 45 days. This was a problem because the Rotterdam plant was already operating at near-maximum capacity, which would cause Merseyside Works customers to buy from competitors until the renovation was completed. Even still, Frank Greystock, a controller at Victoria Chemicals, assumed that this loss of customers would be temporary. Furthermore, Victoria Chemicals owned the tank cars with which Merseyside Works received propylene gas from four petroleum refineries in England. The Transport Division,

which oversaw the movement of all raw, intermediate, and finished materials throughout the company and was responsible for managing the tank cars, realized that it would be required to be increase its allocation of tank cars to Merseyside to support the growth that the renovation would bring. Currently, the allocation could be made out of excess capacity, but doing so would accelerate the need to purchase new rolling stock to support anticipated growth of the firm in other areas. The purchase was estimated at GBP2 million in 2010. Rolling stock would have a depreciable life of 10 years, but could operate much longer with proper maintenance. The rolling stock also could not be used outside of Britain because of differences in track gauges, which meant that the trucks could not be used to ship product to its primary customers in the Middle East. The Transport Division believed that the cost of the tank cars should be included in the initial outlay of Merseyside Works capital program. However, Greystock disagreed, noting that they were doing the company a favor by using the excess capacity and that company has always operated in silos. As such Greystock did not include the charge (cost of excess rolling stock) in the proposal on the grounds that the division should carry the allocation of rolling stock. The Transport Division was not the only division with concerns. The ICG Sales and Marketing department had some questions of their own. The director of sales said that the Greystocks analysis assumed that the company would be able to sell the increased output brought on by the renovation. However, the entire industry was experiencing a downturn; thus, an oversupply of polypropylene could occur. To combat the oversupply, the company would likely shift capacity from Rotterdam to Merseyside, which could result in Merseyside cannibalizing Rotterdam. On the other hand, the V.P. of marketing believed that lowering costs would help Victoria Chemicals compete better with other producers of polypropylene and thus win over customers from competitors. After hearing out both arguments, Greystock did not include charge for loss of business in his analysis as he felt a cannibalization charge was fictitious and including such charges would not allow them to maintain their cost competitiveness. Greystocks discounted cash flow also suggested that the company would earn a 10% return on the project, even though the Treasury staff believed the real return to be 7% due to a 3% in inflation per year. However, Greystock decided to continue to use a discount rate of 10%

because it was the figure promoted in the latest edition of the companys capital-budgeting manual. The high discount rate was problematic because, if the 7% figure was more accurate, using the 10% rate would cause the company to accept projects (those that fall between seven and 10 percent) that should be rejected. On another note, Griffin Tewitt, assistant plant manager and Morriss direct subordinate, proposed that Greystock modify his proposal to include a renovation of the EPC production line at a cost of GBP1 million. He believed that the renovation would give Victoria Chemicals the lowest EPC cost base in the world and would improve cash flows by GBP25,000. The NPV of this project was GBP750,000, which Tewitt argued that the negative NPV ignored strategic advantages from the project and increases in volume and prices when the recession ended. VICTORIA CHEMICALS: EVALUATING THE PROPOSED PROJECT The project was considered an engineering-efficiency and, therefore, was required to meet certain criteria before being approved. The criteria included: 1. Impact on earnings per share: The net income had to be positive when calculated as annual earnings per share (EPS) over its entire life, using the number of outstanding shares at the most recent fiscal year-end as the basis for the calculation. 2. Payback: The payback period maximum was six years. 3. Discounted cash flow: The net present value of all future cash flows had to be positive. 4. Internal rate of return: The IRR had to be greater than 10%. Morris wanted to review Greystocks analysis in order to resolve the issue of the tank cars and the loss of business that could occur. However, she was afraid that further analysis could lead to rejection of the project. The Merseyside project, according to Greystock, met all four investment criteria: 1. Average annual addition to EPS of GBP0.022 2. Payback period of 3.8 years. 3. Net present value of GBP10.6 million 4. IRR of 24.3%

In the following paper, we will analyze the four criteria based on Greystocks findings to determine if the analysis was conducted accurately and reflects true numbers or expectations of return on the Merseyside project investment.

VICTORIA CHEMICALS: EARNINGS PER SHARE (EPS) The impact on EPS is calculated as the average of annual incremental gross profit due to the profit divided by the number of shares. In order to accept this project, the EPS needs to be GBP0.022. [discuss how/if we met this requirement; steps we took to meet it] VICTORIA CHEMICALS: SUNK COSTS The plant manager has included the preliminary engineering costs of GBP 500,000 spent over the past nine months on efficiency and design studies of the renovation. These costs are already incurred and are independent of the project decision. Whether or not the project is going to be approved, these costs are to be borne by the company. Therefore, these costs are not to be considered for the DCF analysis. VICTORIA CHEMICALS: PIGGYBACK PROJECT ETHICAL DILEMMA The assistant plant manager, Griffin Tewitt, proposed to modernize a separate and independent part of Merseyside Works, the production line for EPC. His argument was to include the EPC project as part of the renovation project that is currently being analyzed. To improve the EPC production line it would cost GBP 1 million, but it would improve cash flows by GBP 25,000 indefinitely. The EPC project has a negative NPV of -GBP750,000, and his contention was that the bigger renovation project with a positive NPV of GBP 10.6 million (under the original calculation) can absorb the losses of the EPC project. The benefits of the EPC project will come through when the recession ends and increase in volume and prices happen.

Although the EPC project has potential to become larger, the EPC market has not been largely successful since its inception. In addition, an ethical dilemma occurs where Tewitt is asking Greystock to add his renovation project as part of the polypropylene line renovations stating that in the last 20 years, no one from corporate has monitored renovation projects once the investment decision is made. Even if there would be benefits to the company overall, the EPC project should not be included in the analysis because this product line would not impact the polypropylene product line. The costs and benefits are not relevant to this analysis.

VICTORIA CHEMICALS: COMPETITION WITHIN DIVISIONS The reporting structures and bonus programs have lead to a lack of synergies between divisions and a violation of ethics. There is conflict between Transportation division and polypropylene production division. Having the Transport Division and the Intermediate Chemicals Group reporting to separate executive vice presidents is a problem. Generally, the logistics divisions and manufacturing divisions of a company report to a single executive that oversees the entire supply chain process. This supply chain manager facilitates the manufacturing and movement of all materials in order to increase efficiencies and reduce costs. Additional issues of concern is that the plant managers bonuses are tied to the size of the plants they operate, which is not necessarily the proper incentive plan because operation size does not always positively correlate with efficiency and profit margins. Other issues are that of evaluation of projects on a periodic basis to monitor the costs incurred, progress and benefits occurring on time. In the current system at VC, there is no post evaluation of projects at corporate level after the investment decision is made. The company procedures for capital expenditure approvals should incorporate a post hoc analysis to determine if the project outcome was estimated accurately and if the project was a success or not. The procedure should also be updated to require the analysis to include the appropriate depreciation methods and tax rates, as these factors have a significant effect on NPV and IRR. VICTORIA CHEMICALS: CANNIBALIZATION

The sales department is concerned that the project may lead to excess capacity and due to excessive competition, capacity would be shifted from the Rotterdam plant to Merseyside, and the Rotterdam plant would have to produce less. However, the Marketing department opines that the excess production would yield benefits in a growth period, and Merseyside may be able to cannibalize sales from competitors rather than its own sister plant at Rotterdam. If the plants do not meet their sales volume then they would simply be running the more productive and efficient plant (Merseyside) to capacity and have Rotterdam fulfill the overflow. There is no question of adding a cannibalization charge to the project expense, but it is a matter of concern for such projects.

Criteria #3: Net Present Value (NPV) Criteria #4: Internal Rate of Return (IRR Found this info online. May apply, may not, but just some thoughts: Recommendation: It is recommended that the purchase of the tanks be charged to the project cost, so you

can put this expense into the cost of the project plus tanks and have direct ownership of the plant. It is not considered that this new project can cannibalize the plant in Rotterdam, as the market covered by each plant is different, and the location is difficult for an end to the other plant. Of the four methods, the

two most favorable to use for evaluation would be NPV and IRR while the EPS and PBP would be less favorable to use because of its evaluation process. Using NPV is a good method to use to evaluate the project because it takes into account all the costs relevant to the project and includes all the cash flows of the project. VICTORIA CHEMICALS: CONCLUSIONS There are various problems that keep Victoria Chemicals from achieving its financial goals. One of the first major problems is the fact that the Merseyside plant required a lot of labor in order to produce a similar that a competitors firm could produce for lower labor costs. In order to continue to fall by the wayside, Victoria Chemicals has come up with a plan to turn the firm around. By implementing these changes, they will save energy and improve productivity.

The company is proposing to upgrade the polymerization line in addition to a increasing the production of their EPC line. Although the plant desperately needs renovations, closing down production for 45 days may make customers permanently switch to a competitors brand. The director of sales states that the polypropylene market is highly competitive, therefore, any loss in customers would be detrimental. Victoria Chemicals needs to determine how successful the upgraded plant will be in comparison to the loss of customers. Their data does not take into consideration any customers lost during this renovation. However, without the upgrades they will continue to operate at much higher costs than their competitors. The analysis shows that this project is beneficial to Victoria Chemicals, and they should implement it. Even though Greystocks initial analysis met all of the performance hurdles, he missed some important factors that would have improved the analysis. This could have been accomplished by changing the calculations as discussed; NPV and IRR would prove to be better for the projects projections. VICTORIA CHEMICALS: RECOMMENDATIONS Frank Greystock said that, No one seems satisfied with the analysis so far, but the suggested changes could kill the project. This sort of criticism shows that the analysis has obvious flaws and should be re-written. The company needs to agree on such a plan because it requires a lot of time and money. It is important that the company function as a cohesive unit. Although various departments may not always concur, it is important for the sake of the company to come to a mutual decision. The organizational structure of the company may need to be re-evaluated in order to create efficiency and fewer problems when reporting to separate vice presidents.

The company should not tie managers bonuses with the size of the plant. Instead, they should create incentives for efficiency, revenue, or turnover. A manager could easily grow a plant to collect his or her bonus but this may not be best for the company and its long term success.

In addition to the production of polypropylene, Victoria Chemicals suggested increasing the production of EPC, ethylene-propylene-copolymer rubber. This chemical represents a small portion in the current chemical market and has since its creation. This project will amount to a NPV of -750,000 GBP. Due to the fact that the EPC market is so small, it would be wasteful to spend so much money on the project. Multiple competitors produce similar chemicals. The company should focus on something else that could potentially hold a large part of the market, instead of such a minimal impact product. Although Victoria Chemicals is depreciating their machines using double declining balance method, this may be beneficial due to tax reasons, and it may not look good to potential investors. By paying more in depreciation costs now, the company reduces its revenues. This is potentially troublesome due to the fact the financial performance of the firm has declined in the past few years. It may be more efficient for the firm to use straight-line depreciation to control the loss in revenue.

Você também pode gostar

- VICTORIA ChemicalDocumento24 páginasVICTORIA ChemicalekkyAinda não há avaliações

- Case 22 Victoria Chemicals A DONEDocumento14 páginasCase 22 Victoria Chemicals A DONEJordan Green100% (5)

- Diamond Chemicals Group 5Documento14 páginasDiamond Chemicals Group 5Gressiadi80% (5)

- Summary Victoria AfterDocumento6 páginasSummary Victoria AfterAnindito W WicaksonoAinda não há avaliações

- Victoria ChemicalsDocumento10 páginasVictoria Chemicalshookemvic67% (3)

- Victoria Chemicals PLC Case AnalysisDocumento12 páginasVictoria Chemicals PLC Case Analysisresharofifahutoro0% (1)

- Victoria Chemicals Plc Project Selection: Merseyside vs RotterdamDocumento6 páginasVictoria Chemicals Plc Project Selection: Merseyside vs RotterdamRivki MeitriyantoAinda não há avaliações

- Victoria Chemicals Part 5Documento3 páginasVictoria Chemicals Part 5cesarvirata100% (1)

- Victoria Chemicals PLC: The Merseyside ProjectDocumento15 páginasVictoria Chemicals PLC: The Merseyside ProjectAde AdeAinda não há avaliações

- Concerns with DCF analysis for Intermediate Chemicals Group projectDocumento2 páginasConcerns with DCF analysis for Intermediate Chemicals Group projectJia LeAinda não há avaliações

- Victoria Chemicals (B)Documento6 páginasVictoria Chemicals (B)Siti Najmi Syuhaila92% (13)

- Diamond Chemicals Merseyside ProjectDocumento12 páginasDiamond Chemicals Merseyside ProjectHimanshu DubeyAinda não há avaliações

- Victoria Chemical Case 20Documento4 páginasVictoria Chemical Case 20Shahzad MughalAinda não há avaliações

- Victoria Chemicals Part 1Documento2 páginasVictoria Chemicals Part 1cesarvirataAinda não há avaliações

- Coursework AFE 7 IFM 202122 Semester1Documento10 páginasCoursework AFE 7 IFM 202122 Semester1Batool HamzaAinda não há avaliações

- EPC Modernization Project RejectionDocumento3 páginasEPC Modernization Project Rejectiondontcare32100% (1)

- Victoria Chemicals Plc. (A) The Merseyside ProjectDocumento9 páginasVictoria Chemicals Plc. (A) The Merseyside ProjectAs17 As17Ainda não há avaliações

- Victoria Chemicals DCF analysis of Merseyside projectDocumento2 páginasVictoria Chemicals DCF analysis of Merseyside projecttipo_de_incognito75% (4)

- Case 24 Victoria Chemicals PLC A The Merseyside ProjectDocumento3 páginasCase 24 Victoria Chemicals PLC A The Merseyside ProjectAbdullahIsmailAinda não há avaliações

- Diamond Chemicals DCF AnalysisDocumento2 páginasDiamond Chemicals DCF AnalysisShikha KanwarAinda não há avaliações

- TN20 Diamond Chemicals PLC A and BDocumento39 páginasTN20 Diamond Chemicals PLC A and Bsimoon1100% (5)

- Diamond Chemicals Capital Program AnalysisDocumento3 páginasDiamond Chemicals Capital Program AnalysisSagar Vatkar25% (4)

- Diamond Chemicals Case Study11 - FinalDocumento20 páginasDiamond Chemicals Case Study11 - FinalJoao0% (1)

- DCF Analysis of Merseyside and Rotterdam ProjectsDocumento3 páginasDCF Analysis of Merseyside and Rotterdam ProjectsRakesh100% (2)

- Case 3 Empirical ChemicalsDocumento4 páginasCase 3 Empirical Chemicalssmorga30Ainda não há avaliações

- Victoria Chemicals BriefDocumento3 páginasVictoria Chemicals Briefdobaid1Ainda não há avaliações

- Diamond Chemicals Case ExhibitsDocumento2 páginasDiamond Chemicals Case Exhibitsabhi422100% (1)

- Case 4 - Victoria ChemicalsDocumento18 páginasCase 4 - Victoria ChemicalsYale Brendan CatabayAinda não há avaliações

- Frank's DCF analysis of Merseyside projectDocumento2 páginasFrank's DCF analysis of Merseyside projectriders29Ainda não há avaliações

- Victoria Chemicals PLC (B) - The Merseyside and Rotterdam Projects (SPREADSHEET) F-1544XDocumento4 páginasVictoria Chemicals PLC (B) - The Merseyside and Rotterdam Projects (SPREADSHEET) F-1544XPaco ColínAinda não há avaliações

- American Chemical CorporationDocumento8 páginasAmerican Chemical CorporationAnastasiaAinda não há avaliações

- Diamond ChemicalsDocumento2 páginasDiamond ChemicalsshengAinda não há avaliações

- 13 American Chemical Corporation - Group 13Documento5 páginas13 American Chemical Corporation - Group 13Anonymous MpSSPQi0% (1)

- Case 24 Questions - Victoria ChemicalsDocumento1 páginaCase 24 Questions - Victoria ChemicalsTam Hua0% (1)

- NPV Graph and SpreadsheetsDocumento3 páginasNPV Graph and SpreadsheetsSrinivas Meduri100% (1)

- Discussion Questions: (Victoria Chemicals A)Documento1 páginaDiscussion Questions: (Victoria Chemicals A)burtbert0% (1)

- Victoria Chemicals Part 2Documento2 páginasVictoria Chemicals Part 2cesarvirata100% (3)

- Year 1979 1980 1981 1982 1983 1984 Period 0 1 2 3 4 5Documento30 páginasYear 1979 1980 1981 1982 1983 1984 Period 0 1 2 3 4 5shardullavande33% (3)

- Victoria Chemicals - Student TemplateDocumento1 páginaVictoria Chemicals - Student TemplateBobYuAinda não há avaliações

- Victoria ChemicalsDocumento3 páginasVictoria ChemicalsJia You100% (2)

- Case 3 Empirical ChemicalsDocumento4 páginasCase 3 Empirical ChemicalsStephanie Morgan67% (3)

- Ectn - XLS: InstructorDocumento12 páginasEctn - XLS: Instructorcamr2015100% (1)

- Continental CarriersDocumento6 páginasContinental CarriersVishwas Nandan100% (1)

- Play Time Toy Financial AnalysisDocumento4 páginasPlay Time Toy Financial AnalysischungdebyAinda não há avaliações

- Financial analysis of American Chemical Corporation plant acquisitionDocumento9 páginasFinancial analysis of American Chemical Corporation plant acquisitionBenAinda não há avaliações

- Worldwide Paper CompanyDocumento22 páginasWorldwide Paper Companyroldanvenus89% (9)

- The Wm. Wrigley Jr. Company: Capital Structure, Valuation and Cost of CapitalDocumento19 páginasThe Wm. Wrigley Jr. Company: Capital Structure, Valuation and Cost of CapitalMai Pham100% (1)

- Diamond Chemicals Team 6's DCF Analysis of Merseyside ProjectDocumento1 páginaDiamond Chemicals Team 6's DCF Analysis of Merseyside Projectkwarden13Ainda não há avaliações

- Victoria Chemicals Case - Merseyside Polypropylene Project Go/No-Go DecisionDocumento2 páginasVictoria Chemicals Case - Merseyside Polypropylene Project Go/No-Go DecisionS r kAinda não há avaliações

- Case Study - Hill Country Snack Foods Co.Documento2 páginasCase Study - Hill Country Snack Foods Co.Spencer123455678967% (3)

- Coursework: International Financial Management For Business AFE - 7 - IFMDocumento12 páginasCoursework: International Financial Management For Business AFE - 7 - IFMaaaAinda não há avaliações

- Coursework: International Financial Management For Business AFE - 7 - IFMDocumento11 páginasCoursework: International Financial Management For Business AFE - 7 - IFMPrajit ParajuliAinda não há avaliações

- Victoria Chemicals Part 3Documento2 páginasVictoria Chemicals Part 3cesarvirataAinda não há avaliações

- Victoria ChemicalDocumento10 páginasVictoria ChemicalBobYu0% (1)

- Trabajo Emprical Chemical InternetDocumento11 páginasTrabajo Emprical Chemical InternetManuel LachiraAinda não há avaliações

- AmericanDocumento4 páginasAmericanskull13Ainda não há avaliações

- HydrogenDocumento17 páginasHydrogenPRET1971Ainda não há avaliações

- HP Top Project AwardsDocumento9 páginasHP Top Project AwardsSterlingAinda não há avaliações

- HP Top Project AwardsDocumento9 páginasHP Top Project AwardsSterlingAinda não há avaliações

- KBC White Paper - Maximising Margin in A Competitive EnvironmentDocumento4 páginasKBC White Paper - Maximising Margin in A Competitive EnvironmentAndrew J RobertsAinda não há avaliações

- Husky Group7Documento2 páginasHusky Group7Shruti Mandal80% (5)

- Pull and JIT PDFDocumento66 páginasPull and JIT PDFpranayrulzAinda não há avaliações

- Apple Inc Financial AnalysisDocumento3 páginasApple Inc Financial AnalysisKarim El GazzarAinda não há avaliações

- Start Up Loans Company - Business Plan - TemplateDocumento12 páginasStart Up Loans Company - Business Plan - Templateatul9Ainda não há avaliações

- EB Sales Process PDFDocumento5 páginasEB Sales Process PDFAndry YadisaputraAinda não há avaliações

- PBM 2010Documento298 páginasPBM 2010Dr. AayushmanAinda não há avaliações

- Supply Chain Management: Key ConceptsDocumento21 páginasSupply Chain Management: Key ConceptsRocker BrosAinda não há avaliações

- LECTURE 4 PROBLEMS BOND AND STOCK VALUATIONDocumento4 páginasLECTURE 4 PROBLEMS BOND AND STOCK VALUATIONDahniar AmalinaAinda não há avaliações

- Chapter 01-Introduction Marketing For Hospitality and TourismDocumento26 páginasChapter 01-Introduction Marketing For Hospitality and TourismQuagn TruognAinda não há avaliações

- Cultural Factors For International BusinessDocumento2 páginasCultural Factors For International BusinessJonathan HurtadoAinda não há avaliações

- A Study of Thomas CookDocumento2 páginasA Study of Thomas CookKapil ShereAinda não há avaliações

- LeadsArk Sales ProcessDocumento6 páginasLeadsArk Sales ProcessShashank PrasoonAinda não há avaliações

- Tarang LaunchDocumento10 páginasTarang LaunchBatool Yousuf0% (1)

- 2 David MDocumento39 páginas2 David MAmol Mahajan100% (1)

- Chapter 10Documento28 páginasChapter 10YourMotherAinda não há avaliações

- ACCP303 Accounting for Special Transactions Prefinals ReviewDocumento9 páginasACCP303 Accounting for Special Transactions Prefinals ReviewAngelica RubiosAinda não há avaliações

- Line 2020Documento11 páginasLine 2020Mai NguyenAinda não há avaliações

- Target Costing and Pricing Decisions AnalysisDocumento50 páginasTarget Costing and Pricing Decisions AnalysisBea BlancoAinda não há avaliações

- C Accomplishment Report Service Credits - TeachersDocumento7 páginasC Accomplishment Report Service Credits - TeachersCamelle MedinaAinda não há avaliações

- Project Plant Pals SMART GoalsDocumento2 páginasProject Plant Pals SMART GoalsSagar RapatwarAinda não há avaliações

- Exercise-2 ZhengDocumento3 páginasExercise-2 ZhengHiền NguyễnAinda não há avaliações

- AP 9 Reviewer 2nd QTRDocumento2 páginasAP 9 Reviewer 2nd QTRG05 - Cortiguerra, Samantha Grecel M.Ainda não há avaliações

- Demographic Report by MatthDocumento2 páginasDemographic Report by Matthngoctuan_ntdAinda não há avaliações

- Accounts Receivable q3Documento3 páginasAccounts Receivable q3Omnia HassanAinda não há avaliações

- Clarins Business CaseDocumento16 páginasClarins Business CaseAkshit AgarwalAinda não há avaliações

- Full Feasibility AnalysisDocumento14 páginasFull Feasibility Analysiskasuri.bilal.donAinda não há avaliações

- COMPARISON OF BUSINESS TRANSACTION CYCLESDocumento2 páginasCOMPARISON OF BUSINESS TRANSACTION CYCLESJN Villacruel AbayariAinda não há avaliações

- Balance Sheet Management SolutionDocumento8 páginasBalance Sheet Management SolutionSana NaazAinda não há avaliações

- CAPITAL BUDGETING REPORTDocumento86 páginasCAPITAL BUDGETING REPORTtulasinad123Ainda não há avaliações

- Ch13 HintsDocumento3 páginasCh13 HintsEric ChenAinda não há avaliações