Escolar Documentos

Profissional Documentos

Cultura Documentos

Steel Asia - Company Case Study

Enviado por

Raymond VillegasDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Steel Asia - Company Case Study

Enviado por

Raymond VillegasDireitos autorais:

Formatos disponíveis

STEEL ASIA MANUFACTURING CORPORATION: Company Case Study

STEEL ASIA MANUFACTURING CORPORATION

COMPANY DESCRIPTION

Steel Asia Manufacturing Corporation (SAMC), a joint venture with TATA Steel from India, is located in Bulacan in the Philippines and produces reinforcing steel bars (also referred to as rebar) for use in construction. The plant was commissioned in 1996 and currently has 400 employees. Annual production is 360,000 tons of steel bars compared to its 400,000 tons annual designed capacity, which is mostly consumed by the domestic market. The company participated in the project to sustain their effort to improve the operation, cut down on production cost through energy efficiency and cleaner production and prepare for an application for Integrated Management System (ISO 9001, ISO 14001 and OSHAS 18000) certification.

PROCESS DESCRIPTION

Preheating: Steel billets are received and charged directly in a re-heat walking hearth furnace through the charging door of the furnace. They are reheated for 75 minutes to 1100 using Bunker C (Type #6) fuel oil. The furnace can reheat billets at a maximum rate C of 65 tons per hour. Rolling: Once billets reach the required temperature for rolling, they leave the furnace through the discharging doors and are rolled along a series of 18 tandem (horizontal/vertical) continuous rolling mill stands to obtain the desired size and shape. Each rolling stand is controlled throughout the process by a computerized control system. Cutting and Testing: The bars are then cut to lengths required by customers. Samples are subjected to physical, mechanical and chemical tests in a fully equipped laboratory certified to ISO 17025. Instruments used for quality control include a spectrometer and two universal testing machines. Bundling and Tagging: Finally, the product is then bundled and tagged before being placed in a storage facility.

METHODOLOGY APPLICATION

The draft Company Energy Efficiency Methodology was used as a basis for the plant assessment to identify and implement options to reduce energy and other materials and wastes. Some of the interesting experiences are: Task 1b Form a team and inform staff The company is preparing for an Integrated Management System Certification and recently created an Energy Management Committee that oversees the energy costs and savings. This committee also became the Team for the GERIAP project so that efforts are integrated in the wider management system. Lesson learnt: By using an already existing team as the Team for the energy assessment it is easier to integrate energy management into wider business management systems later. Task 2d Quantify inputs and outputs and costs to establish a baseline The company has no water metering system or any means to measure the allocation of water used by different production processes. This makes it difficult to establish a water baseline from which to measure water savings after the implementation of water conservation options. Lesson learnt: It is not always possible to establish a baseline for resource and energy consumption.

Energy Efficiency Guide for Industry in Asiawww.energyefficiencyasia.org

Step 5- Implementation and monitoring of options Implementation: The company modified some of the options recommended for better monitoring of operation such as use of steel curtain, which have longer life, and use of water metering system with more accurate results. Lesson learnt: If external facilitators are involved it is important that the company checks if any modifications of options are needed, as they know the plant better than anyone Monitoring: The energy savings and greenhouse gas emission reduction resulting from the insulation of the furnace was calculated based on measurement conducted on surface wall temperature. If these savings would have been calculated based on their production data, the actual consumption of bunker fuel would have increased due to a change in the billet feed. However, a relatively larger increase would have been measured if the insulations were not repaired. Lesson learnt: Where possible, use actual measurements to monitor energy reductions to avoid the influence of changes in production input and changes in production processes on monitored results. Calculated savings assumes that similar parameters are maintained other than the options being implemented. Step 6 Continuous improvement The company will continue with energy efficiency making using of already started initiatives: A Productivity Improvement Program aimed at saving fuel and reducing costs by plant staff who are given by cash incentives for good ideas The Energy Management Committee which will oversee the continuation of energy efficiency The Integrated Management System Certification, which will ensure that energy efficiency is fully integrated into the environmental management system Lesson learnt: It is not always necessary to start new initiatives to ensure continuous energy efficiency improvement.

OPTIONS

The focus areas selected for the project were (1) Walking Hearth Reheating Furnace (thermal) (2) Air compressor motors and other electric motors and (3) water system The Team identified a total of five energy and waste minimization options, among which four options were implemented, while the rest are still to be implemented. For the four options implemented, the total investment was US$ 3,179, annual cost savings were US$ 158,528 and the payback period was 5 months. For the three options implemented, annual energy savings were 684,001 liters of bunker fuel and 4,594 kWh For the three options implemented, annual GHG emission reductions were 2,055 tons of CO2 equivalent. The percentage of GHG emission reduction for the entire plant emissions could s not be calculated. Table 1: EXAMPLES OF OPTIONS IMPLEMENTED AND PROPOSED

FOCUS AREA AND OPTION Walking Hearth Reheating Furnace /Installation of ceramic fiber insulation inside the furnace wall at recuperative zone side (see case study) CP TECHNIQUE Good housekeeping FINANCIAL FEASIBILITY Investment: US$ 180 Cost savings: US$ 2,410/yr Payback period: 0.9 months ENVIRONMENTAL BENEFITS Fuel savings: 5,514 l/yr GHG emission reduction: 16.54 tCO2 /yr COMMENTS Improved work conditions around the furnace and reduced pumping cost for bunker.

Energy Efficiency Guide for Industry in Asia www.energyefficiencyasia.org

STEEL ASIA MANUFACTURING CORPORATION: Company Case Study FOCUS AREA AND OPTION Electric motors/ Change of transformer tap settings of electric panel at scale pit pumps (see case study) Water system/ Measurement of water holding tank volume and/or installation of water meters to monitor water consumption (see case study) Walking Hearth Reheating Furnace /Installation of heat resistant cloth canvass on charge and discharge door of furnace to reduce heat loss (see case study) Motors/ Replacement of inefficient and oversized motor at the cooling tower with a downsized standard or high efficient motor (see case study) CP TECHNIQUE Production process/ equipment modification FINANCIAL FEASIBILITY Investment: none Cost savings: US$ 6,806 /yr Payback period: immediate Investment: US$ 454 Cost savings: US$ 1,284/yr Payback period: 4 months Investment US$ 2,545 Cost savings: US$ 148,028/yr Payback period: one week Investment: not given Cost savings: US$ 91/yr ENVIRONMENTAL BENEFITS Electricity savings: 3,761 kWh/yr GHG emission reduction: 3 tCO2 /yr COMMENTS Results are calculated results only

Good housekeeping

Electricity savings: 833 kWh/yr GHG emission reductions: 0.19 tCO2 /yr Water savings: 2,015 m3/yr Fuel savings: 678,487 l/yr GHG emission reduction: 2,035 tCO2 /yr

Water metering system was installed (instead of measurement water holding tank refills)

Good housekeeping

Expected results only as yet to be implemented. Improved work conditions around the furnace. Not yet implemented, since no replacement motor is available at plant

New technology/ equipment

Electricity savings: 196 kWh/yr GHG emission reduction: 0.16 tCO2 /yr

FOR MORE INFORMATION

GERIAP National Focal Point for the Philippines Dr. Alice B. Herrera Officer-in-Charge, Fuels and Energy Division Industrial Technology Development Institute Gen. Santos Ave., Bicutan, Taguig City, Metro Manila Philippines 1631 Tel: +632 837 2071 ext 2190 Tel fax: +632 837 2071 ext 2204 E-mail: aherrera@dost.gov.ph, abherrera@pacific.net.ph GERIAP Company in the Philippines Ms. Belen W. Yao AVP Gen Plant Services Steel Asia Manufacturing Corporation 090 Ciudad Industria, Bo. Bahay-Pari, Meycauyan, Bulacan, Philippines

Disclaimer:

This case study was prepared as part of the project Greenhouse Gas Emission Reduction from Industry in Asia and the Pacific (GERIAP). While reasonable efforts have been made to ensure that the contents o this f publication are factually correct, UNEP does not accept responsibility for the accuracy or completeness of the contents, and shall not be liable for any loss or damage that may be occasioned directly or indirectly through the use of, or reliance on, the contents of this publication. UNEP, 2006.

Energy Efficiency Guide for Industry in Asiawww.energyefficiencyasia.org

Você também pode gostar

- Corporate Financial Analysis with Microsoft ExcelNo EverandCorporate Financial Analysis with Microsoft ExcelNota: 5 de 5 estrelas5/5 (1)

- Productivity Improvement Through The Application of Cleaner Production in The Environmental Management System of Msmes in The Furniture IndustryDocumento36 páginasProductivity Improvement Through The Application of Cleaner Production in The Environmental Management System of Msmes in The Furniture IndustryYork John LopezAinda não há avaliações

- Material Safety Data Sheet: 1 Identification of The Substance & Company InformationDocumento4 páginasMaterial Safety Data Sheet: 1 Identification of The Substance & Company InformationJohn Dolph Facundo100% (1)

- Ellora Time Case StudyDocumento8 páginasEllora Time Case StudyHumayun RashidAinda não há avaliações

- Risk Management Chapter 2 Page 28Documento3 páginasRisk Management Chapter 2 Page 28winarsih0% (1)

- Coca Cola Ethical Analysis Kerala IndiaDocumento12 páginasCoca Cola Ethical Analysis Kerala Indiaabdul mananAinda não há avaliações

- Case Study Presented by Aartiben Bhatt Nisha Sathian Rohit Saini Umang Gandhi Madyane Chabane Parshv JainDocumento8 páginasCase Study Presented by Aartiben Bhatt Nisha Sathian Rohit Saini Umang Gandhi Madyane Chabane Parshv JainRohit SainiAinda não há avaliações

- MSL302 Capital Budgeting Decisions Term Paper Report: Submitted byDocumento10 páginasMSL302 Capital Budgeting Decisions Term Paper Report: Submitted bychioqueAinda não há avaliações

- Case Study Mehran Sugar MillsDocumento3 páginasCase Study Mehran Sugar MillsAndy Tp50% (2)

- Independent University, Bangladesh: Submitted ToDocumento14 páginasIndependent University, Bangladesh: Submitted ToHashib ArmanAinda não há avaliações

- Activity Based CostingDocumento6 páginasActivity Based CostingArie ArganthaAinda não há avaliações

- PEST Analysis - South Africa HospitalityDocumento12 páginasPEST Analysis - South Africa HospitalityNike AlabiAinda não há avaliações

- LB160 Mta Fall 2011 AkDocumento6 páginasLB160 Mta Fall 2011 AkJehdad MoustafaAinda não há avaliações

- Case - Spring GardenDocumento1 páginaCase - Spring GardenTanu GuptaAinda não há avaliações

- Product, Service and Branding Strategy: Consumer GoodsDocumento1 páginaProduct, Service and Branding Strategy: Consumer Goodsnr syaakirahAinda não há avaliações

- FINALE Accounts ManagementDocumento36 páginasFINALE Accounts ManagementGel GarabilesAinda não há avaliações

- Whirlpool Financial AnalysisDocumento5 páginasWhirlpool Financial AnalysisuddhavkulkarniAinda não há avaliações

- STRAMADocumento6 páginasSTRAMAClaude PeñaAinda não há avaliações

- Marketing PlanDocumento7 páginasMarketing PlanKris Elaine FiguracionAinda não há avaliações

- 2-Competing With Information TechnologyDocumento7 páginas2-Competing With Information Technologyanishabataju100% (1)

- Liberty Textile (Project Proposal)Documento41 páginasLiberty Textile (Project Proposal)Zahoor KhanAinda não há avaliações

- Forever21 Marketing AnalysisDocumento4 páginasForever21 Marketing AnalysisNeel Edeling67% (3)

- Financial Analyses On The Various Davao City-Based CompaniesDocumento24 páginasFinancial Analyses On The Various Davao City-Based CompaniesmasterdrewsAinda não há avaliações

- Bio FuelsDocumento63 páginasBio Fuelssbpatil84Ainda não há avaliações

- Beyond Greening Stategies For A Sustainable WorldDocumento25 páginasBeyond Greening Stategies For A Sustainable WorldthaoAinda não há avaliações

- ORDocumento26 páginasORVarun Markandeya50% (2)

- MKTG Analysis - Diversification StrategyDocumento29 páginasMKTG Analysis - Diversification StrategyWan Muhammad Abdul HakimAinda não há avaliações

- Nordam Europe CaseDocumento4 páginasNordam Europe CaseCharm Agripa0% (1)

- Ellora Time's Manufacturing WoesDocumento16 páginasEllora Time's Manufacturing WoesDeepender SharmaAinda não há avaliações

- OPMATQM Unit 2 Activity PART 1 - Agner, Jam Althea O.Documento1 páginaOPMATQM Unit 2 Activity PART 1 - Agner, Jam Althea O.JAM ALTHEA AGNERAinda não há avaliações

- OM AssignmentDocumento10 páginasOM AssignmentashishAinda não há avaliações

- McphersonDocumento9 páginasMcphersonipsi14100% (1)

- Interco Manufacturing CorpDocumento11 páginasInterco Manufacturing CorpShainee Delle PalmeraAinda não há avaliações

- Recommendation On Inventory Control System - TermpaperDocumento4 páginasRecommendation On Inventory Control System - TermpaperiftezarAinda não há avaliações

- Kane County Food Hub (Feasibility Report)Documento35 páginasKane County Food Hub (Feasibility Report)Dulvan Devnaka Senaratne100% (2)

- Case Study of WiproDocumento2 páginasCase Study of WiproAbhi ThakurAinda não há avaliações

- Main Body of WaltonDocumento60 páginasMain Body of WaltonSharifMahmudAinda não há avaliações

- Assignment Week 1Documento6 páginasAssignment Week 1Naveen TahilaniAinda não há avaliações

- DWDG Case 1 - MewDocumento3 páginasDWDG Case 1 - MewJAY BHAVIN SHETH (B14EE014)Ainda não há avaliações

- Group Assignment 4 Al AinDocumento5 páginasGroup Assignment 4 Al AinRambo DeyAinda não há avaliações

- Managerial Accounting STANDARD PDFDocumento0 páginaManagerial Accounting STANDARD PDFMichael YuAinda não há avaliações

- Example 1:: Net Present Value Method Internal Rate of Return Method Payback MethodDocumento3 páginasExample 1:: Net Present Value Method Internal Rate of Return Method Payback Methodcarlo lastimosaAinda não há avaliações

- Analisis AmazonDocumento24 páginasAnalisis AmazonAlejandra IbujesAinda não há avaliações

- IS110 Case FacilitationDocumento37 páginasIS110 Case FacilitationSean WoonAinda não há avaliações

- Additional Questions For Maverick CaseDocumento3 páginasAdditional Questions For Maverick Casefranz_karununganAinda não há avaliações

- GEF Case 2Documento6 páginasGEF Case 2gabrielaAinda não há avaliações

- Case Studies 4Documento4 páginasCase Studies 4Vivek HaldarAinda não há avaliações

- EngrofoodsDocumento4 páginasEngrofoodsMuhammad Akif SarwarAinda não há avaliações

- Suzlon - RePower Case StudyDocumento14 páginasSuzlon - RePower Case StudyPrince VamsiAinda não há avaliações

- MIS535M (GRP 1 - Telecoms & Network Resources v4)Documento83 páginasMIS535M (GRP 1 - Telecoms & Network Resources v4)Irish June TayagAinda não há avaliações

- Pestal AnalysisDocumento8 páginasPestal AnalysisKrunal Tandel0% (1)

- 20180308012211are Farms Becomin Digital FirmsDocumento4 páginas20180308012211are Farms Becomin Digital Firmsnguyễn hoaAinda não há avaliações

- Components of VMDocumento15 páginasComponents of VMNadine YbascoAinda não há avaliações

- Markman Individual Paper FinalDocumento14 páginasMarkman Individual Paper Finalreizch100% (1)

- Project Report On PERT CPMDocumento72 páginasProject Report On PERT CPMpavsbiet0750% (2)

- Ford & Firestone Tire ControversyDocumento2 páginasFord & Firestone Tire ControversySiddhartha MohapatraAinda não há avaliações

- Q CellsDocumento17 páginasQ CellsJosé Carlos MuñozAinda não há avaliações

- Krakatau Steel Company Case Study PDFDocumento4 páginasKrakatau Steel Company Case Study PDFFirmanullah FadlilAinda não há avaliações

- G Steel Company Case StudyDocumento6 páginasG Steel Company Case StudyAmit Kumar SharmaAinda não há avaliações

- Energy Efficiency in Sugar Plant Steam and Power Generation PDFDocumento6 páginasEnergy Efficiency in Sugar Plant Steam and Power Generation PDFSrikanth SriAinda não há avaliações

- Rotating Equipment & ServiceDocumento12 páginasRotating Equipment & Servicenurkasih119Ainda não há avaliações

- WBCS 2023 Preli - Booklet CDocumento8 páginasWBCS 2023 Preli - Booklet CSurajit DasAinda não há avaliações

- Openvpn ReadmeDocumento7 páginasOpenvpn Readmefzfzfz2014Ainda não há avaliações

- A Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyDocumento11 páginasA Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyNova Ariston100% (2)

- Digital Electronics Chapter 5Documento30 páginasDigital Electronics Chapter 5Pious TraderAinda não há avaliações

- Sales Forecast Template DownloadDocumento9 páginasSales Forecast Template DownloadAshokAinda não há avaliações

- MolnarDocumento8 páginasMolnarMaDzik MaDzikowskaAinda não há avaliações

- Final MS Access Project Class-10Documento17 páginasFinal MS Access Project Class-10aaas44% (9)

- PreviewpdfDocumento29 páginasPreviewpdfSoemarlan ErlanAinda não há avaliações

- Case Study - Montana Mountain BikingDocumento6 páginasCase Study - Montana Mountain Bikingbonny MishAinda não há avaliações

- Etextbook PDF For Pharmacology Connections To Nursing Practice 3rd EditionDocumento61 páginasEtextbook PDF For Pharmacology Connections To Nursing Practice 3rd Editionkarla.woodruff22798% (45)

- LFF MGDocumento260 páginasLFF MGRivo RoberalimananaAinda não há avaliações

- Daewoo 710B PDFDocumento59 páginasDaewoo 710B PDFbgmentAinda não há avaliações

- Outline Calculus3Documento20 páginasOutline Calculus3Joel CurtisAinda não há avaliações

- Lancru hzj105 DieselDocumento2 páginasLancru hzj105 DieselMuhammad MasdukiAinda não há avaliações

- 1.161000 702010 New Perspectives 2ndedDocumento43 páginas1.161000 702010 New Perspectives 2ndedbimobimoprabowoAinda não há avaliações

- Benjamin Franklin - The Indian Treaties (1938)Documento450 páginasBenjamin Franklin - The Indian Treaties (1938)Spiritu SanctoAinda não há avaliações

- Pedagogy MCQS 03Documento54 páginasPedagogy MCQS 03Nawab Ali MalikAinda não há avaliações

- Hw10 SolutionsDocumento4 páginasHw10 Solutionsbernandaz123Ainda não há avaliações

- Literature Review of Service Quality in RestaurantsDocumento7 páginasLiterature Review of Service Quality in RestaurantsuifjzvrifAinda não há avaliações

- Animal Health ChecklistDocumento4 páginasAnimal Health ChecklistcapsfastAinda não há avaliações

- Science and Technology in Ancient India by NeneDocumento274 páginasScience and Technology in Ancient India by NeneAshok Nene100% (1)

- Cool Fire Manual 45M620N2UK 01 PDFDocumento198 páginasCool Fire Manual 45M620N2UK 01 PDFPaun MihaiAinda não há avaliações

- KCG-2001I Service ManualDocumento5 páginasKCG-2001I Service ManualPatrick BouffardAinda não há avaliações

- Chapter 20 AP QuestionsDocumento6 páginasChapter 20 AP QuestionsflorenciashuraAinda não há avaliações

- Eapp Melc 12Documento31 páginasEapp Melc 12Christian Joseph HerreraAinda não há avaliações

- Reaction Paper FinalDocumento5 páginasReaction Paper FinalJelo RoxasAinda não há avaliações

- Cultural Sensitivity BPIDocumento25 páginasCultural Sensitivity BPIEmmel Solaiman AkmadAinda não há avaliações

- Nescom Test For AM (Electrical) ImpDocumento5 páginasNescom Test For AM (Electrical) Impشاہد یونسAinda não há avaliações

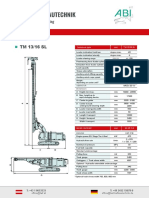

- ABI TM 13 16 SL - EngDocumento1 páginaABI TM 13 16 SL - EngJuan Carlos Benitez MartinezAinda não há avaliações

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessAinda não há avaliações

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionNo EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionNota: 4 de 5 estrelas4/5 (811)

- Financial Literacy for All: Disrupting Struggle, Advancing Financial Freedom, and Building a New American Middle ClassNo EverandFinancial Literacy for All: Disrupting Struggle, Advancing Financial Freedom, and Building a New American Middle ClassAinda não há avaliações

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseNo EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseNota: 3.5 de 5 estrelas3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingNo EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingNota: 5 de 5 estrelas5/5 (5)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingNo EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingNota: 3.5 de 5 estrelas3.5/5 (34)

- Fire Season: Field Notes from a Wilderness LookoutNo EverandFire Season: Field Notes from a Wilderness LookoutNota: 4 de 5 estrelas4/5 (142)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldNo EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldNota: 4.5 de 5 estrelas4.5/5 (18)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorNo EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorNota: 4.5 de 5 estrelas4.5/5 (137)

- The Other End of the Leash: Why We Do What We Do Around DogsNo EverandThe Other End of the Leash: Why We Do What We Do Around DogsNota: 5 de 5 estrelas5/5 (65)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildNo EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildNota: 4.5 de 5 estrelas4.5/5 (44)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeNo EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeNota: 4.5 de 5 estrelas4.5/5 (699)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsNo EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsNota: 4 de 5 estrelas4/5 (223)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsNo EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsNota: 3.5 de 5 estrelas3.5/5 (13)

- Spoiled Rotten America: Outrages of Everyday LifeNo EverandSpoiled Rotten America: Outrages of Everyday LifeNota: 3 de 5 estrelas3/5 (19)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldNo EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldNota: 4 de 5 estrelas4/5 (595)

- The Mind of Plants: Narratives of Vegetal IntelligenceNo EverandThe Mind of Plants: Narratives of Vegetal IntelligenceNota: 4.5 de 5 estrelas4.5/5 (11)

- Come Back, Como: Winning the Heart of a Reluctant DogNo EverandCome Back, Como: Winning the Heart of a Reluctant DogNota: 3.5 de 5 estrelas3.5/5 (10)