Escolar Documentos

Profissional Documentos

Cultura Documentos

O-W Separator Literature

Enviado por

ernesto_sugihartoDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

O-W Separator Literature

Enviado por

ernesto_sugihartoDireitos autorais:

Formatos disponíveis

Section 5-Treatment Controls

BMP Fact Sheets

OIL/WATER SEPARATORS

TC7-1

Considerations

Soils Area Required Slope Water Availability Aesthetics ! Hydraulic Head Environmental Side Effects

DESCRIPTION Oil/water separators are designed to remove one specific group of contaminants: petroleum compounds and grease. However, separators will also remove floatable debris and settleable solids. Two general types of oil/water separators are used: conventional gravity separator and the coalescing plate interceptor (CPI). Oil/water separators are used at all bulk petroleum storage and refinery facilities. SELECTION CRITERIA Applicable to situations where the concentration of oil and grease related compounds will be abnormally high and source control cannot provide effective control. The general types of businesses where this situation is likely are truck, car, and equipment maintenance and washing businesses, as well as a business that performs maintenance on its own equipment and vehicles. Public facilities where separators may be required include marine ports, airfields, fleet vehicle maintenance and washing facilities, and mass transit park-and-ride lots. Conventional separators are capable of removing oil droplets with diameters equal to or greater than 150 microns. A CPI separator should be used if smaller droplets must be removed. LIMITATIONS Little data on oil characteristics in storm water leads to considerable uncertainty about performance. DESIGN AND SIZING CONSIDERATIONS Sizing related to anticipated influent flowrate, oil concentration, water temperature, and the effluent goal. INSPECTION/MAINTENANCE CONSIDERATIONS Clean frequently of accumulated oil, grease, and floating debris, and dispose of properly. COST CONSIDERATIONS Coalescing plate material is costly but requires less space than the conventional separator.

Targeted Constituents

Sediment Nutrients Heavy Metals Toxic Materials Floatable Materials Oxygen Demanding Substances Oil & Grease Bacteria & Viruses

Implementation Requirements

Capital Costs O & M Costs Maintenance Training

Legend

Likely to Have Significant Impact Probable Medium Impact Probable Low Impact ? Unknown or Site Specific Impact

North Central Texas Residential/Commercial BMP Manual

July 1993

Section 5-Treatment Controls

BMP Fact Sheets

Oil/Water Separators

TC7-2

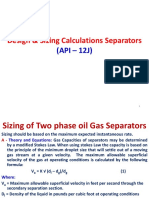

ADDITIONAL INFORMATION Oil/water separators will be needed for a few types of industrial sites where activities result in abnormal amounts of petroleum products lost to exposed pavement, either by accidental small spills or normal dripping from vehicle undercarriages. This will most likely be related to vehicle and mobile equipment maintenance activities. Separators may also be advisable where an area is heavily used by mobile equipment such as loading wharfs at marine ports. Limited data indicates oil/water separators can reduce the oil/grease concentration below 10 mg/l (Lettenmaier, et al. 1985). Wet ponds, vegetated treatment ponds, and vegetated swales and strips will remove petroleum products but their reliability is too uncertain to use in situations where high concentrations of petroleum products may occur frequently. Also, BMPs that rely on vegetation may be damaged or become unsightly if high concentrations of oil and grease occur frequently. The sizing of separators is based upon the rise rate velocity of oil droplets, using oil density and droplet size to calculate rise rate or direct measurement of rise rates. However, with the exception of storm water from oil refineries there are no data describing the characteristics of petroleum products in urban storm water that are relevant to design. Further, it is known (Silverman, 1982) that a significant percentage of the petroleum products are attached to the fine suspended solids and therefore are removed by settling not flotation. Consequently, the performance of oil/water separators is uncertain. The basic configurations of the two types of separators are illustrated in Figure TC7-A. With small installations, a conventional gravity separator has the general appearance of a septic tank, but is much longer in relationship to its width. Larger facilities have the appearance of a municipal wastewater primary sedimentation tank. The CPI separator contains closely spaced plates which enhances the removal efficiency. In effect, to obtain the same effluent quality a CPI separator requires considerably less space than a conventional separator. The angle of the plates to the horizontal ranges from 0o (horizontal) to 60o, although 45o to 60o is the most common. The perpendicular distance between the plates typically ranges from 0.75 to 1 inch. The storm water will either flow across or down through the plates, depending on the plate configuration. A related system is the water quality inlet illustrated in Figure TC7-B. It is essentially a conventional gravity separator but without the appropriate geometric configuration (see Design discussion below). Another name for these systems is a wet vault, essentially an underground wet pond. Water quality inlets have been found to be generally ineffective (Shepp, et al., 1992) because the recommended size (200 to 400 ft3/acre of tributary) is too small. To be effective, a water quality inlet must have the surface area and volume that is defined by USEPA (1986). They may exhibit odor problems during the summer because of the lack of bacterial degradation of accumulated organic matter and the lack of reaeration of the wet pool. Facilities in Washington D.C. have been observed to have odor but, it has been noticeable only when the system is opened for inspection. Design The sizing of a separator is based upon the calculation of the rise rate of the oil droplets using the following equation (modified from API, 1990): Vp = 1.79 (dp - dc)d2 x 10-8/n where: Vp n dp dc d = = = = = rise rate (ft/second) absolute viscosity of the water (poises) density of the oil (gm/cc) density of the water (gm/cc) diameter of the droplet to be removed (microns) July 1993 (1)

North Central Texas Residential/Commercial BMP Manual

Section 5-Treatment Controls

BMP Fact Sheets

Oil/Water Separators

TC7-3

A water temperature must be assumed to select the appropriate values for water density and viscosity from Table TC7-A. The engineer should use the expected temperature of the storm water during the December-January period. There are no data on the density of petroleum products in urban storm water but it can be expected to lie between 0.85 and 0.95. To select the droplet diameter the engineer must identify an efficiency goal based on an understanding of the distribution of droplet sizes in storm water. However, there is no information on the size distribution of oil droplets in urban storm water. Figure 7B is a size and weight distribution for storm water from a petroleum products storage facility (Branion, undated). The engineer must also select a design influent concentration, which carries considerable uncertainty because it will vary widely within and between storms. TABLE TC7-A. WATER VISCOSITIES & DENSITIES Temperature Absolute Viscosity Density Density of Pure Water In air (lbs/ft3) 62.351 62.355 62.358 62.360 62.360 62.360 62.359 62.357 62.354 62.350 62.345 62.339 62.333 62.326 62.317 62.30 62.299 62.289 62.278 62.266 62.254

C 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

F 32.0 33.8 35.6 37.4 39.2 41.0 42.8 44.6 46.4 48.2 50.0 51.8 53.6 55.4 57.2 59.0 60.8 62.6 64.4 66.2 68.0

(Poises) 0.017921 0.017343 0.016728 0.016191 0.015674 0.015188 0.014728 0.014284 0.013860 0.013462 0.013077 0.012713 0.012363 0.012028 0.011709 0.011404 0.011111 0.010828 0.010559 0.010299 0.010050

(slugs/ft.sec.) 0.00120424 0.00116338 0.00112407 0.00108799 0.00105324 0.00102059 0.00098968 0.00095984 0.00093135 0.00090460 0.00087873 0.00085427 0.00084870 0.00080824 0.00078681 0.00076631 0.00074662 0.00072761 0.00070953 0.00069206 0.00067533

(gm/cc) 0.999 0.999 0.999 0.999 1.000 0.999 0.999 0.999 0.999 0.999 0.999 0.999 0.999 0.999 0.999 0.999 0.999 0.999 0.999 0.999 0.998

To illustrate Equation 1: if the effluent goal is 20 mg/l and the design influent concentration is 50 mg/l, a removal efficiency of 60% is required. From Figure TC7-C: this efficiency can be achieved by removing all droplets with diameters 90 microns or larger. Using a water temperature of 10oC gives a water density of 0.999. Using an oil density of 0.898, the rise rate for a 90 micron droplet is 0.0011 feet per second. It is generally believed that conventional separators are not effective at removing droplets smaller than 150 microns (API, 1990). Theoretically, a conventional separator can be sized to remove a smaller droplet but the facility may be so large that the CPI separator may be more cost-effective.

North Central Texas Residential/Commercial BMP Manual

July 1993

Section 5-Treatment Controls

BMP Fact Sheets

Oil/Water Separators

Sizing conventional separator (modified from API, 1990). D= where: D= Q= V= (Q/2V)0.5 (2)

TC7-4

depth, which should be between 3 and 8 feet design flow rate (cfs), limitations (see below) allowable horizontal velocity which is equal to 15 times the design oil rise rate but not greater than 0.05 feet per second.

If the depth exceeds 8 feet, design parallel units dividing the design flow rate by the number of units needed to reach the maximum recommended depth of 8 feet. Then:

Calculate length, L = VD/Vp Select width, W = 2 to 3 times the depth, but not to exceed 20 feet Baffle height to depth ratio of 0.85 for top baffles and 0.15 for bottom baffles Locate the distribution baffle at 0.10L from the entrance Add one foot for freeboard Install a bypass for flows in excess of the design flow

Determining the design flow, Q, requires identification of the design storm. The separator is expected to operate effectively at all flow rates equal to or less than the peak runoff rate of the design storm. The design storm need not be an extreme event, as is typically used in the sizing of flood control facilities. If sized to handle a storm frequency for a 6-month event, the facility will effectively treat the majority of storm water that occurs over time. All events equal to or less than the 6-month event represents about 90% of the precipitation over time. For the design storm selected, calculate the peak runoff rate using an appropriate hydrological method. Oil/water separators used in conjunction with and proceeded by retention basins can reduce the size of the oil/water separator because of the reduction in sediment loads and flow rates.

Sizing CPI Separators Manufacturers can provide packaged separator units for flows up to several cubic feet per second. For larger flows, the engineer must size the plate pack and design the vault. Given the great variability of separator technology among manufacturers with respect to plate size, spacing, and inclination it is recommended that the design engineer consult vendors for a plate package that will meet the engineers criteria. Manufacturers typically identify the capacity of various standard units. However, the engineer must compare his design criteria to that used by the manufacturer in rating its units. The engineer can size the facility using the following procedure. First identify the expected plate angle, H (as degrees), and calculate the total plate area required, A(ft2). A = Q/VpCosineH (3)

CPI separators are not 100% hydraulically efficient; ranging from 0.35 to 0.95 depending on the plate design (Aquatrend, undated). If the engineer wishes to incorporate this factor, divide the result from Equation 3 by the selected efficiency.

North Central Texas Residential/Commercial BMP Manual

July 1993

Section 5-Treatment Controls

BMP Fact Sheets

Oil/Water Separators

TC7-5

Select spacing, S, between the plates, usually 0.75 to 1.5 inch Identify reasonable plate width, W, and length, L Number of plates, N = A/WL Calculate plate volume, Pv(ft3) (NS + LCosineH)(WLSineH) 12 (4)

Pv =

Add a foot beneath the plates for sediment storage Add 6" to 12" above the plates for water clearance so that the oil accumulates above the plates Add one foot for freeboard. Add a forebay for floatables and distribution of flow if more than one plate unit is needed Add afterbay for collection of the effluent from the plate pack area For larger units include a device to remove and store oil from the water surface.

Horizontal plates require the least plate volume to achieve a particular removal efficiency. However, settleable solids will accumulate on the plates complicating maintenance procedures. The plates may be damaged by the weight when removed for cleaning. The plates should be placed at an angle of 45o to 60o so that settleable solids slide to the facility bottom. Experience shows that even with slanted plates some solids will stick to the plates because of the oil and grease. Placing the plates closer together reduces the plate volume. However, if debris is expected such as sticks, plastics, and paper, select a larger plate separation distance. Or install ahead of the plates a trash rack and/or screens with a diameter somewhat smaller than the plate spacing. Recognizing that an oil/water separator also removes settleable solids, it can also be considered a wet vault (TC1). The engineer can use Figure TC1-B to estimate the efficiency of both the conventional and CPI separators. As Figure TC1-B does not include the effect of plate technology, a CPI separator should perform considerably better than indicated in Figure TC1-B for the same Vb/Vr ratio. See API (1990) for further design concepts for both the conventional and CPI separators. Maintenance Check monthly during the wet season and clean several times a year. Always clean in October before the start of the wet season. Properly dispose of the oil. References American Petroleum Institute (API), 1990, Design and Operation of Oil-Water Separators, Publication 421. Aquatrend, undated, Design Manual: Innova Sep Particle Separation System, Shawnee Mission, Kansas. Branion, R., undated, Principles for the Separation of Oil Drops from Water in Gravity Type Separators, Department of Chemical Engineering, University of British Columbia. Lettenmaier, D. and J. Richey, 1985, Operational Assessment of a Coalescing Plate Oil/Water Separator, Municipality of Metropolitan Seattle. Silverman, G, 1982, Wetlands for Oil and Grease Control, Tech Memo. 87, Association of Bay Area Governments.

North Central Texas Residential/Commercial BMP Manual

July 1993

Section 5-Treatment Controls We Oil/Water Separators

BMP Fact Sheets

TC7-6

North Central Texas Residential/Commercial BMP Manual

July 1993

Section 5-Treatment Controls

BMP Fact Sheets

Oil/Water Separators

TC7-7

Figure B Water Quality Inlet North Central Texas Residential/Commercial BMP Manual July 1993

Section 5-Treatment Controls

BMP Fact Sheets

Oil/Water Separators

TC7-8

Figure C Size and Volume Distribution

North Central Texas Residential/Commercial BMP Manual

July 1993

Você também pode gostar

- Oil Water SeperatorDocumento11 páginasOil Water SeperatorAbhay BhoirAinda não há avaliações

- Ebook Building With Pallets PreviewDocumento16 páginasEbook Building With Pallets PreviewGigi FrancoAinda não há avaliações

- Oil Water Separators: Rami E. Kremesti M.SCDocumento39 páginasOil Water Separators: Rami E. Kremesti M.SCAchmad RiadiAinda não há avaliações

- TECHNOLOGY New Program Sizes Pressure-Relief Drums: CloseDocumento7 páginasTECHNOLOGY New Program Sizes Pressure-Relief Drums: CloseCalcetinAinda não há avaliações

- Urban PermacultureDocumento7 páginasUrban PermaculturePaulo Farine MilaniAinda não há avaliações

- Oil Water Separator TheoryDocumento3 páginasOil Water Separator Theoryjlcheefei9258Ainda não há avaliações

- Mechanical CompletionDocumento123 páginasMechanical Completiongst ajahAinda não há avaliações

- The Macrobiotic Genius of Walter RussellDocumento20 páginasThe Macrobiotic Genius of Walter Russellklatifdg100% (2)

- SORG EquipmentDocumento56 páginasSORG Equipmentl0% (2)

- Separator DesignDocumento8 páginasSeparator Designmohamed_sahnoun_enisAinda não há avaliações

- Oil/Water Separators: T P: O WDocumento4 páginasOil/Water Separators: T P: O Wvgogulakrishnan100% (1)

- Desalters 3Documento2 páginasDesalters 3vishnumnair1Ainda não há avaliações

- Grit in Waste WaterDocumento5 páginasGrit in Waste WaterYasir Mohammed BAinda não há avaliações

- Corrugated Plate Separator (CPS) enDocumento2 páginasCorrugated Plate Separator (CPS) enspattacutAinda não há avaliações

- Mesh & Vane Mist Eliminator: FiltersDocumento16 páginasMesh & Vane Mist Eliminator: Filtersgeorgadam1983Ainda não há avaliações

- Bisleri Marketing & Competitor Analysis New ProjectDocumento82 páginasBisleri Marketing & Competitor Analysis New Projecthvsandeep86% (7)

- The Mathematics of Pumping Water: AECOM Design BuildDocumento9 páginasThe Mathematics of Pumping Water: AECOM Design Buildmabrouk2013Ainda não há avaliações

- EXAMPLE SIZING OWS Calculation Per API 421 PDFDocumento1 páginaEXAMPLE SIZING OWS Calculation Per API 421 PDFarnel_ado4412Ainda não há avaliações

- CMPAPPP Separator Vessel and Filter Design GuideDocumento18 páginasCMPAPPP Separator Vessel and Filter Design GuideJWilson73Ainda não há avaliações

- Strainer PDFDocumento64 páginasStrainer PDFSanket SavlaAinda não há avaliações

- APEX Deoiler HydrocycloneDocumento9 páginasAPEX Deoiler HydrocycloneChem.EnggAinda não há avaliações

- Cpi O&m ManualDocumento36 páginasCpi O&m Manualprasad336Ainda não há avaliações

- Sponge Park PDFDocumento9 páginasSponge Park PDFChristineAinda não há avaliações

- Fundamentals of Biological Wastewater Treatment - PrefaceDocumento4 páginasFundamentals of Biological Wastewater Treatment - Prefaceabhi_nddAinda não há avaliações

- Oil Water Separator SizingDocumento6 páginasOil Water Separator Sizingzamijaka100% (2)

- How To Size A ThickenerDocumento7 páginasHow To Size A ThickenerJesus Sing RoblesAinda não há avaliações

- TB8102 Rupture Disc SizingDocumento9 páginasTB8102 Rupture Disc Sizingbabis1980Ainda não há avaliações

- Mist Eliminator-ASK2 MfixDocumento6 páginasMist Eliminator-ASK2 MfixVismit BansalAinda não há avaliações

- SPT Mozley Desanding Hydrocyclones BrochureDocumento2 páginasSPT Mozley Desanding Hydrocyclones BrochureperrychemAinda não há avaliações

- Chlorine LeakDocumento14 páginasChlorine LeakudayAinda não há avaliações

- Structural Tanks and ComponentsDocumento19 páginasStructural Tanks and ComponentsRodolfo Olate G.Ainda não há avaliações

- Lab DI Water SystemsDocumento6 páginasLab DI Water SystemsHaidee Che RizminAinda não há avaliações

- Velocity and Pressure Drop in PipesDocumento5 páginasVelocity and Pressure Drop in PipesManojkumar ThilagamAinda não há avaliações

- Examine Inlet Separation Technologies For Increased Reliability (Nexo Solutions)Documento16 páginasExamine Inlet Separation Technologies For Increased Reliability (Nexo Solutions)DWNLD USRMLAinda não há avaliações

- Mesh & Vane Mist EliminatorsDocumento16 páginasMesh & Vane Mist EliminatorsstressesAinda não há avaliações

- Guidelines For Produced Water Evaporators in SAGD 2007Documento16 páginasGuidelines For Produced Water Evaporators in SAGD 2007pipedown456Ainda não há avaliações

- STP 125 KLDDocumento9 páginasSTP 125 KLDAbhay SisodiaAinda não há avaliações

- Oil SeparatorsDocumento11 páginasOil Separatorsalan.edwards7282Ainda não há avaliações

- Thermal Degassing Fundamentals R4i1 enDocumento6 páginasThermal Degassing Fundamentals R4i1 enAnonymous v5uipHAinda não há avaliações

- API-12J SpecificationDocumento20 páginasAPI-12J Specificationgo251019920% (2)

- Conder Separator Brochure NewDocumento8 páginasConder Separator Brochure Newednavilod100% (1)

- Design and Operation Considerations For Condensate Polishing - T5S5O3-paper PDFDocumento17 páginasDesign and Operation Considerations For Condensate Polishing - T5S5O3-paper PDFNhhVuAinda não há avaliações

- How To Size Liquid Ring Vacuum PumpDocumento3 páginasHow To Size Liquid Ring Vacuum PumpdayrogAinda não há avaliações

- 4 4 7 Oil Grit Separator - Page6pdfDocumento18 páginas4 4 7 Oil Grit Separator - Page6pdfchaker05Ainda não há avaliações

- 10 1016@j Jngse 2016 01 016Documento37 páginas10 1016@j Jngse 2016 01 016saiful bahriAinda não há avaliações

- API Separator and Waste WaterDocumento5 páginasAPI Separator and Waste Waterbctian2004Ainda não há avaliações

- Science 7 ExamDocumento5 páginasScience 7 Examangge21Ainda não há avaliações

- The Difference Between API, DIN, IsO, ASME PumpsDocumento1 páginaThe Difference Between API, DIN, IsO, ASME PumpstoicantailieunhatAinda não há avaliações

- Veturi Design ProcedureDocumento2 páginasVeturi Design Procedureshivanandr2481Ainda não há avaliações

- DemisterDocumento4 páginasDemistermariniabrahanAinda não há avaliações

- Plate Type Wet ScrubberDocumento6 páginasPlate Type Wet ScrubberRoger IsidoreAinda não há avaliações

- Air Stripping: The Removal of Volatile Contaminants From Water and Contaminated SoilsDocumento39 páginasAir Stripping: The Removal of Volatile Contaminants From Water and Contaminated SoilsMohammed Al-DahlanAinda não há avaliações

- Volum Water HydrotestDocumento2 páginasVolum Water HydrotestFerinoviardi100% (1)

- CHAPTER 8 Sizing and CostingDocumento20 páginasCHAPTER 8 Sizing and CostingNurul Amelia Mustaffa0% (1)

- KIRK Sep-Calc SoftwareDocumento4 páginasKIRK Sep-Calc Softwaredhl_tuAinda não há avaliações

- Standard Parts of Pipe SupportsDocumento5 páginasStandard Parts of Pipe SupportsMohit BauskarAinda não há avaliações

- HPAC - Evaluating Deaerator OperationDocumento5 páginasHPAC - Evaluating Deaerator Operationghostamir100% (1)

- CPI BrochureDocumento2 páginasCPI Brochuremashonk okAinda não há avaliações

- VGS Vane Separators Are Recommended ForDocumento1 páginaVGS Vane Separators Are Recommended ForSanthu PeelaAinda não há avaliações

- Losses in Pipe BendsDocumento5 páginasLosses in Pipe BendsLove KumarAinda não há avaliações

- The Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating MethodsDocumento4 páginasThe Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating Methodsgad48050% (2)

- BN-DS-C58 90 Degree Three Weld Long Radius Miter ElbowDocumento7 páginasBN-DS-C58 90 Degree Three Weld Long Radius Miter ElbowGunanithi RathnavelAinda não há avaliações

- Volume 3 Section 2 Process Requirements-FINAL 10062010Documento63 páginasVolume 3 Section 2 Process Requirements-FINAL 10062010Pavle DimitrijevicAinda não há avaliações

- Cartridge English PDFDocumento20 páginasCartridge English PDFkunto prAinda não há avaliações

- A Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesDocumento1 páginaA Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesyogacruiseAinda não há avaliações

- Production Engineer A Complete Guide - 2020 EditionNo EverandProduction Engineer A Complete Guide - 2020 EditionAinda não há avaliações

- STP 07Documento8 páginasSTP 07badelitamariusAinda não há avaliações

- 11.1 Purpose of Oil and Water SeparatorsDocumento10 páginas11.1 Purpose of Oil and Water SeparatorstesteAinda não há avaliações

- Process Intensification in Industrial Wastewater Treatment FinalDocumento10 páginasProcess Intensification in Industrial Wastewater Treatment FinalSantanu BiswasAinda não há avaliações

- Apartemen Pearl GardenDocumento5 páginasApartemen Pearl Gardenernesto_sugihartoAinda não há avaliações

- Apartemen Pearl GardenDocumento5 páginasApartemen Pearl Gardenernesto_sugihartoAinda não há avaliações

- Apartemen Pearl GardenDocumento5 páginasApartemen Pearl Gardenernesto_sugihartoAinda não há avaliações

- Appendix 1: Table 3 in The Attachement Kep - Ka. Bapedal No.4/1995Documento6 páginasAppendix 1: Table 3 in The Attachement Kep - Ka. Bapedal No.4/1995ernesto_sugihartoAinda não há avaliações

- Waterresourcesengineering IDocumento8 páginasWaterresourcesengineering Ihimabindugvsd71Ainda não há avaliações

- Diesel-Water-Air Premixing Injector System in Burner System: A Literature ReviewDocumento14 páginasDiesel-Water-Air Premixing Injector System in Burner System: A Literature ReviewPrathmesh KuraneAinda não há avaliações

- Air Tanah Lengas Tanah Soil Water Soil MoistureDocumento42 páginasAir Tanah Lengas Tanah Soil Water Soil MoistureSisca ArianiAinda não há avaliações

- Gasification Guide Check List Final PDFDocumento6 páginasGasification Guide Check List Final PDFf.BAinda não há avaliações

- TWF TozenDocumento6 páginasTWF TozenAri WibowoAinda não há avaliações

- FINAL11Documento2 páginasFINAL11JendaeAinda não há avaliações

- Aluminum Potassium Sulfate PDFDocumento5 páginasAluminum Potassium Sulfate PDFwawan setiawanAinda não há avaliações

- Rivers and DamsDocumento6 páginasRivers and DamsYashwant SinghAinda não há avaliações

- AP Guidelines For The Design and Operation of Washdown BaysDocumento6 páginasAP Guidelines For The Design and Operation of Washdown BaysFarzin ShahabAinda não há avaliações

- Heat of Combustion Ethanol CompleteDocumento5 páginasHeat of Combustion Ethanol CompleteericaAinda não há avaliações

- STERILIZATION OF WATER USING BLEACHING POWDER Chemistry ProjectDocumento23 páginasSTERILIZATION OF WATER USING BLEACHING POWDER Chemistry ProjectChandaAinda não há avaliações

- Water Demand Management Versus Water Supply Policy: The Ebro River Water TransferDocumento16 páginasWater Demand Management Versus Water Supply Policy: The Ebro River Water TransferJavier Tapia BarconesAinda não há avaliações

- Steam Jenny ManualDocumento48 páginasSteam Jenny ManualPawan SehrawatAinda não há avaliações

- Lab Activity 3 - Light-Matter InteractionDocumento3 páginasLab Activity 3 - Light-Matter InteractionCharles Reginald K. HwangAinda não há avaliações

- Gravity Dam - Y910026Documento17 páginasGravity Dam - Y910026Ashish Sanghavi100% (1)

- UntitledDocumento289 páginasUntitledDeepanshu digariAinda não há avaliações

- Role of Additives in XLPE PDFDocumento5 páginasRole of Additives in XLPE PDFbitconceptsAinda não há avaliações

- Answer For Question 4 by NADYKAADocumento2 páginasAnswer For Question 4 by NADYKAAAdi AbidinAinda não há avaliações

- The Comfortable and Sustainable Home Giacomini 0340EN PDFDocumento4 páginasThe Comfortable and Sustainable Home Giacomini 0340EN PDFAlex CoțAinda não há avaliações

- Specific Heat and Heat Capacity Practice ProblemsDocumento2 páginasSpecific Heat and Heat Capacity Practice Problemsaniedorf100% (1)

- Ardrox 1435: Scale and Carbon Removing AidDocumento4 páginasArdrox 1435: Scale and Carbon Removing Aidjianli wangAinda não há avaliações