Escolar Documentos

Profissional Documentos

Cultura Documentos

PangKimPeck FYP

Enviado por

mandirarfDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PangKimPeck FYP

Enviado por

mandirarfDireitos autorais:

Formatos disponíveis

i i

SCHOOL OF SCIENCE AND TECHNOLOGY

E

E

N

N

G

G

4

4

9

9

9

9

CAPSTONE PROJECT

RF filter for millimeter-wave System-on-

package SOP using Low-Temperature Co-

fired Ceramic LTCC

PREPARED BY : Pang Kim Peck

STUDENT PI : W0604230

SUPERVISOR : DR LUM KUM MENG

i i

Abstract

This paper presents the ability to produce a compact stripline parallel coupled bandpass filter.

With the inclusion of parasitic elements on a multilayer LTCC substrate, the unique properties

effectively function as a divider in the filter which increased the coupling between adjacent

parallel lines, thus resulting in a compact and low loss filter. The process of fabrication is done

by using four layers of a 50-m LTCC substrate in with a build in filter area of just 1.6 mm by

0.66 mm.

A center frequency of 61.81 GHz is obtained by using a fabricated prototype three-pole bandpass

filter chip. This chip comes with a bandwidth of 6.23 %, and an insertion loss of -0.5 dB that

includes input and output transitions. Most importantly, the return losses are below -20 dB in the

pass.

Being equipped with its smallest size package, this fabricated bandpass filter shall be in the top

records with the highest V-band filters which can be easily integrated into the millimeter-wave

LTCC system-on-package.

The proposed 1.5GHz integrated parallel-coupled bandpass filter (BPF) with parasitic element

(RLC) on a multi-layer LTCC substrate (Dupont 951) is designed using Agilent Advanced

Design System (ADS) Software. The substrate of the band-pass filter is replaced by using FR4

substrate so as to achieve a resonant frequency of 1.5GHz due to budget constraint and limitation

of testing equipment available in the school premise. The fabrication of the band-pass filter

includes using Organic Solderability Preservative (OSP) and Hot Air Solder Leveling (HASL)

finishes.

Using the ideal simulated results comparing with the actual prototypes, the return loss shows a

drastic drop using HASL coating method of -24.085dB and a gain on the insertion loss of -

11.835dB. While using the OSP coating method, the return loss has a slight increase of -2.871dB

as compared to HASL method and a great decrease on the insertion loss of -9.7197dB.

ii

Acknowledgment

During this full semester year of working on this project, I have consciously and subconsciously

picked up electronic engineering knowledge through lectures, research papers, books and

relevant materials hence enabled me to develop an understanding of the subject from initial to

the final level.

As for here, I would like to take this opportunity to express my deepest appreciation and

heartfelt gratitude to my mentor Dr. Lum Kum Meng, lecturer of SIM University, for his kind

assistance, encouragement and guidance rendered throughout the course of my final year

project. Without his untiring effort, commitment and expertise in this field, this project would

not have been possible.

Lastly, I would also like to thank my family, beloved wife, daughter and friends for their

manual support, strength, and help for everything during these periods of time.

iii

Contents

Abstract ......................................................................................................................................................... i

Acknowledgment ......................................................................................................................................... ii

Contents ....................................................................................................................................................... iii

Table of Figures ........................................................................................................................................... v

List of Table ................................................................................................................................................ vi

1. Chapter 1 - Introduction ....................................................................................................................... 1

1.1 Problem description ..................................................................................................................... 1

1.2 Overall view of the project .......................................................................................................... 1

1.3 Project Management .................................................................................................................... 2

1.4 Project Planning Gantt Chart .................................................................................................... 6

1.5 Design Process Flow-Charts ....................................................................................................... 7

2. Chapter 2 - Literature Review ................................................................................................................. 8

2.1 Filters .................................................................................................................................................. 8

2.2 System-On-Package (SOP) ............................................................................................................. 11

2.3 LTCC Hardware Component .......................................................................................................... 14

2.4 FR4 material ..................................................................................................................................... 15

2.5 Organic Solderability Preservative (OSP) ...................................................................................... 18

2.6 Hot Air Solder Level (HASL) ......................................................................................................... 19

2.7 SMA connectors ............................................................................................................................... 21

2.8 Microstrip Lines ............................................................................................................................... 22

2.8.1 Microstrip Structure .................................................................................................................. 22

2.8.2 Waves in Microstrips ................................................................................................................ 22

2.8.3 Quasi-TEM Approximation ...................................................................................................... 23

2.8.4 Effective Dielectric Constant and Characteristic Impedance .............................................. 23

i.Guided Wavelength ................................................................................................................. 24

ii.Effect of Strip Thickness ......................................................................................................... 24

2.9 Coupled Lines .................................................................................................................................. 25

2.9.1 Even- and Odd-Mode Capacitances ........................................................................................ 25

2.10 Other types of Microstrip Lines ................................................................................................ 26

2.11 Network Analysis ...................................................................................................................... 26

2.12 Selection of software simulation tool ............................................................................................ 29

2.12.1 Features of ADS Momentum .................................................................................................. 30

3. Chapter 3 - Design Methodology ..................................................................................................... 31

iv

3.1 Microstrip width and length calculation (Validation) ............................................................. 31

3.1.1 LTCC Microstrip width calculation (LineCal) .................................................................... 32

3.1.2 FR4 Microstrip width calculation (LineCal) ....................................................................... 35

3.1.3 LTCC Microstrip length selection calculation ..................................................................... 36

3.1.4 FR4 Microstrip length selection calculation ......................................................................... 37

3.2 Spacing Selection ....................................................................................................................... 38

3.2.1 Coupled strip-line LTCC filter with and without parasitic element .................................... 38

3.2.2 Single strip-line FR4 designed filter with and without parasitic element ........................... 39

4 Chapter 4 - Design Layout On Bandpass Filter ............................................................................... 40

4.1 LTCC BPF Filter with Parasitic Element ................................................................................. 40

4.2 LTCC BPF Filter without Parasitic Element ............................................................................ 40

4.3 Design layout of FR4 BPF Filter without Parasitic Element ................................................. 41

4.4 Design Layout of FR4 Parasitic Element ................................................................................ 41

5 Simulation Results .............................................................................................................................. 42

5.1 Simulation Setup ........................................................................................................................ 42

5.2 Simulation Results ..................................................................................................................... 43

5.2.1 LTCC Band-pass Filter (with parasitic element) Insertion Loss, Return Loss and Center

Frequency ............................................................................................................................................ 44

5.2.2 LTCC Band-Pass filter (with parasitic element) simulated Bandwidth .............................. 45

5.2.3 LTCC (without parasitic element) Insertion Loss, Return Loss and Center Frequency .... 46

5.2.4 LTCC Band-Pass filter (without parasitic element) simulated Bandwidth ......................... 47

5.2.5 FR4 Band-pass Filter (with parasitic element) Insertion Loss, Return Loss and Center

Frequency ............................................................................................................................................ 48

5.2.6 FR4 Band-Pass filter (with parasitic element) simulated Bandwidth ................................. 49

5.2.7 FR4 Band-pass Filter (without parasitic element) Insertion Loss, Return Loss and Center

Frequency ............................................................................................................................................ 50

5.2.8 FR4 Band-Pass filter (without parasitic element) simulated Bandwidth ............................ 51

5.2.9 LTCC Parasitic Element Performance .................................................................................. 52

5.2.10 FR4 Parasitic Element Performance ................................................................................. 53

5.3 Simulation Comparison ............................................................................................................. 54

5.3.1 Design strip-line parallel-coupled LTCC BPF Comparison ................................................ 54

5.3.2 Design strip-line parallel-coupled FR4 BPF Comparison ................................................... 55

6 Chapter 6 - Design Fabrication ......................................................................................................... 56

7 Chapter 7 - Evaluation Tests ............................................................................................................. 59

7.1 Setup on test equipment ............................................................................................................. 59

v

7.2 Actual Test Result ...................................................................................................................... 61

7.2.1 FR4 (HASL) BPF generated results ..................................................................................... 61

7.2.2 FR4 (OSP) BPF generated results ......................................................................................... 62

7.3 Comparison of prototypes and simulated results ..................................................................... 64

8 Chapter 8 - Conclusion ...................................................................................................................... 65

9 Chapter 9 - Suggestion for future works ............................................................................................ 66

10 Reference ........................................................................................................................................ 67

11 Appendix ........................................................................................................................................ 68

Table of Figures

Figure 1: Compact stripline parallel coupled bandpass filter .................................................................... 8

Figure 2: System-On-Package .................................................................................................................. 11

Figure 3: Micro-Strip Structure ................................................................................................................. 22

Figure 4: Cross section of coupled microstrip line ................................................................................... 25

Figure 5: Quasi-TEM modes of a pair of coupled microstrip lines: Even and Odd mode .................... 26

Figure 6: Two-port network showing network variables ......................................................................... 27

Figure 7: Screen shot for ADS lineCal using LTCC material ................................................................. 33

Figure 8: Screen shot for ADS lineCal using FR4 material .................................................................... 35

Figure 9: Parasitic element diagram.......................................................................................................... 38

Figure 10: Final designed layout diagram of BPF filter of LTCC substrate layer at the first and last

sector of the filter top and bottom bonded by parasitic element .............................................................. 40

Figure 11: Final designed BPF filter of LTCC substrate layer and without parasitic element layout

diagram ....................................................................................................................................................... 40

Figure 12: FR4 final design with parasitic element ................................................................................ 41

Figure 13: FR4 final design without parasitic element ............................................................................ 41

Figure 14: shows the simulated values of the Insertion Loss S(1,1): -30.794dB, Return Loss S(2,1): -

0.611dB and Center Frequency freq: 61.81GHz ...................................................................................... 44

Figure 15: LTCC Band-Pass filter (with parasitic element) simulated Bandwidth ................................ 45

Figure 16: Shows the simulated values of the Insertion Loss S(1,1):-29.742dB, Return Loss S(2,1):-

0.695dB and Center Frequency freq: 61.81GHz ...................................................................................... 46

Figure 17: LTCC Band-Pass filter (without parasitic element) final simulated result ........................... 47

Figure 18: Shows the simulated values of the Insertion Loss S(1,1): -45.888dB, Return Loss S(2,1): -

5.434dB and Center Frequency freq: 1.502GHz ...................................................................................... 48

Figure 19: FR4 Band-Pass filter (with parasitic element) final simulated result .................................... 49

vi

Figure 20: Shows the simulated values of the Insertion Loss S(1,1): 25.015dB, Return Loss S(2,1):

5.670dB and Center Frequency freq: 1.535GHz ...................................................................................... 50

Figure 21: FR4 Band-Pass filter (with parasitic element) final simulated result .................................... 51

Figure 22: Arrangement of the 4 layers of FR4 substrate is shown below.56

Figure 23: Design layout versus OSP Coating ......................................................................................... 57

Figure 24: Design layout versus HASL Coating ...................................................................................... 58

Figure 25: Photos of the test equipment a) Spectrum Analyzer b) 2m BNC cable c) BNC to spectrum

analyzer d) 50 SMA connector .............................................................................................................. 59

Figure 26: Diagram shows the SMA connectors are soldier on the 3rd layer of the designed FR4 BPF

........... 60

Figure 27: FR4 (HASL) Test Setup .......................................................................................................... 61

Figure 28: Result on four layer FR4 substrate BPF, 1.59GHz coat with HASL (

11

S

:-21.803dB) ...... 61

Figure 29: Result on four layer FR4 substrate BPF, 1.59GHz coat with HASL (

21

S

: -17.269dB) ..... 62

Figure 30: Four layer FR4 substrate BPF (OSP) Test Setup ................................................................... 62

Figure 31: Result on four layer FR4 substrate BPF, 1.63GHz coat with OSP (

11

S

: -24.579dB) ......... 63

Figure 32: Result on four layer FR4 substrate BPF, 1.63GHz coat with OSP (

21

S

: -7.5493dB) ......... 63

List of Table

Table 1: Comparison of Traditional and SOP-based Technology .......................................................... 12

Table 2: FR4 Data Sheet............................................................................................................................ 16

Table 3: Process benefits comparison of OSP and HASL ....................................................................... 20

Table 4: Shows a list of values needed to calculate the width. ................................................................ 31

Table 5: Trend chart for LTCC micro-stripline length ............................................................................ 36

Table 6: Trend chart for FR4 micro-stripline length ................................................................................ 37

Table 7: Trend chart for single strip line LTCC filter with and without parasitic element .................... 38

Table 8: Single Strip-line FR4 designed filter with and without parasitic element ................................ 39

Table 9: LTCC Parasitic Element performance ....................................................................................... 52

Table 10: FR4 characteristics versus width of Parasitic Element Performance ..................................... 53

Table 11: Design strip-line parallel-coupled LTCC BPF comparison .................................................... 54

Table 12: S-parameters versus spacing between coupled lines on the FR4 BPF ................................... 55

Table 13: Comparison of prototypes and simulated results ..................................................................... 64

i i

1. Chapter 1 - Introduction

In the recent technology policy, strengthening the economy and high demand accelerating the

development of millimeter wave wireless equipment, are solely/highly permitted to the high-

speed wireless applications.

There are numerous of benefits by using low temperature co-fired ceramic (LTCC) millimeter-

wave system-on-package (or system-in-package) approach [1]. It is structural compactness, less

spaces required, low cost fabrication, well affordable, excellent performance in transmission

process and finally high-level of integration with associated parasitic elements.

1.1 Problem description

In this project, an analytical study is conducted on RF filter for millimeter-wave System-on-

package (SOP) using Low-Temperature Co-fired Ceramic (LTCC) demand for high-speed and

high efficiency wireless in the communication system.

By evaluating the performance of both the high-speed RF filter and LTCC technologies, ADS

software is used. The methods of fabrication of the actual prototypes such as HASL and OSP

are implemented. Using such coating methods will help to achieve improved results as

compared to the simulated results due to the tolerance during the fabrication process and the

elimination of oxidation.

Due to the higher cost of LTCC and limitation of the spectrum analyzer range of up to only

3GHz, another material such as FR4 is selected in this study with a bandwidth of 1.5GHz.

1.2 Overall view of the project

There are a total of 8 chapters in this report.

Chapter 1 gives an introduction on the purpose, problem description, overall view of the project.

Mainly highlight the essential elements under the project management.

2

Chapter 2 on Literature Review provides brief introduction on filter, SOP, V-band wireless

system, LTCC technologies, FR4 technologies, OSP, HASL, SMA connector, Microstrip lines

technologies, Network analysis and software simulation tools that are available in the market

today.

Chapter 3 Design Methodology of the microstrip line shows the different design methods of

microstrip line.

Chapter 4 Design Layout on Bandpass filters using two different technologies materials, namely

the LTCC and FR4 material.

Chapter 5 Simulation Result comparisons and conclude on both LTCC and FR4 material.

Chapter 6 Design Fabrication based on FR4 material after evaluating on the simulation results.

Chapter 7 Evaluation Test shall demonstrate the use of the test equipment perform evaluation.

Chapter 8 & 9 shall cover the final conclusion and future works are included to finish the

experiments of this project.

1.3 Project Management

The project tasks are divided into various stages. Below shows the Project Plan of each tasks

and Gantt chart respectively:

Task of entire project is divided into several stages:

Stage 1 - Literature reviews related to LTCC technologies

Stage 2 - Design and modeling of RF circuit (V-band with BPF)

Stage 3- Design and modeling of LTCC circuit geometry

Stage 4 - Test and debug LTCC circuit design with ADS tools

Stage 5 - Design Simulation and demonstration

Stage 6 - Overall project evaluation

Stage 7 - Design Enhancement

3

Detail of elaborate and discuss stages is listed below:

Stage 1: Literature reviews related to LTCC technologies

With good understanding of manufacturing multilayer LTCC engineering technology on

wireless system, it allows the possibility of exploring new technology theory and practically to

obtain an optimal performance, compactness and low cost end product.

Integrated parallel-coupled bandpass filter (BPF) with parasitic element (RLC) on a multi-layer

LTCC substrate is important step in this project.

After comprehend on the extensive advantages, knowledge have been expanded and ability in

apprehend clearly on future advance wireless applications.

Research to be done:

I History and applications of LTCC technology

II V-band BPF wireless system performance and operation specification

III Modeling and demonstrate on software Tools with ADS

4

Stage 2: Design and Modeling of RF circuit (V-band BPF)

To evaluate the design performances, the below parameters are essential elements to incorporate

into the project.

i. Bandwidth selection (V band selected)

ii. Insertion/return loss

iii. Analyze signal pulse

iv. Evaluate signal distorted

v. Signal Fading

Stage 3: Design and modeling on LTCC circuit geometry

Design a LTCC module with highly integrated multi-function circuits, consists of MMICs,

filters and antenna where these design specification serves as input to the next stage of the

model performance. Emphasis shall be focused on the final design to be created.

Stage 4: Test and debug design with ADS tools

With the help of the ADS tools, testing and debug procedure is necessary for development

process so as to ensure that the applicant can perform within its desired specification. In

addition, testing also helps to determine the actual results versus the expected results.

Stage 5: Design Simulation and demonstration

System simulation and demonstration is then carried out to ensure that the module tested is well

coordinated. Final system carries out check on design completeness and robustness.

Stage 6: Overall project evaluation

During this stage of the project, all modules that are evaluated in the former stages are

integrated together as the completed design. Once the system testing is completed, the prototype

is ready for delivery to the users.

5

Stage 7: Design Enhancement

In this stage, Design and development process of the LTCC substrate project has finally come to

an end after evaluation. Listed below are some possible recommendations areas that may be use

for the design enhancement listed:

- Improve signal gain on filter

- Minimize insertion/return loss

- Alternative material for design fabrication

6

1.4 Project Planning Gantt Chart

Involves using Gantt Chart to update and track project schedule based on planned task stated

in the Gantt chart and timeline given. Easy tracking compliance of actual work done against

the planned schedule and knowing the progress of each project tasks.

Project Ti tl e

RF fi l ter for mi l l i meter-wave System-on-package SOP usi ng Low-Temperature Co-fi red Cerami c LTCC

Project Team

Pang Ki m Peck 06-Feb-10

Project Supervi or

DR Lum Kum Meng 15-Nov-10

2010

Feb Mar Apr May Jun Jul Aug Sep Oct Nov

1

Stage 1: Li terature revi ews rel ated to LTCC

technol ogi es

2

(i) Review of bandpass filt er t echnology

3

(ii) Hist ory and Evolut ion of LTCC t echnologies

(SOP)

4

(iii) LTCC t echnology on wireless Applicat ions

5

(iv) LTCC Hardware Component s

6

(v) Require V band wireless Syst em Operat ing Range

and Performance

7

(vi) Design and demonst rat e LTCC circuit wit h

Soft ware Tools

8

TMA: Project Proposal

9

Stage 2A: Desi gn and model i ng of fi l ter ci rcui t

10

(i),Achieving a good knowledge on RF circuit and

filt er design

11

(ii),Achieving a good knowledge on BPFs design

12

Stage 2B: Fami l i ari zati on and demonstrati on of

desi gni ng Tool s (ADS)

13

Stage 3: Modi fi es and demonstrate wi th

desi gned fi l ter

14

Stage 4: Testi ng & Debuggi ng others desi gn

fi l ter (Desi gn materi al usi ng LTCC & FR4)

15

Stage 5: Si mul ati on of Desi gn and fabri cate

prototype usi ng FR4 materi al

16

(i) Final product simulat e on t he filt er design (LTCC

& FR4)

17

(ii) Compare and discuss t he simulat ed & measured

result s

18

Stage 6: Project Eval uati on

19

Stage 7: Enhancement of Desi gn

20

Fi nal Report Wri ti ng

21

Revi ew & Amendment of Fi nal Report

22

Presentati on / Demo

Start Date

Target Compl eti on Date

S/N

Task

7

1.5 Design Process Flow-Charts

Flow 1: Design Process Flow

Selection on bandwidth range of filter

Selection on material use

Selection on filter and specification

Execute simulation

Achieve

Design

Objective?

Hardware fabrication

Perform comparison between measurement result and simulation

result

Fabricated prototype is

ready for implement

N

O

N

O

Y

E

S

Y

E

S

Achieve

prototype

Objective?

Modification on

design specification

Y

E

S

8

2. Chapter 2 - Literature Review

2.1 Filters

Filters have an important role not only in the advance of engineering and science but also in

many modern of RF/microwave applications. Advancement the emerging technology

applications such as wireless communications, continue substantially challenges the

RF/microwave filters. There is a need for control requirements like excellent performance,

minimize the essential in sizes, lighter weight, and lastly the good organization of cost.

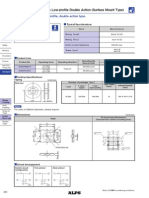

Figure 1: Compact stripline parallel coupled bandpass filter

Therefore, strengthening the economy and high demand accelerating the development of

millimeter wave wireless equipment, are solely/highly recommended for the high speed wireless

application. Further to the technologies of novel unit materials and fabrication process.

Whereby, including the technologies like:

i. High-Temperature-Superconductors (HTS)

ii. Low-Temperature Co-fired Ceramics (LTCC)

iii. Monolithic Microwave Integrated Circuit (MMIC)

iv. Micro-electromechanic System (MEMS)

With a good understanding of the RF engineering technologies, enlighten the rapid evolution of

future microstrip and other filter for RF/microwave application.

50 m

50 m

50 m

50 m

9

This project looks into how computer-aided design (CAD) can be of a tool in the full-wave

electromagnetic (EM) simulators, clinically importance of evaluating the revolutionized RF filter

design.

In order the microstrip filters with matching filtering characteristics to obtain optimal

performance in the RF/Microwave Applications. Furthermore, Miniaturization filters

configuration provides the advanced filtering characteristics, with the platform of technologies,

advanced materials and the purpose of software design tools.

The electromagnetic waves compose with frequencies ranging from 300 MHz up to 300 GHz is

known by the term of microwaves or millimeter waves due to the wavelengths range. For the

applications likes communications, radar, navigation, medical instrumentation, and many others

parts of the industrial.

Looking at the research and development, choice of selecting the particular components always

relied on the market requirement. Both fabrication techniques and operating frequency is the

main dependant of designing the filters.

A short and briefly described as follows:

Firstly, it is a must to understand the designer points of view. Look into advantages like

miniaturization in size, low cost, robust and wide-band or various in band characteristics. Hence,

the design should always comprise of size reduction, integrated element like filters etc,

developing the realization of monolithic microwave integrated circuits (MMIC). With the

emerging fabrication techniques, implementing of the lumped elements will finally allow even

comprehensive wavelength of millimeter-wave.

Things ought to consider when lumped elements are present in the microwave frequencies: the

overall length of the lumped elements, the inductor or capacitor must present only a smaller

fraction in particular wavelength.

In most cases, it is difficult to truly realize the lumped elements, due to other parasitics

integration. Forming shunt capacitance again on the ground plane which will considerably

affecting the performance of the respective inductor.

10

In design stage, lumped elements are over the entire operating frequencies band. By using the

full-wave EM simulation is able to into account of the all the parasitic and various kinds of

effects caused.

Choice of filters, band-pass filter (BPF) consists of parasitic elements is strongly integrated on

multilayer strongly bounded LTCC substrate provides compactness and performance required.

Conventional integrated band-pass filter (BPF) structural huge, implement in complex transitions

furthermore is not fable to cost.

Planar Type Filters operate with huge patch resonators therefore the structure of build up area is

eventually huge. The formation of the substrates is normally thick and emphasize on design procedure

is surely complex [2],[7].

Waveguide Type Filters construct with many vias and via fences also require huge areas and have

level of difficulty connecting the microstrip lines or coplanar waveguides [3-6].

The function of the RF filter is a device that allows attenuation and transmission of the selected range

of frequencies. RF filters likes high pass, low pass, band pass and band reject filter and many other

filters are commonly used in the industrial.

11

2.2 System-On-Package (SOP)

The technologies of SOP have been widely use in almost two decades for the miniaturization

technology, support most of the electronic and bio-systems of feature from a thousand to a

million. Promoting the invention of System Integration Law is well known the Second Law of

Electronics working on the miniaturization of the whole system.

Potential of integrated circuits also known as Moores Law plays an important role in the

miniature portion of the system. In order to facilitate the miniaturization of SOP system and

further allow the more system function implementation enables. Therefore, entail the provision

of SOP in the new generation in electronics communication, bio, healthcare and automotive

industries.

Figure 2: System-On-Package

R

F

SYS-ON-CHIP (SOC)

BIO-SENSORS

THERMAL SOP

STACKED ICs

& PACKAGES

(SIP)

MIXED SIGNAL SOP

DESIGN

SOP ELECTRICAL

TEST

MIXED SIGNAL

RELIABILTY

RF

12

In todays market economics and microsystem technologies correspond to the primary drivers of

information age. Size of microelectronics with integrated technology of giga-scale, wireless

communication system devices in gigabit, terabit optoelectronics, even in motorization from

micro to nano size, and many others medical implants system too, which are all integrated

technology idea of leading to the ultra miniaturization formation.

The traditionally separated areas of between System-on-package (SOP) and the System-on-chip

(SOC) technology, one is at the integrated circuit (IC) stage, second stacked ICs and lastly is

allot at System-in-package (SIP) stage, despite the emphasis on manufacturing stacked of ICs

and packages. Therefore, system technology of SOP consists of the SOC and SIP thermal feature

and sometime even inclusive of the batteries too. Thus, SOP resulting in the interaction, needs

and device emerging in miniaturized into a solo system package.

Multi-layer ceramic and organic-based SOP implementation are capable of overcoming this

limitation by integrating components as part of the module package that would have otherwise

been acquired in discrete form. On-package components not only miniaturize the module, but

also eliminate or minimize the need for discrete components and thereby reduce the assembly

time and cost.

Table 1: Comparison of Traditional and SOP-based Technology

Building

Blocks

Traditional Technology

SOP-based

Technology

Power sources

DC adapter, power cables,

power socket

Embedded thin-film

batteries micro-fluidic

batteries

Integrated circuits

Logic, memory, graphics,

control, and other ICs,

SOCs

Embedded and thinned ICs

in substrate

Stacked ICs in 3D/

Packages ICs in 3D

SIP with wire bond and flip

chip

Wire-bonded and flip-chip

SIPs. Through silicon via

(TSV) SIPs and substrates

Packages or substrates

Multilayer organic

substrates

Multilayer organic and

silicon substrates with TSVs

13

Passive components

Discrete passive

components on printed

circuit board (PSB)

Thin-film embedded

passives in organics, silicon

wafer and Si substrate

Heat removal elements

Bulky heat sinks and heat

spreaders. Bulky fans for

convection cooling

Advanced nano-thermal

interface materials, nano-

heat sinks and heat

spreaders, thin-film

thermoelectric coolers,

micro-fluidic channel based

heat exchangers

System board

PCB-based motherboard

Package and PCB are

merged into the SOP

substrate

Connectors/ sockets

USB port, serial port,

parallel port, slots (for dual

in-line memory modules

(DIMM) and expansion

cards)

Ultrahigh density I/O

interfaces

Sensors

Discrete sensors on PCB

Integrated nano-sensors in

IC and SOP substrate

IC-to -package

interconnections

Flip chip, wire bond

Ultra miniaturized nano-

scale interconnections

Packages wiring

Coarse wiring Line

width:25m

Pitch:75m

Ultrafine pitch, wiring in

low-loss dielectrics Line

width: 2-5m

Pitch: 10-20m

Package-to board

interconnects

Ball grid array (BGA)

bumps, tape automated

bonding (TAB)

None

Board wiring

Very coarse-pitched wiring

(line width/ spacing:100-

200m)

No PCB wiring. Package

and PCB are merged into the

SOP substrate with ultrafine

pitch wiring

14

V-band Wireless System

To overcome the achievement of high transmission rates and wider bandwidths, choice of selecting

the appropriate band selection is essentially important. By selecting V- band will eventually provide

the above requirements. Operating range of V-band is (50 GHz to 75GHz) whereby is way above the

1Gbps.

2.3 LTCC Hardware Component

Material of Low Temperature Co-fired Ceramic (LTCC) is an acronym made of glass ceramic

composite. Specimens structural is pre-processing with multi-layers green-sheet laminated with

required circuits printed. Each laminated layer thickness come with a minimum thickness of 50m

(equivalent to 1.8 mils) is possible. Aim of impedance control and excellent packaging solution

liability is able to command in an LTCC substrate by configuring with the Cavities process. Due to its

unique performance capability, the high-frequency RF circuitry and microwave applications are

widely used in wireless and satellite industries.

The laminates were stacked in various composite (likes resister, capacitors, inductors and passive

components), with single fired process. Create conduction between laminated layers, were subject to

inductive and capacitive, by using the element with strip-line interconnects and ground planes. Those

Passive components embedded between LTCC multi-layers, achieve interconnecting length

minimization, improving, to provide dense integration and structural robustness, and less circuit

geometry is obtained. As the result, relevant levels of quality and high reliability are been resolved.

Highly conductive material (Silver, copper and gold) is used, because of the firing temperature <

1000C, provide best in electrical conductivity and highest Q factor [8]. It was also observed that

LTCC filter dimensions are much smaller, much higher frequency performance as compare to the

ideal discrete component. Manufacture of LTCC substrates by using the co-fired technique.

Computer-aided with unique design techniques for schematics circuitry obtained before specimens

fabricated. An electromagnetic (EM) simulation tool is able to perform the physical layout realization

need.

15

Key Advantages of LTCC technology:

Excellent High Frequency Performance

From the above table shows that dielectric constant is constantly stable for over higher frequency

range.

Moisture free

Excellent in providing passive components (RLC) consists of Resistance, inductance and

capacitance

Provide with high laminated Density of interconnection

Cost of silver is low and easy available

Materialize excellent in thermal management (co-fired)

TCE Closely matches Si , GaAs and Sia (company with others compounds too)

Brazed on Components

Tight and compact packaging

Provide outstanding reliability in present market proven

2.4 FR4 material

Development of FR4 material is made up of various combination sheets of Prepreg, which the

structural in sandwiched plated constructed of fiber glass matting. Which it infuse with the epoxy

resin. The standard thickness of the circuit board is normally 1.6mm, comprising of 8 layers of

Prepreg and including the outer copper layers. The laminate layer of Prepreg and outer Ultra thin

copper foil are pile up together, and forming the final laminate by the matter of placing all the

layer in large press and follow by bonding.

Generally, the copper foil is fabricated, with the help of rotating stainless steel drum is slowly

dipped in the solution producing thin copper plating. As the steel drum turns, offer a great

distinctive advantages allowing the drum electroplate with a thin layer of copper. When the

plated portion leaves the solution, thus lifting the copper plate stripped off from the drum.

Frequency Range in G-

Hz

3 GHz (951) 40GHz (943)

Loss Tangent 0.002 0.002

Dielectric Constant 7.7 7.4

16

The unique of glass cloth is perfectly made up of very fine weaving strands of fiber glass yarn

collectively. This yarn structure in the form of many small and fine threads of glass bonded as

one. Major composite material on cloth strengthens from the toughness on the laminated glass.

Composite material of bisphenol-A and ethylene chloronhydrin are orientation of layer bonded

together called the epoxy resin. Therefore, it is hard for the two composite to separate during

high temperature and powerful oxidizing solution.

Table 2: FR4 Data Sheet

Test/ Specification FR4 Laminate Typical Values

Thermal Stress, Solder bath 288 deg.C >60

Dimensional Stability, E-2/150

< 0.04% Warp/fill

< 1.00% Bow / Twist

Flammability, Classification UL94 V0

Water Absorption E-1 / 105 0.10%

Peel Strength After Thermal Street 11 lb. in After 10s /288 Deg.C

Flexural Strength

100,000 lbf / in2 Lengthwise

75,000 lbf /in2 Crosswise

Resistivity After Damp Heat Volume 10^8 M ohms cm

Resistivity After Damp Heat Surface 10^8 M ohms

Dielectric Breakdown. Parallel to laminate > 60KV

Dielectric Constant @ 1MHz 4.7

Dissipation Factor @ 1 MHz 0.014

Q-Resonance @ 1 MHz > 75

17

Q-Resonance @ 50 MHz > 95

Arc Resistance 125 s

Glass Transition Temperature 135 Deg. C

Temperature Index 130 Deg. C

A few other relevant facts from other sources

Specific Gravity 1.8 1.9

Rockwell Hardness (M scale) 110

18

2.5 Organic Solderability Preservative (OSP)

OSP are the most widely used coating material in the lead-free soldering, due to the excellent

solderability performances, easy processing method as well as its low cost. An anti-oxidant film

applies on the exposed copper surfaces that established a reaction with copper producing a form

of organometallic layer known as the Organic Solderability Preservative. The coating form

invisible capability, with a thickness of 0.1 to 0.5 microns thin layer on the copper surface. OSP

shelf life could last for six months as compare with other solder masks.

The flow diagram below presents the sequence of steps of the typical OSP process. A brief

description of each process steps are as the following diagram flow:

Flow 2: OSP Process Flow

Solders mask residues and surface oil on the

exposed copper surfaces is remove with acidic

cleaner

Etching removes any contaminants and chemically

roughen copper surface with microetch solution

Eliminate excess solution and limit oxidation

configuration on the copper surface

Chemically bonds protective layers, forming a

solderability preservative organometallic layer on the

copper surface

Treating the OSP coat with warm-air and at the same

times remove unwanted residual moisture from the

respective board

Help to even coating across the surface of the entire

Printed Wired Board (PWB)

ACID CLEANING

MICROETCH

AIR KNIFE

OSP

AIR KNIFE

DRY

19

2.6 Hot Air Solder Level (HASL)

A process step during manufacturing of HASL consists of the following, pre-clean, fluxing, hot

air leveling, and a post-clean.

1. Pre-cleaning is simultaneously done with a micro-etch

2. Fluxes comprise with the following function:

- Allowing a thin layer of oxidation forming on the preclean surface act as a layer of

protective function.

- Heat dissipation during solder immersion.

- It enhances oxidation protection during the process of HASL.

In order to achieve balance flux, that liaise between high and lower viscosity fluxes meaning

better the protection and higher heat transfer. With more effective oxidation protection

collaborator with higher viscosity flux and much even solder leveling. But bad points is, it can

reduce overall heat transfer and require longer dwell time too.

The circuit board rapidly past jets of hot air. Reasons to adopting this procedure allow solder to

coat on the exposed copper and solder-free for the masked areas.

In this stage, all the embedded impurities are easily remove by using the method of drossing,

with the help of the hot air leveler. Final stage is to pre-clean using the acid solution

Flow 3: HASL Process Flow

Solder

Air Knife

Post-clean

Dry

Preclean

Flux

20

Table 3: Process benefits comparison of OSP and HASL

Description OSP HASL

Surface Thickness

Uniformity

Good Poor

Pad Coplanarity Good Poor

Finished Hole Size

Uniformity

Good Poor

Plated Hole Size

Compensation (design)

Not Required 0.0002-0.0003

in oversized

Fine Pitch Quality

(25mils or less)

Good Poor

Surface Contrast

(Assembly)

Good Poor

Solder Volume Predictable

(design for)

Varies

SIR, bare board Excellent Acceptable

Environmental Hazard Low High

Personnel Exposure

(safety issue)

Low High

Gold Contact Masking Not required Required

Thermal Stress (PCB

manufacturing process)

No Yes

Manufacturing Cost Low High

Equipment Maintenance

Cost

Low High

Rework ability Easy Difficult

Surface Finish

Durability

Fragile Robust

21

2.7 SMA connectors

Namely, SubMiniature Version A in short known as SMA connectors, it offers great distinctive

advantages providing continuous DC electrical performance conjunction with flexible cables

with extension to 12.4GHz.

The SMA connectors coupling appearance is screw-type. Moreover, the most notable being in

impedance constant at 50 ohms and low reflection performance during the broad band condition.

Thus, with the plus point of properties, low voltage standing wave ratio (VSWR) and signal

attenuation is minimal, that make SMA connectors a most popular core in the microwave

community.

22

2.8 Microstrip Lines

2.8.1 Microstrip Structure

Major structure of a microstrip consists of the following subsystem:

1. Width of the conducting microstrip, W

2. Thickness of the microstrip, t, which located just on top of the dielectric substrate

3. Relative dielectric constant

r

c , with the thickness height h

4. Lastly, the dielectric substrate is connected to the ground plane

Figure 3: Micro-Strip Structure

2.8.2 Waves in Microstrips

The microstrip is made up of inhomogeneous physical structure that consists of two media: the

dielectric below and air located above the structure.

Due to the inhomogeneous formation, it caused the microstrip not in the favour to the pure TEM

wave. Furthermore, the transverse components will only present in the pure TEM wave and also

derive as propagation velocity dependent on material properties represent by the permeability

o

c and

permittivity

r

c .

Air and dielectric substrate play an importance role in the guided-wave media, eliminating the

magnetic and electric fields in the microstrip line waves. Moreover, propagation velocities not just

depend on the material properties but also the microstrip physical dimension.

Ground

plane

W

h

h

h

r

c

r

h

Conducting

Strip

Dielectric

substrate

t

W

h

t

r

c

23

2.8.3 Quasi-TEM Approximation

The of the longitudinal components of the fields for the dominant mode of a microstrip line may be

ignored due to the smaller field area comparing to the transverse components.

With that, not only the dominant mode act like the TEM mode, even the TEM transmission line

theory is applicable to the microstrip line.

For quasi-TEM approximation, it can be applied over almost all the operating frequency ranges of

microstrip

2.8.4 Effective Dielectric Constant and Characteristic Impedance

By using in the quasi-TEM approximation, corresponding to the effective material of dielectric

permittivity between homogeneous and inhomogeneous of dielectric-air media of the microstrip.

In quasi-static analysis [9], obtaining the characteristics or impedance

c

Z

and effective dielectric

constant

re

c

in microstrip are the most important and more efficient parameters in process of

microstrips transmission. In addition, quasi-static analysis provides the systematic mode of

propagation theory of a microstrip condition with the pure TEM. Connected to microstrips

parameters are then determined within the two different requirements of capacitance values are

shown below:

For very thin conductors (ie, t 0), the closed-form expressions that provide accuracy better than

one percent are [10] as follows.

For : 1 s

h

W

( ) a

h

W

W

h

r r

re

2 . 4 1 04 . 0 12 1

2

1

2

1

2 5 . 0

(

(

|

.

|

\

|

+

|

.

|

\

|

+

+

+

=

c c

c

( ) b

h

W

W

h

In Z

re

c

2 . 4 25 . 0

8

2

|

.

|

\

|

+ =

c t

q

24

Where O = t q 120 is the wave impedance in free space.

For : 1 >

h

W

( ) a

W

h

r r

re

3 . 4 12 1

2

1

2

1

5 . 0

|

.

|

\

|

+

+

+

=

c c

c

( ) b

h

W

In

h

W

Z

re

c

3 . 4 444 . 1 677 . 0 393 . 1

1

(

|

.

|

\

|

+ + + =

c

q

i. Guided Wavelength

Furthermore, for a given microstrip, and value of the effective dielectric constant is able to identify,

make easy for calculation of the guided wavelength implementing on the quasi-TEM mode on the

design microstrip is shown as below:

Give the

0

been the most accuracy for free space wavelength at the respective operation frequency,

. f

Where,

f

c

o

=

More conveniently, to facilitate the guided wavelength result in micrometer, with the help of the

respective frequency is given in gigahertz (GHz),

re

g

c

0

=

re

g

GHz f

c

c

) (

=

where c is the velocity of light s m c / 10 3

8

- ~ in free space.

Therefore, for Quarter wavelength, use

4

g

l

= ,

If the design is using a half-wavelength microstrip, then the formula will be using

2

g

l

= ,

Therefore, note that guided wavelength play a very important step in designing the microstrip filters.

ii. Effect of Strip Thickness

Usually, effect on conducting strip thickness t is not taken into consideration, due to the thickness

dimension of the thin film conducting layer is very small. In practice, this is often neglected.

25

2.9 Coupled Lines

In the designing stage, using EM simulation in the form of Coupled microstrip lines, are widely used

for implementing microstrip filters. The reason for cross section of the coupled microstrip lines are

illustrates in this portion. With the width W are placed in parallel, and through a separation, S

configuration are within the recommend limits as shown in Figure 4. While, relatively result can be

achieved for the two quasi-TEM modes.

Figure 4: Cross section of coupled microstrip line

2.9.1 Even- and Odd-Mode Capacitances

There are two main capacitances, namely the odd mode and even mode. i.e., for an even-mode

excitation, both microstrip line are serve in the identical voltage potentials, under this conditions,

even mode excitation carry both the positive charges moderately.

As Figure 5 shows the mode of the odd event, odd mode excitation establishes an opposite voltage

potential between the two lines up microstrip line or in others word the symmetric plane know as the

electric wall act as a charge, where the sign are in opposite.

Normally, both the odd and even modes will excite at one goal, and the operating propagation in

phase velocities is different, since the desirable of the TEM is not pure. Furthermore, that both modes

are having a different permittivities experience too. Effective of the dielectric constants and the

characteristic impedance are well characterized in the coupled microstrip lines between the odd and

even modes [11].

r

c

S

W W

h

W W

S

26

Figure 5: Quasi-TEM modes of a pair of coupled microstrip lines: Even and Odd mode

2.10 Other types of Microstrip Lines

Implementing other types of microstrip line, are normally unclipped for filter applications [12], is a

method of realizing all kind of different filters, impedance in wider range is barely achievable in the

form of lowpass, highpass and even the cascaded formation of wider band bandpass filters.

Understanding the concern of ultra thin dielectric substrates on the low dielectric constant, by this

method dielectric loss will be further reduced. This makes the plus points for developing filters,

potential in micro-machined filters in the unique capabilities for millimeter-wave applications.

2.11 Network Analysis

Filter network plays an important part in microwave engineering industrial and RF sector. The

networks are capable to combine/detach signal and discard/select in numerous frequencies in the

RF/microwave systems and equipment.

Microwave frequencies cannot be measured directly using voltmeters and ammeters. Thus, both

voltage and current are not important role at microwave frequencies for measuring the level of

electrical excitation of a network.

However, in order to optimize the usage of low-frequency network concepts, the operation of a

microwave network as filter is best described in terms of voltages, currents and impedances

values.

Magnetic wall

+

+

+

+

+

+

+

+

+ + + + + +

f

C

p

C

`

f

C

f

C

p

C

`

f

C

ga

C

ga

C

Electric wall

+

+

+

+ + +

- - -

f

C

f

C

p

C

p

C

gd

C

gd

C

27

Reflection coefficient,

1

1

11

a

b

S =

1

1 Re

port at power Incident

port at power flected

=

Transmission coefficient,

1

2

21

a

b

S =

1

2

port at power Incident

port at power d Transmitte

=

Figure 6: Two-port network showing network variables

For two ports network are two by two as shown in Figure 6.

Scattering matrix [13] is also known as S parameters, denotes as [S] for some, also is a set of

matrix formation. The S parameters are in general complex as:

|

|

.

|

\

|

22 12

21 11

S S

S S

Parameter of

11

S and

22

S are both known as the reflection coefficients. As well as, the operating

Parameter of

12

S and

21

S are representing the parameter of transmission coefficients.

Below shown the result designed filter S-parameter generation from ADS momentum.

Achieve a good result on reflection coefficient, with

11

S gain less than -20dB of the filters.

21

S Known as the power efficiency of the filter, also require power loss to be less than -10dB.

1

a

1

b

2

a

2

b

Two- port

Network

28

Intrinsic impedance

Intrinsic impedance, q is been the ratio relation between electric and magnetic field components

respectively. Therefore, is generally known as the Transverse Electromagnetic (TEM) of the RF

studies process.

7

0

10 4 ,

= t ty Permeabili Absolute

12

0

10 85 . 8 ,

= ty Permittivi Absolute c

Field Electric E

x

,

Field Magnetic H

y

,

1 : =

r

r

Note

c

in Free Space propagation

r

r

r

r

y

x

H

E

pedance Intrinsic

c

t

c c

q 120 , Im

0

0

~ = =

29

2.12 Selection of software simulation tool

Selection of software give a detail account of the project undertake from the given synopsis stage

to its completion in the form of a standalone simulation application. As simulation software

selection is part of the highlight in this project, also outlines the various software development

tools available in the market as well as the pros and cons of each Integrated Development

Environment (IDE).

Knowing the platform of selecting the important key points for user friendly and powerful

software tools, as eventually, enlightening the gauging process performance on the designed

antenna. Furthermore, providing the controllability for modifying different various parameters

antenna, such as:

a) Dimension

b) Relative permittivity

c) Different way of defining layers, etc. to achieve fine tuning and optimal design

performance.

In addition, simulation tools is able to perform as expectation, consists of S-parameter, radiation

pattern, visualization on the various antenna design views will be consider provided in the

simulation software product environment, in this project the ADS (Agilent, Advance Design

Software) and HFSS (Ansoft, High Frequency Structural Simulator) are well considered.

HFSS is performing on the simulation of 3D full wave electromagnetic field, which requires a

high computerize processing power and its license fee is far expensive as compare with ADS.

Even though ADS provide only two and half waves simulations, it easily comes with free

evaluation copy and required a low processing power. With all these advantages of ADS, it

stands out to be my choice of software tools for this project.

30

2.12.1 Features of ADS Momentum

In the modern engineering society, simulation tools provide designers with comprehensive

simulation requirement platform whereby ADS is able to enlighten the process of design

performance. Thus, in order to analysis an efficient RF designs.

Below are some capable steps functions on Momentum key:

- Evaluation the Greens calculation of the design substrate

- Performing the patterns of Meshing on the respective signal layers

- Input source of information to MOM, perform the matrix equation calculation

- In this application of S-parameters, which allow calibration and de-embedding

- Adaptive of Frequency sampling selection able to enhance the order modeling.

31

3. Chapter 3 - Design Methodology

3.1 Microstrip width and length calculation (Validation)

In order to validate LineCal results, a set of formulas are applied to calculate the width of Microstrip.

Table 4: Shows a list of values needed to calculate the width.

Material Symbols LTCC FR4

Relative permittivity

r

c

7.7 4.7

Microstrip thickness/width t

17 microns 17 microns

Substrate height h

50 microns 1600 microns

Intrinsic Impedance

q

120 120

Calculation for LTCC material

Effective dielectric constant,

( )

( )

28 . 5

93 . 0 35 . 4

13 35 . 3 35 . 4

12 1 35 . 3 35 . 4

50

50

12 1

2

1 7 . 7

2

1 7 . 7

12 1

2

1

2

1

5 . 0

5 . 0

5 . 0

5 . 0

=

+ =

+ =

+ + =

|

.

|

\

|

+

+

+

=

|

.

|

\

|

+

+

+

=

re

r r

re

W

h

c

c c

c

. 1

1

50

50

1 /

to equal is value Therefore

h

W

h W

>

32

Microstrip impedance,

{ }

{ }

O ~

O =

=

+ + =

)

`

|

.

|

\

|

+ + + =

)

`

|

.

|

\

|

+ + + =

50

69 . 54

3 07 . 164

6 . 0 393 . 1 1

28 . 5

120

444 . 1

50

50

677 . 0 393 . 1

50

50

28 . 5

120

444 . 1 677 . 0 393 . 1

1

1

1

1

t

t

c

q

In

h

W

In

h

W

Z

re

c

Since both LineCal and calculation derived Micro-strip impedance to be 50 when Micro-strip

width is 50m, LineCal result has been successfully validated.

The length of the Microstrip Feed can be calculated as follows:

re

g

GHz f

c

c

) (

=

28 . 5 10 60

10 3

9

8

=

g

97 . 2175 =

g

Therefore, for Quarter wavelength, use

4

g

l

= ,

4

97 . 2175

= l

microns l 544 =

3.1.1 LTCC Microstrip width calculation (LineCal)

Figure 7 is a screenshot captured of LineCal from ADS tools. LineCal is an integrated function has the

ability to create pre-determine physical width parameter.

Therefore, further assists designers in designing the Microstrip line. Whereby, SMA connector is O 50

on the source feed design and Microstrip impedance also is set at O 50 too.

33

Figure 7: Screen shot for ADS lineCal using LTCC material

ADS LineCal obtains Microstrip line length and width is approximate 50m and 568m

respectively. The yellow arrow pointing to the cells indicates the input substrate parameters and

component parameters values required for calculating the length and width of the micro-strip line.

Calculation for FR4 material

. 1

8125 . 1

1600

2900

1 /

than greater is value Therefore

h

W

h W

>

Micro-strip line

approximate

Width is 50m and

length is 568m

34

Effective dielectric constant,

( ) ( )

( )

52 . 3

67 . 0 85 . 2

62 . 7 85 . 1 85 . 2

55 . 0 12 1 85 . 1 85 . 2

2900

1600

12 1

2

1 7 . 4

2

1 7 . 4

12 1

2

1

2

1

5 . 0

5 . 0

5 . 0

5 . 0

=

+ =

+ =

+ + =

|

.

|

\

|

+

+

+

=

|

.

|

\

|

+

+

+

=

re

r r

re

W

h

c

c c

c

Microstrip impedance,

{ }

{ }

O ~

O =

=

+ + =

)

`

|

.

|

\

|

+ + + =

)

`

|

.

|

\

|

+ + + =

50

235 . 50

4 94 . 200

79 . 0 393 . 1 8125 . 1

52 . 3

377

444 . 1

1600

2900

677 . 0 393 . 1

1600

2900

52 . 3

120

444 . 1 677 . 0 393 . 1

1

1

1

1

In

h

W

In

h

W

Z

re

c

t

c

q

Since both LineCal and calculation derived Microstrip impedance to be 50 when Microstrip width

is 2900m, LineCal result has been successfully validated.

The length of the Micro-strip Feed can be calculated as follows:

re

g

GHz f

c

c

) (

=

52 . 3 10 5 . 1

10 3

9

8

=

g

microns

g

106600 =

Therefore, for Quarter wavelength, use

4

g

l

= ,

4

106600

= l

microns l 26650 =

35

3.1.2 FR4 Microstrip width calculation (LineCal)

Figure 8 is a screenshot captured of LineCal from ADS tools. LineCal is an integrate function has the

ability to create pre-determine physical width parameter.

Therefore, further assists designers in designing the Microstrip line. Whereby, SMA connector is O 50

on the source feed design and Microstrip impedance also is set at O 50 too.

Figure 8: Screen shot for ADS lineCal using FR4 material

ADS LineCal obtains Microstrip line length and width is approximate 2900m and 26584m

respectively. The yellow arrow pointing to the cells indicates the input substrate parameters and

component parameters values required for calculating the length and width of the Micro-strip line.

Micro-strip line

approximate

Width is 2900m and

length is 26584m

36

3.1.3 LTCC Microstrip length selection calculation

Table 5: Trend chart for LTCC micro-stripline length

With the generated length: 568m from LineCal as a guide, various different lengths are tested

in the simulation as shown above Table 5. In this project, the required V-band is around 50 GHz

to 75 GHz and the required length needed has to be as compact as 568m or lesser with a

reasonable insertion and return loss.

Both LTCC micro-stripline with and without parasitic length at 400m laid on the V-band range.

Besides that the insertion loss: -3.69 and return loss: -2.461 are both very near to the rest of the

different length designs. Thus, the final LTCC filter length is selected as 400m.

-10

0

10

20

30

40

50

60

70

80

90

300 350 400 450 500 550 600

S

-

p

a

r

a

m

e

t

e

r

s

(

d

B

)

a

n

d

f

e

r

q

u

e

n

c

y

(

G

H

z

)

LTCC, micro-stripline length (m)

Frequency

Frequency PE

S11

S21

37

3.1.4 FR4 Microstrip length selection calculation

Table 6: Trend chart for FR4 micro-stripline length

With the generated length: 26584m from LineCal as a guide, various different lengths are tested

in the simulation as shown above Table 6. Due to the limitation of analyzer used in this project,

the targeted frequency is around 1.5 GHz and the required length needed has to be as compact as

26584m or lesser with a reasonable insertion and return loss.

Both FR4 micro-stripline with and without parasitic length at 21500m laid on the 1.5GHz

range. Besides that the insertion loss: -4.959 and return loss: -2.141 are both very near to the rest

of the different length designs. Thus, the final FR4 filter length is selected as 21500m.

-6

-5

-4

-3

-2

-1

0

1

2

3

S

-

p

a

r

a

m

e

t

e

r

s

(

d

B

)

a

n

d

F

r

e

q

u

e

n

c

y

(

G

H

z

)

FR4, micro-stripline length (m)

Frequency

Frequency PE

S11

S21

38

3.2 Spacing Selection

3.2.1 Coupled strip-line LTCC filter with and without parasitic element

Table 7: Trend chart for single strip line LTCC filter with and without parasitic element

Figure 9: Parasitic element diagram

A signal line is formed on the middle layer and the parasitic elements are patterned above and below

the middle layer. The parasitic elements only cover the first and last filter sections because these

sections are the dominant cause of the process variation sensitivity.

-16

-14

-12

-10

-8

-6

-4

-2

0

10 20 30 40 50 60 70 80 90 100

S

2

1

I

n

s

e

r

t

i

o

n

l

o

s

s

(

d

B

)

Spacing, s (m)

LTCC, S

21

versus spacing between coupled line with

and without parasitic elements

Without parasitic element

With parasitic element

39

Above chart shows the characteristic of the coupled stripline with the parasitic elements versus

spacing between adjacent lines. Above diagram show the port configuration. Line length and line

width are 400m and 50m, respectively. With parasitic element wide is 200 m. The simulation

was performed using a commercial EM simulation. The red square and blue diamond plot coupled

line characteristics with and without parasitic elements, respectively. The increase in insertion loss of

the coupled line with parasitic elements is clearly smaller than that of the normal coupled line, when

the spacing increases. Thus, the final LTCC filter spacing selected is 10m

3.2.2 Single strip-line FR4 designed filter with and without parasitic element

Table 8: Single Strip-line FR4 designed filter with and without parasitic element

Above chart shows the characteristic of FR4 coupled stripline with the parasitic elements versus

spacing between adjacent lines. Above diagram show the port configuration. Line length and line

width are 21500m by2900m, respectively. The parasitic element is 21500m by 10000 m width.

The simulation was performed using a system analyzer. The red square and blue diamond plot

coupled line characteristics with and without parasitic elements, respectively. The increase in

insertion loss of the coupled line with parasitic elements is clearly smaller than that of the normal

coupled line, when the spacing increases. This result indicates that the coupled stripline has low

sensitivity to spacing variation. Thus, the final FR4 filter spacing selected is 400m.

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

S

2

1

(

m

)

FR4, Spacing, S(m)

S21, FR4, Without

parasitic element

S21, FR4, With parasitic

element

40

4 Chapter 4 - Design Layout On Bandpass Filter

4.1 LTCC BPF Filter with Parasitic Element

Below shown the final designed layout diagram of the LTCC with parasitic element after selecting

the right values of length, width and spacing:

Figure 10: Final designed layout diagram of BPF filter of LTCC substrate layer at the first

and last sector of the filter top and bottom bonded by parasitic element

4.2 LTCC BPF Filter without Parasitic Element

Below shown the final designed layout diagram of the LTCC without parasitic element after

selecting the right values of length, width and spacing:

Figure 11: Final designed BPF filter of LTCC substrate layer and without parasitic

element layout diagram

41

4.3 Design Layout of FR4 BPF filter without Parasitic Element

Below shown the final designed layout diagram of the FR4 with parasitic element after selecting the

right values of length, width and spacing:

Figure 12: FR4 final design without parasitic element

4.4 Design Layout of Parasitic Element

Below shown the final designed layout diagram of the FR4 without parasitic element after selecting

the right values of length, width and spacing:

Figure 13: FR4 final design parasitic element

42

5 Chapter 5 - Simulation Results

5.1 Simulation Setup

The following steps are carried out in the process of deviating the spacing requirement:

Step 1: Modify the substrate by entering a thickness of 50m and Permitivity (

r

c ): Real is 7.7 and

loss tangent is 0.002.

Insert the

Thickness

Insert the

Real Value

Insert Loss

Tangent

43

.

Step 2: Insert the substrate layer and layout layer conductivity under metallization layer setting

before processing to simulation setting

Step 3: Insert the simulation settings on the substrate layer as shown above

Stop

Frequency

Sampling

Stop

Change

Frequency

Type

Start

Frequency

44

5.2 Simulation Results

5.2.1 LTCC Band-pass Filter (with parasitic element) Insertion Loss, Return Loss and

Center Frequency

Figure 14: shows the simulated values of the Insertion Loss S(1,1): -30.794dB, Return Loss

S(2,1): -0.611dB and Center Frequency freq: 61.81GHz

45

5.2.2 LTCC Band-Pass filter (with parasitic element) simulated Bandwidth

Figure 15: LTCC Band-Pass filter (with parasitic element) simulated Bandwidth

By using the simulated values generated as shown above, at the 3dB Bandwidth can be

derived:

High center frequency (M4) Low center frequency (M3) / Middle center frequency

(M5)

= [M4(freq)- M3(freq)]/M5(freq)

= [(64.13GHz 60.28GHz)/ 61.81GHz] x 100%

= 6.23%

46

5.2.3 LTCC (without parasitic element) Insertion Loss, Return Loss and Center

Frequency

Figure 16: Shows the simulated values of the Insertion Loss S(1,1):-29.742dB, Return Loss

S(2,1):-0.695dB and Center Frequency freq: 61.81GHz

47

5.2.4 LTCC Band-Pass filter (without parasitic element) simulated Bandwidth