Escolar Documentos

Profissional Documentos

Cultura Documentos

Re 500

Enviado por

mazmamrefTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Re 500

Enviado por

mazmamrefDireitos autorais:

Formatos disponíveis

13

5

2

8

7

1

1

4

2

2

+

9

6

6

1

4

6

0

8

9

7

4

1

4

6

0

6

2

5

5

9

6

6

+

8

0

0

1

2

0

0

0

1

3

w

w

w

.

h

i

l

t

i

.

c

o

m

1

0

1

0

2

7

8

7

1

2

3

9

,

2

3

0

,

0

0

0

H

i

l

t

i

S

a

u

d

i

A

r

a

b

i

a

f

o

r

C

o

n

s

t

.

T

o

o

l

s

K

i

n

g

A

b

d

u

l

A

z

i

z

S

t

r

e

e

t

P

.

O

.

B

o

x

5

2

8

7

l

R

i

y

a

d

h

1

1

4

2

2

T

+

9

6

6

1

4

6

0

8

9

7

4

F

+

9

6

6

1

4

6

0

6

2

5

5

T

o

l

l

F

r

e

e

8

0

0

1

2

0

0

0

1

3

w

w

w

.

h

i

l

t

i

.

c

o

m

C

R

1

0

1

0

2

7

8

7

1

2

L

L

C

P

a

i

d

u

p

c

a

p

i

t

a

l

S

A

R

3

9

,

2

3

0

,

0

0

0

C

o

m

p

l

i

a

n

c

e

S

t

a

t

e

m

e

n

t

R

e

m

a

r

k

C

o

u

n

t

r

y

o

f

o

r

i

g

i

n

A

r

e

a

o

f

a

p

p

l

i

c

a

t

i

o

n

s

t

a

t

u

s

H

i

l

t

i

P

r

o

d

u

c

t

T

e

c

h

n

i

c

a

l

S

p

e

c

i

f

i

c

a

t

i

o

n

s

E

T

A

a

p

p

r

o

v

a

l

G

e

r

m

a

n

y

R

e

b

a

r

a

p

p

l

i

c

a

t

i

o

n

s

a

t

s

u

p

e

r

a

n

d

s

u

b

s

t

r

u

c

t

u

r

e

.

S

u

i

t

a

b

l

e

f

o

r

n

o

n

c

r

a

c

k

e

d

c

o

n

c

r

e

t

e

C

2

0

/

2

5

t

o

C

5

0

/

6

0

C

o

m

p

l

y

H

i

l

t

i

R

E

-

5

0

0

O

n

e

o

f

t

h

e

s

t

r

o

n

g

e

s

t

i

n

j

e

c

t

i

o

n

s

y

s

t

e

m

s

i

n

t

h

e

m

a

r

k

e

t

w

i

t

h

E

T

A

a

p

p

r

o

v

a

l

f

o

r

r

e

d

u

c

e

d

r

e

b

a

r

e

m

b

e

d

m

e

n

t

d

e

p

t

h

r

a

n

g

e

N

o

e

x

p

a

n

s

i

o

n

f

o

r

c

e

s

i

n

c

o

n

c

r

e

t

e

a

l

l

o

w

f

o

r

s

e

c

u

r

e

a

p

p

l

i

c

a

t

i

o

n

s

e

v

e

n

c

l

o

s

e

t

o

t

h

e

e

d

g

e

s

a

n

d

/

o

r

w

i

t

h

s

m

a

l

l

s

p

a

c

i

n

g

L

o

w

s

e

n

s

i

t

i

v

i

t

y

t

o

o

v

e

r

s

i

z

e

d

,

w

e

t

h

o

l

e

s

d

u

e

t

o

n

e

g

l

i

g

i

b

l

e

s

h

r

i

n

k

a

g

e

a

n

d

a

d

h

e

s

i

v

e

p

r

o

p

e

r

t

y

t

h

u

s

l

e

s

s

r

i

s

k

o

f

i

n

s

t

a

l

l

a

t

i

o

n

f

a

i

l

u

r

e

L

o

n

g

w

o

r

k

i

n

g

t

i

m

e

,

t

h

e

r

e

f

o

r

e

a

l

w

a

y

s

e

n

o

u

g

h

t

i

m

e

f

o

r

a

l

i

g

n

i

n

g

w

o

r

k

a

n

d

i

n

s

t

a

l

l

a

t

i

o

n

o

f

b

i

g

d

i

a

m

e

t

e

r

s

a

t

d

e

e

p

e

m

b

e

d

m

e

n

t

E

a

s

y

s

e

t

t

i

n

g

i

n

a

w

i

d

e

r

a

n

g

e

o

f

t

e

m

p

e

r

a

t

u

r

e

a

n

d

l

o

n

g

w

o

r

k

i

n

g

t

i

m

e

e

v

e

n

a

t

e

l

e

v

a

t

e

d

t

e

m

p

e

r

a

t

u

r

e

F

i

e

l

d

s

o

f

A

p

p

l

i

c

a

t

i

o

n

A

n

y

h

i

g

h

p

e

r

f

o

r

m

a

n

c

e

c

o

n

c

r

e

t

e

f

a

s

t

e

n

i

n

g

s

s

u

c

h

a

s

-

r

e

b

a

r

c

o

n

n

e

c

t

i

o

n

s

a

n

d

r

e

p

a

i

r

w

o

r

k

F

o

r

f

a

s

t

e

n

i

n

g

o

f

t

h

r

e

a

d

e

d

r

o

d

,

s

o

c

k

e

t

s

a

n

d

r

e

b

a

r

d

i

a

m

e

t

e

r

r

a

n

g

i

n

g

f

r

o

m

8

m

m

t

o

4

0

m

m

i

n

t

o

c

o

n

c

r

e

t

e

l

d

e

a

l

s

o

l

u

t

i

o

n

f

o

r

d

i

a

m

o

n

d

c

o

r

e

d

a

n

d

w

e

t

b

o

r

e

h

o

l

e

s

o

v

e

r

s

i

z

e

d

h

o

l

e

s

W

e

t

o

r

u

n

d

e

r

w

a

t

e

r

a

n

c

h

o

r

i

n

g

a

p

p

l

i

c

a

t

i

o

n

s

B

a

s

e

M

a

t

e

r

i

a

l

C

o

n

c

r

e

t

e

(

n

o

n

-

c

r

a

c

k

e

d

)

,

S

t

o

n

e

(

h

a

r

d

n

a

t

u

r

a

l

ww

Hi

Kin

P.O

T +

F +

Tol

ww

CR

LLC

wwhiltisa

ilti Saudi Ar

g Abdul Aziz Stre

O. Box 5287 l Riya

+966 1 460 8974

+966 1 460 6255

l Free 800120001

ww.hilti.com

R 1010278712

C Paid up capital S

1- Hi

2- Pr

3- Hi

4- Hi

5- Hi

6- Hi

7- Hi

8- Hi

rabia for Cons

et

adh 11422

3

SAR 39,230,000

lti compan

roject refer

lti HIT-RE

lti HIT-RE

lti HIT-RE

lti HIT-RE

lti HIT RE-

lti HIT RE-

st. Tools

y profile

rence

500

500 with re

500 with H

500 with H

-500 epoxy

-500 mater

CO

ebar techn

HIT-V / HA

HIS-(R)N te

y adhesive

rial safety d

ONTEN

nical data

S technica

echnical da

e anchor

data sheet

39,230

NTS

al data

ata

LEEDs Inf

t

0,000

fo

11422

+9

9 +

8

1010278

-

RNS

5287

966 1 460 8974

1 460 6255 966

8001200013

www.hilti.c

712

1

11

13

15

34

55

69

70

com

14

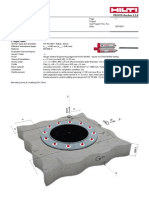

Hilti HIT-RE 500

with rebar

Hilti HIT-RE 500 with rebar

Injection mortar system Benefits

Hilti

HIT-RE 500

330 ml foil pack

(also available

as 500 ml

and 1400 ml

foil pack)

Statik mixer

rebar BSt 500 S

- suitable for non-cracked concrete

C 20/25 to C 50/60

- high loading capacity

- suitable for dry and water

saturated concrete

- under water application

- large diameter applications

- high corrosion resistant

- long working time at elevated

temperatures

- odourless epoxy

- embedment depth range:

from 60 160 mm for 8

to 128 640 mm for 32

Concrete

Small edge

distance

and spacing

Variable

embedment

depth

European

Technical

Approval

CE

conformity

Hilti anchor

design

software

Approvals / certificates

Description Authority / Laboratory No. / date of issue

European technical approval

a)

DIBt, Berlin ETA-04/0027 / 2009-05-20

a) All data given in this section according ETA-04/0027, issue 2009-05-20.

Basic loading data (for a single anchor)

All data in this section applies to For details see Simplified design method

- Correct setting (See setting instruction)

- No edge distance and spacing influence

- Steel failure

- Base material thickness, as specified in the table

- One typical embedment depth, as specified in the table

- One anchor material, as specified in the tables

- Concrete C 20/25, f

ck,cube

= 25 N/mm

- Temperate range I

(min. base material temperature -40C, max. long term/short term base material temperature: +24C/40C)

- Installation temperature range +5C to +40C

15

Hilti HIT-RE 500

with rebar

Embedment depth

a)

and base material thickness for the basic loading data.

Mean ultimate resistance, characteristic resistance, design resistance, recommended loads.

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

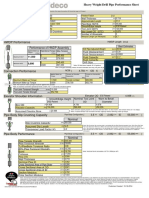

Anchor size 8 10 12 14 16 20 25 28 32 36 40

Typical embedment depth [mm] 80 90 110 125 125 170 210 270 300 330 360

Base material thickness [mm] 110 120 145 165 165 220 275 340 380 420 470

a) The allowed range of embedment depth is shown in the setting details. The corresponding load values can be

calculated according to the simplified design method.

Mean ultimate resistance: concrete C 20/25 f

ck,cube

= 25 N/mm, anchor rebar BSt 500S

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

Tensile N

Ru,m

BSt 500 S [kN] 29,4 45,2 65,1 89,3 94,1 149,2 204,9 298,7 349,9 403,6 459,9

Shear V

Ru,m

BSt 500 S [kN] 14,7 23,1 32,6 44,1 57,8 90,3 141,8 177,5 232,1 293,9 362,9

Characteristic resistance: concrete C 20/25 f

ck,cube

= 25 N/mm, anchor rebar BSt 500 S

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

Tensile N

Rk

BSt 500 S [kN] 28,0 42,4 58,3 70,6 70,6 111,9 153,7 224,0 262,4 302,7 344,9

Shear V

Rk

BSt 500 S [kN] 14,0 22,0 31,0 42,0 55,0 86,0 135,0 169,0 221,0 279,9 345,6

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm, anchor rebar BSt 500 S

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

Tensile N

Rd

BSt 500 S [kN] 14,4 20,2 27,7 33,6 33,6 53,3 73,2 106,7 125,0 144,2 164,3

Shear V

Rd

BSt 500 S [kN] 9,3 14,7 20,7 28,0 36,7 57,3 90,0 112,7 147,3 186,6 230,4

Recommended loads

a)

: concrete C 20/25 f

ck,cube

= 25 N/mm, anchor rebar BSt 500 S

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

Tensile N

rec

BSt 500 S [kN] 10,3 14,4 19,8 24,0 24,0 38,1 52,3 76,2 89,3 103,0 117,3

Shear V

rec

BSt 500 S [kN] 6,7 10,5 14,8 20,0 26,2 41,0 64,3 80,5 105,2 133,3 164,6

a) With overall partial safety factor for action J = 1,4. The partial safety factors for action depend on the type of

loading and shall be taken from national regulations. According ETAG 001, annex C, the partial safety factor is

J

G

= 1,35 for permanent actions and J

Q

= 1,5 for variable actions.

16

Hilti HIT-RE 500

with rebar

Service temperature range

Hilti HIT-RE 500 injection mortar may be applied in the temperature ranges given below. An elevated base material

temperature may lead to a reduction of the design bond resistance.

Temperature range

Base material

temperature

Maximum long term

base material

temperature

Maximum short term

base material

temperature

Temperature range I -40 C to +40 C +24 C +40 C

Temperature range II -40 C to +58 C +35 C +58 C

Temperature range III -40 C to +70 C +43 C +70 C

Max short term base material temperature

Short-term elevated base material temperatures are those that occur over brief intervals, e.g. as a result of

diurnal cycling.

Max long term base material temperature

Long-term elevated base material temperatures are roughly constant over significant periods of time.

Materials

Mechanical properties of rebar BSt 500S

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

Nominal

tensile

strength f

uk

BSt 500 S [N/mm] 550 550 550 550 550 550 550 550 550 550 550

Yield

strength f

yk

[N/mm] 500 500 500 500 500 500 500 500 500 500 500

Stressed

cross-

section A

s

BSt 500 S [mm] 50,3 78,5 113,1 153,9 201,1 314,2 490,9 615,8 804,2 1018 1257

Moment of

resistance

W

BSt 500 S [mm] 50,3 98,2 169,6 269,4 402,1 785,4 1534 2155 3217 4580 6283

Material quality

Part Material

rebar

BSt 500 S

Geometry and mechanical properties according to DIN 488-2:1986 or

E DIN 488-2:2006

Setting

installation equipment

Anchor size 8 10 12 14 16 20 25 28 32 36

Rotary hammer TE 2 TE 16 TE 40 TE 70

Other tools compressed air gun or blow out pump, set of cleaning brushes, dispenser

Additional

Hilti recommended tools

DD EC-1, DD 100 DD xxx

a)

a) For anchors in diamond drilled holes load values for combined pull-out and concrete cone resistance have to be

reduced (see section Simplified design method)

17

Hilti HIT-RE 500

with rebar

Setting instruction

Dry and water-saturated concrete, hammer drilling

a)

a) Note: Manual cleaning only for h

ef

250 mm and anchor size d 16mm

Brush bore hole with required steel brush HIT-RB

For detailed information on installation see instruction for use given with the package of the product.

18

Hilti HIT-RE 500

with rebar

Water filled bore hole or submerged, hammer drilling

Brush bore hole with required steel brush HIT-RB

For detailed information on installation see instruction for use given with the package of the product.

19

Hilti HIT-RE 500

with rebar

Dry and water-saturated concrete, diamond coring drilling; Hilti technical information only

For anchors in diamond drilled holes load values for combined pull-out and

concrete cone resistance have to be reduced. Load reduction factor: 0.7

Brush bore hole with required steel brush HIT-RB

For detailed information on installation see instruction for use given with the package of the product.

20

Hilti HIT-RE 500

with rebar

Curing time for general conditions

Data according ETA-04/0027, issue 2009-05-20 Additional Hilti technical data

Temperature

of the

base material

Curing time before

anchor can be fully

loaded t

cure

Temperature

of the

base material

Working time in

which anchor can

be inserted and

adjusted t

gel

Preparation work

may continue.

Do not apply design

load. t

cure, ini

40 C 4 h 40 C 12 min 2 h

30 C to 39 C 8 h 30 C 20 min 4 h

20 C to 29 C 12 h 20 C 30 min 6 h

15 C to 19 C 24 h 15 C 1 h 8 h

10 C to 14 C 48 h 10 C 2 h 12 h

5 C to 9 C 72 h 5 C 2 h 18 h

For dry concrete curing times may be reduced according to the following table.

For installation temperatures below +5 C all load values have to be reduced according to

the load reduction factors given below.

Curing time for dry concrete

Additional Hilti technical data

Temperature

of the

base material

Reduced curing time

before anchor can be

fully loaded t

cure,dry

Working time in which

anchor can be inserted

and adjusted t

gel

Load reduction factor

40 C 4 h 12 min 1

30 C 8 h 20 min 1

20 C 12 h 30 min 1

15 C 18 h 1 h 1

10 C 24 h 2 h 1

5 C 36 h 2 h 1

0 C 50 h 3 h 0.7

-5 C 72 h 4 h 0.6

21

Hilti HIT-RE 500

with rebar

Setting details

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

Nominal diameter of

drill bit

d

0

[mm] 12 14 16 18 20 25 32 35 40 45 55

h

ef,min

[mm] 60 60 70 75 80 90 100 112 128 144 160

Effective anchorage

and drill hole depth

range

a)

h

ef,max

[mm] 160 200 240 280 320 400 500 560 640 720 800

Minimum base

material thickness

h

min

[mm]

h

ef

+ 30 mm

100 mm

h

ef

+ 2 d

0

Minimum spacing s

min

[mm] 40 50 60 70 80 100 125 140 160 180 200

Minimum edge

distance

c

min

[mm] 40 50 60 70 80 100 125 140 160 180 200

Critical spacing for

splitting failure

s

cr,sp

2 c

cr,sp

1,0hef for h / hef 2,0

4,6 hef - 1,8 h for 2,0 > h / hef > 1,3:

Critical edge distance

for splitting failure

b) c

cr,sp

[mm]

2,26 hef for h / hef 1,3:

Critical spacing for

concrete cone failure

s

cr,N

2 c

cr,N

Critical edge distance

for concrete cone

failure

c)

c

cr,N

1,5 h

ef

For spacing (edge distance) smaller than critical spacing (critical edge distance) the design loads have to be

reduced.

a) h

ef,min

h

ef

h

ef,max

(h

ef

: embedment depth)

b) h: base material thickness (h h

min

)

c) The critical edge distance for concrete cone failure depends on the embedment depth h

ef

and the design bond

resistance. The simplified formula given in this table is on the save side.

Simplified design method

Simplified version of the design method according ETAG 001, TR 029. Design resistance

according data given in ETA-04/0027, issue 2009-05-20.

Influence of concrete strength

Influence of edge distance

22

Hilti HIT-RE 500

with rebar

Influence of spacing

Valid for a group of two anchors. (The method may also be applied for anchor groups

with more than two anchors or more than one edge distance. The influencing factors

must then be considered for each edge distance and spacing. The calculated design

loads are then on the save side: They will be lower than the exact values according

ETAG 001, TR 029. To avoid this, it is recommended to use the anchor design software

PROFIS anchor)

The design method is based on the following simplification:

No different loads are acting on individual anchors (no eccentricity)

The values are valid for one anchor.

For more complex fastening applications please use the anchor design software PROFIS Anchor.

Tension loading

The design tensile resistance is the lower value of

- Steel resistance: N

Rd,s

- Combined pull-out and concrete cone resistance:

N

Rd,p

= N

0

Rd,p

f

B,p

f

1,N

f

2,N

f

3,N

f

h,p

f

re,N

- Concrete cone resistance: N

Rd,c

= N

0

Rd,c

f

B

f

1,N

f

2,N

f

3,N

f

h,N

f

re,N

-

Concrete splitting resistance (only non-cracked concrete):

N

Rd,sp

= N

0

Rd,c

f

B

f

1,sp

f

2,sp

f

3,sp

f

h,N

f

re,N

Basic design tensile resistance

Design steel resistance N

Rd,s

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

N

Rd,s

BSt 500 S [kN] 20,0 30,7 44,3 60,7 79,3 123,6 192,9 242,1 315,7 400 494

Design combined pull-out and concrete cone resistance

N

Rd,p

= N

0

Rd,p

f

B,p

f

1,N

f

2,N

f

3,N

f

h,p

f

re,N

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

Typical embedment depth

h

ef,typ

[mm]

80 90 110 125 125 170 210 270 300 330 360

N

0

Rd,p

Temperature range I [kN] 14,4 20,2 29,6 36,7 41,9 71,2 102,1 147,0 186,7 192,8 216,1

N

0

Rd,p

Temperature range II [kN] 11,5 16,2 23,7 31,4 32,9 56,0 86,4 113,1 143,6 154,2 172,9

N

0

Rd,p

Temperature range III [kN] 6,7 9,4 13,8 18,3 20,9 33,1 51,1 67,9 86,2 92,5 103,7

a) Additional Hilti technical data (not part of ETA-04/0027, issue 2009-05-20):

The design values for combined pull-out and concrete cone resistance may be increased by 20 % for anchor

installation in dry concrete (concrete not in contact with water before/during installation and curing).

23

Hilti HIT-RE 500

with rebar

Design concrete cone resistance

a)

N

Rd,c

= N

0

Rd,c

f

B

f

1,N

f

2,N

f

3,N

f

h,N

f

re,N

Design splitting resistance N

Rd,sp

a)

= N

0

Rd,c

f

B

f

1,sp

f

2,sp

f

3,sp

f

h,N

f

re,N

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

N

0

Rd,c

[kN] 17,2 20,5 27,7 33,6 33,6 53,3 73,2 106,7 125,0 144,2 164,3

a) Additional Hilti technical data (not part of ETA-04/0027, issue 2009-05-20):

The design values for concrete cone and splitting resistance may be increased by 20 % for anchor installation

in dry concrete (concrete not in contact with water before/during installation and curing).

Influencing factors

Influence of concrete strength on combined pull-out and concrete cone resistance

Concrete strength designation

(ENV 206)

C 20/25 C 25/30 C 30/37 C 35/45 C 40/50 C 45/55 C 50/60

f

B,p

= (f

ck,cube

/25N/mm)

0,1 a)

1 1,02 1,04 1,06 1,07 1,08 1,09

a) f

ck,cube

= concrete compressive strength, measured on cubes with 150 mm side length

Influence of embedment depth on combined pull-out and concrete cone resistance

f

h,p

= h

ef

/h

ef,typ

Influence of concrete strength on concrete cone resistance

Concrete strength designation

(ENV 206)

C 20/25 C 25/30 C 30/37 C 35/45 C 40/50 C 45/55 C 50/60

f

B

= (f

ck,cube

/25N/mm)

1/2 a)

1 1,1 1,22 1,34 1,41 1,48 1,55

a) f

ck,cube

= concrete compressive strength, measured on cubes with 150 mm side length

Influence of edge distance

a)

c/c

cr,N

c/c

cr,sp

0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1

f

1,N

= 0,7 + 0,3c/c

cr,N

f

1,sp

= 0,7 + 0,3c/c

cr,sp

0,73 0,76 0,79 0,82 0,85 0,88 0,91 0,94 0,97 1

f

2,N

= 0,5(1 + c/c

cr,N

)

f

2,sp

= 0,5(1 + c/c

cr,sp

)

0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1

a) The the edge distance shall not be smaller than the minimum edge distance c

min

given in the table with the

setting details. These influencing factors must be considered for every edge distance smaller than the critical

edge distance.

Influence of anchor spacing

a)

s/s

cr,N

s/s

cr,sp

0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1

f

3,N

= 0,5(1 + s/s

cr,N

)

f

3,sp

= 0,5(1 + s/s

cr,sp

)

0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1

a) The anchor spacing shall not be smaller than the minimum anchor spacing s

min

given in the table with the

setting details. This influencing factor must be considered for every anchor spacing.

24

Hilti HIT-RE 500

with rebar

Influence of embedment depth on concrete cone resistance

f

h,N

= (h

ef

/h

ef,typ

)

1,5

Influence of reinforcement

h

ef

[mm] 40 50 60 70 80 90 100

f

re,N

= 0,5 + h

ef

/200mm 1 0,7

a)

0,75

a)

0,8

a)

0,85

a)

0,9

a)

0,95

a)

1

a) This factor applies only for dense reinforcement. If in the area of anchorage there is reinforcement with a

spacing 150 mm (any diameter) or with a diameter 10 mm and a spacing 100 mm, then a factor f

re

= 1

may be applied.

Shear loading

The design shear resistance is the lower value of

- Steel resistance: V

Rd,s

-

Concrete pryout resistance: V

Rd,cp

= k lower value of N

Rd,p

and N

Rd,c

- Concrete edge resistance: V

Rd,c

= V

0

Rd,c

f

B

f

f

h

f

4

f

hef

f

c

Basic design shear resistance

Design steel resistance V

Rd,s

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti

technical

data

Anchor size 8 10 12 14 16 20 25 28 32 36 40

V

Rd,s

BSt 500 S [kN] 9,3 14,7 20,7 28,0 36,7 57,3 90,0 112,7 147,3 186,6 230,4

Design concrete pryout resistance V

Rd,cp

= lower value

a)

of k N

Rd,p

and k N

Rd,c

k = 1 for h

ef

< 60 mm

k = 2 for h

ef

60 mm

a) N

Rd,p

: Design combined pull-out and concrete cone resistance

N

Rd,c

: Design concrete cone resistance

Design concrete edge resistance V

Rd,c

= V

0

Rd,c

f

B

f

f

h

f

4

f

hef

f

c

Anchor size 8 10 12 14 16 20 25 28 32 36 40

Non-cracked concrete

V

0

Rd,c

[kN] 5,9 8,6 11,6 15,0 18,7 27,0 39,2 47,3 59,0 71,7 85,5

25

Você também pode gostar

- Physics: FiitjeeDocumento1.319 páginasPhysics: FiitjeeBISWAJEET100% (2)

- Rcc95 Continuous Beams (Tables)Documento8 páginasRcc95 Continuous Beams (Tables)Steve JsobAinda não há avaliações

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- Duct Static Loss CalculationDocumento8 páginasDuct Static Loss CalculationYe Thiha Min100% (2)

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Documento8 páginasContinuous Concrete Beam Design To Bs 81101997 Table 3.5sarv_kishoreAinda não há avaliações

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Documento8 páginasContinuous Concrete Beam Design To Bs 81101997 Table 3.5Victor AndradeAinda não há avaliações

- Thickness Cal. Fo DM Water Storage Tank-API 650Documento15 páginasThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- Hilti - Profis Anchor Design Report 594Documento5 páginasHilti - Profis Anchor Design Report 594Madhu GuptaAinda não há avaliações

- Stainless Steel Grades 2008 01 PDFDocumento2 páginasStainless Steel Grades 2008 01 PDFRahul LavandAinda não há avaliações

- All-in-One Manual of Industrial Piping Practice and MaintenanceNo EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceNota: 5 de 5 estrelas5/5 (1)

- Api Plan 11Documento6 páginasApi Plan 11johnsaballaAinda não há avaliações

- Hilti Hit Re 500 With Hit V HasDocumento16 páginasHilti Hit Re 500 With Hit V HaslaurentiubnAinda não há avaliações

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocumento6 páginasPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguAinda não há avaliações

- SOPORTERIADocumento28 páginasSOPORTERIAWilliamsh1aAinda não há avaliações

- Geberit HDPE: Installation GuideDocumento78 páginasGeberit HDPE: Installation GuideSong ThomsonAinda não há avaliações

- Hilti Bolt DesignDocumento7 páginasHilti Bolt Designcheligp1981Ainda não há avaliações

- HeavyWeight 3.5 25.58lbs NC-38Documento3 páginasHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаAinda não há avaliações

- Theodore Sider - Logic For Philosophy PDFDocumento377 páginasTheodore Sider - Logic For Philosophy PDFAnonymous pYK2AqH100% (1)

- K.T. Chau, R.H.C. Wong, T.-f. Wong (Auth.), STAVROS K. KOURKOULIS (Eds.) - Fracture and Failure of Natural Building Stones_ Applications in the Restoration of Ancient Monuments-Springer Netherlands (2Documento581 páginasK.T. Chau, R.H.C. Wong, T.-f. Wong (Auth.), STAVROS K. KOURKOULIS (Eds.) - Fracture and Failure of Natural Building Stones_ Applications in the Restoration of Ancient Monuments-Springer Netherlands (2Daniel Ruperto CanoAinda não há avaliações

- Wärtsilä NOXDocumento35 páginasWärtsilä NOXDeepesh MerchantAinda não há avaliações

- Hilti HIT HY 150 MAX With RebarDocumento14 páginasHilti HIT HY 150 MAX With RebarNelly BuquironAinda não há avaliações

- Hilti - Calculo Manual de Re500Documento41 páginasHilti - Calculo Manual de Re500James ClaytonAinda não há avaliações

- Hilti Hit Hy 150 Max Con Barra CorrugadaDocumento20 páginasHilti Hit Hy 150 Max Con Barra Corrugadalandsv01Ainda não há avaliações

- Hilti HIT-HY 150 With Rebar PDFDocumento16 páginasHilti HIT-HY 150 With Rebar PDFMuzammil HawaAinda não há avaliações

- Hilti HST 1Documento11 páginasHilti HST 1Mihnea-Bogdan NicolaescuAinda não há avaliações

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocumento6 páginasPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliAinda não há avaliações

- 2011 Hit-Re 500 With His - (R) NDocumento3 páginas2011 Hit-Re 500 With His - (R) NDifa LiuAinda não há avaliações

- Hilti Hit Re 500 Cu Has Hit-V His-N 1Documento36 páginasHilti Hit Re 500 Cu Has Hit-V His-N 1Sorin RaduAinda não há avaliações

- PROFIS Anchor 2.2.6: WWW - Hilti.inDocumento6 páginasPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007Ainda não há avaliações

- Anchor Design - Hilti (HP)Documento6 páginasAnchor Design - Hilti (HP)Harikrishnan PAinda não há avaliações

- Chumbador HiltDocumento14 páginasChumbador HiltSamanta FigueredoAinda não há avaliações

- Inst Aids Calc CSM93020C1Documento18 páginasInst Aids Calc CSM93020C1Lê Hữu NamAinda não há avaliações

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocumento6 páginasPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliAinda não há avaliações

- 44 - HVZ Adhesive AnchorDocumento14 páginas44 - HVZ Adhesive AnchorHuan VoAinda não há avaliações

- Teddington Catalogue 2013Documento76 páginasTeddington Catalogue 2013Joanna NewtonAinda não há avaliações

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Documento12 páginasHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuAinda não há avaliações

- 198 Faf2500 Flanged y Type StrainerDocumento4 páginas198 Faf2500 Flanged y Type Strainerinfo8176Ainda não há avaliações

- 60 Series Tube Fittings and TubingDocumento5 páginas60 Series Tube Fittings and TubingNilesh MistryAinda não há avaliações

- WIT-PE 500 Design Manual RBDocumento24 páginasWIT-PE 500 Design Manual RBMadusha TisseraAinda não há avaliações

- Beam End Connection ReportDocumento6 páginasBeam End Connection ReportHibri HalimAinda não há avaliações

- Section PropertiesDocumento4 páginasSection PropertiesOng George SammyAinda não há avaliações

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocumento6 páginasPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliAinda não há avaliações

- LV Hydraulic Calculations Fire Hose System Reports: Prepared By: K&ADocumento11 páginasLV Hydraulic Calculations Fire Hose System Reports: Prepared By: K&AkhalloudeeAinda não há avaliações

- Robotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icDocumento8 páginasRobotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icAsrul Arashi IrdianaAinda não há avaliações

- Pipe Rack Hilti Bolt CalculationsDocumento6 páginasPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVAinda não há avaliações

- BST EMS18 DocumentationDocumento2 páginasBST EMS18 DocumentationDemingAinda não há avaliações

- Perimeter Fence System Components Index: Page Date Naams Codes DescriptionDocumento39 páginasPerimeter Fence System Components Index: Page Date Naams Codes DescriptionjessicaAinda não há avaliações

- Rowad Debugging MachineDocumento6 páginasRowad Debugging MachineRonnie De Joya AguirreAinda não há avaliações

- Catalogo Huck C50L PDFDocumento8 páginasCatalogo Huck C50L PDFVladimir SepulvedaAinda não há avaliações

- Rebar and CAB Brochure 09Documento4 páginasRebar and CAB Brochure 09wijesinghetkAinda não há avaliações

- API - A Specialist in Precast Concrete ProductsDocumento3 páginasAPI - A Specialist in Precast Concrete Productsalgebra1975100% (1)

- Valve Ari ArmaturenDocumento16 páginasValve Ari ArmaturenReza TambaAinda não há avaliações

- Base CHS X 10tDocumento7 páginasBase CHS X 10tCollin NguAinda não há avaliações

- FTM '12 HKD Push-In AnchorDocumento14 páginasFTM '12 HKD Push-In AnchorShankerAinda não há avaliações

- Penstocks Catalogue 2007-07Documento19 páginasPenstocks Catalogue 2007-07dundee2012Ainda não há avaliações

- Example Vessel Re RatingDocumento9 páginasExample Vessel Re RatingRBKUMARAinda não há avaliações

- Shaft B, Hb1 Kempinski 11-1-17.pa2Documento7 páginasShaft B, Hb1 Kempinski 11-1-17.pa2sobhiAinda não há avaliações

- 2Documento26 páginas2Ioana PopescuAinda não há avaliações

- 1 Input Data: Profis Anchor 2.6.6Documento6 páginas1 Input Data: Profis Anchor 2.6.6Collin NguAinda não há avaliações

- Hilti HIT-HY 150 With HIT-V or HAS PDFDocumento19 páginasHilti HIT-HY 150 With HIT-V or HAS PDFfkh3dAinda não há avaliações

- Hilti Hvu HasDocumento12 páginasHilti Hvu HasAMCRUZ77Ainda não há avaliações

- Spreadsheets To BS 8110: Column InternalDocumento9 páginasSpreadsheets To BS 8110: Column InternalJennifer TangAinda não há avaliações

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IINo EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffAinda não há avaliações

- Handout RPS - V1.0Documento121 páginasHandout RPS - V1.0Adegbola AdedipeAinda não há avaliações

- Object Kpis For The Digital Transformation: June 2020Documento12 páginasObject Kpis For The Digital Transformation: June 2020MUHAMMAD FIKRI DEVIANESAinda não há avaliações

- GD33-12 12V33AH: GD SERIES-Deep Cycle BatteryDocumento2 páginasGD33-12 12V33AH: GD SERIES-Deep Cycle BatteryMarcel BaqueAinda não há avaliações

- Cabinas de Bioseguridad HealforceDocumento8 páginasCabinas de Bioseguridad HealforceJose HurtadoAinda não há avaliações

- EXPERIMENT 3 OHMS LAW (1) GUY DERVILLE Cc7b49ceDocumento4 páginasEXPERIMENT 3 OHMS LAW (1) GUY DERVILLE Cc7b49ceDully CleverAinda não há avaliações

- B 1815Documento4 páginasB 1815Angelo MachadoAinda não há avaliações

- Seismic Enhancement of Circular RC Bridge Piers With Fiber CompositesDocumento9 páginasSeismic Enhancement of Circular RC Bridge Piers With Fiber CompositesGerardoSosaDavilaAinda não há avaliações

- Assignment 5 With Answer KeyDocumento2 páginasAssignment 5 With Answer KeyAbhishek MohiteAinda não há avaliações

- ProblemsDocumento1 páginaProblemsBeesam Ramesh KumarAinda não há avaliações

- Geometry and Trigonometry PDFDocumento46 páginasGeometry and Trigonometry PDFnewspaperAinda não há avaliações

- 74LVC14APWDHDocumento11 páginas74LVC14APWDHIlie GrecuAinda não há avaliações

- 2022 Cayley Contest: The Centre For Education in Mathematics and Computing Cemc - Uwaterloo.caDocumento282 páginas2022 Cayley Contest: The Centre For Education in Mathematics and Computing Cemc - Uwaterloo.catony dooAinda não há avaliações

- FTKM 0419 B L (Leaflet)Documento2 páginasFTKM 0419 B L (Leaflet)Wan SyahlanAinda não há avaliações

- Altronics CPU-2000 BLLTN 10-2009 PDFDocumento4 páginasAltronics CPU-2000 BLLTN 10-2009 PDFSMcAinda não há avaliações

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocumento18 páginasSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudAinda não há avaliações

- CBSE NCERT Solutions For Class 9 Science Chapter 10: Back of Chapter QuestionsDocumento9 páginasCBSE NCERT Solutions For Class 9 Science Chapter 10: Back of Chapter QuestionsRTAinda não há avaliações

- Update DES Day Pit 9 Per Jam 08Documento1 páginaUpdate DES Day Pit 9 Per Jam 08Iccang DewiAinda não há avaliações

- Partially Object-Oriented Programming LanguageDocumento3 páginasPartially Object-Oriented Programming LanguageMusthafaAinda não há avaliações

- FireEdge FE400 PLC Interface Tech NoteDocumento2 páginasFireEdge FE400 PLC Interface Tech NoteTuyên VũAinda não há avaliações

- Sci Problem SolutionsDocumento10 páginasSci Problem SolutionsVS PUBLIC SCHOOL BangaloreAinda não há avaliações

- Basic of Statistical DataDocumento15 páginasBasic of Statistical DatacataiceAinda não há avaliações

- Final Lab Report-20bci7108Documento22 páginasFinal Lab Report-20bci7108rupa sreeAinda não há avaliações

- 01 - 6.2 Global Bike in SACDocumento34 páginas01 - 6.2 Global Bike in SACjroldan0313Ainda não há avaliações

- LI 6500WX: Making Life Easier and SaferDocumento17 páginasLI 6500WX: Making Life Easier and SaferkellyburtonAinda não há avaliações

- Holiday Homework Class 12 MathematicsDocumento2 páginasHoliday Homework Class 12 MathematicsKartik SharmaAinda não há avaliações

- Thermal Radiation System: Instruction Manual and Experiment Guide For The PASCO Scientific Model TD-8553/8554A/8555Documento28 páginasThermal Radiation System: Instruction Manual and Experiment Guide For The PASCO Scientific Model TD-8553/8554A/8555CoupeyAinda não há avaliações