Escolar Documentos

Profissional Documentos

Cultura Documentos

Chapter18 Beam Subjected To Torsion & Bending II

Enviado por

Vincent TengDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chapter18 Beam Subjected To Torsion & Bending II

Enviado por

Vincent TengDireitos autorais:

Formatos disponíveis

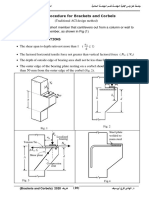

BEAMS SUBJECTED TO TORSION & BENDING-II

18

1.0

BEAMS SUBJECTED TO TORSION AND BENDING - II

INTRODUCTION

In the previous chapter, the basic theory governing the behaviour of beams subjected to torsion was discussed. A member subjected to torsional moments would twist about a longitudinal axis through the shear centre of the cross section. It was also pointed out that when the resultant of applied forces passed through the longitudinal shear centre axis no torsion would occur. In general, torsional moments would cause twisting and warping of the cross sections. When the torsional rigidity (GJ) is very large compared with its warping rigidity (E), the section would effectively be in uniform torsion and warping moment would unlikely to be significant from the designer's perspective. Examples of this behaviour are closed hot-rolled sections (e.g. rectangular or square hollow sections) and rolled angles and Tees. Note that warping moment is developed only if warping deformation is restrained. Warping deformation in angle and T-sections are not small, only warping moment would be small. On the other hand, most thin walled open sections have much smaller torsional rigidity (GJ) compared with warping rigidity (E) values and these sections will be exhibiting significant warping moment. Hot rolled I sections and H sections would exhibit torsional behaviour in-between these two extremes and the applied loading is resisted by a combination of uniform torsion and warping torsion.

2.0

DESIGNING FOR TORSION IN PRACTICE

Any structural arrangement in which the loads are transferred to an I beam by torsion is not an efficient one for resisting loads. The message for the designers is "Avoid Torsion - if you can ". In a very large number of practical designs, the loads are usually applied in a such a manner that their resultant passes through the centroid. If the section is doubly symmetric (such as I or H sections) this automatically eliminates torsion, as the shear centre and centroid of the symmetric cross section coincide. Even otherwise load transfer through connections may - in many cases - be regarded as ensuring that the loads are effectively applied through the shear centre, thus eliminating the need for designing for torsion. Furthermore, in situations where the floor slabs are supported on top flanges of channel sections, the loads may effectively be regarded as being applied through the shear centre since the flexural stiffness of the attached slab prevents torsion of the channel. Where significant eccentricity of loading (which would cause torsion) is unavoidable, alternative methods of resisting torsion efficiently should be investigated. These include

Copyright reserved

Version II

18 -1

BEAMS SUBJECTED TO TORSION & BENDING-II

design using box sections, tubular (hollow) sections or lattice box girders which are fully triangulated on all faces. All these are more efficient means of resisting torsional moments compared with I or H sections. Unless it is essential to utilise the torsional resistance of an I section, it is not necessary to take account of it. The likely torsional effects due to a particular structural arrangement chosen should be considered in the early stages of design, rather than left to the final stages, when perhaps an inappropriate member has already been chosen. 3.0 PURE TORSION AND WARPING

In the previous chapter, the concepts of uniform torsion and warping torsion were explained and the relevant equations derived. When a torque is applied only at the ends of a member such that the ends are free to warp, then the member would develop only pure torsion. The total angle of twist ( ) over a length of z is given by GJ where Tq = applied torque GJ = Torsional Rigidity

Tq z

(1)

When a member is in non-uniform torsion, the rate of change of angle of twist will vary along the length of the member. The warping shear stress (w) at a point is given by

w =

E S wms t

(2)

where E = Modulus of elasticity Swms = Warping statical moment at a particular point S chosen. The warping normal stress (w) due to bending moment in-plane of flanges (bi-moment) is given by

w = - E .Wnwfs . ''

where Wnwfs = Normalised warping function at the chosen point S.

4.0

COMBINED BENDING AND TORSION

There will be some interaction between the torsional and flexural effects, when a load produces both bending and torsion. The angle of twist caused by torsion would be amplified by bending moment, inducing additional warping moments and torsional shears. The following analysis was proposed by Nethercot, Salter and Malik in reference (2). Version II 18 -2

BEAMS SUBJECTED TO TORSION & BENDING-II

4.1

Maximum Stress Check or "Capacity check"

The maximum stress at the most highly stressed cross section is limited to the design strength (fy /m). Assuming elastic behaviour and assuming that the loads produce bending about the major axis in addition to torsion, the longitudinal direct stresses will be due to three causes. M yt (3) byt = Zy w = E.Wnwfs . '' byt is dependent on Myt, which itself is dependent on the major axis moment Mx and the twist .

bx =

Mx Zx

Myt = Mx Thus the "capacity check" for major axis bending becomes:

(4)

bx + byt +w fy /m.

(5)

Methods of evaluating , , and for various conditions of loading and boundary conditions are given in reference (2).

4.2 Buckling Check

Whenever lateral torsional buckling governs the design (i.e. when pb is less than fy) the values of w and byt will be amplified. Nethercot, Salter and Malik have suggested a simple "buckling check" along lines similar to BS 5950, part 1

byt + w Mx Mx + 1 1 + 0.5 Mb f y / m Mb

(6) mx Mx

where M x , equivalent uniform moment

and Mb , the buckling resistance moment =

B + B 2 M E M p

ME M p

Version II

18 -3

BEAMS SUBJECTED TO TORSION & BENDING-II

in which

M p + ( LT + 1) M E 2

MP , the plastic moment capacity = fy . Zp / m Zp = the plastic section modulus ME , the elastic critical moment

=

Mp 2 E

where LT is the equivalent slenderness.

4.3

LT 2

fy

Applied loading having both Major axis and Minor axis moments

When the applied loading produces both major axis and minor axis moments, the "capacity checks" and the "buckling checks" are modified as follows:

Capacity check:

bx + byt +w + by fy/m

Buckling check:

My byt + w Mx Mx + + 1 + 0.5 1 Mb fy Zy / m fy / m Mb

(7)

(8)

where M y = m y M y

byt = M y / Z y

4.4 Torsional Shear Stress

Torsional shear stresses and warping shear stresses should also be amplified in a similar manner: Mx vt = ( t + w ) 1 + 0.5 (9) Mb This shear stress should be added to the shear stresses due to bending in checking the adequacy of the section.

5.0 DESIGN METHOD FOR LATERAL TORSIONAL BUCKLING

The analysis for the lateral torsional buckling is very complex because of the different types of structural actions involved. Also the basic theory of elastic lateral stability cannot be directly used for the design purpose because

Version II

18 -4

BEAMS SUBJECTED TO TORSION & BENDING-II

the formulae for elastic critical moment ME are too complex for routine use and there are limitations to their extension in the ultimate range A simple method of computing the buckling resistance of beams is given below. In a manner analogous to the Perry-Robertson Method for columns, the buckling resistance moment, Mb, is obtained as the smaller root of the equation (ME - Mb) (Mp - Mb) = LT. ME Mb As explained in page 3, Mb is given by, ME M p Mb = B + B2 M E M p (10)

where

M p + ( LT + 1) M E 2

= = = = Elastic critcal moment fy . Zp / m Perry coefficient, similar to column buckling coefficient Plastic section modulus]

[ As defined above, ME Mp

LT

Zp

In order to simplify the analysis, BS5950: Part 1 uses a curve based on the above concept (Fig. 1 ) (similar to column curves) in which the bending strength of the beam is expressed as a function of its slenderness (LT ). The design method is explained below. The buckling resistance moment Mb is given by Mb= pb .Zp (11)

where pb = bending strength allowing for susceptibility to lateral -torsional buckling. Zp = plastic section modulus. It should be noted that pb = fy for low values of slenderness of beams and the value of pb drops, as the beam becomes longer and the beam slenderness, calculated as given below, increases. This behaviour is analogous to columns. The beam slenderness (LT) is given by,

LT = 2

E LT fy

(12)

where

LT =

Mp ME

Version II

18 -5

BEAMS SUBJECTED TO TORSION & BENDING-II

300

Beam fails by yield

200

Beam buckling

pb N/mm2

100

0 50 100

LT

150

200

250

Fig.1 Bending strength for rolled sections of design strength 275 N/mm2 according to BS 5950

Fig. 2 is plotted in a non-dimensional form comparing the observed test data with the two theoretical values of upper bounds, viz. Mp and ME. The test data were obtained from a typical set of lateral torsional buckling data, using hot-rolled sections. In Fig. 2 three distinct regions of behaviour can be observed:-

stocky beams which are able to attain the plastic moment Mp, for values of LT below about 0.4. Slender beams which fail at moments close to ME, for values of LT above about 1.2 beams of intermediate slenderness which fail to reach either Mp or ME . In this case 0.4 < LT < 1.2

Beams having short spans usually fail by yielding. So lateral stability does not influence their design. Beams having long spans would fail by lateral buckling and these are termed "slender". For the practical beams which are in the intermediate range without lateral restraint, design must be based on considerations of inelastic buckling. In the absence of instability, eqn. 11 permits that the value of fy can be adopted for the full plastic moment capacity pb for LT < 0.4 . This corresponds to LT values of around 37 (for steels having fy= 275 N/mm2) below which the lateral instability is NOT of concern.

Version II

18 -6

BEAMS SUBJECTED TO TORSION & BENDING-II

Plastic yield

1.0

ME / MP

0.8

0.6

M / Mp

0.4

stocky

0.2

intermediate

slender

0.2

0.4

0.6

0.8

1.0

1.2

1.4

LT =

MP ME

Fig.2 Comparison of test data (mostly I sections) with theoretical elastic critical moments

For more slender beams, pb is a function of LT which is given by ,

LT = uv

ry

(13)

u is called the buckling parameter and x, the torsional index.

For flanged sections symmetrical about the minor axis,

4 Z p2 4 u = 2 2 x = 0.566 hs A and J A h s For flanged sections symmetrical about the major axis I y Z p 2 u = A2

1 4

( )

and

A x = 1.132 Iy J

In the above Zp = plastic modulus about the major axis

Iy = 1 Ix A = cross sectional area of the member

Version II

18 -7

BEAMS SUBJECTED TO TORSION & BENDING-II

J hs t1, t2 b1, b2

We can assume

= = = = =

torsional warping constant

hs t1 t2 b1 b2

12 t1 b13 + t2 b23

the torsion constant the distance between the shear centres of the flanges flange thicknesses flange widths

u = 0.9 for rolled UBs, UCs, RSJs and channels = 1.0 for all other sections. v = a function of , x is given in Table 14 of BS5950: Part I ry (for a preliminary assessment v = 1) x = D/T providing the above values of u are used.

5.1 Unequal flanged sections

For unequal flanged sections, eqn. 11 is used for finding the buckling moment of resistance. The value of LT is determined by eqn.13 using the appropriate section properties. In that equation u may be taken as 1.0 and v includes an allowance for the degree of monosymmetry through the parameter N = Ic / (Ic + It ) . Table 14 of BS5950: Part 1 must now be entered with (E /ry )/x and N .

5.2 Evaluation of differential equations

For a member subjected to concentrated torque with torsion fixed and warping free condition at the ends ( torque applied at varying values of L), the values of and its differentials are given by

Tq

(1-

For

0 z

sinh a Tq .a z z = + cosh sinh (1 ) a a a GJ tanh a

Version II

18 -8

BEAMS SUBJECTED TO TORSION & BENDING-II

Tq = (1 ) GJ

Tq

sinh a z + cosh cosh a a tanh a

sinh a z cosh sinh GJa a a tanh a

sinh a z cosh cosh a a tanh a

Tq G J a2

Similar equations are available for different loading cases and for different values of . Readers may wish to refer Ref. (2) for more details. We are unable to reproduce these on account of copyright restrictions.

6.0 SUMMARY

This chapter is aimed at explaining a simple method of evaluating torsional effects and to verify the adequacy of a chosen cross section when subjected to torsional moments. The method recommended is consistent with BS 5950: Part 1.

7.0 REFERENCES

(1)

(2) (3) (4)

British Standards Institution, BS 5950: Part 1: 1985. Structural use of steelwork in Building part 1: Code of Practice for design in simple and continuous construction: hot rolled sections. BSI, 1985. Nethercot, D. A., Salter, P. R., and Malik, A. S. Design of Members Subject to Combined Bending and Torsion , The Steel construction Institute , 1989. Steelwork design guide to BS 5950: Part 1 1985, Volume 1 Section properties and member capacities. The Steel Construction Institute, 1985. Introduction to Steelwork Design to BS 5950: Part 1, The Steel Construction Institute, 1988.

Version II

18 -9

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 1 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN Date Jan. 2000 Date Jan. 2000

Example 1

The beam shown below is unrestrained along its length. An eccentric load is applied to the bottom flange at the centre of the span in such a way that it does not provide any lateral restraint to the member. The end conditions are assumed to be simply supported for bending and fixed against torsion but free for warping. For the factored loads shown, check the adequacy of the trial section.

W = 100 kN 2000mm = 4000 mm

e = 75 mm

Stiffener to prevent flange and web buckling W = 100 kN

Replace the actual loading by an equivalent arrangement, comprising a vertical load applied through the shear centre and a torsional moment as shown below.

=

e W W

Tq = W.e negative angle of twist due to Tq

Version II

18 -10

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 2 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN Date Jan. 2000 Date Jan. 2000

Loadings due to plane bending and torsion are shown below.

W

Tq

(i) Plane

(ii) Torsional

Loading (Note: These are factored loads and are not to be multiplied by f) Point load, W = 100 kN Distributed load (self weight), w = 1 kN/m (say) Eccentricity, e = 75 mm Bending effects ( at U.L.S) Moment at B, Shear at A, Shear at B, Torsional effects ( at U.L.S) Torsional moment, Tq = W.e Tq = 100 75 10-3 = 7.5 kNm This acts in a negative sense, Tq = -7.5 kNm Generally wide flange sections are preferable to deal with significant torsion. In this example, however, an ISWB section will be tried. Try ISWB 500 250 @ 95.2 kg/m Section properties from steel tables. Depth of section Width of section D = 500 mm B = 250 mm MxB = 102 kNm FvA = 52 kN FvB = 50 kN

Version II

18 -11

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 3 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN

B = 250 mm

Date Jan. 2000 Date Jan. 2000

Web thickness Flange thickness Moment of inertia Moment of inertia Radius of gyration Elastic modulus Elastic modulus Cross sectional area Additional properties Torsional constant, =

t T Ixx Iyy ry Zx Zy A

= 9.9 mm = 14.7 mm = 52291 cm4 = 2988 cm4 = 49.6 mm = 2092 cm3 = 239 cm3 = 121.2 cm2

9.9 mm

D = 500 mm

14 7 mm

J =

1 2 250 14.7 3 + (500 2 14.7 ) 9.9 3 3

4 2 2988 10 4 (500 14.7 ) 4 = I y h2

1 2BT 3 + (D 2T ) t 3 3

]

= 682 103 mm4

Warping constant, = Shear modulus,

= 1.76 1012 mm6

E 2 (1 + )

2 10 5 2 = 2 (1 + 0.3) = 76.9 kN / mm

Torsional bending constant,

E GJ

1 2

2 10 5 1.76 1012 76.9 10 3 682 10 3

= 2591 mm

Version II

18 -12

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 4 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN Date Jan. 2000 Date Jan. 2000

Normalized warping function,

Wnwfs

= =

=

hB 4 (500 14.7 ) 250 4

Warping statical moment,

S wms

30331 mm2 h B2 T = 16 485.3 250 2 14.7 = 16 = 2787 104 mm4 = Af . yf = ( 120.05 14.7) 242.7 = 428.2 103 mm3

Statical moment for flange,

Qf

Statical moment for web,

Qw

= (A/2) yw

yw

235.3 14.7 250 242.7 + 9.9 235.3 2 = 14.7 250 + 9.9 235.3

= 194.2 mm

Qw

= 6061 194.2 = 1166 103 mm3

Version II

18 -13

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 5 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN

250 1.15 250 500 2 240.1 470.6 2 4 4

Date Jan. 2000 Date Jan. 2000

= 507 kNm

Material Properties

Shear modulus, G = 76.9 kN/mm2

Design strength, py = 250 / m = 250 / 1.15

Check for Combined bending and torsion

= 217 N/mm2

(i)

Buckling check

( at Ultimate Limit State)

byt + w Mx Mx + 1 + 0.5 fy Mb Mb m

Mx m = m M xB = 1.0

M x = 1.0 M xB = 102 kNm

Effective length E = 1.0 L The buckling resistance moment,

Mb

E = 4000 mm

=

B + B 2 M E M p

M p + ( LT + 1) M E 2

ME M p

B

where ME = elastic critical moment Mp = plastic moment capacity = fy.Zp / m =

BS 5950: Part I App.B.2

Version II

18 -14

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 6 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN

= Mp 2 E

Date Jan. 2000 Date Jan. 2000

Elastic critical moment,

ME

LT 2 p y

LT

= the equivalent slenderness = nuv = the minor axis slenderness = E / ry = 4000 / 49.6 = 80.7 u = 0.9

BS 5950: Part I App.B.2.2

n = 0.86,

v = slenderness factor (according to N and /x) I cf N = = 0.5 ( for equal flanged sections) I cf + I tf

x A = 1.132 I y .J

1 2

BS 5950: Part I Table 14

12122 1.76 1012 = 1.132 2988 10 4 681.6 10 3

BS 5950: Part 1 App.B.2.5

2

= 36.63

/x

v

= 80.7 / 36.6 = 0.948 = nuv =

= 2.2

LT

0.86 0.9 0.948 80.7 = = 583 10 6 2 2 10 5 59.2 2 217 1143 kNm

59.2

ME

Version II

18 -15

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 7 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN

M p + ( LT + 1) M E 2

Date Jan. 2000 Date Jan. 2000

BS 5950: Part 1 App.B.2.3

B

The Perry coefficient,

LT

= b ( LT - LO )

2 E = 0.4 py 2 2 = 3 8 .2 = 0.15

1 1

Limiting equivalent slenderness, LO

LT

2 2 10 5 = 0.4 217 = 0.007 ( 59.2 38.2 )

B

Mb =

507 + (0.15 + 1) 1143 2 ME M p

= 911 kNm

B + B2 M E M p

= 911 + 911 Myt = Mx .

)1 2

)

1

1143 507

2

= 411 kNm

1143 507 2

To calculate

/ a = 4000 / 2591 = 1.54 = 0.5 z = , = 0.5 4000 = 2000 / a = 0.77

Version II

18 -16

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 8 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN Date Jan. 2000 Date Jan. 2000

Ref. 2.0 App. B

sinh a Tq .a z z = + cosh sinh (1 ) GJ a a a tanh a 76.9 10 = 0.023 rads = 7.5 10 6 2591

3

cosh0.77 sinh0.77 (1 0.5 ) 0.77 + tanh1.54 681.6 10 3

sinh0.77

Myt =

102 0.023

M yt Zy

= 2.36 kNm

= 9.89 N / mm 2

byt =

2.36 10 6 = 239 10 3

E . Wnwfs .

To calculate

sinh Tq z a cosh sinh a a GJa tanh a

7.5 10 6 76.9 10 681.6 10 1.8 10 8 = 109 N / mm2

3 3

Ref. 2.0 App. B

= =

sinh0.77 tanh1.54 cosh 0.77 sinh0.77 2591

= 2 105 30331 1.8 10-8

Version II

18 -17

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 9 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN

1

Date Jan. 2000 Date Jan. 2000

byt + w Mx Mx + 1 + 0.5 fy Mb Mb m

102 10 6 411 10 6 +

(9.9

+ 109.2 250 1.15

102 10 6 1 + 0.5 411 10 6

0.86

<

(i)

Buckling is O. K Local "capacity" check

bx + byt + w bx

= Mx / Zx

fy / m

= 102 106 / 2092 103 = 48.8 N / mm2

48.8 + 9.9 + 109.2 = 168 N / mm2 < 217 N / mm2 O. K

Strictly the shear stresses due to combined bending and torsion should be checked, although these will seldom be critical. Shear stresses due to bending (at Ultimate Limit state) At support:In web,

bw

FVA . Qw I x .t

= =

52 10 3 1166 10 3 52291 10 4 9.9 11.7 N / mm 2

Version II

18 -18

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 10 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN

= = 52 10 3 428.2 10 3 52291 10 4 14.7 2.9 N / mm 2

Date Jan. 2000 Date Jan. 2000

In flange,

bf

FVA . Q f I x .T

At midspan :In web,

bw

= =

11.3 N / mm2 2.8 N / mm2

In flange, bf

Shear stresses due to torsion ( at Ultimate Limit state ) Stress due to pure torsion, Stress due to warping,

t

w

=

=

G.t. E . S wms . t

z cosh a

To calculate and sinh a Tq = (1 ) + GJ tanh a

cosh

Ref. 2.0 App.B

At = 0.5, a sinh

sinh a G J a 2 tanh a

Tq = 0.5 4000 2591 cosh

z cosh cosh a a 0.77 = 1.313, tanh a = 0.913

= 0.851,

Version II

18 -19

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 11 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Date Jan. 2000 Checked by RN Date Jan. 2000

At support,

z = 0

z a = 2000 cosh cosh z a = cosh(0) = 1.0

At midspan, z

= cosh(0.77) = 1.313

At support

= = = =

7.5 106 76.9 10 3 681.6 10 3 25912 0.812 10 11 7.5 106 76.9 10 3 681.6 10 3 1.7 10 5

0.851 0.913 1.313 1

0.851 (1 0.5 ) + 0.913 1.313 1

Stresses due to pure torsion. In web,

tw tw

= = =

G.t. 76.9 103 9.9 (-1.7 10-5 ) - 12.95 N / mm2 G. T . 76.9 103 14.7 (-1.7 10-5) - 19.22 N / mm2

In flange,

tf tf

= = =

Version II

18 -20

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 12 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN Date Jan. 2000 Date Jan. 2000

Stresses due to warping in flange, E. S wms . wf = T 2 10 5 2787 10 4 0.812 10 11 wf = 14.7 At midspan

= 3.1 N / mm 2

= 0

= = 7.5 10 6 0.851 1.313 1.313 3 3 2 76.9 10 681.6 10 2591 0.913 1.06 10 11

Stresses due to pure torsion, In web, In flange,

tw tf

= =

G.t. G.T.

= 0 = 0

Stresses due to warping in flange, E. S wms . wf = T 2 10 5 2787 10 4 1.06 10 11 wf = 14.7

= 4.02 N / mm 2

By inspection the maximum combined shear stresses occur at the support.

Version II

18 -21

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 13 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN Date Jan. 2000 Date Jan. 2000

0 1 2 3

At support

vt

( t

tw vt

Mx + w ) 1 + 0.5 Mb = =

In web at 3,

12.95 N / mm 2 102 12.95 1 + 0.5 411 = 14.6 N /mm 2

This must be added to the shear stresses due to plane bending.

bw

vt

= - 26.3 N / mm2( acting downwards)

= 11.7 - 14.6

In the top flange at 1,

tf wf

= - 19.2 N / mm2 = - 3.1 N / mm2

vt

= bf + vt

( 19.2

102 3.1) 1 + 0.5 411

= 25.1 N / mm 2

= - 27.9 N / mm2 ( acting left to right)

Version II

18 -22

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 14 of 14 Rev. Job title: Design of members subjected to bending and torsion Worked Example. Flexural member Made by RSP Checked by RN Date Jan. 2000 Date Jan. 2000

Shear strength, fv Since

= 0.6 fy / m = 0.6 250 /1.15 = 130 N / mm2 27.9 < 130 N / mm2

< fv

Section is adequate for shear

Referring back to the determination of the maximum angle of twist , in order to obtain the value at working load it is sufficient to replace the value of torque Tq with the working load value as is linearly dependent on Tq. Since Tq is due to solely the imposed point load W, dividing by the appropriate value of f will give :-

Working load value of Tq is

7.5 1.6

= 4.7 kNm

0.026 = 0.016 rads = 0.93 1.6 On the assumption that a maximum twist of 2 is acceptable at working load, in this instance the beam is satisfactory. the corresponding value of =

Version II

18 -23

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 1 of 6 Rev. Job title: Design of members subjected to bending and torsion Worked Example.Flexural member Made by RSP Date Jan 2000 Checked by RN Date Jan 2000

Example 2 Redesign the member shown in example 1, using a rectangular hollow section.

Try 300 200 8 @ 60.5 kg / m R. H. S Section properties. Depth of section Width of section Web thickness Flange thickness Area of section Moment of inertia Radius of gyration Elastic modulus Elastic modulus Plastic modulus Additional properties Torsional constant t3 h + 2 K Ah 3 Area enclosed by the mean perimeter of the section, Ah = (B - t ) (D - T) (neglecting the corner radii) = ( 200 - 8 )(300 - 8) J =

=

D B t T A Ix ry Zx Zy Zp

= 300 mm = 200 mm = 8 mm = 8 mm = 77.1 cm2 = 9798 cm4 = 8.23 cm = 653 cm3 = 522 cm3 = 785 cm3

8 mm D = 300

8 mm

200

56064 mm2

The mean perimeter,

= =

2[(B - t) + ( D - T)] 2[( 200 - 8) + ( 300 - 8)] = 968 mm

Version II

18 -24

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 2 of 6 Rev. Job title: Design of members subjected to bending and torsion Worked Example.Flexural member Made by RSP Date Jan 2000 Checked by RN Date Jan 2000

2 56064 8 968 = = =

2 Ah t h

927 mm 2

Torsional constant, J

8 3 968 + 2 927 56064 3 104 106 mm 4

J t + K t 104 106 8 + 927 8

Torsional modulus constant, C

= =

= 840 10 3 mm3

Material properties

Shear modulus, G Design strength, py

E = 2 (1 + )

2 10 5 = 76.9 kN / mm 2 2 (1 + 0.3)

250 / 1.15 = 217 N / mm2

= 250 / m =

Check for combined bending and torsion (i) Buckling check

( byt + w ) 1 + 0.5 M x Mx + fy Mb Mb

m

Since slenderness ratio (E / ry = 4000 / 82.3 = 48.6) is less than the limiting value 350 275 250 = 385 given in BS 5950 Part 1, table 38, lateral torsional 250 f y buckling need not be considered..

Version II

18 -25

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 3 of 6 Rev. Job title: Design of members subjected to bending and torsion Worked Example.Flexural member Made by RSP Date Jan 2000 Checked by RN Date Jan 2000 Mcx 0.6 fy / m . Av

Hence

Mb

= =

Shear capacity Pv Shear area Av

Pv

Since FVB Mcx

D 300 2 = D + B A = 300 + 200 77.1 = 46.3 cm 2 = 0.6 (250 /1.15) 46.3 10 10-3 = 604.3 kN

< 0.6 Pv = fy. Zp / m

50 < 363

1.2 fy / m. Zx ( for plastic sections)

BS 5950: Part 1 4.2.5 BS 5950: Part 1 4.3.7.2 table 13

Mcx

M m M To calculate

= 1.2 (250 /1.15) 653 10-3 = 170 kNm = m M xB = 1.0 = 1.0 102 = 102 kNm

The 100 kN eccentric load gives a value of Tq = 100 0.75 = 7.5 kNm

100 kN 100 kN 75 mm

L T0 = Tq / 2 T0 = Tq / 2

Version II

18 -26

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 4 of 6 Rev. Job title: Design of members subjected to bending and torsion Worked Example.Flexural member Made by RSP Date Jan 2000 Checked by RN Date Jan 2000

T0

= =

T0 z GJ Tq 2 = 7.5 2 = 3.75 kNm

At centre of span,

z =

= / 2 = 2000 mm 3.75 106 2000 76.9 10 3 104 106 = 0.001 radians

Myt =

. MxB

M yt Zy =

= 0.001 102 = 0.102 kNm

byt

0.102 10 6 = 0.195 N / mm 2 3 522 10

Warping stresses ( w ) are insignificant due to the type of section employed. Check becomes Mx Mb

byt

fy

Mx 1 + 0.5 Mb =

102 0.195 102 + 1 + 0.5 170 250 170 1.15

0.6

<1

O. K

(ii ) Local capacity check

bx + byt + w bx

fy /m

= MxB / Zy

Version II

18 -27

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 5 of 6 Rev. Job title: Design of members subjected to bending and torsion Worked Example.Flexural member Made by RSP Date Jan 2000 Checked by RN Date Jan 2000 = 196 N / mm 2

=

bx

102 106 522 10 3

196 + 0.195 + 0

196.2

< 217 N / mm2

O. K Shear stresses due to bending ( at Ultimate Limit state) Maximum value occurs in the web at the support.

200

bw

Qw A1

FVA . Qw I x .t1

= = A 2

A1 y

150

150 8

150 2 + 184 8 146 2 10 3 = A1 = A1 395 A1 = = 395 cm3

395 cm A1

Qw

bw

52 10 3 395 10 3 9798 10 4 2 8

13.1 N / mm 2

Shear stresses due to torsion T0 C

( at Ultimate limit State) Tq 2C 7.5 106 = 2 837 10 3

= 4.5 N / mm 2

Version II

18 -28

BEAMS SUBJECTED TO TORSION & BENDING-II

Structural Steel Design Project

CALCULATION SHEET

Job No. Sheet 6 of 6 Rev. Job title: Design of members subjected to bending and torsion Worked Example.Flexural member Made by RSP Date Jan 2000 Checked by RN Date Jan 2000

Total shear stress

( at Ultimate Limit State )

vt

= =

bw

vt

Mx + w ) 1 + 0.5 Mb ( 4.5 + 0 ) 1 + 0.5 102 = 170 = 13.1 + 5.9 = 19 N / mm2

( t

5.9 N / mm 2

Shear strength Since

pv

0.6 fy / m = 0.6 250 /1.15 = 130 N /mm2 19 < 130 N / mm2

< pv

BS 5950: Part 1 4. 2. 3

the section is adequate for shear.

Version II

18 -29

Você também pode gostar

- Beam Design Notes Nzs 3404Documento24 páginasBeam Design Notes Nzs 3404sdewss100% (3)

- SN007 - TorsionDocumento11 páginasSN007 - TorsionflorinAinda não há avaliações

- Instantaneous Center of Rotation MethodDocumento3 páginasInstantaneous Center of Rotation MethodrammohanAinda não há avaliações

- Chapter 2 - Classification of Cross-SectionDocumento20 páginasChapter 2 - Classification of Cross-SectionMuhd Zuhairi100% (2)

- Prestressed Concrete 3Documento41 páginasPrestressed Concrete 3gundulpAinda não há avaliações

- Assignment 1 GRAD 2019Documento4 páginasAssignment 1 GRAD 2019RamonErnestoICAinda não há avaliações

- 343 400Documento58 páginas343 400MakaraSoyAinda não há avaliações

- COLUMN EFFECTIVE LENGTH - Yura1971q2Documento6 páginasCOLUMN EFFECTIVE LENGTH - Yura1971q2ellisbl100% (1)

- Screw Connections Subject To Tension Pull-Out and Shear ForcesDocumento63 páginasScrew Connections Subject To Tension Pull-Out and Shear ForcesSalik TrambooAinda não há avaliações

- Chapter Five, Torsion of BeamsDocumento7 páginasChapter Five, Torsion of BeamsTemesgenAbiyAinda não há avaliações

- Design of Members Subjected To TorsionDocumento3 páginasDesign of Members Subjected To TorsionIvan JovanovicAinda não há avaliações

- Deep Beams and Special Structural ElementsDocumento14 páginasDeep Beams and Special Structural Elementsomar100% (1)

- RC Practice Set 2 2016 SolutionsDocumento5 páginasRC Practice Set 2 2016 SolutionsSayed YusufAinda não há avaliações

- Beam ColumnsDocumento21 páginasBeam ColumnsSherif Mohamed Ibrahim100% (1)

- 4-Flexural Members or Beams PDFDocumento39 páginas4-Flexural Members or Beams PDFKellen Brumbaugh100% (1)

- 1-Structural-Design 2012 Yield LineDocumento52 páginas1-Structural-Design 2012 Yield LineJake BloggerAinda não há avaliações

- LEC - 25 Buckling of Columns - Part 1Documento29 páginasLEC - 25 Buckling of Columns - Part 1Asif HameedAinda não há avaliações

- Design of Steel Tension MembersDocumento15 páginasDesign of Steel Tension MembersSelamawitTafesse100% (1)

- Sidesway Web Buckling of Steel BeamsDocumento12 páginasSidesway Web Buckling of Steel BeamsYuth Yuthdanai100% (1)

- Brackets and Corbels ACI 318 L # 1Documento7 páginasBrackets and Corbels ACI 318 L # 1soran azizAinda não há avaliações

- CE 407 Lecture 2 (Materials) 1Documento62 páginasCE 407 Lecture 2 (Materials) 1Yasser AlghrafyAinda não há avaliações

- BucklingDocumento24 páginasBucklingmyusuf_engineerAinda não há avaliações

- Timoshenko Beam TheoryDocumento8 páginasTimoshenko Beam Theoryksheikh777Ainda não há avaliações

- Beam Formulas With Shear and Mom PDFDocumento16 páginasBeam Formulas With Shear and Mom PDFPanagiotis StamatisAinda não há avaliações

- Beam ExampleProblemsDocumento10 páginasBeam ExampleProblemsApril IngramAinda não há avaliações

- Inelastic Buckling Theory ExplainedDocumento4 páginasInelastic Buckling Theory ExplainedAbhishek Pal100% (1)

- Con 1302Documento12 páginasCon 1302Sanket Arun More100% (1)

- Design of Concentrically Braced FramesDocumento22 páginasDesign of Concentrically Braced FramesAnonymous iS33V5100% (1)

- Design of Reinforced Concrete BeamsDocumento38 páginasDesign of Reinforced Concrete BeamsZul AshraffAinda não há avaliações

- Chapter 3 Column and Compression MembersDocumento60 páginasChapter 3 Column and Compression Membersbihanba100% (1)

- Study Guide 001 (Both) For TST271ZDocumento332 páginasStudy Guide 001 (Both) For TST271Zstevens50% (2)

- Plastic Design in Steel (1957) PDFDocumento19 páginasPlastic Design in Steel (1957) PDFAnonymous wVxXLsZetxAinda não há avaliações

- Rectangular Reinforced Concrete BeamDocumento60 páginasRectangular Reinforced Concrete BeamMedianna Novita100% (1)

- 01 Lecture Notes Torsion (1) AS 3600Documento7 páginas01 Lecture Notes Torsion (1) AS 3600April IngramAinda não há avaliações

- Serviceability Limit States (SLS)Documento62 páginasServiceability Limit States (SLS)Calin Alexandru100% (2)

- Experimental Tests and Numerical Modeling of Cellular Beams With Sinusoidal OpeningsDocumento16 páginasExperimental Tests and Numerical Modeling of Cellular Beams With Sinusoidal OpeningscaesarAinda não há avaliações

- Block Shear Failure PresentationDocumento24 páginasBlock Shear Failure Presentationpraxie83% (12)

- Pre Stressed Concrete 18Cv641: Topic: Magnels MethodDocumento14 páginasPre Stressed Concrete 18Cv641: Topic: Magnels MethodShobhaAinda não há avaliações

- Part2 - Lateral Earth Pressure PDFDocumento29 páginasPart2 - Lateral Earth Pressure PDFChan Nov100% (1)

- Chapter 3.limit State Design For Flexure and ServiceabilityDocumento34 páginasChapter 3.limit State Design For Flexure and ServiceabilityHaftom Gebreegziabiher100% (4)

- Torsion in Structural DesignDocumento73 páginasTorsion in Structural Designjakeer7100% (1)

- Partial Fixity BaseDocumento24 páginasPartial Fixity Basekhemindra narain100% (1)

- Tall Buildings Chap 3 ADocumento7 páginasTall Buildings Chap 3 ATharangi MunaweeraAinda não há avaliações

- 9 Beam DeflectionDocumento34 páginas9 Beam DeflectionBharat JajoriaAinda não há avaliações

- Reinforced Concrete Slab DesignDocumento29 páginasReinforced Concrete Slab DesignMapanguriSitoeAinda não há avaliações

- Prestressed Cantilever and Continuous Beam - Seminar - Group 5Documento30 páginasPrestressed Cantilever and Continuous Beam - Seminar - Group 5Ganesh MistercoolAinda não há avaliações

- Lateral Support For Tier Building FramesDocumento4 páginasLateral Support For Tier Building Framesuhu_plus6482Ainda não há avaliações

- Ce2404-Prestressed Concrete StructuresDocumento1 páginaCe2404-Prestressed Concrete StructuresDhivya RamachandranAinda não há avaliações

- Discussion - Design of W-Shapes For Combined Bending and TorsionDocumento2 páginasDiscussion - Design of W-Shapes For Combined Bending and TorsionnaimAinda não há avaliações

- Torsion Design of Prestressed ConcreteDocumento20 páginasTorsion Design of Prestressed ConcreteDr. M.V.Krishna RaoAinda não há avaliações

- Reinforced Concrete I: Lecture-1Documento54 páginasReinforced Concrete I: Lecture-1Temesgen BihonegnAinda não há avaliações

- Introduction To Beams: Part ADocumento49 páginasIntroduction To Beams: Part AMorad AJAinda não há avaliações

- Prestressing FlexuralDocumento22 páginasPrestressing FlexuralGhulamRanger100% (1)

- Chapter 7 COLUMNSDocumento9 páginasChapter 7 COLUMNSPraveen Kumar RAinda não há avaliações

- Investigation of the Chirajara Bridge CollapseNo EverandInvestigation of the Chirajara Bridge CollapseAinda não há avaliações

- Mat Chapter 18Documento29 páginasMat Chapter 18hemant_durgawaleAinda não há avaliações

- Cyclic Deformation Capacity, Resistance and Effective Stiffness of RC Members With or Without RetrofittingDocumento8 páginasCyclic Deformation Capacity, Resistance and Effective Stiffness of RC Members With or Without RetrofittingDave WelchAinda não há avaliações

- Lecture Notes PDFDocumento73 páginasLecture Notes PDFBurhan KanjetaAinda não há avaliações

- STRUT AND TIE MODELLING BACKGROUND AND NEW AS 3600 PROVISIONSDocumento27 páginasSTRUT AND TIE MODELLING BACKGROUND AND NEW AS 3600 PROVISIONSVincent Teng100% (1)

- Project Management-Harvard ReferencingDocumento26 páginasProject Management-Harvard ReferencingVincent TengAinda não há avaliações

- APSEC 2006 Proceedings on Design of RC BeamsDocumento17 páginasAPSEC 2006 Proceedings on Design of RC BeamsvinthfAinda não há avaliações

- Bearing Capacity of SoilsDocumento138 páginasBearing Capacity of SoilsMuqeem Khan100% (1)

- Structural Stability From Theory To PracticeDocumento7 páginasStructural Stability From Theory To PracticeVincent TengAinda não há avaliações

- Design of Water Retaining Structures To ECDocumento44 páginasDesign of Water Retaining Structures To ECVincent Teng100% (4)

- Hoardings Good PracticeDocumento46 páginasHoardings Good PracticeVincent TengAinda não há avaliações

- Design Practice To Prevent Floor VibrationsDocumento28 páginasDesign Practice To Prevent Floor VibrationsVincent TengAinda não há avaliações

- Writing Work Method Statement Plain English Guidelines 0231Documento24 páginasWriting Work Method Statement Plain English Guidelines 0231Vincent TengAinda não há avaliações

- Strip FootingDocumento3 páginasStrip FootingVincent TengAinda não há avaliações

- Demolition E2004 (HK)Documento180 páginasDemolition E2004 (HK)Daniel YongAinda não há avaliações

- SAMPLE RetainerAgreementDocumento2 páginasSAMPLE RetainerAgreementBleu Chameleon Web DesignAinda não há avaliações

- CIDECT Design Guide 3Documento156 páginasCIDECT Design Guide 3paris062100% (1)

- RC18 Column02Documento8 páginasRC18 Column02assaad006Ainda não há avaliações

- QLASSICDocumento2 páginasQLASSICVincent Teng0% (1)

- Mosfet PDFDocumento13 páginasMosfet PDFTad-electronics TadelectronicsAinda não há avaliações

- MACROECONOMICSDocumento95 páginasMACROECONOMICSClaudine Jeanne NillamaAinda não há avaliações

- Approvals Management Responsibilities and Setups in AME.BDocumento20 páginasApprovals Management Responsibilities and Setups in AME.BAli LoganAinda não há avaliações

- Aggregate Demand and Supply: A ReviewDocumento36 páginasAggregate Demand and Supply: A ReviewYovan DharmawanAinda não há avaliações

- DX DiagDocumento31 páginasDX DiagJose Trix CamposAinda não há avaliações

- EPA - Regulatory Impact AnalysisDocumento822 páginasEPA - Regulatory Impact AnalysisSugarcaneBlogAinda não há avaliações

- Nº SSR-1 NS-R-3 Draf R1 Site Evaluation For Nuclear Installations FRDocumento33 páginasNº SSR-1 NS-R-3 Draf R1 Site Evaluation For Nuclear Installations FRdaniel addeAinda não há avaliações

- Fin 464 Chapter-03Documento18 páginasFin 464 Chapter-03Shantonu Rahman Shanto 1731521Ainda não há avaliações

- SQL DBA Mod 1 IntroDocumento27 páginasSQL DBA Mod 1 IntroDivyaAinda não há avaliações

- Festo Process Control - CatalogDocumento3 páginasFesto Process Control - Cataloglue-ookAinda não há avaliações

- Final Year Project - Developing A Plastic Bottle Solar CollectorDocumento78 páginasFinal Year Project - Developing A Plastic Bottle Solar CollectorLegendaryN0% (1)

- This Study Resource Was: ExercisesDocumento1 páginaThis Study Resource Was: Exercisesىوسوكي صانتوسAinda não há avaliações

- Kooltherm PipeDocumento8 páginasKooltherm Pipenaseema1Ainda não há avaliações

- Virtual Content SOPDocumento11 páginasVirtual Content SOPAnezwa MpetaAinda não há avaliações

- Lab Equipment Catalog Research Concept LabDocumento40 páginasLab Equipment Catalog Research Concept LabSeetanshu AwasthiAinda não há avaliações

- CSCE 3110 Data Structures and Algorithms NotesDocumento19 páginasCSCE 3110 Data Structures and Algorithms NotesAbdul SattarAinda não há avaliações

- Reason Document 0n Rev.3Documento58 páginasReason Document 0n Rev.3d bhAinda não há avaliações

- Project Description and DefinitionDocumento7 páginasProject Description and DefinitionAlbert Jonnel DomingoAinda não há avaliações

- Solid Waste On GHG Gas in MalaysiaDocumento10 páginasSolid Waste On GHG Gas in MalaysiaOng KaiBoonAinda não há avaliações

- Method Statement For LVAC Panel TestingDocumento9 páginasMethod Statement For LVAC Panel TestingPandrayar MaruthuAinda não há avaliações

- Distribution Requirements PlanningDocumento8 páginasDistribution Requirements PlanningnishantchopraAinda não há avaliações

- Soal Pat Inggris 11Documento56 páginasSoal Pat Inggris 11dodol garutAinda não há avaliações

- Personal Selling ProcessDocumento21 páginasPersonal Selling ProcessRuchika Singh MalyanAinda não há avaliações

- CIGB B164 Erosion InterneDocumento163 páginasCIGB B164 Erosion InterneJonathan ColeAinda não há avaliações

- 02 - AbapDocumento139 páginas02 - Abapdina cordovaAinda não há avaliações

- Analytic Solver Platform For Education: Setting Up The Course CodeDocumento2 páginasAnalytic Solver Platform For Education: Setting Up The Course CodeTrevor feignarddAinda não há avaliações

- Supply AnalysisDocumento5 páginasSupply AnalysisCherie DiazAinda não há avaliações

- Black Box Components and FunctionsDocumento9 páginasBlack Box Components and FunctionsSaifAinda não há avaliações

- Christmasworld Trend Brochure 2024Documento23 páginasChristmasworld Trend Brochure 2024Ольга ffAinda não há avaliações

- PH Measurement TechniqueDocumento5 páginasPH Measurement TechniquevahidAinda não há avaliações