Escolar Documentos

Profissional Documentos

Cultura Documentos

PQR Gmaw3g

Enviado por

devendrasingh2021Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PQR Gmaw3g

Enviado por

devendrasingh2021Direitos autorais:

Formatos disponíveis

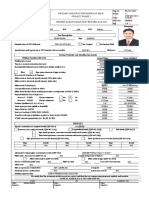

ANNEX N

AWS D1.1/D1.1M:2010

PROCEDURE QUALIFICATION RECORD (PQR)

Company Name: Modern Prefab Systems Pvt. Ltd. Welding Process GMAW-S/CO2 Supporting WPS No. MPS-WPS-2

JOINT DESIGN USED Type: Butt Tee Corner

Identification # Revision 00 . Authorized by . Type- Manual Mechanized

MPS-PQR-2 Date: 19/04/2012 By Date: 27/04/2012 Semiautomatic Automatic

Lap Edge Double Weld Single Backing: YES NO Backing Material NA Root Opening 2.5 mm Root Face Dimension 2.5mm Radius (J-U) NA Groove Angle: 60 Back Gouging: Yes NO Method NA .

POSITION

Position of Groove: 3G . Fillet: Vertical Progression: Up Down NA .

Electrical Characteristics

Transfer Mode (GMAW) Short-Circuiting Globular Spray Current: AC DCEP DCEN PULSED Other _____________ __________________ Tungsten Electrode (GTAW) Size: _____NA __ Type: ____NA ___

BASE METALS

Material Spec. IS 2062 Type of grade Grade B * Thickness: Groove 12mm Diameter (Pipe) NA

Fillet NA

TECHNIQUE FILLER METALS

AWS Specification AWS A 5.18 AWS Classification ER 70 S-6 Stringer or Weave Bead: WEAVE Multi -Pass or Single Pass (per side) MULTIPLE Number of Electrodes One Electrode Spacing Longitudinal NA Lateral NA 15 . Angle 100% . Contact Tube to work Distance 20 MM . Peening NA Interpass Cleaning: WIRE BRUSHING . . . .

SHIELDING

Flux Gas CO2 Composition Electrode-Flux (Class) NA Flow Rate 17 L/MIN Gas Cup Size 20mm NA .

. . .

POST WELD HEAT TREATMENT Preheat

Preheat Temp. Min Interpass Temp. Min. NA NA . Max. NA . . Temp. Time NA NA . .

Pass or Weld Larer(s)

Process

Filler Metals Class Diam.

WELDING PROCEDURE Current Type & Polarity

Amps or Wire Feed Speed

Volts

Travel Speed

(IPM)

Joint Details

1 2 3

GMAW GMAW GMAW

ER 70-S-6 1.2mm ER 70-S-6 1.2mm ER 70-S-6 1.2mm

DCEP DCEP DCEP

116 - 120 A 128 - 132 A 128 - 132 A

18-19 21-22 21-22

6-7 6-7 6-7

60

12mm

2.5mm 2.5mm

12mm

* Material chemical composition is (C%= 0.22max, Mn%= 1.50max, P%= 0.045max, S%=0.045, Si%= 0.03-0.4max), CE%= 0.41max Form N-1 (Front)

12mm

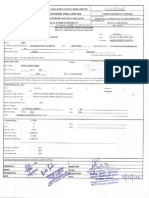

ANNEX N PROCEDURE QUALIFICATION RECORD (PQR) # MPS-PQR-2

TEST RESULTS

AWS D1.1/D1.1M:2010

ID Mark TT1 TT2

Width (mm) 20.00 19.94

Thickness (mm) 11.20 11.24

Area 2 (mm ) 224.00 224.12

TENSILE TEST Ultimate Tensile Load, KN 130.5 131.5

Ultimate Unit Stress, N/mm2 583 587

Character of failure and Location

BROKEN IN HAZ, DUCTILE FRACTURE. BROKEN IN WELS METAL, DUCTILE FRACTURE.

ID Mark SB1 SB2 SB3 SB4

Type of Bend SIDE BEND SIDE BEND SIDE BEND SIDE BEND

GUIDE BEND TEST Result SATISFACTORY SATISFACTORY SATISFACTORY SATISFACTORY

Remarks ACCEPTABLE ACCEPTABLE ACCEPTABLE ACCEPTABLE

VISUAL INSPECTION Appearance ACCEPTABLE Undercut None Piping Porosity None Convexity Yes Test Date: 27/04/2012 Witnessed By:

Radiographic/Ultrasonic Examination RT Report No.: 0412/26A Result UT Report No.: NA Result FILLET WELD TEST RESULTS Manimum size multiple pass Maximum size single pass Macroetch Macroetch 1. .3. .1. . 2. . 2. . All-weld-metal tension test Tensile strength, psi Yield point / strength, psi Elongation in 2 in, % Laboratory Test No. NA NA NA NA Sample No. WM1 .

Other Tests :

Macroetch Test 1. Satisfactory

Welder's Name: Test Conducted By: .

Clock No. Laboratory. Test No. Per

W-1

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in conformance with the requirements of Clause 4 of AWS D1.1/D1.1M, (2010 ) Structural Welding CodeSteel.

Signed: _Modern Prefab Systems Pvt. Ltd. By : Title: Sr. Engineer (Q.C.) Date: 27/04/2012 Form N-1 (Back)

____

AWS D1.1/D1.1M:2010

-2

Character of failure and Location

BROKEN IN HAZ, DUCTILE FRACTURE. BROKEN IN WELS METAL, DUCTILE FRACTURE.

marks PTABLE PTABLE PTABLE PTABLE

Passed NA

ULTS ze single pass 3. .

. WM1

pared, welded, and tested in el.

stems Pvt. Ltd.

____

Você também pode gostar

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocumento3 páginasWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaAinda não há avaliações

- Wps SawDocumento2 páginasWps Sawdevendrasingh2021100% (6)

- WPS TITLEDocumento2 páginasWPS TITLERichard Periyanayagam86% (14)

- WPQR Welding Procedure Qualification RecordsDocumento3 páginasWPQR Welding Procedure Qualification Recordsramesh rajaAinda não há avaliações

- wqt4 Gmaw 4gDocumento2 páginaswqt4 Gmaw 4gdevendrasingh20210% (1)

- Val Caraig WPQTDocumento1 páginaVal Caraig WPQTMark Jason M. BrualAinda não há avaliações

- WPS For Smaw06-001 (Pipe 6G CS)Documento10 páginasWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- WQT Record for Pipeline Welder QualificationDocumento99 páginasWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- GMAW welding parameters for SS400 pipeDocumento2 páginasGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- Visual Plate Inspection Report SummaryDocumento4 páginasVisual Plate Inspection Report SummaryLaith Salman100% (1)

- WPS & PQRDocumento46 páginasWPS & PQRJohn Candidate CIns88% (8)

- WPS 316 LDocumento4 páginasWPS 316 Llaz_k100% (2)

- PQRDocumento2 páginasPQRSreenivas Kamachi Chettiar100% (1)

- Toshiba Brazing Procedure SpecificationDocumento3 páginasToshiba Brazing Procedure Specificationsheikmoin100% (1)

- WPS Format For ASME IX - WQTDocumento1 páginaWPS Format For ASME IX - WQTThe Welding Inspections CommunityAinda não há avaliações

- Welding Procedure Specification (WPS)Documento2 páginasWelding Procedure Specification (WPS)Ramadhan AdityaAinda não há avaliações

- PT Kuwera Karya Me: PanduDocumento2 páginasPT Kuwera Karya Me: PanduGalang Pratama PutraAinda não há avaliações

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocumento3 páginasWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniAinda não há avaliações

- WPS GmawDocumento2 páginasWPS Gmawasikur100% (6)

- PQR - 152Documento3 páginasPQR - 152MAT-LIONAinda não há avaliações

- 004 Gtaw P5aDocumento16 páginas004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Documento5 páginasWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- PQR FormatDocumento2 páginasPQR Formatravi0009880% (5)

- FIT UP ReportDocumento2 páginasFIT UP Reportsiva8000Ainda não há avaliações

- Welder qualification test recordDocumento3 páginasWelder qualification test recordTuTuy AnAinda não há avaliações

- WPS PQR-03Documento12 páginasWPS PQR-03Ranjan KumarAinda não há avaliações

- WPS PQR FormatDocumento1 páginaWPS PQR FormatJatin Kamdar100% (2)

- ASME IX Sample WPS GTAW SMAWDocumento1 páginaASME IX Sample WPS GTAW SMAWDeepak ShrivastavAinda não há avaliações

- WPS PQR-09Documento11 páginasWPS PQR-09Ranjan KumarAinda não há avaliações

- Slamet WPQRDocumento1 páginaSlamet WPQRChandra Bintang W.PAinda não há avaliações

- Welding Consumable Baking Register PDFDocumento1 páginaWelding Consumable Baking Register PDFKandula Raju100% (1)

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocumento4 páginasWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidAinda não há avaliações

- Gtaw WPQDocumento3 páginasGtaw WPQMuhammadShabbirAinda não há avaliações

- Wps Gmaw SawDocumento2 páginasWps Gmaw Sawupedro26Ainda não há avaliações

- WPQ-1083 3G PDFDocumento2 páginasWPQ-1083 3G PDFduendex360100% (1)

- Fcaw 16 THKDocumento5 páginasFcaw 16 THKparesh2387Ainda não há avaliações

- 19403955-WPS M.S. Is 2062Documento10 páginas19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- WPQT FormatDocumento176 páginasWPQT FormatRafiqKu50% (2)

- Reports - QAQC - R0Documento10 páginasReports - QAQC - R0talupurumAinda não há avaliações

- Wps Repair WorDocumento1 páginaWps Repair WorMajdi JerbiAinda não há avaliações

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Documento2 páginasWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniAinda não há avaliações

- WQTDocumento1 páginaWQTRamkunwar YadavAinda não há avaliações

- Wps p91 - BhelDocumento2 páginasWps p91 - BhelAshish Gupta100% (4)

- DQR Project Welding Summary Report FormDocumento1 páginaDQR Project Welding Summary Report Formminhnn100% (4)

- Sample Wps-Carbon Steel GTAW+SMAWDocumento2 páginasSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Documento2 páginas(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- OSD Welding ProcedureDocumento6 páginasOSD Welding ProcedureVijayakumar Chandran100% (1)

- Weld Joint 1Documento81 páginasWeld Joint 1rajibali27100% (1)

- PQR SAW ProcessDocumento1 páginaPQR SAW Processdevendrasingh202133% (3)

- Welding Procedure Qualification Records (WPQR) GuideDocumento3 páginasWelding Procedure Qualification Records (WPQR) Guideramesh rajaAinda não há avaliações

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Documento3 páginasWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaAinda não há avaliações

- PQR-WPS-WPQR XXX Rev 0Documento6 páginasPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- WPS GTAW Stainless SteelDocumento4 páginasWPS GTAW Stainless SteelAnand NarayananAinda não há avaliações

- PQR 014 (Qualified Sa 106 GR BDocumento5 páginasPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Welder Cirt TotalDocumento78 páginasWelder Cirt TotalNguyễn ChâuAinda não há avaliações

- Procedure Qualification SpecificationDocumento4 páginasProcedure Qualification Specificationriyas.hvacworkAinda não há avaliações

- WPQR No. 2016 02Documento14 páginasWPQR No. 2016 02GANESH AAinda não há avaliações

- Loading Unloading Temperature Welding ProgressionDocumento5 páginasLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocumento5 páginasBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaAinda não há avaliações

- WPS - Smaw - 2Documento6 páginasWPS - Smaw - 2Harkesh RajputAinda não há avaliações

- Offer List Vinayak Transo Limited: Date: 22-04-2021Documento1 páginaOffer List Vinayak Transo Limited: Date: 22-04-2021devendrasingh2021Ainda não há avaliações

- Offer List Vinayak Transo Limited: Date: 22-04-2021Documento1 páginaOffer List Vinayak Transo Limited: Date: 22-04-2021devendrasingh2021Ainda não há avaliações

- Non Confirming IssuesDocumento1 páginaNon Confirming Issuesdevendrasingh2021Ainda não há avaliações

- Sr. No. Sample Name Cast Number Sample Size Thickness Observations (MM) 1 2 3 4 5 6 7 8 9 10 Average ThicknessDocumento1 páginaSr. No. Sample Name Cast Number Sample Size Thickness Observations (MM) 1 2 3 4 5 6 7 8 9 10 Average Thicknessdevendrasingh2021Ainda não há avaliações

- Non Confirming IssuesDocumento1 páginaNon Confirming Issuesdevendrasingh2021Ainda não há avaliações

- Non Confirming IssuesDocumento1 páginaNon Confirming Issuesdevendrasingh2021Ainda não há avaliações

- Non Confirming IssuesDocumento1 páginaNon Confirming Issuesdevendrasingh2021Ainda não há avaliações

- Non Confirming IssuesDocumento1 páginaNon Confirming Issuesdevendrasingh2021Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento18 páginasDisclosure To Promote The Right To InformationRatnakumarChittoorAinda não há avaliações

- Standard Testing Procedure - Tensile TestingDocumento3 páginasStandard Testing Procedure - Tensile Testingdevendrasingh2021100% (1)

- (A) Dimensions: (D) Cupping TestDocumento5 páginas(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- PQR SAW ProcessDocumento1 páginaPQR SAW Processdevendrasingh202133% (3)

- Comparision of Steel PropertyDocumento2 páginasComparision of Steel Propertydevendrasingh2021Ainda não há avaliações

- Comparision of Steel PropertyDocumento2 páginasComparision of Steel Propertydevendrasingh2021Ainda não há avaliações

- Welder Id SampleDocumento1 páginaWelder Id Sampledevendrasingh202157% (7)

- Structural mechanics course detailsDocumento54 páginasStructural mechanics course detailsAlhaz UddinAinda não há avaliações

- 4 Post Tensioned Concrete SilosDocumento8 páginas4 Post Tensioned Concrete SilosSaqlain AwanAinda não há avaliações

- Exam Assessment Level Full Marks Program BCT A Pass Marks Year/Part I/II TimeDocumento4 páginasExam Assessment Level Full Marks Program BCT A Pass Marks Year/Part I/II Timeविशाल पुडासैनीAinda não há avaliações

- Phy CHP 8 NotesDocumento16 páginasPhy CHP 8 Notesayaan ahmedAinda não há avaliações

- Pearson Ps CH 16 EdlineDocumento20 páginasPearson Ps CH 16 EdlineRajendra PilludaAinda não há avaliações

- Topic 07 StrengtheningMechanisms (Compatibility Mode)Documento39 páginasTopic 07 StrengtheningMechanisms (Compatibility Mode)Selviya AvaurumAinda não há avaliações

- Thin Walled Pressure VesselDocumento13 páginasThin Walled Pressure VesselaalijanaabAinda não há avaliações

- MTLE4050-Syllabus Intro To PolymersDocumento3 páginasMTLE4050-Syllabus Intro To Polymerskushie0Ainda não há avaliações

- 9 10 enDocumento2 páginas9 10 enparth kananiAinda não há avaliações

- Engineering Thermodynamics 1 THRM1001: Basic Concepts and DefinitionsDocumento50 páginasEngineering Thermodynamics 1 THRM1001: Basic Concepts and DefinitionsTashi BestAinda não há avaliações

- Characteristics of Polyglycerol Ester and Its Different FractionsDocumento10 páginasCharacteristics of Polyglycerol Ester and Its Different FractionsliliAinda não há avaliações

- GE - Probe - Coarse Grain Materials PDFDocumento2 páginasGE - Probe - Coarse Grain Materials PDFAnonymous 5qPKvmuTWCAinda não há avaliações

- RAFT FOOTING (SPILLWAY) FinalDocumento3 páginasRAFT FOOTING (SPILLWAY) FinalSUPERINTENDING ENGINEERAinda não há avaliações

- DataSheet-ThinSheet v4Documento2 páginasDataSheet-ThinSheet v4suri_girishAinda não há avaliações

- Novel Innovations in Dental Implant Biomaterials Science: Zirconia and PEEK PolymersDocumento5 páginasNovel Innovations in Dental Implant Biomaterials Science: Zirconia and PEEK PolymersSatya AsatyaAinda não há avaliações

- Notes On Serviceability LimitsDocumento9 páginasNotes On Serviceability LimitsOsama DabbasAinda não há avaliações

- Polymer Science: Average Molecular WeightDocumento2 páginasPolymer Science: Average Molecular WeightVasantha SudasinghaAinda não há avaliações

- EE305Documento19 páginasEE305api-3853441Ainda não há avaliações

- Boundary Conditions at A Naturally Permeable WallDocumento11 páginasBoundary Conditions at A Naturally Permeable WallOscar A. LuévanoAinda não há avaliações

- CFD Simulation of Dust Particle Removal Efficiency of A Venturi Scrubber in CFXDocumento9 páginasCFD Simulation of Dust Particle Removal Efficiency of A Venturi Scrubber in CFXCristian MartínezAinda não há avaliações

- Fluidization 180402101141Documento13 páginasFluidization 180402101141suraj nakumAinda não há avaliações

- Adsorption and Pore Condensation of Krypton On MesoporousDocumento7 páginasAdsorption and Pore Condensation of Krypton On MesoporousSibnath KayalAinda não há avaliações

- Expt 6 The Cage Rotor Induction MotorDocumento5 páginasExpt 6 The Cage Rotor Induction MotorRyan De GuzmanAinda não há avaliações

- Technical TermodynamicsDocumento8 páginasTechnical TermodynamicsPajooheshAinda não há avaliações

- Productflyer - 978 0 387 74364 6Documento1 páginaProductflyer - 978 0 387 74364 6Dhruv PatelAinda não há avaliações

- Minfm66645 Astm A312 Grade s32615Documento4 páginasMinfm66645 Astm A312 Grade s32615Oleg ShkolnikAinda não há avaliações

- 4.1 Anchor Principles and Design (130-148) PDFDocumento22 páginas4.1 Anchor Principles and Design (130-148) PDFpabmataAinda não há avaliações

- PolymersDocumento8 páginasPolymersLauren LloydAinda não há avaliações

- Mixing Liquids in Laminar Flow: Relating Thoroughness to Shear and InterfaceDocumento2 páginasMixing Liquids in Laminar Flow: Relating Thoroughness to Shear and InterfaceJosé Roberto LazoAinda não há avaliações

- Chapter 24 - Capacitance and DielectricsDocumento16 páginasChapter 24 - Capacitance and DielectricsAlexis OrganisAinda não há avaliações