Escolar Documentos

Profissional Documentos

Cultura Documentos

Chemistry in Industry

Enviado por

Arnav JatukaranDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chemistry in Industry

Enviado por

Arnav JatukaranDireitos autorais:

Formatos disponíveis

Option C: Chemistry in Industry & Technology C.1.

1 State the main sources of iron The two major sources of iron include iron ores and scrap iron. The various methods in which they are obtained are listed below: Iron Ore Mined as oxides: Fe2O3 (haematite), Fe3O4 (FeOFe2O3, magnetite) and the sulphide FeS2 (iron pyrites). Scrap Iron Roasted in the air to form oxide and sulphide dioxide: 4FeS2(s) + 11O2(g) 2Fe2O3(s) + 8SO2(g)

C.1.2 Describe and explain the reaction that occur in the blast furnace In the reaction that occurs within the blast furnace, a mixture of raw material (known as the solid charge) including limestone (calcium carbonate CaCO3), coke (C), iron ore (ex. Iron (III) oxide, Fe2O3) is fed through the hopper of the blast furnace. This hopper serves as the top of the blast furnace. The coke is oxidized exothermically to produce carbon dioxide by a large volume of hot air released from the bottom of the blast furnace. This oxidation reaction is described below: C(s) +O2 (g) CO2 (g) + heat The hot air at the bottom of the furnace causes the temperature to be as high as 2200K. Higher up the furnace, the carbon dioxide reacts with coke in an endothermic reaction to form carbon monoxide. Being an endothermic reaction, the temperature of the furnace is cooled to 1400K. This endothermic reaction is described below: CO2 (g) + C(s) + heat 2CO(g) We can also cause an incomplete combustion reaction if natural gas could be injected along with the hot air. Carbon monoxide will be formed in this reaction and less coke shall be used: 2CH4(g) + O2(g) 2CO(g) + 4H2(g) The carbon monoxide formed in the process plays a critical role in the reduction of the ore towards the top of the furnace. The process of reduction is exothermic: Fe2O3(s) + 3CO(g) 2Fe(l) + 3CO2(g) + heat Alternatively, Fe3O4(s) + 4CO(g) 3Fe(l) + 4CO2(g) + heat Another reduction agent used at this stage can be hydrogen gas that is produced on partial oxidation by injecting methane: Fe3O4(s) + 4H2(g) 3Fe(l) + 4H2O(g) + heat Coke can also be a reduction agent for the oxide. The reaction in this process would be: Fe2O3(s) + 3C(s) 2Fe(l) + 3CO(g)

This resulting iron produce is able to sink down the furnace. The higher temperatures at the bottom, serve to accomplish two things: they keep the iron at a molten state and also the limestone decomposes to form calcium oxide and carbon dioxide. The reaction is as follows: Heat + CaCO3(s) CaO(s) + CO2(g) This calcium oxide is highly basic. In contact with the acidic silicon (IV) oxide in the sand of the impure ore and atmospheric aluminium oxide, calcium oxide forms a molten slag of calcium silicate (IV) and calcium aluminate (III). This product continues down the stack in the following reactions: CaO(s) + SiO2(s) CaSiO3(l) CaO(s) + Al2O3(s) CaAl2O4(l) This molten iron is known as the pig iron. It is impure and contains about 4-5% carbon, 1-2% silicon and small bits of elements such as manganese, phosphorus and sulphur. Denser pig iron can be found on the bottom of the furnace. The lighter slag is found on the top. This slag can be tapped off over a period of time. This slag is used to make cement for roads and also for roads. Furnaces can function effectively for several years without having to replace them.

Image Obtained from: http://www.chemguide.co.uk/inorganic/extraction/iron.html

C.1.3. Describe and explain the conversion of iron into steel using the basic oxygen converter. The most common method of making steel from the impure iron is to blast it with pure oxygen. The scrap steel is placed in the bottom of the oxygen convertor. The converter is tilted and the molten pig iron produced from the blast furnace is placed in the converter. The water-cooled pipes allow for the passing of the oxygen and the calcium oxide (lime)

onto the surface of the metal at high pressures. This oxygen has the ability to oxidize the impurities of the molten iron by penetrating it. Acidic oxides of C, S, P and Si are created. These escape out as gasses or combine with lime to form slag in reactions such as the ones stated below. These oxidation reactions are exothermic and the heat that is emitted from this reaction can be used to keep the contents of the furnace in a molten state. C + O2 CO2 S + O2 SO2 4P + 5O2 P4O10 Si + O2 SiO2 SiO2 + Cao CaSiO3 (slag) This slag can form layers above the crude steel and also remain behind as liquid steel that can be further poured off. The molten state of the contents allows for the alloying of elements such as manganese and cobalt. These allow for the creation of alloys with desired characteristics and specific properties. C.1.4. Describe alloys as a homogeneous mixture of metals or a mixture of a metal and a non-metal. Alloys are a mixture of two or more elements, of which, at least one component is a metal. Therefore, it is a homogenous mixture of metals. It can also be a mixture of nonmetal and metals in which the metal is known as the base metal and is found in a larger proportion. These mixtures are formed when the base metal is mixed with the other components in molten form and the allowed to cool down to form the desired alloy. C.1.5. Explain how alloying can modify the properties of metals. Common characteristics of metals that allow for particles of metals to be shifted under applied stress are (1) the fact that metals have a lattice of cations in a sea of electrons with an orderly arrangement of atoms and (2) no rigid or directional bonds present in the metallic crystal structures. The fact that metals can be slide over under applied stress illustrates their characteristics of being soft, ductile and malleable. These are properties of some typical metals. A different element that has different sized atoms and cations allows for the modification of the microstructures of the base metal by disrupting the regular, repeating lattice. This makes it harder for a layer of atoms to slide over another. Through the process of alloying metals, we can see that we can develop desired characteristics in the elements such as hardness, malleability and properties such as tensile strength and resistance to corrosion. Examples of this concept are stainless steel and bronze that are stronger and much more corrosive than their base metals iron and copper.

C.1.6. Describe the effects of heat treatment of steel. Despite the use of the basic oxygen convertor, the steel might not have the desired characteristics or properties. Thus the steel is subject to high levels of heat that allow for changes at the micro-crystal structural level. One such process is the method of annealing under slow heating and then holding the steel at a particular temperature (about half its melting point). This allows for changes at the structural level. After the annealing process, the steel is allowed to cool off. The rate of heating and also of the cooling varies greatly from the type of steel used and the type of characteristics of the finished article desired. The process of annealing is used to soften the steel and make it more ductile and malleable. Quenching is the process of immediately cooling down the hot steel by submerging it in cold water or in oil. This process allows for structural characteristics seen at higher temperatures, able to exist at lower temperatures. These crystal structures tend to be a lot harder. The quenching process allows for steel to become brittle. However, to make the steel less brittle, a separate heating process of tempering is conducted. Here, the steel is re-heated to about 200-600 degrees Celsius and then it is re-cooled. C.1.7. Describe the properties and uses of iron and steel. Iron is shiny, soft, ductile and malleable. It has high strength, which could be shaped into objects. Iron also rusts to form hydrated iron (III) oxide. The reaction of iron rusting is described below: 4Fe(s) + 3O2(g) + xH2O(l) 2Fe2O3xH2O(s) Iron can be used in tin cans, ornamental gates, bridges, reinforcing concrete with steel and use as a catalyst in the Haber process. Much of the produced iron is used to produce steel.

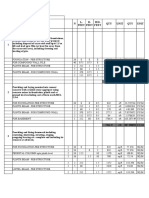

Iron + Other Metals Titanium Steel Chromium Steel Cobalt Steel Manganese Steel (10-18%) Stainless Steel containing about 20% chromium and 10% nickel

Important Properties Withstand high pressures Hard High magnetic permeability Tough tool steel; resistant to wear Non-rusting

Some Uses Gas turbines, spacecraft Ball bearings Magnets Earthmoving machinery, railway lines Cutlery, sinks, car accessories, surgical instruments

C.1.8. Describe and explain the production of aluminium by electrolysis of alumina in molten cryolite. Aluminium is obtained individually by the electrolysis of molten aluminium oxide: Al2O3. This is taken from bauxite, which is impure hydrated aluminium oxide, Al2O3xH2O. Bauxite iron is impure because of the presence of iron (III) oxide and silicon (IV) oxide. Under a reaction with hot sodium hydroxide, the silicon (IV) oxide and the aluminium oxide dissolve. These reactions produce either sodium silicate or sodium aluminate, with water. SiO2(aq) + 2NaOH(aq) H2O(l) + Na2SiO3(aq) Other impurities, such as iron (III) oxide, remain and have to be removed by filtration. The previous reaction is diluted by water, and seeded with solid sodium hydroxide to reverse the reaction and precipitate aluminium hydroxide. The reaction is stated below: 2H2O(l) + NaAlO2(aq) Al(OH)3(s) + NaOH(aq) By heating the product aluminium hydroxide, we can obtain pure aluminium oxide: 2Al(OH)3(s) Al2O3(s) + 2H2O(g) This aluminium, being very radioactive, is obtained by the electrolysis of molten salts, requiring high temperatures to maintain its molten state as the melting point of Al2O3 is greater than 2000 degrees Celsius. However, by mixing it with molten cryolite, Na3AlF6, the melting point is lowered to about 900 degrees Celsius. This works towards improving the conductivity. The mixture of cryolite and alumina is electrolyzed in a cell with graphite (carbon) positive electrodes, or the anode, and a graphite cell lining that is the negative electrode or cathode. During the electrolysis process, the molten aluminium sinks to the bottom of the cell. The (-) electrode half reaction is as follows: Al3+ + 3e- Al(l) The (+) electrode half reaction is as follows: 2O2-(l) O2(g) + 4eThus, the overall reaction is: 4Al3+(l) + 6O2-(l) 4Al(l) + 3O2(g) C.1.9. Describe the main properties and uses of aluminium and its alloys. The main properties of aluminium and their uses are summarized in the table below: Aluminium alloy with: Properties Uses Copper Increased strength Automobiles Iron and Silicon Increased strength; heat resistant Foil

Up to 12% Silicon Magnesium Zinc (small amts. of Mg, Cu, Cr)

Lowers the melting range Welding Hardened alloy; corrosion resistant Marine work High strength Airplane Frames

C.1.10. Discuss the environmental impact of iron and aluminium production. All processes of making iron from the use of blast furnace to the final hear treatment and the production of aluminium by electrolysis use a lot of energy. To produce a ton of steel, one ton of coal is consumed and a ton of slag is produced. By mining for ores, scars can be left upon the landscape unless the mining company chooses to re-vegetate the area. C.2.1. Compare the use of oil as an energy source and as a chemical feedstock. Crude oil has become the most important raw material. About 10% of the refined oil are used as chemical feedstock, which is the raw materials required for an industrial process to produce petrochemicals. Crude oil, by itself is not very useful. However, it consists of a mixture of very useful hydrocarbons, which are sources of energy such as petrol and other fuels for transport and oil heating systems. Fractional distillation of crude oil produces lubricating oils, wax candles, ointments, polishes and chemicals. These are then used to produce fibres, agricultural chemicals, synthetic rubber and solvents. C.2.2. Compare catalytic cracking, thermal cracking and steam cracking. Petroleum with fraction ranging from 1-12 are much more popular than the rest. Thus, through the process of cracking, the larger, less useful hydrocarbon fractions are broken into smaller chains. These smaller chains are more useful alkanes and alkenes that are used as fuels and petrochemical feedstock. This process is very important in the oil industry. Cracking can be achieved under various temperatures, presence or absence of a catalyst, presence or absence of steam or hydrogen gas. Thermal cracking is known as pyrolysis. It is the breaking using higher temperatures. For example, a catalyst reduces the temperature required for cracking. However, in the absence of a catalyst, higher temperatures and pressures are required. Steam cracking requires pre-heating and vaporizing the feedstock and mixing it with steam at higher temperatures to form low molar mass alkenes. C.1.3. Describe and explain how the properties of polymers depend on their structural features. Polymers are long chains of macromolecules that are created by joining repeating units of monomers. Polythene is an example of a typical addition polymer. It is a giant molecule made of thousands of ethane monomers joined together to make a long chain polymer.

If the polymer has greater average chain length, the greater the intermolecular forces it will have. Therefore, the polymer will also have higher strength and also a greater melting point. Other structural features that determine properties of addition polymers are: Branching: Polythene can be made from either high-density polythene (HDPE) or as lowdensity polythene (LDPE). HDPE has less branching; therefore, it is a linear polymer in which the carbon backbone of the chain has a zig-zag pattern because of the tetrahedral structure for the carbon bonded to the four other atoms. HDPE can pack a lot closer together. It is strong and has high melting point. HDPE can be used for making rigid articles such as buckets, milk bottle crates, disposable syringes etc. LDPE, because of its branches, has limitations for how close polymer chains can come to each other. This lowers the intermolecular forces causing for a lower density and lower melting point. This can be used to make plastic bags, wrappers, plastic bowls etc. Position of the alkyl group along polymer backbone chain: For example, the hydrogen atom and the methyl side chain (CH3) can appear on either side of the backbone. Isotactic polymers are ordered with the same orientation, i.e., the methyl group is on the same side, and the hydrogen atoms on the opposite sides. These polymers pack more closely and have stronger intermolecular forces. They are tough and can be used for making ropes, fibres, carpets, automobile bumpers etc. Atactic polymers have random arrangements of the methyl groups. They cannot pack closely and are not held tightly making them very flexible and soft. They also have a low melting point. These can be used for making sealants and waterproofing materials.

Image Obtained from: http://www.globalarchitectsguide.com/library/Isotactic.php

C.3.2. Describe the ways of modifying the properties of addition polymers. By adding plasticizers to polymers such as the polyvinyl chloride (strong D-D IMF, rigid plastic), the IMFs are reduced and allow polymer chains to slide over each other to create soft plastics. This helps to make medical products such as blood bags and intravenous drip tubes. 10% concentration of plasticizer makes a semi-rigid polyvinyl chloride. Higher concentration leads to more flexibility. To reduce the density of polymers such as polystyrene, volatile hydrocarbons is used in the polymerization of styrene. Volatile hydrocarbons such as C5H12 vaporize causing the polystyrene to expand several times its original size and hence have a reduced density. These product polystyrenes can be used for thermal insulators to make things such as disposable coffee mugs.

C.3.3. Discuss the advantages and disadvantages of polymer use. Advantages: Polymers are light, impermeable to water and can be pigmented giving rise to articles with a wide variety of attractive colours. They have weak van der Waals forces that cause the polymers to be soft. They also melt on heating so they can be moulded to form thin films and sheets and rods and tubes. Their strong covalent bonds make them resistant to chemical reactions and give them good electrical insulation properties. Other advantages include: strength & high density (HDPE, rigid PVC, polystyrene), flexibility & low density (LDPE, flexible PVC), insulators (expanded polystyrene etc.) Disadvantages: source of polymers is petroleum that is a non-renewable source. Volume occupied by plastics in landfills causes substantial environmental impact as the nondegradable collect and the toxic fumes caused by burning plastics is released. Disposal of plastics is also an issue. However, there are four possible methods to dispose of the plastics: Incineration: completely burning the waste. Creates carbon dioxide and water. Reduces plastic waste greatly and creates useful energy. However, CO2 produced is greenhouse gas. The chlorinated polymers such as PVCs produce hydrogen chloride on combustion leading to acid rain. If the incineration temperature isnt high enough, toxic chemical such as dioxins are formed. Biodegradability: use of bacteria or fungi to break down plastics. Recycling & Conservation (reduction) C.4.0. Homogeneous and heterogeneous catalysts background. Catalyst is a substance that increases the rate of a chemical reaction without being chemically changed. It speeds up the reaction by lowering the activation energy. Catalysts can react at the surface or participate in the reaction. In homogeneous catalysis, the reactants and the catalyst are in the same phase. Thus, the catalyst allows the reaction to take place under a different mechanism with a lower Ea, and hence increasing reaction rate. In this type of reaction, the catalyst reacts in a step of the mechanism and is reproduced at a later step. An example of this is that of aqueous solutions, S2O82- and I- in the presence of Fe2+(aq). S2O82-(aq) + 2I-(aq) 2SO42-(aq) + I2(aq) The catalyst in this case, Fe2+(aq), oxidizes to Fe3+(aq) and reduced back to Fe2+(aq) in the following step: S2O82-(aq) + 2Fe2+(aq) 2SO42-(aq) + 2Fe3+(aq) 2I-(aq) + 2Fe3+(aq) 2Fe2+(aq) + I2(aq)

In heterogeneous catalysis, the reactants and the catalyst are in different phases (typically solid catalyst with reactants being in gas or liquid phase). The catalyst provides surface upon which the reaction could take place. Example of heterogeneous catalysis reactions include: 1. The Contact Process: production of SO3 for the manufacture of sulphuric acid: 2SO2(g) reacts with O2(g) under catalyst V2O5(s) to produce 2SO3(g) 2. The Haber Process: Production of ammonia for fertilizers/TNT in a reaction of gaseous nitrogen, hydrogen gas under catalyst Fe(s). 3. Hydrogenation of an alkene containing CC double bond. Ni(s) C2H4(g) + H2(g) C2H6(g) Enzymes have characteristics of both homogenous and heterogeneous catalysts. C.4.1. Compare the modes of actions of homogeneous and heterogeneous catalysts. The ability to form a range of oxidation states by transition metal compounds: Transition metals have relatively stabled multiple oxidation states by gaining or losing electrons in redox reactions. This is seen in homogeneous catalysis where Iron (II)/(III) speeds up the slow reaction between acidified hydrogen peroxide and iodide ions. Here, the iron (II) is oxidized by the peroxide to iron (III) that has to then be reduced by the iodide ions to regenerate catalyst iron (II): H2O2(aq) + 2H+(aq) + 2Fe2+(aq) 2H2O(l) + 2Fe3+(aq) 2I-(aq) + 2Fe3+(aq) I2(s) + 2Fe2+(aq) In heterogeneous catalysts, a reaction involving the change in oxidation number of the transition metal ion catalyst is the use of vanadium (V) in the Contact Process. In the first step, sulphur dioxide is oxidized to V(IV). Then, the V(IV) is oxidized by oxygen to regenerate the catalyst. SO2(g) + V2O5(s) SO3(g) + V2O4(s) V2O4(s) + O2(g) V2O5(s) The shape of the catalyst: Enzymes substrates only are effective with the specific 3D shape which complement one and other (lock and key model). If the enzyme changes shape, the substrate will no longer be able to bind to the active site. Denaturation can take place if the environment changes even minutely. Temperature can increase the rate of reaction, however, increase in temperature after a specific point sees the speed of the reaction drop sharply. Similarly, extreme changes to the pH can cause denaturation to occur. At low and high pH values, the enzyme irreversibly denatures and the rate drops sharply.

Availability of active sites: The region of the catalyst, which binds to one or more reactants, is called the active site. Heterogeneous catalyst contains active sites that are able to adsorb one or more reactants onto it to facilitate the reaction and reduce the activation energy. Adsorption is the increase in the concentration of one substance, the reactant, at the surface of another, the catalyst. C.4.2. Outline the advantages and disadvantages of homogeneous and heterogeneous catalysts. Homogeneous Catalysts Advantages High activity as all the catalyst is exposed to the reactants High selectivity for single product as the catalyst has unique active site Disadvantages Difficult to recover from the reaction mixture for reuse Heterogeneous Catalysts Solid catalysts are easy to remove & recover from products by filtration Long catalytic life. Only effective on the surface hence most of the solid is not used; also, any coating on surface reduces activity

C.4.3. Discuss the factors in choosing a catalyst for a process. Selectivity: Enzymes only catalyse one type of reaction. Good selectivity allows for producing only the desired product and not producing unwanted by-products. Efficiency: How rapidly the catalyst forms the desired product. Ability to work under mild/sever conditions: One of the disadvantages of enzymes is that they get easily denatured if there is a slight change in temperature or pH. On the other hand, heterogeneous catalysts such as iron are effective under vastly different conditions. Environmental Impact: Great demand of catalysts in industries raises environmental questions. Some metals are lost in the environment and might cause health risks, as they are dangerous to the toxicity of living cells. Catalyst Poisoning: If catalyst becomes impure over time, or their surfaces become coated, they are rendered as ineffective. C.5.1 Describe how hydrogenoxygen fuel cell works. A fuel cell is a device that converts the chemical energy of fuels into electrical energy. Fuel cells is a much more effective way of getting electric energy than traditional method of burning fuels converting chemical energy to heat which converts electricity steam. In a hydrogen-oxygen fuel cell, the negative electrode (anode) is made of porous carbon with catalyst Pd or Pt. The positive electrode (cathode) is made of porous carbon containing the catalyst Pt. Between these electrodes there is aqueous hydroxide

electrolyte (KOH or NaOH). The oxidation of hydrogen gas by oxygen gas takes place in a controlled manner.

Image Obtained from: http://www.science.org.au/nova/023/023box01.htm

The oxidation process leads to the loss of electrons on the hydrogen gas at the anode. The electrons flow out of the fuel cell and back to the positive cathode via an external circuit to reduce the oxygen gas (O2) to hydroxide ions (OH-). The anode and cathode half reaction, as well as the overall reaction, are stated below: (-) Anode oxidation half reaction: 2H2(g) + 4OH-(aq) 4H2O(l) + 4e(+) Cathode reduction half reaction: O2(g) + 2H2O(l) + 4e- 4OH-(aq) The net reaction is: 2H2(g) + O2(g) 2H2O(l) These half reactions can also occur in acidic conditions: (-) Anode oxidation half reaction: 2H2(g) 4H(aq) + 4e(+) Cathode reduction half reaction: O2(g) + 4H+(aq) + 4e- 2H2O(l) Advantages of using a fuel cell are that they are highly efficient since they convert the chemical energy of the fuels directly to electrical energy. Thus, it greatly reduces thermal pollution. No release of greenhouse gases from the combustion of fossil fuels. They are also lightweight. C.5.2. Describe the workings of rechargeable batteries. Rechargeable batteries are examples of secondary cells. These electrochemical cells are reversible and can be recharged. Applying an external source of electricity in the opposite direction can restore the reactant concentration.

Lead-acid Storage Battery: Major Components: Two or more grids of porous lead forms the anode of each cell in a Lead stored battery. The cathode, on the other hand, consists of lead coated with lead dioxide. A solution of sulfuric acid forms the electrolyte of the battery. Also consists of a lead plate. Major Characteristics: The half reaction of the anode is shown by the following equation: Pb(s) + SO42-(aq) PbSO4(s) + 2e-. The reduction of lead is shown in the half cell reaction of the cathode: PbO2(s) + 4H+ + SO42-(aq) + 2e- PbSO4(s) 2H2O(l) Thus, the overall reaction is: Pb(s) + PbO2(s) + 2SO42-(aq) 4H+ 2PbSO4(s)+ 2H2O(l) Automobile lead storage batteries have six cells connected in series with each one of the cells containing multiple electrodes in grids. These cell generate approximately 2V that add up to a total output of 12V. Additionally, the PbSO4(s) is a feature of both the reaction products of the oxidation and reduction reactions. Therefore, the reactants are available regardless if the battery is discharging or recharging. Also, Sulfuric acid is reduced as the battery goes through the reaction. This lowers the density of the electrolyte solution. Using this information, we can measure the battery's state of charge by measuring the density of the electrolyte. Applications: Used in standard automobile batteries as it provides sufficient initial supply of energy to power energy; it also has a longer shelf life and is often trustable in lower temperatures. Nickel-Cadmium (NiCad) Batteries These batteries are rechargeable, lightweight dry cells that produce constant potential of 1.4V. At the negative (anode) end, the oxidation half reaction takes place in the presence of hydroxide ions and Cd is oxidised to Cd2+. Cd(s) + 2OH-(aq) Cd(OH)2(s) + 2eThe positive nickel electrode (cathode), sees a reduction half reaction where Ni3+ in NiO(OH) is reduced to Ni2+ e- + NiO(OH)(s) + H2O(l) Ni(OH)2(s) + OH-(aq) Thus, the overall reaction will be: Cd(s) + 2NiO(OH)(s) + 2H2O(l) Cd(OH)2(s) + 2Ni(OH)2(s) Here, the oxidation state of Cadmium goes from 0 to +2. Nickel is reduced from +3 to +2. The reducing agent (Cd) and the oxidizing agent (NiO(OH)) are regenerated upon recharging: Cd(OH)2(s) + 2Ni(OH)2(s) Cd(s) + 2NiO(OH)(s) + 2H2O(l)

Lithium Batteries: Major Components: Some lithium batteries use similar cathode reactions seen in zinccarbon dry cells. Most commonly, liquid carbonate-based electrolytes are used in lithium batteries. Dry polymer, due to its ease of fabrication, good electrochemical stability, low flammability and toxicity, can be used in secondary lithium batteries. Major Characteristics: Most energetic rechargeable battery in the market. They are a lot lighter than other batteries of the same size as they are made of lightweight carbon and lithium. Lithium is very reactive thus allowing a greater capacity of energy to be stored within its atomic bonds. This gives high energy density for lithium-ion batteries. These batteries can be subject to infinite charge/discharge cycles. Applications: Laptops, PDA's, Cell phones, iPods etc. C.5.3. Discuss the similarities and differences between fuel cells and rechargeable batteries. Similarities: Both devices convert chemical energy directly into electrical energy using spontaneous redox reactions. Both have similar modes of operation, namely, negative anode electrodes where an oxidation half-reaction takes place and positive cathode electrodes where a reduction half reaction takes place. Differences: Fuel cells are energy conversion devices; rechargeable batteries are energy storage devices. Fuel cells require constant supply of reactants and produce electrical energy only as long as fuel is made available to the cell. Batteries have stored chemical energy in a closed system and produce power until stored chemicals are used up. Batteries need to be recharged which uses electrical energy to carry out the reverse reaction. Fuel cells do not need recharging. It can have a continuous supply of fuel providing longer operating life. Fuel cells are more expensive than rechargeable cells. C.6.1 Describe the meaning of the term liquid crystals. Liquid crystals are fluids that have physical properties (such as electrical, optical and elasticity) that are dependent on the molecular orientation relative to some fixed axis in the material, making them unique in their properties and uses. Examples of LCs are cell membranes (phospholipids), aqueous polymeric DNA solutions, some viruses such as the tobacco mosaic virus, the solution extruded by a spider to form silk threads, micelles such as soap solutions, colloidal solutions, graphite and cellulose etc.

Note: LCs might not always be in liquid phase, similar to how water is not always in liquid form. C.6.2. Distinguish between thermotropic and lyotropic LCs. Thermotropic LCs are pure substances that show LC behaviour over a certain temperature range between the solid and liquid states. At temperatures below the range, the substance forms a solid crystal; above the temperature, it turns into liquid phase. Biphenyl nitriles are common examples. Lyotropic LCs are solutions that show LC state at certain concentrations. Examples include soap and water. C.6.3. Describe the liquid crystal structure in terms of the arrangement of the molecules and explain thermotropic behaviour. (Nematic LCs) Nematic LCs occur after smectic LCs are further heated to disrupt the long-range positional order. Here, no layer arrangement exists. The rod-shaped molecules are distributed randomly, however, they usually point in the same direction. Increased thermal agitation disrupts this directional order until it is lost when the normal liquid phase is formed. C.6.4. Outline the principles of the liquid crystal display device. Polarizers allow light in which the electric field vibrates in only one direction to pass through. The ability for liquid crystal molecules to transmit light depends on the orientation of the molecules. The orientation of the polar molecules can be controlled by the application of a small voltage across a small film of the material. The areas of the display that are light and dark can thus be controlled. Liquid crystal displays are used in digital watches, calculators and laptops because of their small current requirements. C.6.5. Discuss the properties needed for a substance to be used in liquid crystal displays. Chemical stability: they do not decompose in the instruments. LC phase stable over a suitable range of temperatures: operational at room temperature and through a wide range of temperatures (-10 to 60 degrees Celsius) Polar in order to change orientation when an electric field is applied: they have dipoles and have poles or are easily polarizable. Rapid switching speed: switching speed does not allow for any lag between orientations.

C.7.1. Define the term nanotechnology. Nanotechnology involves research and technology development at the 1nm to 100nm range. Nanotechnology creates and uses structures that have novel properties because of their small size. Nanotechnology builds on the ability to control or manipulate atomic scale. ~ Booker, R and Boysen, E. 2005. Nanotechnology for Dummies C.7.2. Distinguish between physical and chemical techniques in manipulating atoms to form molecules. Physical Techniques: Scanning probe microscopes can move individual atoms one at a time, or allow the controlled deposition of single atomic or molecular layers one on top of the other. Metals can be vaporized and atomic layer deposition leads to nanoparticles when cooled. Chemical Techniques: Position atoms in molecules using chemical reactions. Voltages can be used to chemically bind atoms together. C.7.3. Describe the structure and properties of carbon nanotubes. Main cylinder of carbon nanotube (CNT) is made of rolled graphite along an axis consisting of carbon hexagon and closed at the ends with pentagons. Nanotubes are hollow cylinders made of carbon atoms and can be one atom thick or multi-walled carbon nanotubes consisting of concentric nanotubes with a smaller one in a larger one (Russian dolls). CNTs are structurally rigid and a lot stronger than steel. They also exhibit unique electrical properties and can act either as electrical conductors or semiconductors depending on the length and multi-walls present. The narrower the diameter of the tube, the less it behaves like graphite. As the diameter gets wider, the more its bulk properties are similar to those of graphite. C.7.4. Discuss some of the implications of nanotechnology. Possible applications: invisible sunscreen, bactericidal bandages, production of spillproof, water repellent and wrinkle free garments. Vaccines and drugs drugs can be targeted just to cancer cells in the correct dosage. Electronics can be made cheaper, more lightweight. Health and environment effects and concerns: Small size means that nanoparticles could be inhaled. Nanoparticles could be cancer causing. Toxicity concerns: Nanoparticles have altogether different properties than macro particles. Inert materials may become very reactive at the nano-scale, and the current

standards of toxicity for that substance may not apply, as it would be at the nano level and not the macro. Industries need to deal with harmful effects of nanotechnology responsibly and not abuse the laws. Ethical and political issues: there is need for public education, for informed debate and for public involvement in policy discussions. For nanotechnology to be beneficial for all will require a joint effort by government, industry, academia and business from around the world.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Final Estimation For Rate PreparationDocumento5 páginasFinal Estimation For Rate PreparationmanojAinda não há avaliações

- 1 Storage ProductsDocumento292 páginas1 Storage ProductsJon BlacAinda não há avaliações

- Loop Type 1 Mounting InstructionsDocumento8 páginasLoop Type 1 Mounting InstructionsDilon FernandoAinda não há avaliações

- Automated Controlled Shot Peening of Metallic Articles Prior To Nickel, Autocatalytic Nickel, or Chromium Plating, or As Final FinishDocumento9 páginasAutomated Controlled Shot Peening of Metallic Articles Prior To Nickel, Autocatalytic Nickel, or Chromium Plating, or As Final FinishDanZel DanAinda não há avaliações

- Complete Application Manual PDFDocumento101 páginasComplete Application Manual PDFNerinel CoronadoAinda não há avaliações

- Metalargy MCQDocumento12 páginasMetalargy MCQANANT CHAUBEYAinda não há avaliações

- UntitledDocumento16 páginasUntitledemir akbarAinda não há avaliações

- Chemistry Worksheet 5 IG I (1) MAKING USE OF METALSDocumento3 páginasChemistry Worksheet 5 IG I (1) MAKING USE OF METALSRaj MalkanAinda não há avaliações

- Machine Design 4Documento6 páginasMachine Design 4Paul AbonitaAinda não há avaliações

- ch11 PDFDocumento4 páginasch11 PDFLarasati FitriaAinda não há avaliações

- MM102 NotesDocumento7 páginasMM102 NotesHassan AliAinda não há avaliações

- Effects of Root Gap and Bevel AngelDocumento74 páginasEffects of Root Gap and Bevel AngeldaimaheshAinda não há avaliações

- Xtek Crane BrochureDocumento8 páginasXtek Crane BrochureBeniamine SarmientoAinda não há avaliações

- SMST-Tubes Product Range en 2010 WebDocumento16 páginasSMST-Tubes Product Range en 2010 Webalbejo_r9Ainda não há avaliações

- Cold GalvanizationDocumento9 páginasCold GalvanizationRathinavel SubramanianAinda não há avaliações

- Chemistry Answer KeyDocumento8 páginasChemistry Answer KeyNnaer Ortiz NasupmilacAinda não há avaliações

- CHG 308LDocumento1 páginaCHG 308LImmalatulhusnaAinda não há avaliações

- U-2 Sheet Metal OperationsDocumento72 páginasU-2 Sheet Metal Operationsapi-271354682Ainda não há avaliações

- Is - 1161 - Steel TubesDocumento8 páginasIs - 1161 - Steel TubesAsif Ali100% (1)

- ASTM A29 Standard Specification Steel Bars Carbon and Alloy Hot Wrought General RequirementsDocumento16 páginasASTM A29 Standard Specification Steel Bars Carbon and Alloy Hot Wrought General RequirementsAndrés Molina100% (2)

- Food Safety - Magnetic SeparatorsDocumento2 páginasFood Safety - Magnetic SeparatorsRenAinda não há avaliações

- Unit 2 Atomic Coatings - The Size of An Atom Lab 2006Documento2 páginasUnit 2 Atomic Coatings - The Size of An Atom Lab 2006Brett0% (1)

- Astm D 3182Documento8 páginasAstm D 3182Monalisa RodriguesAinda não há avaliações

- Induction Heating Lab ManualDocumento7 páginasInduction Heating Lab ManualAshish VermaAinda não há avaliações

- Chemistry - Chapter 9 Study GuideDocumento4 páginasChemistry - Chapter 9 Study GuideJohnHanaAinda não há avaliações

- Seleccion de Bombas NetzschDocumento47 páginasSeleccion de Bombas Netzschcarlangas77100% (1)

- Vibration Damping Materials Procedures for Installation, Maintenance, Repairs 减震材料的安装、维护和维修程序,Mil-std-2148Documento90 páginasVibration Damping Materials Procedures for Installation, Maintenance, Repairs 减震材料的安装、维护和维修程序,Mil-std-2148qingtaoAinda não há avaliações

- Rando HDZ 46Documento2 páginasRando HDZ 46Marcin MarcinkiewiczAinda não há avaliações

- Metallography: Standard Terminology Relating ToDocumento33 páginasMetallography: Standard Terminology Relating ToHassan MokhtarAinda não há avaliações

- The Piping GuideDocumento214 páginasThe Piping GuideMohamed RjebAinda não há avaliações