Escolar Documentos

Profissional Documentos

Cultura Documentos

ST7LP 9851 2599 01 D - tcm835-1532855

Enviado por

Luis Lillo GuerreroTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ST7LP 9851 2599 01 D - tcm835-1532855

Enviado por

Luis Lillo GuerreroDireitos autorais:

Formatos disponíveis

atlas Copco Underground loaders

Scooptram ST7lP

Technical specification

The low-prole Scooptram ST7LP is a robust LHD that is built for demanding low-seam applications where the back heights are as low as 1 600 mm. Features

Safe working environment

Spring applied, hydraulic released (SAHR) brakes Automatic brake-test with diagnostics and logging ISO ROPS/FOPS approved cabin, oil-free operators compartment and door interlock (applies brakes, blocks steering and bucket/boom movement when door opens) Operators visibility enhanced with the use of monitors - Cameras, forward and reverse mounted on the right side of the machine, provide good visibility in both tramming directions Increased leg-room with AC footbox Rubber mounted cab, reduced vibration level Ergonomic multi-function control joysticks Comfortable T-back seat Simple, clear and multi-function display with intuitive operator interface Fuel efficient, clean burning EPA Tier 3/EU Stage IIIA engine Rock tough catalytic purifier Proven powertrain components On board diagnostics give the operator a clear indication of the machine status Machine status indication lights, inform the machine status to personnel outside the operators cabin Load weighing system (optional) L&M V-tube Core radiator

Peak performance

Superior operators comfort

Load sensing variable displacement hydraulic pump for increased tractive effort and reduced fuel consumption Integrated de-clutch function, saves fuel and improves life of drivetrain components Traction control, improves loading performance, reduces tyre slip, improves the life of the tyres Easy access to service points, filters and valve blocks Atlas Copco Rig Control System (RCS) provides service information in clear text on the monitor Filter sensors with data collection for air, hydraulic and transmission filters Patented automatic lubrication system with low level warning and lube fault detection Quick and easy service resulting in more time for production All daily check points from ground level

Serviceability

Environmental

Reliability for enhanced productivity

Scooptram ST7LP

Specifications

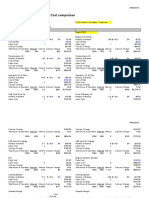

CapaCities

kg Tramming capacity* Breakout force, hydraulic Breakout force, mechanical 6 800 12 000 10 300 sec

Motion tiMes

sec Boom raising Boom lowering Dumping 3.7 2.8 3.7

Weights

Vehicle equipped with eoD bucket kg Approximate weight Axle load, front end Axle load, rear end 19 100 9 300 9 800

*Tramming capacity with EOD bucket 5 800 kg

Engine

Cummins diesel engine ... QSB6.7 EPA Tier 3/EU Stage IIIA Power rating at 2 200 rpm ............................ 144 kW/193 hp . Maximum torque at 1 400 rpm ................................. 931 Nm MSHA Part 7 ventilation: Ventilation rate ........................................... 241 m3/min Particulate index ......................................... 269 m3/min Dry type air cleaner Catalytic exhaust purifier and silencer Exhaust heat protection L&M V-tube Core radiator and charge air cooler

Operators compartment

Canopy ISO ROPS/FOPS Two point retractable seat belt Open door retainer External sound level according to ISO 6393 LwA 124,5 dB(A) Sound level in canopy according to ISO 6394 LpA 105 dB(A) Whole body vibration value according to below EN 14253 A(8)w maximum 0.55+/-0.2m/s

Hydraulic system

Heavy duty load sensing pump...............1 x Rexroth A10VO Hydraulic leakage detection system Steering soft stop System pressure.......................................................24.0 MPa Hydraulic tank capacity........................................... 111 litres Filtration, return line.....................................................12 m Electric pump for hydraulic tank fill (option) Cylinders; chrome plated stems, diameter: Steer cylinders (2)............................................. 80 mm Hoist cylinders (2)............................................110 mm Stabilizer cylinder.............................................140 mm

Transmission

Automatic power shift with integral converter, fully modulated 4 speed shifting, forward/reverse with de-clutch function Funk ............................................................................DF150 .

Axles

Spiral bevel differential, full floating, planetary wheel end drive Rock Tough.......................................................................406 Degree of rear axle oscillation...........................................14 Differentials: Front ................................................................ No spin Rear ..................................................................... Open

Control system

Logging of production data (number of buckets) Joystick controls for dump and hoist and steering Automatic and semi automatic transmission control Bucket float Operator display Brake test function with logging Engine and transmission diagnostics Radio Remote Control interface Machine status indicator light

Brakes

Fully enclosed, force cooled, multiple wet discs at each wheel end Service/parking/emergency brakes ..............................SAHR

Electrical system

24/12 V converter Isolation switch lockout Forward and reverse cameras Mine duty high output alternator............................140 Amps Driving lights halogen, H3 bulb: Rear lights........................................................6 x 70W Front lights.......................................................2 x 70W

Fuel

Fuel tank capacity ................................................... 190 litres Anti-siphon fuel supply Fuel filtration: Primary, including water trap.................................2m Secondary................................................................3m

Other

Boom up lock Central manual lubrication system Fire extinguisher Audio-visual reverse alarm

Tyres

Tubeless, smooth, tread design for underground mine service Tyre size ................................................17.5x25 20 ply L5S*

* As applications and conditions vary, Atlas Copco recommends that the user consults with tyre suppliers to obtain the optimum tyre selection

Scooptram ST7LP

Grade performance

graDe perforManCe - eMpty buCket

% ratio km/h grade grade 1st gear 2nd gear 3rd gear 4th gear 4.6 7.7 14.9 24.0 0.0 4,6 7.5 14.3 22.2 2.0 4.5 7.4 13.6 19.6 4.0 4.5 7.2 12.8 16.5 6.0 4.3 7.0 12.0 12.2 8.0 10.0 1:10 4.3 6.9 11.1 12.5 1:8 4.1 6.7 9.4 14.3 1:7 4.1 6.4 4.1 6.2 16.0 4.0 6.1 18.0 20.0 1:5 4.0 5.7 25.0 1:4 3.8 5.1

3% rolling resistance assumed. Actual performance may vary depending on the application graDe perforManCe - loaDeD buCket

% ratio km/h grade grade 1st gear 2nd gear 3rd gear 4th gear 4.3 7.2 14.0 22.2 0.0 4,3 7.0 13.1 19.3 2.0 4.1 6.9 12.2 15.6 4.0 4.1 6.7 11.1 6.0 4.0 6.4 9.8 8.0 10.0 1:10 4.0 6.2 8.3 12.5 1:8 3.8 5.9 14.3 1:7 3.8 5.6 3.8 5.3 16.0 3.7 4.9 18.0 20.0 1:5 3.5 4.6 25.0 1:4 3.3 3.5

3% rolling resistance assumed. Actual performance may vary depending on the application

Optional Equipment

System

Ansul manually actuated fire suppression with engine shut-down Ansul Checkfire, automatic actuation of fire suppression system Lincoln auto lube Wiggins fast fuel fill Atlas Copco Scooptram RRC (Line of sight - Radio Remote Control) Premium package including: - Auto lube with Lincoln pump - Steering soft stop - Load weighing (logging of production data, weight per bucket, number of buckets and accumulated payload CD/MP3 player

Power unit

Cold weather package 120V or 240V: - Block heater - Battery warmer - Fuel heater - Hydraulic oil heater - Transmission oil heater - Arctic oil DCL exhaust cleaning system Optional bucket sizes EOD buckets Wheel chocks and brackets Knockdown construction LinkOne parts catalogue, CD LinkOne reader Operator and maintenance manual - plasticized 1 000 hour consumables Face mechanics tool set Shop mechanics tool set Service tool box for RCS

Main Frame

Electrical System Hydraulic System

Documentation

Brake release retriever tow hook Steering soft stop Electric pump for hydraulic tank fill Blockout 3rd and 4th gears Production logging Maintenance logging Brake apply after 3 sec in neutral Load weighing system 17.5R25 X-Mine D2 (lugged)

Parts Kit Other

Controls and Instruments

Tyres

Scooptram ST7LP

Measurements

Dimensions

42.5 2 970 3 640

All dimensions are shown in millimetres All dimensions and calculations shown are based on standard vehicle configuration with 27 mm tyre deflection, unloaded

Copyright 2010, Atlas Copco Rock Drills AB, rebro, Sweden. All product names in this publication are trademarks of Atlas Copco. Any unauthorized use or copying of the contents or any part thereof is prohibited. Illustrations and photos in this brochure may show equipment with optional extras. No warranty is made regarding specifications or otherwise. Specifications and equipment are subject to change without notice. Consult your Atlas Copco Customer Center for specific information.

R2 34 0

R5

780

3 460 4 130

2 000x45

RIGHT anD lEFT TuRn

2 060

2 320

2 500

14

660

290 1 380 1 430 1 470 2 880 29

2 610

SIDE VIEw

1 650 8 470

1 410

T1 2 800

2 660

1 920

1 700

TOP VIEw

* For sizing of buckets and boxes, please consult your local Customer Center

buCket Data*

Volume, nominal heaped (m3) Maximum material density (t/m3) Width, bucket (mm) tramming position: axle centreline to bucket lip (mm) tramming position: ground to bucket tip (mm) reach (mm) raised position: max height (mm) raised position: bucket tip, height (mm)

T1 T2 L1 H1 H2

2 200

640

H2 1 350 T2 1 400

1 390

eoD 3.8 1.8

-

3.4 2.0

-

2.7 2.2

2 200 2 800 1 400

2 680

45

3 780

2.8 2.4

-

H1 3 920

-

3 920 1 350

9851 2599 01 d 08/2010

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Uei Catalog v13 WebDocumento48 páginasUei Catalog v13 WebrockymadhuAinda não há avaliações

- Visual InspectionDocumento20 páginasVisual InspectionKrishnamoorthi Venkatesan100% (2)

- Catalogue Fire 0163ENDocumento52 páginasCatalogue Fire 0163ENDanny M Hurtado TaypeAinda não há avaliações

- CBLM Final1Documento115 páginasCBLM Final1Victor Rosales89% (72)

- 1 Huawei 3g Capacity OptimizationDocumento25 páginas1 Huawei 3g Capacity OptimizationCharles W Gitahi100% (1)

- Comitrol Processor Model 1700: Versatile Size ReductionDocumento2 páginasComitrol Processor Model 1700: Versatile Size Reductionthaihoangminh93Ainda não há avaliações

- Serviwrap Outerwrap Data SheetDocumento1 páginaServiwrap Outerwrap Data SheetAdam HarikaAinda não há avaliações

- Multikwik Specification Guide March 2016 Website Version PDFDocumento48 páginasMultikwik Specification Guide March 2016 Website Version PDFNisar Ahmed AnsariAinda não há avaliações

- Inovance SveDocumento202 páginasInovance SveDragan LugonićAinda não há avaliações

- Cisco Cli Command ListDocumento313 páginasCisco Cli Command Listghbeo592365y83hgselo100% (1)

- HP ProBook 4720s Wistron Laptop SchematicsDocumento62 páginasHP ProBook 4720s Wistron Laptop SchematicsjoaquinmjuanAinda não há avaliações

- Dell Latitude D610 Free Laptop SchematicDocumento50 páginasDell Latitude D610 Free Laptop SchematicSalus VitalAinda não há avaliações

- Costo de Mantenimiento Retroexcavadora CAT Vs John DeereDocumento9 páginasCosto de Mantenimiento Retroexcavadora CAT Vs John DeereLuis Llanos Llanos Sanchez100% (1)

- ConfigurationData 2020 06 16 12 17 09Documento4.077 páginasConfigurationData 2020 06 16 12 17 09Anonymous oLo6cDDAinda não há avaliações

- Science Fair GuideDocumento4 páginasScience Fair Guideapi-94846453Ainda não há avaliações

- Demantra Performance TuningDocumento4 páginasDemantra Performance TuningchandanjeeAinda não há avaliações

- Ieee C37.42Documento42 páginasIeee C37.42NataGBAinda não há avaliações

- RLG PDFDocumento62 páginasRLG PDFVanessa ArceAinda não há avaliações

- Source CodeDocumento24 páginasSource CodeMr. PerfectAinda não há avaliações

- 1 5736Documento2 páginas1 5736solidwormAinda não há avaliações

- Management ReviewDocumento17 páginasManagement ReviewRamesh Acharya100% (4)

- Manual Ceberus EcoDocumento60 páginasManual Ceberus EcoAad Pupu SaputraAinda não há avaliações

- Symantec Network Security Administration GuideDocumento432 páginasSymantec Network Security Administration GuideTibor CsizovszkyAinda não há avaliações

- Moja TV Live StreamsDocumento3 páginasMoja TV Live StreamsAmina MujčinovićAinda não há avaliações

- GIMP Tutorial PDFDocumento29 páginasGIMP Tutorial PDFAlexandre PereiraAinda não há avaliações

- Behn MeyerDocumento4 páginasBehn MeyerSomnath Mangaraj0% (1)

- H12-711 huawei exam questionsDocumento28 páginasH12-711 huawei exam questionsdeltakio@gmail.comAinda não há avaliações

- Technical Schedule: Section - Vi-EDocumento7 páginasTechnical Schedule: Section - Vi-EAnonymous 7ZYHilDAinda não há avaliações

- OSN 1800 II Packet V100R006C10 Hardware Description 02Documento784 páginasOSN 1800 II Packet V100R006C10 Hardware Description 02Niazul KarimAinda não há avaliações