Escolar Documentos

Profissional Documentos

Cultura Documentos

Main Tracks and Objectives of The WING COMPOSITES Program

Enviado por

nlrlibraryDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Main Tracks and Objectives of The WING COMPOSITES Program

Enviado por

nlrlibraryDireitos autorais:

Formatos disponíveis

UNCLASSIFIED

Nationaal Lucht- en Ruimtevaartlaboratorium National Aerospace Laboratory NLR

Executive summary

Main tracks and objectives of the WING COMPOSITES Program

Report no. NLR-TP-2009-251 Author(s) B.J.G. Eussen M.H.L. Hounjet J. van Muijden B.B. Prananta Report classification UNCLASSIFIED Date September 2009 Knowledge area(s) Aro-elasticiteit & Vliegtuigbelastingen Computational Physics & Theoretische Arodynamica Computational Mechanics & Simulation Technology Vliegtuigmaterialen Testen van vliegtuigconstructies en -materialen Descriptor(s) Aeroelasticity Structural Dynamics F-16 Composites

Problem area The main objective of the project described in this paper is the buildup of capability to operate military platforms that utilize composite materials in their primary structures. The use of composites has increased over the last decades and is used in UAVs and helicopters, expected soon in the inventory of the Dutch armed forces, as well as in their future fighter aircraft. The capability to judge the impact these composites and their derived structures will have for the platforms on airworthiness, certification & qualification, performance, stability & control, maintenance and platform life span & fatigue life has never been developed before in The

Netherlands. This is however an important capability for the armed forces to be able to operate as smart specifier and smart buyer and to successfully introduce new platforms and become a smart maintainer. Description of work This report describes an overview of the project. In the project the capability buildup is achieved through a theoretical design study using the existing operational F-16MLU as flown by the RNLAF. The design study is completed with a virtual (mini) DT&E. No physical hardware is developed. In the available theoretical models of the F-16 the existing and well-known wing skin

This report is based on a presentation held at the International Forum on Aeroelasticity and Structural Dynamics IFASD-2009, Seattle, U.S.A., 21-25 June 2009. UNCLASSIFIED

UNCLASSIFIED

Main tracks and objectives of the WING COMPOSITES Program

structure is replaced by an in-house designed composite skin structure, while leaving the inside metal structure intact. Static and dynamic performance analyses under operational conditions are performed using the newly developed models of the F16 with the hybrid metal composite wing structure. Spin-off is the improvement of the structurally dynamic modeling of the current F16 fleet of the RNLAF. The feasibility of the F-16 for this study is emphasized by the already successfully operated Mitsubishi F-2, having a metal composite wing structure. Apart from a technical capability built-up, an important part of the project is a simultaneous increase of national and international awareness in the areas of structural dynamics, materials and aeroelasticity by employing the in-house technical capability builtup. Dutch armed forces will be positioned more favorably in future acquisition of new, or updates of existing, materiel. Results and conclusions This program has shown that the operational support as traditionally given for F-16 can be continued at the same smart level in the future for modern fighter aircraft, using our inhouse structural dynamic/aeroelastic toolbox,

with customer combined workforces expertise. New structural concepts are identified and analyzed. Methods and models to model the dynamic behavior with adequate resolution have become available. The impact of hybrid metalcomposite primary structure on platform properties such as airworthiness and qualification, performances, stability and control, maintenance and structural integrity has been assessed. The acquired capability build-up acts as a catalyst to identify unknown or hidden operational bottlenecks for future fighter technology and operations.

Direct Applicability The developed detailed F-16 models can be used to reliably identify expensive operational configurations and can prevent the premature loss of operational aircraft. Future Applicability The results of the Netherlands Wing Composites Program will be used in future programs concerning operational bottlenecks in power and heat management for high performance platforms with (super) insulated hybrid metal-composite structures.

Nationaal Lucht- en Ruimtevaartlaboratorium, National Aerospace Laboratory NLR Anthony Fokkerweg 2, 1059 CM Amsterdam, P.O. Box 90502, 1006 BM Amsterdam, The Netherlands Telephone +31 20 511 31 13, Fax +31 20 511 32 10, Web site: www.nlr.nl

UNCLASSIFIED

Nationaal Lucht- en Ruimtevaartlaboratorium National Aerospace Laboratory NLR

NLR-TP-2009-251

Main tracks and objectives of the WING COMPOSITES Program

B.J.G. Eussen, M.H.L. Hounjet, J. van Muijden and B.B. Prananta

This report is based on a presentation held at the International Forum on Aeroelasticity and Structural Dynamics IFASD-2009, Seattle, U.S.A., 21-25 June 2009. The contents of this report may be cited on condition that full credit is given to NLR and the authors. This publication has been refereed by the Advisory Committee AEROSPACE VEHICLES. Customer Contract number Owner Division NLR Distribution Classification of title Approved by:

Author Reviewer Managing department

NLR ---NLR Aerospace Vehicles Unlimited Unclassified September 2009

NLR-TP-2009-251

Summary

The present paper gives an overview of the objectives and technical activities of the National Technology Program (NTP) Wing Composites Research Program. The main objective is the creation of new knowledge and capabilities in the Netherlands to support the operation of military air vehicles with primary structure of composite materials. This new knowledge and capabilities will be first used to support the Netherlands Defense Materiel Organization / RNLAF in the near future to act as smart buyer and specifier of a successor of the F-16. Later, as smart operator of the successor of the F-16 fighter aircraft, this knowledge and capabilities are of utmost importance to avoid unrecoverable situations. To obtain the new knowledge and capabilities mentioned, exploratory research based on theoretical studies has been conducted at the National Aerospace Laboratory NLR in the past three years. This exploratory research is dealing with many aspects, ranging from material issues up to aero-elastic and performance issues. A pilot study (or virtual mini DT&E) has been conducted to investigate the feasibility of replacing the current metallic wing of the F-16 fighter aircraft with a hybrid metal-composite structure. In this hybrid metal-composite concept the wing skin is replaced with a composite skin while the underlying wing spars and ribs are maintained in original form and material. The hybrid metal-composite wing is designed to match the metal wing with respect to primary characteristics, and to improve the flutter/LCO behavior slightly. Many aspects have been explored. The design goals have been met. Novel tools and models have been developed. The flutter speed of the new wing is 50% higher for a heavy store configuration.

NLR-TP-2009-251

Contents

1 2 3 4 5 6

Introduction Objectives Netherlands Wing Composites Program Structure Technical Program Flow Structural wing concept Static and dynamic Finite Element Modeling of the hybrid metalcomposite wing

5 5 7 8 10

10 12 13 14 15 17 17 18

7 8 9 10 11 12

Static Finite Element Model verification Dynamic Analysis Capability Build-up Conclusions Future Work Acknowledgements

References

NLR-TP-2009-251

Abbreviations

CFRP CVS DT&E FE LCO MLA MoD MOC MORSA MTC NASTRAN POD RNLAF Carbon Fibre Reinforced Plastics Concurrent Versions System Developmental Test & Evaluation Finite Element Limit Cycle Oscillation Military Airworthiness Certification Office Ministry of Defense Means of Compliance Model Order Reduction for Aerospace Structural Applications Military Type Certificate NASA STRuctural ANalysis software Proper Orthogonal Decomposition Royal Netherlands Air Force

NLR-TP-2009-251

1 Introduction

The presentation describes a National Technology Project (NTP) of the Netherlands aiming at building up new technology for the application of composite material for primary structures of military platforms. Composite material is more and more applied in primary structures of next generation fighters, unmanned aircraft and helicopters, but also in land, marine and space vehicles. Obtaining knowledge on the impact of composite primary structures on platform properties such as airworthiness & qualification, performance, stability & control, maintenance & structural integrity is important for the Dutch armed forces as a smart specifier, a smart buyer and smart operator. It is also important to introduce new military platforms successfully without too many recoveries, and to support the definition of requirements for the acquisition of a military type certificate (MTC) of new military platforms by military aviation boards (e.g. MLA). New technology has been obtained by means of a theoretical study, using the F-16 aircraft as study object. It is not the intention of the Netherlands Wing Composites Program to build a test article and no hardware is devised. The existing and well-known F-16 wing structure is replaced in the available theoretical models by a hybrid metal-composite structure. This structure was designed to match the existing design performance-wise. As a consequence, a provision is made in the theoretical models to deal with the new structure. With the adapted theoretical models, static and dynamic analyses of the hybrid metal-composite wing structure under operational conditions are carried out and assessed. The activities which have lead to new models and technology are further described in the following chapters. The feasibility of the F-16 as object of the study in the Netherlands Wing Composites Program is based on the already flying and operated Mitsubishi F-2 in Japan, of which primary structures are carried out in composite material, Ref [1]-[2].

2 Objectives

The Netherlands Wing Composites Program deals with the development and evaluation of a hybrid metalcomposite wing capable of matching the performance of the metal F-16 wing. The aim is to conduct the design of the hybrid metalcomposite wing, to develop new theoretical models and establish an international network which will induce: Development of enhanced technology to support F-16 operations in the Netherlands. Establishment of links with other Dutch research programs on Airworthiness, Certification and Qualification (LCK), Maintenance and Structural Integrity (O&L) and Structures and Materials (C&M).

NLR-TP-2009-251

Development of new knowledge on modern structures. Enhancement of smart customer / smart buyer / smart operator role. Initiation of the technology development needed to reach a sufficiently high Technology Readiness Level at the introduction of the F-16 successor. Affirmation and/or adaptation of the airworthiness requirements and their Means or Compliance (MOC) for the examined composite structures. Support of the military aviation authority (MLA) regarding the Military Type Certificate (MTC) for the F-16 successor, in which the examined composite structures are likely to appear.

Support of the Military Airworthiness Certification Office (MLA) in defining MTC/MOC for the F-16 successor. Better chances of obtaining technical information from OEMs. Establishment of international contacts in the field of structural dynamics and aeroelasticity, in association with the MoD, to improve the rate of technology maturation towards the state-of-art.

Improvement of the structurally dynamic modeling of the current F-16 fleet of the Netherlands. Realization of the direct link in the long term between the application of the new composite material in primary structures and the consequences on the use of the platform (Ref[3]).

Further, the innovative character of the outcome of the Netherlands Wing Composites Program should be mentioned: New structural concepts are identified and analyzed in detail. Methods and models to model the dynamic behavior with adequate resolution have been made available. The impact of hybrid metal-composite primary structure on platform properties such as airworthiness and qualification, performances, stability and control, maintenance and structural integrity has been assessed. The acquired capability build-up acts as a catalyst to identify new operational

bottlenecks for future fighter technology and operations.

The Netherlands Wing Composites Program of the MoD is conducted at NLR, within a multidisciplinary team of specialists. The three and a half year project will end in July 2011, delivering a unique platform on which to develop and test new wing structural designs. This unique platform will create a direct link between fighter developments and operators thus optimizing the flow of state-of-the-art fighter design at the MoD. At the end of this collaborative research there will be a significant improvement in the design and analysis tools available in the Netherlands. The Netherlands Wing Composites Program leans on already

NLR-TP-2009-251

present experience at the MoD and the NLR, developed in previous programs and projects, see for instance ref. [4].

3 Netherlands Wing Composites Program Structure

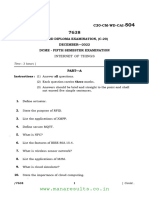

The structure of the Netherlands Wing Composites Program is depicted in figure 1. The research approach is based on a logical definition of the various phases, each phase having clearly defined objectives. The program consists of two major activities being Capability Buildup and Technical Execution. The work conducted in the Technical Execution has a multidisciplinary nature, and uses the F-16 fighter as study object. The Technical Execution is divided into four work packages: a. b. c. d. WP1: Concept WP2: Modeling WP3: Model Verification WP4: Dynamic Analysis

The activities in these work packages can be considered as projects on their own. The project management and the Capability Build-up are together making up work package 5 (WP5). The paper will describe the Capability Build-up activities and the relation between the Capability Build-up activities and the Technical Execution. The associated results from these interactions are presented.

Figure 1 NTP Wing Composites Program Structure

Figure 2 NTP Wing Composites Technical Program Flow

NLR-TP-2009-251

4 Technical Program Flow

Flow diagrams of the technical activities in the Technical Execution of the program are depicted in figure 2. This figure shows the relation between the activities in the four work packages. Five accompanying papers describe in detail major technical activities in the Netherlands Wing Composites Program as follows: Structural wing concept (WP1): see ref[5], Static and dynamic Finite Element Modeling of the hybrid metalcomposite wing (WP2): ref[6] and ref[7], Static Finite Element Model verification (WP3): ref[8], Dynamic analysis (WP4): ref[9].

In this paper the objectives and interrelation of the work packages and the according activities are described. Furthermore this paper acts as a roadmap to describe the interactions of the work packages within the technical program flow. The relation between the work packages is reflected in figure 3-8. The process starts with the development of a hybrid metalcomposite wing concept in work package 1, see figure 3. Next, static and dynamic Finite Element Modeling of the hybrid metalcomposite wing is carried out in work package 2, see figure 4-6. This is followed by model checking in work package 3, see figure 7. In this work package, the static criteria for the F-16 operated in the Netherlands are applied on the model developed in work package 2. If these static criteria are violated, a feedback (1) process is activated and the modeling of material characteristics is adapted. This process is repeated until the static criteria are satisfied. When the process does not convergence a feedback (2) process is activated to the development of a new wing concept. When the process has converged on the static criteria, dynamic analyses are conducted in the last work package, see figure 8. In this work package, the model of the F-16 with a hybrid metalcomposite wing is reviewed to a set of dynamic criteria of the F-16 operated in the Netherlands. At this stage the program ends. If the dynamic criteria are violated no feedback process is activated. Next, the work packages are described in detail and separately.

NLR-TP-2009-251

Figure 3 Structural wing concept (WP1)

Figure 4 Modelling roadmap (WP2)

Figure 5 Modelling PART I (WP2)

Figure 6 Modelling PART II (WP2)

Figure 7 Model Verification (WP3)

Figure 8 Dynamic Analyses (WP4)

NLR-TP-2009-251

5 Structural wing concept

Work package 1 is the starting point for development of a hybrid metal-composite wing of a modern fighter. In this work package several composite structural wing concepts are investigated and the materials and structural details are defined including finite elements models. Based on simple hand calculations and basic design rules for composites, a conceptual design of an F-16 aircraft with CFRP wing skins is realised. Although skin thicknesses in the conceptual design are increased by 30-40%, the total mass of the composite design is still 25% lower than the original metal wing. The increased wing thickness has no significant effect on the aerodynamic performance for the operational conditions studied. Preliminary aero-elastic analysis indicates that the lower mass combined with application of a soft lay-up in the outer wing skin and a hard lay-up in the inner wing skin resulted in improved flutter speed. FE analyses show that the design is capable of fulfilling most (if not all) strength and stiffness requirements for the wing, such that a feasible design has been obtained. It is noticed that the low far-field strains in the conceptual design allow for some design optimisation. A design with 100% of the original thicknesses of the outer wing section and 80% of the original thicknesses of the inner wing section is selected for all future analyses. The design forms the starting point for the evaluation of the short-term and long-term aero-elastic and structural dynamic performance of the composite wing compared to the conventional metallic design. It is expected that the higher torsional stiffness and more or less equivalent bending stiffness compared to the metallic wing will result in lower LCO sensitivity of the composite wing design. Finally, it is noted that thermal stresses have not been considered in the concept phase. The large temperature range combined with the difference in coefficients of thermal expansion for the metallic substructure and composite skins may lead to significant additional stresses in both skins and metallic substructure. Especially the lower temperatures are of interest, because they lead to tensile stresses in the metal possibly affecting the fatigue life.

6 Static and dynamic Finite Element Modeling of the hybrid

metalcomposite wing

Work package 2 (see figure 4) consists of two parts, in which the output of part I (see figure 5) acts as the input to part II (see figure 6). Part I is a stand-alone project, that is no part of the overall feedback process, necessary for the design optimization of a hybrid metal-composite wing model for the F-16.

10

NLR-TP-2009-251

The aim of part I is to develop a structural dynamic model with adequate resolution of the current F-16. To this end two existing models, a NASTRAN stress model (cgFEM) and a NASTRAN flutter model (flutFEM), are combined with masses into a new model designated dyn-cgFEM. The advantage of this dynamic model is adequate structural resolution while retaining the proper dynamic behavior of the NASTRAN flutter model flutFEM. This dynamic model with adequate structural resolution serves as an input for part II of the modelling process. Adequate structural resolution makes it possible to replace components (skin panels). Within this dynamic model with adequate structural resolution the existing components are replaced by other new components defined in Work package 1. The result is a dynamic model with adequate structural resolution of an existing F-16 with a hybrid wing, designated as dynCcgFEM. Subsequently, model reduction is applied to the new dyn(C)cgFEM for reasons of turn-around time for dynamic analyses, and for reasons of growth potential. Feedback from static Finite Element Model verification activities conducted in Workpackage 3 is obtained. The following important activities were covered: Inventory of the available mass data of the selected RNLAF F-16 aircraft, and a systematic combination of this data to construct reliable mass data. Development of methods to introduce a mass model in the original NASTRAN stress cgFEM finite element model, based on reliable mass data. Development of two methods for transferring concentrated mass data from one model into another model: the mass warping method and the neutral interface method. Construction of a dynamic Finite Element Model with adequate structural resolution dyncgFEM of the existing F-16. Successful static Finite Element Model verification and validation of dyn-cgFEM using both Seek-Eagle test data of a F-16 wing box and the NASTRAN flutter model flutFEM. Successful structural dynamic model verification and validation, based on normal mode analysis and aero-elastic analysis. A study to select a robust and accurate model reduction method. Modern structural designs are based on Finite Element Models that are large having a growing number of degrees-offreedom in the computational models. A study is conducted concerning model reduction methods to reduce the number of degrees-of-freedom of structural dynamic models. Such models are used in the design and certification of structural modifications of the F-16 aircraft of the RNLAF. Several criteria on model reduction methods are developed and evaluated to ensure that the reduced model still contains the characteristics of the dynamic model with adequate structural resolution dyn-cgFEM. This is essential for subsequent aeroelastic analysis. Three methods have been selected for evaluation, namely the Krylov

11

NLR-TP-2009-251

method, the generalized coordinate reduction, and the proper orthogonal decomposition (POD) method. The Model Order Reduction for Aerospace Structural Applications (MORSA) tool was created. Development of the dynamic model with adequate resolution of an existing F-16 with a hybrid composite wing designated as dynCcgFEM. A restricted temperature analysis of the hybrid composite wing. Special attention was given to the attachment of the composite wing skin to the interior structure and the wing attachment to the fuselage. Some highlights of the outcome of the activities are as follows: The inventory of the available mass data of the selected RLNAF F-16 aircraft, and the systematic combination of this data to construct reliable mass data. The mass of the dynamic model with adequate structural resolution dyn-cgFEM is within 6 from the target mass of the selected RNLAF aircraft. Almost the same applies to the center of gravity location. A better match cannot be achieved. Normal mode analyses using NASTRAN can be carried out in a reasonable turn-around time of about 2 hours on a desktop computer. Verification and validation test cases are carried out using a comprehensive set of Lockheed Martin data. Sufficient engineering agreement is obtained. The MORSA tool can be used as a black-box method up to fairly large numbers of degreesof-freedom. For large numbers of degrees of freedom user intervention is required to obtain correct results. It may be concluded that the dynamic model with adequate structural resolution dyn-cgFEM has been successfully developed. It is ready for application in further static and structural dynamics analysis and can be viewed as the baseline model for future F-16 updates and modifications. From this model dynCcgFEM has been successfully developed.

7 Static Finite Element Model verification

In work package 3, the static performance of the new designs is assessed and feedback is provided to the structural wing concept (WP1) and static and dynamic Finite Element Modeling of the hybrid metalcomposite wing (WP2). Different versions of a hybrid metal composite wing of an F-16 aircraft, in which the metal skin of the torsion box is replaced with a composite skin consisting of fiber-reinforced plastics, are examined on their static aero-elastic properties by means of high-fidelity FEM and CFD models. Aerodynamic coefficients, spanwise loads and

12

NLR-TP-2009-251

the consequences for operational performance are compared with those of the baseline metal wing. Operational performance is assessed on the basis of turn performance diagrams (dog house plots) and flight envelopes, derived from calculated aerodynamic coefficients obtained from static aero-elastic simulations. The static aero-elastic simulations in this study are conducted in an innovative way, by coupling the aerodynamic flow solver directly with the dynamic Finite Element Model with adequate structural resolution dyn-cgFEM. In order to reduce the effort required for coupling, the concept of a neutral interface is used. The neutral interface allows the lumping of the aerodynamic loads to a limited set of characteristic interface points. It also allows for the redistribution of loads from the interface points onto the force nodes of the finite element model. Similarly, the deformations are transferred from the finite element model to the aerodynamic surface mesh using the neutral interface. Highlights of the outcome of the activities are: Despite changes in material properties, it is found that within the investigated envelope the performance of the aircraft with a hybrid metalcomposite wing remains almost identical to the baseline aircraft. Some minor operational performance benefits are achieved due to weight savings in the hybrid metalcomposite wing versions. All hybrid metalcomposite wing versions under consideration are found to be less flexible than the baseline wing. Therefore, control surface reversal is not deemed to be an issue for the current hybrid wing designs. Based on the static aero-elastic results obtained, it can be concluded that the three hybrid metal composite wing designs comply with the strength and deformation requirements that apply in static conditions. In view of stress and strain analysis, the hybrid 100-80 wing seems most appropriate for further investigations, comprising local structural optimization at critical locations and investigating its dynamic aero-elastic behavior.

8 Dynamic Analysis

In Work Package 4 the implications of a hybrid metalcomposite wing on the dynamic behavior are studied with the emphasis on heavy store configurations. Attention is given to dynamic criteria, performance, flutter, LCO, handling & ride qualities, FCS, loads & fatigue for a limited number of critical control points and loads cases. Flutter analyses are performed for the selected RLNAF F-16 aircraft and the aircraft with a hybrid metalcomposite wing in a heavy store

13

NLR-TP-2009-251

configuration, both based on the dynamic model with adequate structural resolution dyn-cgFEM with one million of Degrees-Of-Freedom. Highlights of the outcome of the activities are: The flutter analysis of the metallic wing based on the dynamic model with adequate structural resolution dyn-cgFEM compares favorably to standard results using the NASTRAN flutter model flutFEM. The replacement of the metallic skin with the composite skin leads to a 50% higher flutter speed, caused by a further separation of vibration modes responsible of flutter compared to the metallic wing. The best flutter property is exhibited by the hybrid metal-composite wing variant with a weakening in the inner part of the wing.

9 Capability Build-up

Apart from the coordination of the technical activities of the project between specialists of different disciplines and the project management, work package 5 (WP5) contains the realization of the Capability Build-up, see figure 1. This is illustrated by the integration of the results of the technical activities with the establishment and coordination of national and international networks and the gaining of relevant knowledge and experience available in- and outside the Netherlands. National and international networks are initiated by experienced technical specialists with extended track records in their fields and established and continued through the exchange of the results from the technical work packages. Initiating, establishing and extending these networks is an important activity and spin-off of the Netherlands Wing Composites Program, in association with the MoD, to improve the rate of technology maturation towards state-of-the-art. Combination and recombination of results from technical activities with (inter)nationally collected knowledge and experience creates a window and opens doors into hidden operational challenges for future platforms.

14

NLR-TP-2009-251

Figure 9 Technical activities

10

Conclusions

The present paper gives an overview of the objectives and technical activities (see also figure 9) of the Netherlands Wing Composites Program, aimed at building-up new knowledge in the Netherlands on the operational consequences of military air vehicles with composite primary structures. This program has shown that the operational support as traditionally given for F-16 can be continued at the same smart level in the future for modern fighter aircraft, using our in-house structural dynamic/aeroelastic toolbox, with customer combined workforces expertise. The outcome of the Wing Composites Program has been reflected in the following tracks: 1. New structural concepts are identified and analyzed in detail: Foreign experience confirms that a hybrid composite wing structure is preferred over a

15

NLR-TP-2009-251

full composite wing structure for fighters. 2. A theoretically LCO-free high performance fighter wing is feasible using hybrid metalcomposite structures. Methods and models to model the dynamic behavior with adequate resolution have been made available: The developed detailed F-16 models can be used to reliably identify expensive operational configurations and can prevent the premature loss of operational aircraft. These models and the experience gained through these models enable the operator to more safely operate in the final stages of the remaining airframe life-time (to lower the edge of the bathtub curve). 3. To safeguard technology an automated F-16 model configuration generator to record all developmental steps along a genealogical tree will be implemented using CVS. The impact of hybrid metal-composite primary structure on platform properties such as airworthiness and qualification, performances, stability and control, maintenance and structural integrity has been assessed: Hybrid metal-composite structures pose challenges, due to non-uniform use of material, far beyond those gained during 70 years of operational experience with uniform full metal airplanes with respect to temperature induced fatigue, affecting lifecycle predictions. 4. The acquired capability build-up has already acted as a catalyst to identify a probable operational bottleneck for future fighter technology and operations: The robust management of limited electrical power and limited cooling capacity give rise to operational handicaps (envelope restrictions) in the near future for high performance platforms making extensive use of (super) insulating hybrid metalcomposite structures. The stealthy character of modern fighters amplifies the afore-mentioned handicap.

The acquired knowledge on the impact of composite primary structures on platform properties such as airworthiness and qualification, performance, stability and control, maintenance and structural integrity is important for the Dutch armed forces as smart specifier, smart buyer, smart operator and smart maintainer. It is important for the successful introduction of new military platforms.

16

NLR-TP-2009-251

11

Future Work

The Netherlands Wing Composites Program will continue for another year. Therefore work is still continuing on dynamic analyses. Assessment of the impact of composite primary structure on LCO and maneuver simulations, life-cycle fatigue and dynamic load analyses is ongoing. The results of the Netherlands Wing Composites Program will be used in future programs concerning operational bottlenecks in power and heat management for platforms with hybrid metal-composite structures.

12

Acknowledgements

The work presented in this paper is partly funded by the Netherlands Ministry of Defence through the NTP WING COMPOSITES project; contract number NTP 06/19 and partly by the NLR within the research program Kennis voor Beleid. The contributions of many NLR colleagues to this project and the valuable guidance of the project supervisors from the Royal Netherlands Air Force are gratefully acknowledged.

17

NLR-TP-2009-251

References

[1] Kageyama, Masami and Yoshida, Sinichi, Development of co-cured composite structures for XF-2 fighters (abstract), AIAA-2000-1372, 41st SDM, Atlanta, GA, April 2000. [2] Kageyama, Masami and Yoshida, Sinichi, Development of XF-2 fighter composite structures (cocured composite wings), AIAA-2000-1372, 41st SDM, Atlanta, GA, April 2000. [3] Anderson, William D. and Mortara, Sean, F-22 Aeroelastic Design and Test Validation, AIAA-2007-1764, 48st SDM, Honolulu, Hawaii, April 2007. [4] Eussen B.J.G. and Hounjet M.H.L., Loads analysis methods for manoeuvring fighter type aircraft, RTO-AVT-154-14, Loen, Norway, April 2008. [5] Creemers, R.J.C., Botma, J. and Eussen, B.J.G., Conceptual design for the retrofit of the metallic skin of a fighter type wing by a composite skin, IFASD2009, Seattle, paper 017, also available as NLR-TP-2009-231. [6] Kos, J., Maas, R., Prananta, B.B., Hounjet, M.H.L. and Eussen, B.J.G., Structural Dynamics Model reduction and aeroelastic application to fighter aircraft, IFASD2009, Seattle, paper 069, also available as NLR-TP-2009-229. [7] Tongeren, J.H. van, Prananta, B.B., Hounjet, M.H.L. and Eussen, B.J.G., Development of a fighter aircraft aeroelastic model based on an existing global-stress FEM model, IFASD2009, Seattle, paper 036, also available as NLR-TP-2009-?. [8] Muijden, J. van, Hounjet, M.H.L., Prananta, B.B. and Eussen, B.J.G., Impact of a hybrid metal-composite wing retrofit of a current fighter aircraft on static loads and performance, IFASD2009, Seattle, paper 112, also available as NLR-TP-2009-218. [9] Prananta, B.B., Hounjet, M.H.L. and Eussen, B.J.G., Flutter analyses of fighter aircraft with metallic and hybrid metal-composite wings, IFASD2009, Seattle, paper 037, also available as NLR-TP-2009-222.

18

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Learning Curve - Interpreting The Results of Four Years of Safety Culture Surveys.Documento8 páginasLearning Curve - Interpreting The Results of Four Years of Safety Culture Surveys.nlrlibraryAinda não há avaliações

- AFM April2020-FullIssue REV2 PDFDocumento59 páginasAFM April2020-FullIssue REV2 PDFnlrlibraryAinda não há avaliações

- Streamlining Cross-Organisation Product Design in AeronauticsDocumento30 páginasStreamlining Cross-Organisation Product Design in AeronauticsnlrlibraryAinda não há avaliações

- Integration of Remotely Piloted Aircraft Systems in European AirspaceDocumento32 páginasIntegration of Remotely Piloted Aircraft Systems in European AirspacenlrlibraryAinda não há avaliações

- Low-Frequency Closed-Form Expressions For Crosstalk Between Twisted Wire PairsDocumento16 páginasLow-Frequency Closed-Form Expressions For Crosstalk Between Twisted Wire PairsnlrlibraryAinda não há avaliações

- Modelling and Simulation of Particle Upwash During Helicopter LandingDocumento26 páginasModelling and Simulation of Particle Upwash During Helicopter LandingnlrlibraryAinda não há avaliações

- Early Concept Development and Safety AnalysisDocumento12 páginasEarly Concept Development and Safety AnalysisnlrlibraryAinda não há avaliações

- Continuous Cell-To-Cell Mapping and Dynamic PsaDocumento8 páginasContinuous Cell-To-Cell Mapping and Dynamic PsanlrlibraryAinda não há avaliações

- Understand Intellectual PropertyDocumento13 páginasUnderstand Intellectual PropertynlrlibraryAinda não há avaliações

- NLR TP 2014 286Documento39 páginasNLR TP 2014 286nlrlibraryAinda não há avaliações

- Study of The Quality of Safety Assessment Methodology in Air TransportDocumento14 páginasStudy of The Quality of Safety Assessment Methodology in Air TransportnlrlibraryAinda não há avaliações

- Comparison of Ruin Probability Approximations in Case of Real DataDocumento75 páginasComparison of Ruin Probability Approximations in Case of Real DatanlrlibraryAinda não há avaliações

- Flatness Based Trajectory Generation For A Helicopter UAV: S. TaamallahDocumento25 páginasFlatness Based Trajectory Generation For A Helicopter UAV: S. TaamallahnlrlibraryAinda não há avaliações

- Hybrid Petri Nets With Diffusion That Have Into-Mappings With Generalised Stochastic Hybrid ProcessesDocumento35 páginasHybrid Petri Nets With Diffusion That Have Into-Mappings With Generalised Stochastic Hybrid ProcessesnlrlibraryAinda não há avaliações

- Airframe Loads & Usage Monitoring of The CH-47DDocumento33 páginasAirframe Loads & Usage Monitoring of The CH-47DnlrlibraryAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- WWW - Manaresults.co - In: Internet of ThingsDocumento3 páginasWWW - Manaresults.co - In: Internet of Thingsbabudurga700Ainda não há avaliações

- Giuliani Letter To Sen. GrahamDocumento4 páginasGiuliani Letter To Sen. GrahamFox News83% (12)

- Spare Parts ManagementDocumento21 páginasSpare Parts Managementdajit1100% (1)

- List of Light Commercial LED CodesDocumento8 páginasList of Light Commercial LED CodesRenan GonzalezAinda não há avaliações

- DC0002A Lhires III Assembling Procedure EnglishDocumento17 páginasDC0002A Lhires III Assembling Procedure EnglishНикола ЉубичићAinda não há avaliações

- Spine Beam - SCHEME 4Documento28 páginasSpine Beam - SCHEME 4Edi ObrayanAinda não há avaliações

- On Applied EthicsDocumento34 páginasOn Applied Ethicsamanpatel78667% (3)

- Ambient Lighting Vol 6 CompressedDocumento156 páginasAmbient Lighting Vol 6 Compressedadvait_etcAinda não há avaliações

- Central Banking and Monetary PolicyDocumento13 páginasCentral Banking and Monetary PolicyLuisaAinda não há avaliações

- 254 AssignmentDocumento3 páginas254 AssignmentSavera Mizan ShuptiAinda não há avaliações

- CC Anbcc FD 002 Enr0Documento5 páginasCC Anbcc FD 002 Enr0ssierroAinda não há avaliações

- Https Code - Jquery.com Jquery-3.3.1.js PDFDocumento160 páginasHttps Code - Jquery.com Jquery-3.3.1.js PDFMark Gabrielle Recoco CayAinda não há avaliações

- VRIODocumento3 páginasVRIOJane Apple BulanadiAinda não há avaliações

- Procurement Audit PlanDocumento12 páginasProcurement Audit PlanMustafa Bilal100% (1)

- Tech Mahindra Sample Verbal Ability Placement Paper Level1Documento11 páginasTech Mahindra Sample Verbal Ability Placement Paper Level1Madhav MaddyAinda não há avaliações

- Oasis 360 Overview 0710Documento21 páginasOasis 360 Overview 0710mychar600% (1)

- It14 Belotti PDFDocumento37 páginasIt14 Belotti PDFHolis AdeAinda não há avaliações

- Modal Case Data Form: GeneralDocumento4 páginasModal Case Data Form: GeneralsovannchhoemAinda não há avaliações

- MDC PT ChartDocumento2 páginasMDC PT ChartKailas NimbalkarAinda não há avaliações

- Supply Chain Risk Management: Resilience and Business ContinuityDocumento27 páginasSupply Chain Risk Management: Resilience and Business ContinuityHope VillonAinda não há avaliações

- Tan Vs GumbaDocumento2 páginasTan Vs GumbakjsitjarAinda não há avaliações

- ILRF Soccer Ball ReportDocumento40 páginasILRF Soccer Ball ReportgabalauiAinda não há avaliações

- Mathematical Geophysics: Class One Amin KhalilDocumento13 páginasMathematical Geophysics: Class One Amin KhalilAmin KhalilAinda não há avaliações

- Business Occupancy ChecklistDocumento5 páginasBusiness Occupancy ChecklistRozel Laigo ReyesAinda não há avaliações

- RFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonDocumento8 páginasRFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonSteven MoietAinda não há avaliações

- Jainithesh - Docx CorrectedDocumento54 páginasJainithesh - Docx CorrectedBala MuruganAinda não há avaliações

- Faida WTP - Control PhilosophyDocumento19 páginasFaida WTP - Control PhilosophyDelshad DuhokiAinda não há avaliações

- Flyer Manuale - CON WATERMARK PAGINE SINGOLEDocumento6 páginasFlyer Manuale - CON WATERMARK PAGINE SINGOLEjscmtAinda não há avaliações

- Completed NGC3 ReportDocumento4 páginasCompleted NGC3 ReportTiCu Constantin100% (1)

- Double Inlet Airfoil Fans - AtzafDocumento52 páginasDouble Inlet Airfoil Fans - AtzafDaniel AlonsoAinda não há avaliações