Escolar Documentos

Profissional Documentos

Cultura Documentos

Accurately measure oil, water and gas flow without separation

Enviado por

Cristhian TorresDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Accurately measure oil, water and gas flow without separation

Enviado por

Cristhian TorresDireitos autorais:

Formatos disponíveis

AGAR MPFM-300 SERIES MULTIPHASE FLOW METER (OIL/WATER/GAS)

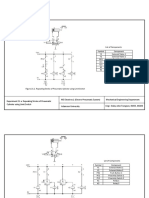

MPFM-300 Installation - Application - Well Testing and Diluent Optimization at high viscosity operation

MPFM-300 Installation on an Offshore Platform

The AGAR MPFM-300 Series is a true multiphase ow meter that provides on-line, real-time well production information for oil, water and gas ow rates, without separation of the phases. No longer is there a need for expensive, secondary equipment such as phase separators and pumps. The MPFM-300 Series is fully selfcontained and compact for use in rugged eld conditions.

Features of the AGAR MPFM-300 Series:

The AGAR MPFM-300 Series Multiphase Flow Meter provides accurate measurements of oil/gas/water owing simultaneously, without physically separating the phases. AGAR Corporations patented technology achieves unprecedented accuracy in multiphase measurements. The system can be used in all ow patterns with both oil-continuous and water-continuous uid streams. The MPFM-300 Series is specially designed for low maintenance and ease of operation. No eld calibration or prior knowledge of the uid properties, such as density and salinity, is required to attain the specied accuracies.

Advantages of the AGAR MPFM-300 Series:

Highly accurate, real-time ow measurement Self-verication capability in the eld No nuclear (radioactive) sources Can be used in all ow patterns Requires little maintenance Compact, portable, and easy to transport and install Not affected by changes in uid properties Measures in both oil- and water-continuous phases Gas void fraction 0-97%

Four Primary Sub-Systems Are Used to Achieve Accuracy:

The Volumetric Flow Meter is a positive displacement meter that accurately measures the total ow (gas and liquid). This meter is selected from a range of commercially available products with proven eld records. The volumetric ow data is fed into the MPFM Data Analysis System (DAS) which performs calculations for the multiphase measurement.

The AGAR Momentum Meter uses a unique venturi

conguration to establish the gas volume fraction of the ow stream. Data from the momentum meter is fed into the MPFM DAS.

The AGAR Watercut Meter (OW-201) is a microwave-

based oil/water monitor. The OW-201 uses a microwave transmitter broadcasting at over 2 Gigahertz and receivers to measure bulk electrical properties of the uid. Engineering advances allow the OW-201 to measure water content accurately over the full range of 0-100% in both oil and watercontinuous phases. Accuracy is not affected by changes in velocity, salinity, pH, viscosity, temperature or density. Watercut data is fed into the MPFM DAS.

The AGAR Data Analysis System (DAS) performs

on-line analysis of data acquired from the above subsystems to determine the oil, water, gas, and total uid ow rates.

GENERAL SPECIFICATIONS OF THE AGAR MPFM-300 SERIES METER: Process Conditions:

Instantaneous Void Fraction Watercut Flow Patterns Design Pressure Ambient Temperature Process Temperature Viscosity Salinity Sand/Particulate Max. Pressure Drop Corrosion Resistance Wetted Parts : : : : : : : : : : : : 0 to 97% 0 to 100% All: (e.g. Bubbly, Wavy, Slug, Annular ows, etc.) Up to 10,000PSI / 680 BARS -4F to 158F (-20C to 70C) Optional Low Temp -40F to 158F (-40C to 70C) Standard Model 32F to 212F (0C to 100C) High Temperature Model 32F to 450F (0C to 232C) .5 to 100 Centipoise (Higher viscosity optional) Up to 0 to 20% by weight Up to 5% by volume Less than 15 PSI (1 bar) Standard NACE MR-01-75 Latest Edition Stainless Steel; Carbon Steel; Teon; Ceramic, PEEK.

Typical Dimensions:

Model Weight

(ANSI 300, DOWN-LEG AND SKID-MOUNTED OPTIONS)

Dimensions (F/FXWXH)

(Lbs.) 301-20 301-30 301-40 301-60 1200 1700 2100 3700

(Kg.) 545 773 955 1682

(Inches) 44X35.5X100 44X35.5X115 60X52X123 70X62X146

(Centimeters) 111X90X254 111X90X292 155X132X312 178X157X418

Electrical:

Power Supply: 110, 220 VAC or 12, 24 VDC (Optional) Power Requirments: 36 Watts with pneumatic actuator

Safety Certications:

ATEX- EEx ia IIC T6 UL/C-UL - Class 1, Division 1, Group C & D, T4

Data Communication (Standard and Optional):

Standard: Standard: Standard: Standard: Standard: Optional: Optional: Keyboard & Color Screen Text (Screen, File, Printer) indicating Temperature; Pressure; Volumetric Flow Rate of Gas, Oil, Water, and Total Flow. Graphics (Screen) indicating Time trending and bar graphs of gas, oil and water ow rates, temperature, and pressure. One RS232 and one RS485 outputs (baud rate up to 1115.2 Kbps), Modicon MODBUS and ASCII protocol. Other types optional. Hard Disk, Floppy Drive. Analog Output Card to handle up to 6 outputs: 4-20 mA / 1-5VDC / 2-10VDC / 0-5VDC / 0-10VDC / Relay / Pulse Outputs or a combination of the above Analog Input Card

Capacity of the AGAR MPFM-300 Series:

Total Volumetric Capacity (Range) MPFM Model Number Min. 300-10 300-15 300-20 300-30 300-40 300-60 10 24 40 79 159 382 M3/D Max. 198 500 800 1,600 3,180 7,600 Min. 60 150 250 500 1,000 2,400 BBL/D Max. 1,250 3,100 5,000 10,000 20,000 48,000

* Not all models and capacities are listed. Volumetric capacities are for .5 - 100 cP viscosity range. Capacities vary by viscosity, temperature, liquid/gas ratio, pressure and other factors. Contact Factory for specific application information.

This graph shows the effect of Gas to Liquid Ratio (GLR) on liquid capacity of the MPFM-300:

Accuracy of the AGAR MPFM-300 Series:

Worst Case Instantaneous Errors (Quoted to 1 sigma):

Oil Flow Rate Water Flow Rate Gas Flow Rate Total Fluid Flow Rate

Accuracies are not affected by changes in salinity, viscosity, density, temperature, pressure, or pH.

2% of full scale, plus 5% of reading 2% of full scale, plus 5% of reading 5% of full scale, plus 5% of reading 2% of reading

12/2004

Você também pode gostar

- Floboss S600 Pro Training Manual Appendix B - Batching: B.1 Station Volume LoadingDocumento17 páginasFloboss S600 Pro Training Manual Appendix B - Batching: B.1 Station Volume LoadingAldeline Sungahid100% (2)

- Volume 5dDocumento387 páginasVolume 5dFabian GuzmanAinda não há avaliações

- Improving Turbine Meter Measurement by Alternate Fluid Calibration PDFDocumento11 páginasImproving Turbine Meter Measurement by Alternate Fluid Calibration PDFcsierracdtAinda não há avaliações

- FlowCheck User ManualDocumento88 páginasFlowCheck User Manualrobercl51Ainda não há avaliações

- Electronic Liquid Measurement - API Chapter 21.2Documento4 páginasElectronic Liquid Measurement - API Chapter 21.2Jose gonzalezAinda não há avaliações

- F05Documento23 páginasF05Sang SekAinda não há avaliações

- SNMP OPC GettingStarted en PDFDocumento10 páginasSNMP OPC GettingStarted en PDFalejocmedAinda não há avaliações

- Barton Model 6001 & 6002 Differential Pressure Transmitter and Flow Transmitter PDFDocumento10 páginasBarton Model 6001 & 6002 Differential Pressure Transmitter and Flow Transmitter PDFsaulAinda não há avaliações

- API manual errata updates referencesDocumento2 páginasAPI manual errata updates referencesAdrian MontoyaAinda não há avaliações

- Calibration Method - Gas FlowDocumento9 páginasCalibration Method - Gas FlowMazhar MahadzirAinda não há avaliações

- 12" Steel Model K12: Smith Meter CT Series PD Meter For Crude TransportationDocumento4 páginas12" Steel Model K12: Smith Meter CT Series PD Meter For Crude Transportationjuan carlosAinda não há avaliações

- Manual Sonda Agar Ow 300Documento61 páginasManual Sonda Agar Ow 300jfmendez0108100% (1)

- Yokogawa ADMAG AXF Magnetic FlowmeterDocumento133 páginasYokogawa ADMAG AXF Magnetic Flowmeter1234567890Ainda não há avaliações

- Páginas desdeAPI MPMS 4.8 - PROVER RECALIBRATION FREQUENCY PDFDocumento2 páginasPáginas desdeAPI MPMS 4.8 - PROVER RECALIBRATION FREQUENCY PDFAngel AvilaAinda não há avaliações

- Manual de Instalación de RadarDocumento120 páginasManual de Instalación de RadarJanson AlexanderAinda não há avaliações

- Temperature Probes Thermowells: Smith Meter® Electronic EquipmentDocumento4 páginasTemperature Probes Thermowells: Smith Meter® Electronic EquipmentiptusAinda não há avaliações

- MODELS 202E/208E Differential Pressure Recorders Installation ManualDocumento48 páginasMODELS 202E/208E Differential Pressure Recorders Installation Manualcami90_384375Ainda não há avaliações

- MPFM-401CM Series Instruction Manual OR110424.3Documento64 páginasMPFM-401CM Series Instruction Manual OR110424.3Pedro NuñezAinda não há avaliações

- SUMMIT 8800 HandbookDocumento42 páginasSUMMIT 8800 HandbookPero Perić67% (3)

- AGA-9 Revision Draft 082403Documento49 páginasAGA-9 Revision Draft 082403mathijn75Ainda não há avaliações

- Circuit diagram of a remote control system with a transformer and power supply detailsDocumento2 páginasCircuit diagram of a remote control system with a transformer and power supply detailshassan hassanAinda não há avaliações

- 981101B Audit TrialDocumento9 páginas981101B Audit Trialsyed jeelani ahmedAinda não há avaliações

- Technical Bulletin IndexDocumento223 páginasTechnical Bulletin IndexedwinmenaAinda não há avaliações

- FMD Not So Small Prover - 2017 - No VideosDocumento39 páginasFMD Not So Small Prover - 2017 - No VideosMelina SbhAinda não há avaliações

- 970803B Meter Fact. LinearDocumento4 páginas970803B Meter Fact. Linearsyed jeelani ahmedAinda não há avaliações

- BS&W Models 4528EZ & 4728 Monitors FMCDocumento14 páginasBS&W Models 4528EZ & 4728 Monitors FMCFernando MendezAinda não há avaliações

- C Pi 370Documento22 páginasC Pi 370sadeghmsgAinda não há avaliações

- The “Not So Small” Small Volume Prover Optimizes Flow MeasurementDocumento43 páginasThe “Not So Small” Small Volume Prover Optimizes Flow MeasurementMelina SbhAinda não há avaliações

- Config 600 Software User Manual en 132292Documento817 páginasConfig 600 Software User Manual en 132292Moises Valente Sanchez RiveraAinda não há avaliações

- Automatic SamplerDocumento2 páginasAutomatic SamplerRicardo Hernan Gomez BAinda não há avaliações

- Aga 7Documento37 páginasAga 7vaibhav100% (1)

- ASME B16.47 Series B Flanges Class 150 SpecsDocumento1 páginaASME B16.47 Series B Flanges Class 150 SpecsD.RameshkumarAinda não há avaliações

- E 644 - 04 - Rty0naDocumento17 páginasE 644 - 04 - Rty0naCindy Tremblay100% (1)

- ISA RP3.2 (1960) Flange Mounted Sharp Edged Orifice Plate For Flow MeasurementDocumento8 páginasISA RP3.2 (1960) Flange Mounted Sharp Edged Orifice Plate For Flow Measurementmtrj59100% (1)

- Valve Repair Company ReTop Valve Repair CoDocumento3 páginasValve Repair Company ReTop Valve Repair CoErnesto AriasAinda não há avaliações

- Pac 7000 PDFDocumento6 páginasPac 7000 PDFJorgeLuisUriarteAinda não há avaliações

- HSV86 PDFDocumento48 páginasHSV86 PDFMohamed El MaadawyAinda não há avaliações

- API 12.2 Calculation of Petroleum Quantities Using Dynamic Second Edition, July 2021Documento69 páginasAPI 12.2 Calculation of Petroleum Quantities Using Dynamic Second Edition, July 2021FRescudero100% (1)

- Teach Me About SamplingDocumento12 páginasTeach Me About SamplingApostolos PatsiasAinda não há avaliações

- Floboss 103 104 Flow Managers Instruction Manual en 132384Documento106 páginasFloboss 103 104 Flow Managers Instruction Manual en 132384AugustoAinda não há avaliações

- ROTAMASS Instruction Manual PDFDocumento202 páginasROTAMASS Instruction Manual PDFrhomadonaAinda não há avaliações

- FB 1200Documento110 páginasFB 1200Bernardo Campos PereiraAinda não há avaliações

- Mini Pak HoneywellDocumento78 páginasMini Pak Honeywellliviu_dovaAinda não há avaliações

- Accuload Comm ManualDocumento166 páginasAccuload Comm ManuallataAinda não há avaliações

- Operating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355Documento138 páginasOperating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355farhan100% (1)

- DRESSER Regulators FlowgridDocumento12 páginasDRESSER Regulators Flowgridzalziza100% (1)

- Dresser-Rand GFC Databook - Gas Field Policies-4Documento4 páginasDresser-Rand GFC Databook - Gas Field Policies-4kistaiAinda não há avaliações

- Calibrate Fire & Gas Detection SystemsDocumento5 páginasCalibrate Fire & Gas Detection Systemskirandevi1981Ainda não há avaliações

- Oil Water Meter Training ManualDocumento79 páginasOil Water Meter Training ManualmelisaB100% (1)

- AGA3 FormulaDocumento2 páginasAGA3 FormulaDio Masera100% (1)

- Saso Iso 17089 2 2020 eDocumento45 páginasSaso Iso 17089 2 2020 elucky yadavAinda não há avaliações

- The Outstanding FH8500 Ultrasonic Metering SolutionDocumento4 páginasThe Outstanding FH8500 Ultrasonic Metering SolutionRadityaA.PerdanaAinda não há avaliações

- ISO 4267-2 - 1988 - Part 2 Dynamic Measurement - INDDocumento2 páginasISO 4267-2 - 1988 - Part 2 Dynamic Measurement - INDYuri MateusAinda não há avaliações

- Coriolis Flow Meter FSI Workshop 15.0Documento22 páginasCoriolis Flow Meter FSI Workshop 15.0Reza NazariAinda não há avaliações

- Leak Detection in Pipeline-JijoDocumento17 páginasLeak Detection in Pipeline-Jijoamulbaby31Ainda não há avaliações

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocumento8 páginasAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosAinda não há avaliações

- M23-9 12Documento8 páginasM23-9 12OLuizaAinda não há avaliações

- Omega Flow MweterDocumento2 páginasOmega Flow MweterIan G. WalkerAinda não há avaliações

- Gas Metering System-Woodward - SwiftDocumento4 páginasGas Metering System-Woodward - Swiftkats2404Ainda não há avaliações

- Turbine Meter NufloDocumento8 páginasTurbine Meter NufloJaime SeguraAinda não há avaliações

- List of ComponentsDocumento2 páginasList of ComponentsRainwin TamayoAinda não há avaliações

- History and Evolution of Hybrid VehiclesDocumento24 páginasHistory and Evolution of Hybrid VehiclesShrvan HirdeAinda não há avaliações

- Guide to Rubber Expansion JointsDocumento7 páginasGuide to Rubber Expansion JointsHu HenryAinda não há avaliações

- Service Accessories: CatalogDocumento32 páginasService Accessories: CatalogdummaAinda não há avaliações

- Marketing Research of Pre-Start-UpDocumento2 páginasMarketing Research of Pre-Start-UpafsalpkgroupAinda não há avaliações

- Ln26r71bd Ln-s2652d Ln26r71b Ln32r71bd LN s3252d DiagramaDocumento261 páginasLn26r71bd Ln-s2652d Ln26r71b Ln32r71bd LN s3252d DiagramaVictor Julio AlvarezAinda não há avaliações

- Multipoint Socket Profile VW 010 43: KonzernnormDocumento4 páginasMultipoint Socket Profile VW 010 43: KonzernnormRicardo Vitoriano100% (1)

- Eaton 9130 Rack 700-3000vaDocumento4 páginasEaton 9130 Rack 700-3000vaJose Luis PintoAinda não há avaliações

- Formalin MsdsDocumento10 páginasFormalin MsdsMank WidhieAinda não há avaliações

- (Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerDocumento332 páginas(Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerFuadAshadLAinda não há avaliações

- Padlock Sharper Image FingerprintDocumento1 páginaPadlock Sharper Image FingerprintHenryW.CampbellJr.Ainda não há avaliações

- Casing & Compressor of Air ConditionerDocumento22 páginasCasing & Compressor of Air ConditionerAbdullah Zakirin Abdul 'AzamAinda não há avaliações

- Mindmup Group-2Documento10 páginasMindmup Group-2api-271772521Ainda não há avaliações

- Mapping UCLA Network DrivesDocumento2 páginasMapping UCLA Network DriveswebscaleAinda não há avaliações

- Restaurant Pub VIP Lounge Camp Pune SaleDocumento4 páginasRestaurant Pub VIP Lounge Camp Pune SaleChandrashekhar Naikare0% (1)

- ACEEE - Best Practices For Data Centres - Lessons LearnedDocumento12 páginasACEEE - Best Practices For Data Centres - Lessons LearnedtonybudgeAinda não há avaliações

- My Ideal Week PDFDocumento1 páginaMy Ideal Week PDFAnonymous QE45TVC9e3Ainda não há avaliações

- VF1 Technicalspecifications 031997 EN PDFDocumento43 páginasVF1 Technicalspecifications 031997 EN PDFelectricistAinda não há avaliações

- Jobber JR DetailsDocumento2 páginasJobber JR DetailsUrvish PatelAinda não há avaliações

- MTO Response Letter 0609Documento3 páginasMTO Response Letter 0609hwy7and8Ainda não há avaliações

- Project Management Book PDFDocumento55 páginasProject Management Book PDFSerigne Mbaye Diop94% (16)

- Critical Reading As ReasoningDocumento18 páginasCritical Reading As ReasoningKyle Velasquez100% (3)

- CONSTRUCTION OF INTERNAL ROADS & INFRASTRUCTURE WORKS FOR SECTOR EAST 25, PHASE 2, ABU DHABI - DELAY EVENT IMPACT CALCULATIONSDocumento10 páginasCONSTRUCTION OF INTERNAL ROADS & INFRASTRUCTURE WORKS FOR SECTOR EAST 25, PHASE 2, ABU DHABI - DELAY EVENT IMPACT CALCULATIONS143Ainda não há avaliações

- AIR Intelligence Manual 33 308100 004 RemoteDocumento88 páginasAIR Intelligence Manual 33 308100 004 RemoteLeChancheAinda não há avaliações

- Schools Division of Pasay City outlines 5S workplace organizationDocumento9 páginasSchools Division of Pasay City outlines 5S workplace organizationJhaexelle allenah AlfonsoAinda não há avaliações

- Types of Camera AnglesDocumento2 páginasTypes of Camera AnglesMaJudith JavilloAinda não há avaliações

- BS en 50160 2007Documento24 páginasBS en 50160 2007Pepe Eulogio OrtízAinda não há avaliações

- Greddy E-Manage Installation ManualDocumento6 páginasGreddy E-Manage Installation ManualTHMotorsports.net100% (2)

- Blasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyDocumento3 páginasBlasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyEjike Francis ChizobaAinda não há avaliações