Escolar Documentos

Profissional Documentos

Cultura Documentos

All SOPs

Enviado por

Hasan RiazDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

All SOPs

Enviado por

Hasan RiazDireitos autorais:

Formatos disponíveis

Standard Operating Procedures

Antennas and Scattering Laboratory (aka Compact Range)

Standard Operating Procedures for

Page

1. Drilling 2. Sawing 3. Loading and unloading activity 4. Working on movable platform ladder 5. Pedestal Setup 6. Feed Setup

2-3 4-5 6 7 8-9 10

Notes: The Standard Operating Procedures presented here are not exhaustive. For areas that you are in doubts, please clarify with laboratory technologist.

1 Property of Antennas & Scattering Laboratory

Standard Operating Procedures

1. Drilling 1.1 Utilize clamping devices such as F- or G-clamp or bench vice to firmly secure the material to the work bench. 1.2 1.3 Select required drill bit from the drill bits box. Insert and tighten the drill bit to the drilling machine by using the locking key provided together with the drilling machine. 1.4 Before operation, please ensure that loose clothing like sleeves and shirts are tucked out of the working area. 1.5 Personal protection equipment like ear plugs and safety goggle must be worn at all times. 1.6 1.7 Position the drill bit above the material and over the spot to be drilled. NEVER started off drilling with the highest drilling speed. Always start off with slow speed and gradually increased to medium and then to high as appropriate. 1.8 With the button lightly depressed and drill bit revolve slowly, position it over the material and exert downward force gradually. 1.9 Keeping up the pressure, increasing the drilling speed by depressing the button harder. 1.10 After the drill penetrate the material, reverse the drilling direction and slowly withdraw the drill bit from the material. 1.11 Repeat above steps if drilling on other areas are required. 1.12 Remove power supply to drilling machine and remove drill bit if no longer required. 1.13 Housekeeping activity is required to be performed on the work bench and on the saw to remove debris. 1.14 Pack sawing machine in its original kept location.

2 Property of Antennas & Scattering Laboratory

Standard Operating Procedures

Remarks: The drill in this lab is portable machines. It is not meant for large items and precision operation. As a safety rule of thumb, DO NOT use these machines if the material to be operated cannot be firmly clamp using the vice bench. These activities are not for those who lack the basic understanding or have no prior experience. If in doubts, please seek Laboratory Technologist assistance.

3 Property of Antennas & Scattering Laboratory

Standard Operating Procedures

2. Sawing 2.1 2.2 Locate an empty area on the material to be clamped firmly to the work desk. Firmly secured the material using F or G clamp or bench vice as appropriate with area to be cut exposed. 2.3 Select appropriate cutting blade; Red for metallic object and Yellow for wooden materials. 2.4 Insert blade into the Saw and tighten the holding screw on the head of the handle. 2.5 Before operation, please ensure that loose clothing like sleeves and shirts are tucked out of the working area. 2.6 Personal Protection Equipment; Safety Goggle, ear plug must be worn at all times when machine is in operation. 2.7 2.8 2.9 Ensure no other persons are standing in the front when sawing start. Select a cutting speed, preferably using a slower velocity in the beginning. Place the saw and blade on the area to be cut and press the ON switch at the bottom of the round handle. 2.10 Move the saw blade along the area to be cut and increase speed if required. 2.11 When finishing cutting, please keep the saw blade in its final cut position and release the speed button to allow the blade to come to a complete stop before removing blade from material. 2.12 Repeat above steps if cutting on other areas are required. 2.13 Remove power supply to sawing machine and remove blade if no longer required. 2.14 Housekeeping activity is required to be performed on the work bench and on the saw to remove debris. 2.15 Pack sawing machine in its original kept location

4 Property of Antennas & Scattering Laboratory

Standard Operating Procedures

Remarks: The Sawing Machine in the lab is a portable machine. It is not meant for large items and precision operation. As a safety rule of thumb, DO NOT use these machines if the material to be operated cannot be firmly clamp using the vice bench. These activities are not for those who lack the basic understanding of electrical saw operation or have no prior experience. If in doubts, please seek Laboratory Technologist assistance.

5 Property of Antennas & Scattering Laboratory

Standard Operating Procedures

3. Loading and unloading activity 3.1 Only trained personnel will be allowed to operate the overhead hoist. New trained operator must submit photocopy of their certificate for the laboratory to update the list of authorized personnel. 3.2 Authorized personnel must familiar with the pendant operation of the hoist before actual hoisting activity commence. 3.3 Hoisting activities must be performed with at least TWO personnels exclusive of crane operator. 3.4 3.5 Helmets must be worn at all times during operation.. The operator at the ground floor of the preparation hall must ensure that no other persons are allowed to be standing or working near the hoisting area. A safety circumference of about 5 meters must be setup. 3.6 Weight of the load must be known so that proper lifting gears/slings can be used. 3.7 The center of gravity of object must be identified so the correct position to place the slings or lifting gears can be determined to ensure good balance hoisting. 3.8 All lifting and lowering activity preferably perform with slow speed.

Remarks: Two types of lifting slings are provided in the laboratory for general loading and unloading activities. For objects that are odd shapes, additional lifting gears may be use like harness or net as supplied by users. For additional lifting gears not supplied by the laboratory, the user must ensure the gears are checked and verified to be in good working conditions complying to MOM guidelines.

6 Property of Antennas & Scattering Laboratory

Standard Operating Procedures

4. Working on movable platform ladder 4.1 Movable platform ladder (hereafter refer to as ladder) will be pushed to the required location. 4.2 The locking screw at the right side of the ladder will be tightened to bolt the ladder to the required location. 4.3 Once ladder is secured, user will climbed up the ladder by accessing the tilted stair with both hands. 4.4 For working near the tip of the platform, user must wear safety harness supplied. 4.5 The total mass exerted on the tip of the platform should not exceed 200kg for both weights of test objects and users. 4.6 All users will be required to evacuate from the ladder when ladder is being pushed or in motion. Remarks: At no time should the user be allowed to step beyond the yellow lines drawn on the tip of the platform. Users who have medical reasons like hypertension and Acrophobia (phobia with height) should not attend to climb the ladder. This activity is highly unsuitable for Female users who are wearing skirts or high heels.

7 Property of Antennas & Scattering Laboratory

Standard Operating Procedures

5. Pedestal Setup Pre-checks Functional and validity checks on Slings and control pendant of overhead hoist must be verified before actual operation. Hoist operator must be on the authorized list of personnel that are allowed to operate the overhead hoist. All mains must be switched off. PPE such as Mask, Arm sleeves and Talcum powder should be used. 5.1 Carbon paper Radar Absorbing Material (RAM) along the moving tracks further away from the collimator must be removed. 5.2 5.3 All control cables must be tucked nicely away from the pedestal and tracks. Depending on type of measurement, PP1 pedestal (for RCS) and PP2 pedestal (for Antenna) will be hoisted to the outermost tracks and pushed into the empty chamber. 5.4 Once pedestal in place, the four screws on the pedestal will be tightened on the shoe housings supplied until the wheels just managed to roll freely. 5.5 The Control cables will be connected to the pedestal.

For PP1 (RCS) Pedestal: 5.6 The connectors on the rear of the Positional controller (in control room) connected to X31, X30, X29, X27 & X23 with PP1/2 switched to PP1. 5.7 Power up the Positional Controller (in control room, beside AcquirePC) and zeroed the mechanical Azimuth and Elevation axis by using the controller manual override; Position 1 (for elevation) and position 2 (for azimuth) . 5.8 Place level gauge on the test object support and tighten the 3 screws to achieve a balanced setting for the gauge; vary only 3 screws with 1 fixed. 5.9 Replace the RAM blocks and ensure that maximum floor area are being covered by RAM.

8 Property of Antennas & Scattering Laboratory

Standard Operating Procedures

For PP2 (Antenna) Pedestal: 5.10 he connectors on the rear of the Positional controller (in control room) connected to X31, X30, X28, X26 & X24 with PP1/2 switched to PP2. 5.11 Power up the Positional Controller (in control room, beside AcquirePC) and zeroed the mechanical Azimuth and Elevation axis by using the controller manual override; Position 1 (for azimuth) and position 2 (for elevation). 5.12 Fold over the fibre glass scattering net from the front part of the pedestal and placed the two zero gauges perpendicular to each other as indicated on the pedestal. Two pre-adjustable gauge set to +9 minutes placed parallel and -17 minutes placed perpendicular to the collimator. 5.13 3 of the 4 screws will be adjustable to achieve balance of the air bubble in the gauges. 5.14 Once balance is achieved, the scattering net will be pulled back down to cover the pedestal. Remarks: o Users have to perform visual checks on the integrity and physical condition of the slings and hoisting aids before operation. o The Laboratory will ensure that all these lifting gears and equipment supplied complied with the recommendations of the equipment manufacturer and the requirements stipulated by Ministry of Manpower. o Users are advised to check with a certified profession (eg, doctor) whether they are suitable to use the N95 mask. Paper mask are supplied as alternative to those who have problem breathing in N95 mask. However, please be advised that paper mask will not provide sufficient coverage to the user.

Tools required: At least two wrenches with 16 and 17 sockets. Two units of pre-adjusted precision level gauges. Overhead hoist and slings. 9 Property of Antennas & Scattering Laboratory

Standard Operating Procedures

6. Feed Setup 6.1 6.2 User has to determine the test frequency (frequencies). The appropriate feeds to be used can be consulted using the system software in the acquire PC or the system manual. 6.3 Extract the feeds and support from the shelves and placed it on the working bench for assembling. 6.4 6.5 Place feed assemblies on the floor near the feed housing. Use two hands to flip open the feed housing with care exercising to prevent the housing floor topping over. 6.6 6.7 Insert two guiding pins onto the feed installation plate. The feed assemblies will be placed in position on the feed housing area via the two guiding pins inserted earlier. 6.8 6.9 Wing nuts will be used to tighten feed assemblies on the feed housing. Connect the appropriate RF cable into the waveguide adaptor.

6.10 The horizontal and vertical position of the feed(s) can be checked and adjusted by using the level gauge. Remarks: o Users have to perform visual checks on the integrity and physical condition of the feeds to be used by ensuring the feeds apertures are intact and in good condition. o Users are advised to check with a certified profession (eg, doctor) whether they are suitable to use the N95 mask. Paper mask are supplied as alternative to those who have problem breathing in N95 mask. However, please be advised that paper mask will not provide sufficient coverage to the user.

Tools required: Digital or bubble level gauge. Microwave assemblies torque wrench for 2.4mm and 3.5mm connectors.

10 Property of Antennas & Scattering Laboratory

Você também pode gostar

- China Railway Const Company - KAP5 Project - TYCO Novec SystemDocumento5 páginasChina Railway Const Company - KAP5 Project - TYCO Novec SystemHasan RiazAinda não há avaliações

- China Railway - KAP5 Site 103 - Novec SystemDocumento9 páginasChina Railway - KAP5 Site 103 - Novec SystemHasan RiazAinda não há avaliações

- Al Rashid Trading and Contracting - KKIA 3 & 4 - Novec SystemDocumento5 páginasAl Rashid Trading and Contracting - KKIA 3 & 4 - Novec SystemHasan RiazAinda não há avaliações

- National Guard Housing Project QuotationDocumento14 páginasNational Guard Housing Project QuotationHasan RiazAinda não há avaliações

- The Science of ParentingDocumento29 páginasThe Science of ParentingHasan RiazAinda não há avaliações

- Duct Accessories - Safid - 37348-Alfanar-Fadhili Gas Plant DampersDocumento9 páginasDuct Accessories - Safid - 37348-Alfanar-Fadhili Gas Plant DampersHasan RiazAinda não há avaliações

- Duct Accessories - Safid - 37348-Alfanar-Fadhili Gas Plant DampersDocumento9 páginasDuct Accessories - Safid - 37348-Alfanar-Fadhili Gas Plant DampersHasan RiazAinda não há avaliações

- Solar Plant Air Handling QuotationDocumento8 páginasSolar Plant Air Handling QuotationHasan RiazAinda não há avaliações

- Asme Boiler StandardsDocumento2 páginasAsme Boiler StandardsHasan RiazAinda não há avaliações

- Hasan RiazDocumento2 páginasHasan RiazHasan RiazAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Last But Not Least: Drilling MethodsDocumento38 páginasLast But Not Least: Drilling MethodsNeilAinda não há avaliações

- Instructions: 6 Speed Transmission Super KitDocumento14 páginasInstructions: 6 Speed Transmission Super KitthailanAinda não há avaliações

- Diy Recycled Jewelry TutorialsDocumento19 páginasDiy Recycled Jewelry Tutorialstarcisia100% (2)

- Ole BrochureDocumento65 páginasOle BrochureNotfound ByuAinda não há avaliações

- Wooden Gear Clock - Clock Instructions 9Documento66 páginasWooden Gear Clock - Clock Instructions 9bird100% (1)

- MCM CatalogDocumento71 páginasMCM Catalogjerji_jerjiAinda não há avaliações

- Loop Loc Install GuideDocumento12 páginasLoop Loc Install GuideJustin CaseAinda não há avaliações

- Piranha, B&D, AccessoriesDocumento12 páginasPiranha, B&D, AccessoriesSebaAinda não há avaliações

- Dewalt Feb 2014Documento8 páginasDewalt Feb 2014Riverland Welding and Tool SuppliesAinda não há avaliações

- Main CatalogDocumento151 páginasMain CatalogНикита МельниковAinda não há avaliações

- Drilling and Demolition: Hilti. Outperform. OutlastDocumento31 páginasDrilling and Demolition: Hilti. Outperform. OutlastShashank SrivastavaAinda não há avaliações

- Tritium Design BriefDocumento49 páginasTritium Design Briefapi-355924891Ainda não há avaliações

- Production Technology SyllabusDocumento9 páginasProduction Technology SyllabusPankaj SharmaAinda não há avaliações

- A Simple Homemade Propane BurnerDocumento5 páginasA Simple Homemade Propane Burnerraul_zamora100% (1)

- 06 Catalog Krisbow9 Cutting ToolDocumento10 páginas06 Catalog Krisbow9 Cutting ToolEnrique da MattaAinda não há avaliações

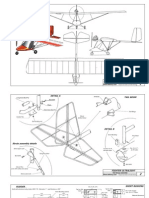

- Fighter Ultralight PlansDocumento24 páginasFighter Ultralight PlansMaps98% (46)

- 2.drilling & Demolition Chapter - 3wDocumento32 páginas2.drilling & Demolition Chapter - 3wincineratoriumAinda não há avaliações

- SF - RE500 + G500 Rebar (Sep2015)Documento88 páginasSF - RE500 + G500 Rebar (Sep2015)Wesleykit WongAinda não há avaliações

- Power, Bench and Machine ToolsDocumento1 páginaPower, Bench and Machine ToolsPAUL BRAMONT ARIAS HILASACAAinda não há avaliações

- Project ReportDocumento54 páginasProject ReportNithin K BAinda não há avaliações

- Bosch 20182019 Catalog - Drillingfastening PDFDocumento52 páginasBosch 20182019 Catalog - Drillingfastening PDFPray OcampoAinda não há avaliações

- Construir Uma Guitarra Elétrica - Sem As Ferramentas de FantasiaDocumento15 páginasConstruir Uma Guitarra Elétrica - Sem As Ferramentas de FantasiaTradulineAinda não há avaliações

- Fitting ShopDocumento20 páginasFitting ShopRandomAinda não há avaliações

- 814649-1 09 RUKO Core Drilling Machines enDocumento50 páginas814649-1 09 RUKO Core Drilling Machines enBogdan AndreiAinda não há avaliações

- Basic Engineering Terms Defined in DetailDocumento31 páginasBasic Engineering Terms Defined in Detailvijay kumarAinda não há avaliações

- Roller Catalogue Edea October-2021 LRDocumento33 páginasRoller Catalogue Edea October-2021 LRAsesoresAinda não há avaliações

- CUTTING TOOLS GUIDE: DRILLS, REAMERS, ENDS MILLSDocumento10 páginasCUTTING TOOLS GUIDE: DRILLS, REAMERS, ENDS MILLSnanang arifAinda não há avaliações

- Manufacturing Tech-1Documento6 páginasManufacturing Tech-1Vikram Rao0% (1)

- PG22 Maverick 22 Short Revolver Build GuideDocumento6 páginasPG22 Maverick 22 Short Revolver Build GuideTimAinda não há avaliações

- Equipment Type Code Equipment TypeDocumento24 páginasEquipment Type Code Equipment TypeFarrukh AhmedAinda não há avaliações