Escolar Documentos

Profissional Documentos

Cultura Documentos

Ackerman Steering

Enviado por

Quinn Golden0 notas0% acharam este documento útil (0 voto)

102 visualizações3 páginasPrinciples of Steering pertaining to vintage rods.

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoPrinciples of Steering pertaining to vintage rods.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

102 visualizações3 páginasAckerman Steering

Enviado por

Quinn GoldenPrinciples of Steering pertaining to vintage rods.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 3

Th e Ack er ma n n P r i n ci pl e of St eer i n g

And How lt Relates to the Model T Ford

By Ted Aschman

Ackermann is not a misspelling oI this writer s

name but reIers to Rudolph Ackermann, who

advanced a method oI vehicular steering that made

possible the high speed automobiles oI today. He

was born in Stolberg in Saxony, in 1764. At n early

age he began his apprenticeship in coach building

and design at his Iather s shop. AIter becoming a

journeyman he leIt and traveled to other German

towns, Paris, and Iinally to London where Ior ten

years he was engaged as a designer Ior many oI the

principal coach builders in that area. He died in

1834, long beIore the earliest automobiles, crude as

they were, appeared. He spent most oI his later

years in the publishing business.

Perhaps, at this point, it might be proper to

enter into the principle oI steering. In the old horse

and buggy days, pulling on one oI the reins would

swing the horse to that side. The shaIt or pole

attached to the horse is also attached to the Iront

axle, which is pivoted on a king pin.

Going straight ahead, the Iront and rear wheels

oI any vehicle move in a straight line. In making a

turn to one side or the other, the Iront wheels are

turned so that they are at an angle to the the rear

wheels. In a horse-drawn vehicle, the wheels are

square with the axle as the wheels and axle swing

or turn together, In an automobile, the Iront axle

does not swing; instead, each wheel pivots at the

end oI the axle. It would not be practical to steer an

automobile like a horse drawn vehicle as the axle

would have to be quite heavy to support the weight,

making it quite hard to turn. Also, the height oI the

automobile would be excessive to allow Ior wheel

clearance when making a short turn,

On the Iixed Iront axle oI the Model T and other

early cars, the pivot on which the Iront wheels

swing is as close to the hubs as possible so to make

the steering as easy as possible, among other

reasons.

ReIerring to Eigure 1, it will be noted that since

the Iront axle swings on a kingpin, it always points

to the center oI a circle, and both wheels are

perpendicular to the same radius oI the circle. In an

automobile this is not true. ReIerring to Eigure 2,

each wheel is turned at a diIIerent angle and at a

diIIerent radius to the center oI the circle due to the

two steering arms not being parallel. Now, once

again reIerring to the illustrations, it is easy to note

that when making a leIt turn, the right Iront wheel

covers a greater distance than the leIt, and when

turning right it is the opposite. Note, too, that when

making a turn the inside wheel makes a sharper (or

shorter) turn, to allow Ior the shorter distance it

travels. II the spindle arms are parallel to one

another, they would turn at the same angle and

there would be considerable scuIIing on one (maybe

both) oI the tires. To provide Ior the diIIerent

turning angle oI each Iront wheel, the steering

arms are bent inward iI the connecting (tie) rod is

behind the axle. (In some oI the other old cars, the

connecting rod was in Iront oI the axle and the

steering arms on these hat an outward bend.) II the

steering arms were parallel each wheel would be

parallel with the other no matter which direction

the wheels were turned.

Eorgetting Ackermann and his principle Ior the

time being, the reason Ior this treatise should be

made known. While on the Model T Rally is

Australia this past Iall, a trio oI 'bushmen, who

many avoided because oI their appearance, invited

this writer to take a look at their TT. They were a

bit puzzled over the Iact that Ior a number oI years

they had been experiencing diIIicult steering and a

lot oI Iront tire scuIIing, even though the camber,

caster, and toe-in were set according to Iactory

speciIications.

Not knowing exactly how to cure this problem,

the smallest oI the three (and perhaps the wittiest)

resorted to some 'gum tree engineering (the

Australian equivalent oI the American 'shade tree

variety). By their own admission, they didn t quite

know what to do, so they made a trip to the local

trade school and borrowed every text they could

locate dealing with the automotive Iront end

alignment and steering. (That is where they

learned oI Ackermann.) In one oI the books were

several diagrams, portraying the Ackermann

Principle, and two or three pages oI descriptive

narrative. Applying this new-Iound knowledge to

their TT, it didn t take them long to Iigure out that

something was amiss.

One reIerence stated that the Ackermann

Principle was simply 'the Iront wheels must turn

in such a manner that they always have a constant

relationship to the rear wheels; sort oI an

engineering cop-out that didn t give the uninitiated

much to work with. The principle, as inIerred by

these drawings, more adequately illustrated, that

an imaginary straight line drawn Irom the center oI

the kingpin (spindle bolt) through the center oI the

spindle arm connecting rod bolt, should (must) pass

through the exact center oI the rear axle. With the

aid oI a chalk string, the tests run by the three

indicated that these imaginary lines centered about

23

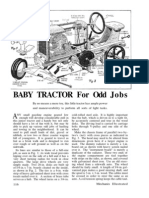

Eig. 1. Showing how a Iront axle oI a horse-drawn

vehicle gives the direction the vehicle runs.

Eig. 2. Showing how the Iront wheels oI an automobile

give the direction the car runs.

24

twenty-two inches ahead oI the rear axle. To get it

all into the proper perspective, they had to bend

each spindle arm outward about Iive-eights inch

This gave birth to another

problem which is not unusual with a Model T -

you cure one thing and get set upon by another.

This alteration made it necessary to lengthen

the connecting (tie) rod about an inch and a halI.

Erom then on, the truck handled well. Turns were

made with an ease previously unknown (even with

just one hand) and there was no tire scuIIing

(Ieathering oI the tread).

Another dimension that enters into the proper

spindle arm adjustment is the wheel base oI a

Model T. While most oI us think oI it as being 100

inches, Iactory data tells us that it is ninety-nine

inches (the truck is 123 inches). Surprised? So was

this writer when he learned this some years back.

Erom experience, very Iew T s observed had a

ninety-nine inch wheelbase. Most oI the early T s

checked came up short by up to three-quarters

inch, while the later ones measured in excess oI

ninety-nine inches, and in one example, 100.75

inches. It is the consensus this situation could be

caused by whether the Iront radius rod was

Iastened to the top oI the axle or to the bottom; i.e.,

an early or late Model T. With the radius rod

Iastened to the top oI the axle, there is a tendency,

aIter years oI chuck holes and bumps, Ior the Iront

axle to be rotated, eIIectively shortening the

wheelbase. In the later Model T s, with the

wishbone Iastened to the bottom oI the axle, there

is a tendency Ior the Iront axle to be rotated in the

opposite direction, substantially lengthening the

wheelbase.

The big one oI the three (and he was BIG) asked

iI Eord ever made diIIerent spindle arms - one

type Ior the passenger cars and another Ior the

trucks. Parts books show Eord made a straight

armed spindle that was used on both sides oI the

early (until 1919) T s, and Irom then until the end

oI production, Eord employed an arm that was bent

vertically to clear the wishbone when it was moved

to the bottom side oI the axle. This change required

the use oI two arms; one Ior each side. Whether or

not one was made especially Ior the TT s could not

be resolved at that time.

These boys were concerned why Eord didn t

make the arms correct in the Iirst place. A good

query, but at this point it is a rather moot question.

It is possible the reasoning behind this was Eord

wanting to keep parts and the resultant conIusion

to a minimum. Maybe, as the TT traveled at a

relatively slow speed, altering the steering arms to

Iit the truck, with its longer wheelbase, was

considered to be hardly worth the trouble.

Returning home, Iive NOS spindle arms Irom

the parts bin were checked and none oI them had

exactly the same degree oI inward bend. Close but

not quite the same. All were genuine Eord parts

(the indicated that they had been made

by diIIerent suppliers), so apparently a precise

measurement in this area was not considered

critical or even necessary. Moving on; the spindle

arms on the three T s (a 1912, a 1921, and a 1925)

sitting in the barn were also gauged, and they, too,

didn t have the same degree oI bend.

With winter on its way there was only time to

work on one oI the T s Since the 25 touring was

the handiest, it was chosen. A chalk string was dug

out oI one oI the work bench drawers, and with one

end Iastened to the bottom oI the spindle bolt (it

was threaded through the cotter pin hole) and the

other end was secured to t he center oI t he

diIIerential housing. The ends oI neither spindle

arm came close to aligning with the string. The

right spindle arm was bent outward one-halI oI an

inch, and the leIt one three-quarters oI an inch. The

bending was accomplished with a six Ioot length oI

pipe, but not beIore the Iront wheels were secured

by vise-like clamps Iashioned Irom some pieces oI

two inch angle iron.

As was expected, the connecting rod was too

short and had to be lengthened. It was removed

Irom underneath the car and aIter being secured in

a vise, it was cut in two, exactly at the center. Each

end was threaded; one with a standard right-hand

thread and the other with a leIt-hand die borrowed

Irom a local machine shop. This same shop made

up a sleeve, threaded with matching threads. Each

end oI this sleeve was split about an inch, and once

the alignment was correct, heavy clamps were

secured to these split ends. This way, the integrity

oI the adjustment would be preserved.

It i s i mportant, beIore resorti ng t o t hi s

adaptation, to make doubly sure that camber,

caster, and toe-in are correct (toe-in, oI course,

being determined by the adjustment oI the modiIied

tie rod).

It now appears that all we T owners are Iaced

with Iour, not three, i mport ant Iront end

adjustments: toe-in, camber, caster, and spindle

arm angle - all this, thanks to three inquisitive

Australian 'swagmen. C est la guere!

One thing Ior sure, iI we were still using the

center pin, IiIth wheel wagon type oI steering in our

modern cars, thirty miles per hour would be a

perilous experience, so maybe the old Ackermann s

Principle has merit. II you doubt this, just watch

the gyrations oI the last trailer oI a triple bottom

eighteen wheeler the next time you venture out on

the interstate.

Editor s notes:

Ted did not comment in the above article as to

whether or not there was an improvement in the

steering oI his 1925 - so I called him. He said that

while it was too cold to really give the car a good

25

Você também pode gostar

- Pusher - A Free-Flight Model AirplaneDocumento5 páginasPusher - A Free-Flight Model AirplaneBob KowalskiAinda não há avaliações

- Full Download Book Microeconomics 3 PDFDocumento22 páginasFull Download Book Microeconomics 3 PDFdanny.broad150100% (15)

- Full Download Ebook PDF Managing Organizational Behavior What Great Managers Know and Do 2Nd Edition Ebook PDF Docx Kindle Full ChapterDocumento23 páginasFull Download Ebook PDF Managing Organizational Behavior What Great Managers Know and Do 2Nd Edition Ebook PDF Docx Kindle Full Chapteraudrey.benbow405100% (38)

- GearsDocumento30 páginasGearsDà Ahmed Jilani100% (1)

- Pulley ParadoxDocumento3 páginasPulley Paradoxsher123Ainda não há avaliações

- The Steering Bible: Steering: Essential To DrivingDocumento10 páginasThe Steering Bible: Steering: Essential To DrivingAlykAinda não há avaliações

- 2706 Building SpeedsterDocumento10 páginas2706 Building Speedstersjdarkman1930100% (1)

- Build Racing BodyDocumento6 páginasBuild Racing BodyluisimtzAinda não há avaliações

- Steering: Essential To Driving: Latest Blog EntryDocumento8 páginasSteering: Essential To Driving: Latest Blog EntrySoham DeAinda não há avaliações

- Made How: Ferris WheelDocumento8 páginasMade How: Ferris WheelnamasralAinda não há avaliações

- Differential (Mechanical Device) : VerificationDocumento12 páginasDifferential (Mechanical Device) : VerificationHendri Yoga SaputraAinda não há avaliações

- 3 Wheel Go KartDocumento5 páginas3 Wheel Go KartLucas BrasilAinda não há avaliações

- Abdul Bari (Dome)Documento83 páginasAbdul Bari (Dome)A.F. MominAinda não há avaliações

- Differential DesignDocumento49 páginasDifferential DesignprajuAinda não há avaliações

- Design of Connecting RodDocumento26 páginasDesign of Connecting RodAbijit GudaAinda não há avaliações

- Lec-2, RailsDocumento25 páginasLec-2, Railshaidarullah0060116Ainda não há avaliações

- Couplings & Hoses: Return To Index PageDocumento1 páginaCouplings & Hoses: Return To Index PagepepelsAinda não há avaliações

- Suburba Car, Chassis For ADocumento7 páginasSuburba Car, Chassis For AJim100% (9)

- Steering SystemDocumento8 páginasSteering Systemnehascribd1Ainda não há avaliações

- PDFDocumento596 páginasPDFBranko NikolicAinda não há avaliações

- Torsion BarDocumento3 páginasTorsion BarGigi UrsuAinda não há avaliações

- Machinery's - Reference - Series - No - 15 Spur GearingDocumento49 páginasMachinery's - Reference - Series - No - 15 Spur GearingJohnAinda não há avaliações

- Jones Ch2 Traditional Design MethodsDocumento10 páginasJones Ch2 Traditional Design Methodssambedanayak22Ainda não há avaliações

- Ackerman Steering MechanismDocumento17 páginasAckerman Steering MechanismNinad Mirajgaonkar50% (2)

- Constructing A Year Clock by C.B. ReeveDocumento13 páginasConstructing A Year Clock by C.B. ReeveJohn Smith0% (1)

- Gyro GliderDocumento3 páginasGyro GliderEmerson UR100% (1)

- Phil Irving - Web PDFDocumento3 páginasPhil Irving - Web PDFprakash saralayaAinda não há avaliações

- Instructions PDFDocumento10 páginasInstructions PDFKiss Mátyás JuliánuszAinda não há avaliações

- Diferent I AlDocumento10 páginasDiferent I AlJef PerezAinda não há avaliações

- Construccion de EngranajesDocumento8 páginasConstruccion de Engranajesg7835389Ainda não há avaliações

- Car TransporterDocumento12 páginasCar TransporterDr DAinda não há avaliações

- Tractor Ploughing Manual, The, 2nd Edition: The Society of Ploughman Official HandbookNo EverandTractor Ploughing Manual, The, 2nd Edition: The Society of Ploughman Official HandbookNota: 5 de 5 estrelas5/5 (2)

- DorisDocumento78 páginasDorisjaviercj5477100% (1)

- DifferentialsDocumento8 páginasDifferentialstzeAinda não há avaliações

- He Story of The Austin Eight 1939Documento56 páginasHe Story of The Austin Eight 1939Kkbhuvan KkAinda não há avaliações

- Building One Lung KartsDocumento7 páginasBuilding One Lung KartsJim100% (5)

- Load-Equalizing Trailer Hitch You Can Make IDocumento4 páginasLoad-Equalizing Trailer Hitch You Can Make IFrenchwolf420Ainda não há avaliações

- TrainDocumento5 páginasTrainRoberpol100Ainda não há avaliações

- ERCO 415-A ErcoupeDocumento8 páginasERCO 415-A ErcoupeAviation/Space History LibraryAinda não há avaliações

- Modeling and Fatigue Analysis of Automotive Wheel RimDocumento46 páginasModeling and Fatigue Analysis of Automotive Wheel RimKannan SAinda não há avaliações

- Historical Development of The WheelDocumento4 páginasHistorical Development of The Wheelgsuresh40Ainda não há avaliações

- RockArmGeometry PDFDocumento10 páginasRockArmGeometry PDFMike100% (1)

- Leaf SpringDocumento34 páginasLeaf SpringjonAinda não há avaliações

- Model rs-36Documento12 páginasModel rs-36pwmvsiAinda não há avaliações

- Observations of Some Douglas Cylinder Heads: by Doug KephartDocumento6 páginasObservations of Some Douglas Cylinder Heads: by Doug KepharttosalemalAinda não há avaliações

- A Model Boat Builder's Guide to Rigging - A Collection of Historical Articles on the Construction of Model Ship RiggingNo EverandA Model Boat Builder's Guide to Rigging - A Collection of Historical Articles on the Construction of Model Ship RiggingAinda não há avaliações

- Lathe Alignment: by Tubal CainDocumento7 páginasLathe Alignment: by Tubal CainmarkschooleyAinda não há avaliações

- Vintage Farm Impliment Plans 1950sDocumento91 páginasVintage Farm Impliment Plans 1950sudivljini100% (4)

- Steering and Suspension BasicsDocumento38 páginasSteering and Suspension Basicsattitude0330100% (1)

- FTW Weav 4Documento64 páginasFTW Weav 4Kannan KumarAinda não há avaliações

- Model Elbow EngineDocumento5 páginasModel Elbow EngineJim100% (3)

- Scientific American Supplement, No. 794, March 21, 1891No EverandScientific American Supplement, No. 794, March 21, 1891Ainda não há avaliações

- Scientific American Supplement, No. 794, March 21, 1891No EverandScientific American Supplement, No. 794, March 21, 1891Ainda não há avaliações

- Introduction To GearsDocumento30 páginasIntroduction To GearsPrakash Joshi100% (5)

- Trusses - Part Two: How A Truss WorksDocumento19 páginasTrusses - Part Two: How A Truss WorksAkshay KasarAinda não há avaliações

- Testing The Alco HaulicsDocumento3 páginasTesting The Alco Haulicsstaustell92Ainda não há avaliações

- Planuri GyrocopterDocumento21 páginasPlanuri GyrocopterDRAGOS BILGAAinda não há avaliações

- SpitfireDocumento30 páginasSpitfireΚυριάκος ΒαφειάδηςAinda não há avaliações

- Suspension Fturur (Video Tutorial) SolidWorks - YouTubeDocumento2 páginasSuspension Fturur (Video Tutorial) SolidWorks - YouTubekuldip singhAinda não há avaliações

- ETL SQUIX2 en PDFDocumento12 páginasETL SQUIX2 en PDFAnonymous EDWe9ZAinda não há avaliações

- Reach TrucksDocumento3 páginasReach TrucksBiniyam12100% (2)

- Questionnaire MarketingDocumento4 páginasQuestionnaire MarketingAppu SpecialAinda não há avaliações

- 3RD CLUTCH - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsDocumento2 páginas3RD CLUTCH - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsashraf elsayedAinda não há avaliações

- Manuale Carrello A Gas 1.5-3.5 Tonnellate GRENDiA ESDocumento17 páginasManuale Carrello A Gas 1.5-3.5 Tonnellate GRENDiA ESryo asg3Ainda não há avaliações

- August 15 State Vehicle AuctionDocumento5 páginasAugust 15 State Vehicle AuctionPAindyAinda não há avaliações

- Trafic Range PDFDocumento28 páginasTrafic Range PDFCaroline PuckettAinda não há avaliações

- Automobile University QuestionsDocumento4 páginasAutomobile University QuestionsMr.Kumar K MAinda não há avaliações

- Bus Seat PlanDocumento1 páginaBus Seat PlanTesa GDAinda não há avaliações

- Volvo History LessionDocumento3 páginasVolvo History LessionmackAinda não há avaliações

- 303-14 Electronic Engine Controls - Diagnosis and TestingDocumento38 páginas303-14 Electronic Engine Controls - Diagnosis and TestingCARLOS LIMADAAinda não há avaliações

- Mitsubishi Colt 2007 Front SuspensionDocumento4 páginasMitsubishi Colt 2007 Front SuspensionnalokinAinda não há avaliações

- BCM Pq25Documento5 páginasBCM Pq25Totall Automotríz100% (2)

- 27 RegulatorsDocumento23 páginas27 RegulatorsRafael_jorge_7067% (3)

- Trojan Trailer ComponentsDocumento44 páginasTrojan Trailer ComponentsMarty DelimaAinda não há avaliações

- TD-40E Extra: Engine CoolingDocumento6 páginasTD-40E Extra: Engine CoolingMateusz JaskułaAinda não há avaliações

- All in One Box: Service-, Repair-And Wear Part Kits For Soil RollersDocumento4 páginasAll in One Box: Service-, Repair-And Wear Part Kits For Soil Rollersmsreddy27100% (1)

- THT-KANOO-BAPCO-COLD COLLECTOR-TP-4.00M.PF - For PermitDocumento1 páginaTHT-KANOO-BAPCO-COLD COLLECTOR-TP-4.00M.PF - For PermitEdward CelebreAinda não há avaliações

- Jungheinrich EFG 213-320 Operating Manual PDFDocumento109 páginasJungheinrich EFG 213-320 Operating Manual PDFAndy100% (1)

- New Tiguan Full Brochure 2023Documento19 páginasNew Tiguan Full Brochure 2023Vikas GahlotAinda não há avaliações

- Specifications 7 Series 730i 730li PDFDocumento2 páginasSpecifications 7 Series 730i 730li PDFKhawaja Arslan AhmedAinda não há avaliações

- Pt. Bumi Nikel Nusantara Absensi HarianDocumento11 páginasPt. Bumi Nikel Nusantara Absensi Harianhasna yusufAinda não há avaliações

- Honda Maestro Wiring DiagramDocumento246 páginasHonda Maestro Wiring Diagramedam laksanaAinda não há avaliações

- MHT-X 790Documento5 páginasMHT-X 790JpbAinda não há avaliações

- The Auto Industry: Flexible NetworksDocumento7 páginasThe Auto Industry: Flexible Networks常超Ainda não há avaliações

- Chevrolet Corvette (C6)Documento12 páginasChevrolet Corvette (C6)robertoAinda não há avaliações

- Electric Aisle-Master Parts ManualDocumento100 páginasElectric Aisle-Master Parts ManualNabot tecnicos100% (5)

- 3 Win Diesel PartsDocumento59 páginas3 Win Diesel PartsEphrem MichaelAinda não há avaliações

- FatBaggers Catalog 2010Documento116 páginasFatBaggers Catalog 2010sbinkerd1Ainda não há avaliações