Escolar Documentos

Profissional Documentos

Cultura Documentos

Double Block and Bleed Valves - Instrumentation - Oliver Valves

Enviado por

Kehinde AdebayoDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Double Block and Bleed Valves - Instrumentation - Oliver Valves

Enviado por

Kehinde AdebayoDireitos autorais:

Formatos disponíveis

Double Block and Bleed Valves - Instrumentation - Oliver Valves

http://www.valves.co.uk/double-block-and-bleed.php

Home Product Features Products Blog Careers Media Solutions Company

Search Products

Double Block and Bleed Valves

Oliver Valves in the early 80s pioneered this concept, which has very much now become a standard world wide. Each Double Block and Bleed has a unique number recording its factory history and we are now way above 100,000 of these units in installation worldwide. A smaller unit vs the traditional hook-up, bringing both piping and instrumentation isolation into one unit this means; Less weight, which is significant on the top side of a platform, when you combine all the pressure instrument take-offs. Typical installation it is reduced from 33kg to 7kg, a weight reduction of 75%! Weight reduction is also an issue when take-off is horizontal, this instils a bending moment and could cause critical fracture of pipeline interface and is generally overcome by adding more stanchions & cussetting to support traditional installation, which adds even more weight. Cost reduction typically 30% saving over traditional installation, which jumps up to 70% in the case of valves made from exotic materials for more exacting processes! Cost saving on site the cost of one factory tested component, as opposed to different piping valves, instrument valves, flanges, connections and flanged seal rings and then the cost to raise purchase orders and expediting department to chase the parts in goods receivable, etc., and then the shipping costs are larger and weightier, specs must all be taken into account, rises in cost can be 30% of the overall cost. Coded welders could be required as well. Safety including spool pieces the type of valve, i.e. standard 3-piece valve used in installation may have as many as nine additional leak points. Health & safety legislation is moving more and more towards testing at a considerable cost to each one of these joints after installation, cost of which can be excessive. Health & Safety USA and abroad process safety management document OCEA 3132, here in the UK Health & Safety Executive application HSG253 which is readily downloadable free, states double block and bleed must be used. All these documents stem from the Piper Alpha disaster over 20 years ago and the P36 disaster in Brazil, both of which indicated double block and bleed as a marked improvement for safety. The top-hat or T-section forging use of the body of the valve, and the H section use of flange to flange variance is upset forged, which means the grain flow of the material flows into the flange, making for a very strong body. First isolation is to a full piping valve ASME V111 specification, ball configurations whether they be standard 2-ball valves isolate and needle valve vent, 3-needle valves or 3-ball valves are all firesafe certified valves. Delivery the DBB part machine program that was set-up many years ago, in which we machined all aspects of the double block and bleed apart from one aspect, the customer specifies which is the flange, which leads to very quick lead times. Any different variations, including vent and injection, ball range, exotic materials, all the options available from standard ball and needle valves.

Email: Password:

Forgotten password? Register

T: +44 (0) 1565 632 636 F: +44 (0) 1565 654 089 E: sales@valves.co.uk

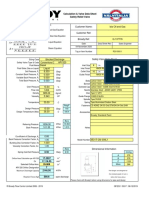

EXPLOSIVE DECOMPRESSION Explosive decompression occurs when gas at high pressure permeates into seal materials. When the gas pressure is reduced the absorbed gas expands which can cause the seals to swell and blister. Oliver Valves only use seal material within their Double Block and Bleed Valve range that are resistant to explosive decompression. 1 - ADVANCED DESIGNS Our products conform to the latest international design specifications and are approved by leading companies. 2 - TOUGH HANDLES Rugged, 316 stainless steel, low torque, quarter turn handles will not rust in offshore service. 3 - POSITIVE STOP PINS A 316 stainless steel pin held into the body by a machined anti-vibration spline assures an absolute 90 turn.

1 of 4

9/5/2012 8:17 AM

Double Block and Bleed Valves - Instrumentation - Oliver Valves

http://www.valves.co.uk/double-block-and-bleed.php

4 - HIGH PERFORMANCE SEATS Unique enclosed seats offer great process compatibility but restrict creep or distortion in service. Our approach achieves high levels of seat integrity at low and high pressures. 5 - FIRESAFE BALL VALVES Go metal to metal in a fire to reduce leakage due to seat destruction. 6 - BALL This precision machined component is super finished assuring low operating torques. 7 - THROUGH BORE OF BALL VALVES True positive 90 opening combined with clear through bores across the range allows rodding. 8 - PRECISION PROCESS THREADS Super finished screwcut not tapped threads using advanced CNC machines ensure easy assembly and leak tight threads with reduced risk of galling. 9 - SOLID BACKSEATED ANTIBLOWOUT SPINDLE Precision, rugged one piece stem incorporates anti-blow out feature and maintains seal integrity at all pressures. Anti-vibration lock nuts are standard to all products. 10 - BODY SEALS Totally contained O ring type body seals for body integrity and additionally protecting internal body threads from process media. 11 - DROP FORGED BODY A rigid one piece drop forged body, eliminates potential leak points experienced with conventional hook ups. 12 - BLOK-LOK (PATENT PENDING) Anti-removable pin, non-welded connector locking system which prevents accidental disassembly when in service. 13 - HEAVY DUTY FIRESAFE NEEDLE VALVES Olivers proven heavy duty needle pattern head unit features a rugged firesafe and tested construction.

Double Block and Bleed Valve Options

CARBON STEEL DOUBLE BLOCK AND BLEED VALVES have stainless steel end adaptors, seal housings and inserts as standard construction. The parts mentioned can also be made from carbon steel if specifically requested. Plating as standard with painting options available. HANDLE LOCKING - /HL Oliver unique handle locking system will prevent accidental operation tamper-proof. SPANNER ACTUATION - /SA Oliver tamper-proof spanner actuation for ball valve handles only.

Double Block and Bleed Valve Standard

FIRESAFE - /FS Firesafe construction compliant with BS 6755 part 2. API 607 and API 6FA. Fully certified to Lloyds type approval certificate numbers 88/0345, 91/0117, 92/0140 and 93/00068. High temperature Graphitereplaces PTFE for seals. NACE - /NA Compliance to NACE specification MR-01-75 latest revision suitable for sour service resistant to sulphide stress corrosion cracking. 316 stainless steel is solution annealed for trims.

Your Problem

Length = 42" (12" piping + 30" instrumentation).

Oliver DBB Valve Solution

Length = 7".

2 of 4

9/5/2012 8:17 AM

Double Block and Bleed Valves - Instrumentation - Oliver Valves

http://www.valves.co.uk/double-block-and-bleed.php

Weight = 100kg (Based on 1.5" 1500 class). 3 Ball & needle valve manifolds. 24 Bolts. 6 Gaskets. * Pipe support required due to high movement/additional weight

Weight = 7kg. 3 Double Block and Bleed Valve. 1 Gasket.

Your Key Selling Points

We eliminate a terrific amount of space when compared with welding three individual valves together. We save a huge amount of direct labour and site installation costs. We have reduced leakage points massively - a huge benfit as fugitive emissions are so important. We have reduced costs. We only have one component to be ordered, not many as in the old applications, which can save on inventory and site confusion. We can get away from local site support by reducing the bending movement. We can bring the pressure instrument a lot closer to the point of pressure measurement thus saving space which is most important on skip mounting applications. Unique numbering system on each valve recording factory history (the original manufacture being over 25 years and 200,000+ sold).

Olivers unique approach offers the designer of sampling, draining, injection and pressure instrument take-off points a simple, rigid, compact, safe, low-cost option to "CONVENTIONAL PRACTICE". Our double block and bleed valves are used in critical applications, where cost, weight and space saving are paramount for: Pressure instrument take-off points. Sampling systems, where a pipeline probe is integral with our valve. Chemical injection systems, where a check valve is part of our valve assembly. Drains for tanks and pipes, where space is restricted. High pressure firesafe diverter valves. Hydraulic power unit systems. Reduced vibrational stresses. Cost savings with exotic material designs are huge.

How to Order Double Block and Bleed Valves

3 of 4

9/5/2012 8:17 AM

Double Block and Bleed Valves - Instrumentation - Oliver Valves

http://www.valves.co.uk/double-block-and-bleed.php

Products

OliverValves

DBB Valves

Bolted Construction DBB Valves

Forged DBB Valves

Instrument DBB Valves

Recruitment

RSS Feeds

Privacy Policy

Copyright Oliver Valves Ltd 2012 E&OE

4 of 4

9/5/2012 8:17 AM

Você também pode gostar

- Corporate DatasheetsDocumento10 páginasCorporate DatasheetsNyomanIdabagusAinda não há avaliações

- Surface Preparation EssentialsDocumento18 páginasSurface Preparation EssentialsVincent LecoursAinda não há avaliações

- Offshore Magazine November 2015Documento88 páginasOffshore Magazine November 2015Shu En SeowAinda não há avaliações

- 05887E01Documento96 páginas05887E01brome2014Ainda não há avaliações

- Protecta FR Board: Technical Data SheetDocumento2 páginasProtecta FR Board: Technical Data SheetDejan DosljakAinda não há avaliações

- HERTEL Metal GasketsDocumento40 páginasHERTEL Metal Gasketshvdb72Ainda não há avaliações

- Standards For Pipeline Coatings: CanadDocumento11 páginasStandards For Pipeline Coatings: CanadMohamed DewidarAinda não há avaliações

- U BoltsDocumento14 páginasU BoltsLuz DuarteAinda não há avaliações

- Model Pipe Resting On The Seabed Floor - AutoPIPE - Pipe Stress and Vessel Design - Wiki - Pipe Stress and Vessel Design - Bentley CommunitiesDocumento7 páginasModel Pipe Resting On The Seabed Floor - AutoPIPE - Pipe Stress and Vessel Design - Wiki - Pipe Stress and Vessel Design - Bentley CommunitiesLK AnhDungAinda não há avaliações

- Wave BallDocumento23 páginasWave BallJomar VillenaAinda não há avaliações

- BVS-01 Stress AnalysisDocumento11 páginasBVS-01 Stress AnalysisSiva baalan100% (1)

- Flat-Bottom SilosDocumento64 páginasFlat-Bottom Siloskhan_mmusaAinda não há avaliações

- PE PandGJ AMPL PDFDocumento4 páginasPE PandGJ AMPL PDFTinuoye Folusho OmotayoAinda não há avaliações

- 6200 Cosasco Coupon HolderDocumento2 páginas6200 Cosasco Coupon HolderSaurabh MundheAinda não há avaliações

- Sizing CalcDocumento1 páginaSizing CalcHilary AbaratuAinda não há avaliações

- 6.1 Data Sheet For Pipeline Ball ValveDocumento3 páginas6.1 Data Sheet For Pipeline Ball ValveDeepak PalAinda não há avaliações

- PMSS Ball ValveDocumento1 páginaPMSS Ball ValveGourav SharmaAinda não há avaliações

- Technical Vol IIA of II PDFDocumento358 páginasTechnical Vol IIA of II PDFSALMAN ANSARIAinda não há avaliações

- AV GasketsDocumento2 páginasAV GasketsAliAinda não há avaliações

- GeoMatt Datasheet TB11 Ed1 2017 ASTM ADDocumento1 páginaGeoMatt Datasheet TB11 Ed1 2017 ASTM ADganmosesAinda não há avaliações

- Connectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsDocumento2 páginasConnectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsTTAinda não há avaliações

- Non Metallic Flat GasketsDocumento4 páginasNon Metallic Flat GasketsMarko ZoricicAinda não há avaliações

- QuillsDocumento4 páginasQuillsajostosAinda não há avaliações

- BV Gate Valve DS 15111Documento2 páginasBV Gate Valve DS 15111yulianus_srAinda não há avaliações

- 00300E04Documento30 páginas00300E04halim_kaAinda não há avaliações

- 010 Subsea Hose PDFDocumento16 páginas010 Subsea Hose PDFJhonatan FerreiraAinda não há avaliações

- Typical Ball Valve Material SelectionDocumento12 páginasTypical Ball Valve Material SelectionabsherlockAinda não há avaliações

- Pipe Size Calc - Gas - LINDocumento1 páginaPipe Size Calc - Gas - LINjollyAinda não há avaliações

- U-Bolts Supports PDFDocumento4 páginasU-Bolts Supports PDFNguyen Thanh NguyenAinda não há avaliações

- MME Group Anode BookletDocumento158 páginasMME Group Anode BookletYurizki LhzAinda não há avaliações

- FMC KL-Clamp ConnectorsDocumento3 páginasFMC KL-Clamp ConnectorsBalamir YasaAinda não há avaliações

- Ball Valve: Zhejiangbeiercontrol Valveco.,LtdDocumento16 páginasBall Valve: Zhejiangbeiercontrol Valveco.,LtdSandipan GhoshAinda não há avaliações

- Swaged Sleeve Welding For Pipe in PipeDocumento12 páginasSwaged Sleeve Welding For Pipe in PipeSridharan ChandranAinda não há avaliações

- Monobore Sub SeaDocumento9 páginasMonobore Sub Seacamilo777Ainda não há avaliações

- BEL - 6D Through Conduit GateDocumento2 páginasBEL - 6D Through Conduit Gateasoka.pwAinda não há avaliações

- Cryogenic Ball Valve: Lishui Oak Valve Parts Co,.LtdDocumento7 páginasCryogenic Ball Valve: Lishui Oak Valve Parts Co,.LtdShams TabrezAinda não há avaliações

- Ball Valve Catalogue-2Documento12 páginasBall Valve Catalogue-2tndeshmukhAinda não há avaliações

- Stress Corrosion Cracking of A723 Steel Pressure Vessel Two Case StudiesDocumento38 páginasStress Corrosion Cracking of A723 Steel Pressure Vessel Two Case Studieslitao2314Ainda não há avaliações

- Through Conduit Gate Valves Slab & ExpandingDocumento7 páginasThrough Conduit Gate Valves Slab & ExpandingRockny310Ainda não há avaliações

- Perar Trunnion Ball ValvesDocumento54 páginasPerar Trunnion Ball ValvesUday GokhaleAinda não há avaliações

- Flanged Ball Trunnion ValvesDocumento24 páginasFlanged Ball Trunnion ValvesMahdi DalyAinda não há avaliações

- Trunnion Mounted Ball ValveDocumento20 páginasTrunnion Mounted Ball ValveJignesh PandyaAinda não há avaliações

- BS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedDocumento24 páginasBS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedtienlamAinda não há avaliações

- Trunnion Mounted Ball Valve Catalog from Walworth ValvesDocumento84 páginasTrunnion Mounted Ball Valve Catalog from Walworth ValvesWilmer CelisAinda não há avaliações

- Upheaval & Lateral Buckling Calculations For Buried Pipelines - TR Engineering Consultancy LLCDocumento2 páginasUpheaval & Lateral Buckling Calculations For Buried Pipelines - TR Engineering Consultancy LLCRaakze MoviAinda não há avaliações

- BSEE Steel Catenary Riser Integrity Management ReportDocumento26 páginasBSEE Steel Catenary Riser Integrity Management ReportEyoma EtimAinda não há avaliações

- Piping GuideDocumento257 páginasPiping Guideveluchamymuthukumar100% (2)

- Induction Bends in Material Grade X80Documento0 páginaInduction Bends in Material Grade X80Nandhakumaran RajagopalanAinda não há avaliações

- MATERIAL SPECIFICATIONDocumento5 páginasMATERIAL SPECIFICATIONamini_mohiAinda não há avaliações

- API 6D-IsO 14313 23rd Edition Errata 6Documento3 páginasAPI 6D-IsO 14313 23rd Edition Errata 6adil_farooq_6100% (1)

- ASTM B557 10 Standard Test MethodDocumento15 páginasASTM B557 10 Standard Test MethodmehmetAinda não há avaliações

- Specification For Line Pipe (Tensile Properties)Documento2 páginasSpecification For Line Pipe (Tensile Properties)jan_matej5651Ainda não há avaliações

- FRP PipesDocumento20 páginasFRP PipesThomasFrenchAinda não há avaliações

- Versa ValveDocumento24 páginasVersa ValvetalangocdayAinda não há avaliações

- Analysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsDocumento5 páginasAnalysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsIJIRAE- International Journal of Innovative Research in Advanced EngineeringAinda não há avaliações

- Double Block and Bleed Valves DesignDocumento16 páginasDouble Block and Bleed Valves DesignUncircleDecoderAinda não há avaliações

- E-Series Flanged Ball Valves: ANSI 150 and 300 Regular and Full-PortDocumento16 páginasE-Series Flanged Ball Valves: ANSI 150 and 300 Regular and Full-PortAhmed RashiedAinda não há avaliações

- Double Block and Bleed ValveDocumento16 páginasDouble Block and Bleed ValveBa Jun Thối100% (1)

- Fire Pump System ChecklistDocumento4 páginasFire Pump System ChecklistAhmed Sayed Abdel Tawab100% (1)

- Cosasco Access FittingsDocumento2 páginasCosasco Access FittingsE_Rodriguez20Ainda não há avaliações

- Access Fittings (Non Tee)Documento3 páginasAccess Fittings (Non Tee)anup_sahaniAinda não há avaliações

- FPSODocumento143 páginasFPSORagunath KarthickAinda não há avaliações

- Sweco CatDocumento21 páginasSweco CatArmandoZacariasAcostaAinda não há avaliações

- NPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Documento38 páginasNPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Kehinde AdebayoAinda não há avaliações

- Overview of Piping Layout.Documento4 páginasOverview of Piping Layout.Kehinde AdebayoAinda não há avaliações

- 1 - Pipe Schedule & Weight MeasurementDocumento1 página1 - Pipe Schedule & Weight MeasurementSutrisno KlsAinda não há avaliações

- Astm d1785Documento5 páginasAstm d1785Kehinde AdebayoAinda não há avaliações

- 2010 Pipe Materials GuideDocumento36 páginas2010 Pipe Materials GuideAlmeghalawyAinda não há avaliações

- SmartTrap Launcher ReceiverDocumento4 páginasSmartTrap Launcher ReceiverKehinde AdebayoAinda não há avaliações

- METRIC_ENGLISHDocumento14 páginasMETRIC_ENGLISHKehinde AdebayoAinda não há avaliações

- Pump document title under 40 charactersDocumento32 páginasPump document title under 40 charactersKehinde Adebayo100% (1)

- Piping Design ProcedureDocumento42 páginasPiping Design ProcedureKehinde Adebayo75% (4)

- Vista Complate Pressure Vessels CatalogeDocumento11 páginasVista Complate Pressure Vessels CatalogeKehinde Adebayo100% (1)

- Class 1500 2500 3pc Flanged Ball Valve-Ningbo Valve FactoryDocumento3 páginasClass 1500 2500 3pc Flanged Ball Valve-Ningbo Valve FactoryKehinde AdebayoAinda não há avaliações

- Argus Automatic Pigging BrochureDocumento6 páginasArgus Automatic Pigging BrochureKehinde AdebayoAinda não há avaliações

- Stress Analysis of Piping1Documento90 páginasStress Analysis of Piping1sateesh chand100% (2)

- Table of Contents and Piperack Design GuidelinesDocumento20 páginasTable of Contents and Piperack Design GuidelinesKehinde AdebayoAinda não há avaliações

- Stress Analysis Training - Caesar IIDocumento2 páginasStress Analysis Training - Caesar IIKehinde Adebayo100% (2)

- Process Plant Layout and Piping DesignDocumento460 páginasProcess Plant Layout and Piping Design~E~97% (32)

- The Two Most Common Methods of Measuring The Volume of Petroleum Liquids Are Tank Gauging and Liquid MeteringDocumento4 páginasThe Two Most Common Methods of Measuring The Volume of Petroleum Liquids Are Tank Gauging and Liquid MeteringKehinde AdebayoAinda não há avaliações

- Table of Contents and Piperack Design GuidelinesDocumento20 páginasTable of Contents and Piperack Design GuidelinesKehinde AdebayoAinda não há avaliações

- Wellheadcon NumenclatureDocumento2 páginasWellheadcon NumenclatureKehinde AdebayoAinda não há avaliações

- Cooling Water SystemDocumento14 páginasCooling Water SystemKehinde AdebayoAinda não há avaliações

- Variable Spring Hangers - Installation & Maintenance GuideDocumento3 páginasVariable Spring Hangers - Installation & Maintenance GuideKehinde AdebayoAinda não há avaliações

- Table of Contents and Piperack Design GuidelinesDocumento20 páginasTable of Contents and Piperack Design GuidelinesKehinde AdebayoAinda não há avaliações

- Preliminary Piping Design - 45Documento1 páginaPreliminary Piping Design - 45Kehinde AdebayoAinda não há avaliações

- PumpsDocumento22 páginasPumpsKehinde AdebayoAinda não há avaliações

- 17-185 Salary-Guide Engineering AustraliaDocumento4 páginas17-185 Salary-Guide Engineering AustraliaAndi Priyo JatmikoAinda não há avaliações

- Sensors & Accessories User ManualDocumento114 páginasSensors & Accessories User ManualAbrakain69Ainda não há avaliações

- Model HA-310A: Citizens BandDocumento9 páginasModel HA-310A: Citizens BandluisAinda não há avaliações

- Retool Your Linux Skills For Commercial UNIXDocumento19 páginasRetool Your Linux Skills For Commercial UNIXPauloAinda não há avaliações

- The Grand Landscape - Ian PlantDocumento145 páginasThe Grand Landscape - Ian PlantJohanny Bravo100% (1)

- 2022 Australian Grand Prix - Race Director's Event NotesDocumento5 páginas2022 Australian Grand Prix - Race Director's Event NotesEduard De Ribot SanchezAinda não há avaliações

- Organizational BehaviorDocumento15 páginasOrganizational Behaviorjuvy anne PobleteAinda não há avaliações

- Aits 2223 PT III Jeea Paper 1Documento15 páginasAits 2223 PT III Jeea Paper 1Suvrajyoti TaraphdarAinda não há avaliações

- Simulation of The Pyrolysis Process From Plastic WasteDocumento5 páginasSimulation of The Pyrolysis Process From Plastic WasteManicks VelanAinda não há avaliações

- Archana PriyadarshiniDocumento7 páginasArchana PriyadarshiniJagriti KumariAinda não há avaliações

- HL Essay RubricDocumento2 páginasHL Essay Rubricapi-520941535Ainda não há avaliações

- Deflected Profile of A BeamDocumento2 páginasDeflected Profile of A BeamPasindu MalithAinda não há avaliações

- No. of Periods UNIT - 1: Antenna FundamentalsDocumento8 páginasNo. of Periods UNIT - 1: Antenna Fundamentalsbotla yogiAinda não há avaliações

- Semi Detailed LP in Math 8 Inductive Reasoning by Jhon Edward G. Seballos San Roque NHS BulalacaoDocumento3 páginasSemi Detailed LP in Math 8 Inductive Reasoning by Jhon Edward G. Seballos San Roque NHS BulalacaoRuth Matriano100% (2)

- File Download ActionDocumento45 páginasFile Download Actionecarter9492Ainda não há avaliações

- Fracture Mechanics HandbookDocumento27 páginasFracture Mechanics Handbooksathya86online0% (1)

- International Journal of Organizational Innovation Final Issue Vol 5 Num 4 April 2013Documento233 páginasInternational Journal of Organizational Innovation Final Issue Vol 5 Num 4 April 2013Vinit DawaneAinda não há avaliações

- Lewatit VP OC 1600 LDocumento3 páginasLewatit VP OC 1600 Lphucuong2410Ainda não há avaliações

- Practical Exercise - Analysis of The Collapse of Silicon Valley BankDocumento2 páginasPractical Exercise - Analysis of The Collapse of Silicon Valley Bankhanna.ericssonkleinAinda não há avaliações

- Indonesian Hotel Annual ReviewDocumento34 páginasIndonesian Hotel Annual ReviewSPHM HospitalityAinda não há avaliações

- 43041515Documento68 páginas43041515KomtelecAinda não há avaliações

- Study Guide For Kawabata's "Of Birds and Beasts"Documento3 páginasStudy Guide For Kawabata's "Of Birds and Beasts"BeholdmyswarthyfaceAinda não há avaliações

- Cheatsheet HomebrewDocumento1 páginaCheatsheet HomebrewfredmnAinda não há avaliações

- Replit Ubuntu 20 EnablerDocumento4 páginasReplit Ubuntu 20 EnablerDurval Junior75% (4)

- Compiled Lecture in Engineering Economy PDFDocumento78 páginasCompiled Lecture in Engineering Economy PDFLJ dela PazAinda não há avaliações

- Jene Sys 2016 ApplicationformDocumento4 páginasJene Sys 2016 ApplicationformReva WiratamaAinda não há avaliações

- TPS6 LecturePowerPoint 11.1 DT 043018Documento62 páginasTPS6 LecturePowerPoint 11.1 DT 043018Isabelle TorresAinda não há avaliações

- Hrm-Group 1 - Naturals Ice Cream FinalDocumento23 páginasHrm-Group 1 - Naturals Ice Cream FinalHarsh parasher (PGDM 17-19)Ainda não há avaliações

- Life Orientation September 2022 EngDocumento9 páginasLife Orientation September 2022 EngTondaniAinda não há avaliações

- SQL QuestionsDocumento297 páginasSQL Questionskeysp75% (4)