Escolar Documentos

Profissional Documentos

Cultura Documentos

Aure Ioannides TRB2010

Enviado por

Anastasios KarahaliosDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Aure Ioannides TRB2010

Enviado por

Anastasios KarahaliosDireitos autorais:

Formatos disponíveis

Simulation of Crack Propagation in Concrete Beams with Cohesive Elements in ABAQUS

Temesgen W. Aure and Anastasios M. Ioannides

This paper discusses the simulation of crack propagation in concrete beam specimens with a nite element package, ABAQUS, version 6.7-1. Special-purpose cohesive elements are used to model the fracture process by means of the ctitious crack model. Two- as well as three-dimensional nite element discretizations are carried out. Parameters inuencing the responses, such as mesh neness, cohesive zone width, type of softening curve, and analysis technique, are studied. The responses are then compared with previous experimental and numerical investigations conducted by various independent researchers, and it is shown that cohesive elements can be used in modeling crack propagation as required in pavement engineering.

The development of a mechanisticempirical approach for the design of pavement systems has received increased attention recently, reigniting the debate over the use of statisticalempirical transfer functions, whose experimental verification is questionable, at best (1, 2). Following an exhaustive examination of various fracture mechanics options offered as replacements to Miners hypothesis (3), Hillerborg et al.s ctitious crack model (FCM) was found to be the most promising for studying crack propagation in portland cement concrete (PCC) pavements (4), and a step-by-step approach was outlined for its implementation (5). Accordingly, Ioannides and Sengupta (6) formulated a two-dimensional (2-D) numerical procedure to simulate crack propagation on the basis of the FCM for a simply supported beam. The response of the beam over the elastic region was analyzed with the commercial nite element (FE) software GTSTRUDL (7 ), while its fracture behavior was studied with a specially coded FORTRAN program, called CRACKIT. To facilitate the generalized application of the concepts implicit in the GTSTRUDLCRACKIT combination, Ioannides et al. (8) subsequently implemented their approach by using the general purpose FE package ABAQUS (9). They reported that the applicability of the built-in fracture analysis capabilities of ABAQUS was too limited for pavement engineering, especially because the FCM was not used. Consequently, in their 2-D study of simply supported beams, the investigators employed a nonlinear spring element from the ABAQUS library, JOINTC, to model the fracture zone. An alternative approach was developed by Song (10),

Department of Civil and Environmental Engineering, University of Cincinnati (ML-0071), P.O. Box 210071, Cincinnati, OH 45221-0071. Corresponding author: T. W. Aure, auretw@mail.uc.edu. Transportation Research Record: Journal of the Transportation Research Board, No. 2154, Transportation Research Board of the National Academies, Washington, D.C., 2010, pp. 1221. DOI: 10.3141/2154-02

who coded a user-dened subroutine in ABAQUS, thereby creating a user element (UEL); an application of this UEL is described in the 2-D study of crack propagation in simply supported asphalt concrete beams by Song et al. (11). A series of such 2-D four-noded UEL elements was inserted at the center of the beam to simulate fracture. The corresponding case involving a three-dimensional (3-D) PCC pavement slab on grade was rst considered by Ioannides and Peng (12), who once again used JOINTC elements from the ABAQUS library. A 3-D cohesive zone UEL was also formulated by Song (10) and was applied to a cylindrical asphalt concrete specimen. Such efforts received a boost with the release in early 2005 of ABAQUS version 6.5, which for the rst time included a family of cohesive elements for modeling deformation and damage in nitethickness adhesive layers between bonded parts. Cohesive elements are typically connected to underlying elements with surface-based tie constraints, so the mesh used for the cohesive layer can be independent of the mesh used for the bonded components (13). Gaedicke and Roesler (14) reported using these cohesive elements in their study of crack propagation in concrete beams and slabs. The investigation presented in this paper is a continuation of the step-by-step development and application of fracture mechanics tools that are based on the FCM in pavement engineering initiated at the University of Cincinnati in the late 1990s. The main objective is to implement the built-in cohesive elements that have recently been added to the ABAQUS library and to compare the performance of these elements to that reported in earlier investigations. It is hoped that, in this manner, a contribution will be made to the ongoing effort for more mechanistic pavement design procedures that will use fracture mechanics concepts, thereby replacing the purely empirical statistical transfer functions and Miners hypothesis, which are currently in use. Validating an FE simulation of crack propagation in a simply supported beam is considered to be a necessary precursor to a more comprehensive analysis of slabs-on-grade required for in situ pavement systems.

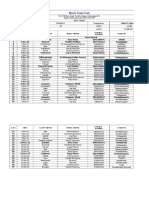

METHODOLOGY The present study focuses on the postcracking response of simply supported PCC beams by means of the commercial, general purpose FE program ABAQUS (Standard) version 6.7-1 (15). The geometric and material properties of the beams considered in this paper are shown in Table 1. To begin with, however, a linear elastic analysis using 2-D and 3-D elements is described, and the results are compared with available closed-form solutions. This initial step is considered essential in ensuring the robustness of the proposed FE formulation.

12

Aure and Ioannides

13

TABLE 1

Geometry and Material Properties of Beams Studied Youngs Modulus E (ksi) 4,000 5,405 4,641 Tensile Strength f t (ksi) 0.463 0.463 0.602 Fracture Energy GF (lbf/in.) 0.431 0.431 0.954

Beam A B C

Source Sengupta (16) Liu (19) Roesler et al. (20)

Span S (in.) 16.0 12.0 39.4

Length L (in.) 16.0 12.0 43.3

Depth h (in.) 6.0 3.0 9.8

Width b (in.) 1.5 1.0 3.2

NOTE: 1 lbf = 4.444 N; 1 in. = 25.4 mm; 1 ksi = 6.89 MPa.

Upon the successful conclusion of the linear elastic analysis, the simulation of crack propagation can be carried out, by implementing the built-in cohesive elements of ABAQUS, on the basis of the FCM for fracture. In all analyses, Elements CPS4 and C3D27 are used for 2-D and 3-D discretizations of the intact material, respectively, while the cohesive fracture zone is simulated with COH2D4 (2-D) and COH3D8 (3-D) elements. Program runs reported here capture the effects of the numerical analysis technique, mesh fineness, cohesive-zone width, and softening-curve type. The resulting simulation is nally used to reproduce numerical and experimental studies conducted by other independent researchers, thereby adding to its credibility.

pared with values computed in accordance with various theories, as summarized by Shames and Dym (18). It was found that the FE idealization exhibited near-perfect agreement with the theory of elasticity accounting for Poissons ratio effect. Moreover, the FE solution provided an excellent approximation (98.86% and 98.66% for 2-D and 3-D, respectively) to the beam with a shear deformation solution. It was, therefore, concluded that the numerical approach implemented in this study was robust as far as the linear elastic aspects of the analysis were concerned and that it might be considered a good candidate for investigating the more-demanding fracture mechanics issues of crack propagation in simply supported beams.

ANALYSIS OF LINEAR ELASTIC RESPONSE This section reports on testing of the robustness of the proposed FE formulation through simulation of the linear elastic response of Beam A (Table 1). This beam was originally used by Sengupta (16) and was later adopted by Ioannides et al. (8), whose results are, therefore, available for comparison, along with published closedform solutions. Both concentrated and uniformly distributed loads are considered. Beam A was assumed to be simply supported on rollers, requiring 2 degrees of freedom (vertical displacement) to be xed at the two support nodes. Because of symmetry, half of the beam was meshed uniformly with 64 48 CPS4 and 40 30 5 C3D27 elements, for the 2-D and 3-D discretizations, respectively. All elements used were nearly square, which thereby eliminated any signicant aspect ratio effects. Once the mesh for the half of the beam on the right-hand side was dened, a mirror image was created along the plane of symmetry and surface-based tie constraints used to connect surfaces on either side of the symmetry plane. The simulations rst considered a concentrated load of 33.7 kips, applied at the midspan. For the 2-D model, the load was applied on the top node at the midspan. To avoid localized effects in the 3-D idealization, a small loaded area 0.4 1.5 in. (two elements along the symmetry line) was dened at the center of the beam, on which a pressure of 56.17 ksi was applied. The same beam was also subjected to a uniformly distributed load of 10 kips/in. This load was applied at a pressure of 6.667 ksi (10 kips/in. divided by 1.5 in.) over the top-surface elements. Simulation results were compared with closed-form solutions. For the beam subjected to concentrated load, the midspan deection was compared with that reported by Timoshenko and Goodier (17) as accounting for the shear deformation, with which it was found to agree within 2.3% and 0.3%, for the 2-D and 3-D discretizations, respectively. For the uniformly distributed load, results were com-

SIMULATION OF CRACK PROPAGATION BY USING BUILT-IN COHESIVE ELEMENTS This section outlines the FE formulation of the cohesive elements recently introduced in ABAQUS and their implementation in accordance with the FCM for investigating the postfracture response of simply supported concrete beams. The sensitivity of the FE solution to a variety of aspects of the numerical procedure employed is also examined.

Idealization of Cohesive Zone Among the three classes of cohesive elements that are available in ABAQUS, those based on the so-called tractionseparation formulation are the most suitable for use in crack propagation studies that use the FCM. Accordingly, the load-response process can be subdivided into three stages: precrack, initiation of crack, and postpeak (or softening) behavior.

Precrack Behavior

During the precrack stage, the material along the beam centerline is considered to experience a very small but finite separation and the cohesive-element response is governed by the following elastic straindisplacement relations (15): wn 1 ws s = T0 wt t

n

(1)

where and w are the nominal strain and elastic separation, respectively, in the normal (n) and two shear directions (s and t) and T0 is

14

Transportation Research Record 2154

initial width of the cohesive zone. The elastic stress components can then be computed from Equation 2: t n K nn t s = t t symm K ns K ss K nt K st Ktt s t

n

(2)

at which the separationtraction stress pair is wk , f ; and (c) the t critical (or maximum) separation, wf , for which the traction stress is zero. The crack evolution for any kind of softening is facilitated by using a dimensionless damage variable defined as shown in Equation 4 (14, 15): D = 1 ts ti wcr w wf (4)

where K is a nominal stiffness (also referred to as penalty stiffness) and t is the nominal stress, in the normal and two shear directions, respectively. If the shear and normal components are uncoupled, Equation 2 will reduce to t n K nn t s = 0 t t 0 0 K ss 0 0 0 Ktt s t

n

where t is the traction stress for separation w, along the softening s curve, and ti is the traction stress that would have corresponded to w had the precrack stiffness endured, as explained in Figure 1. For linear softening, Equation 4 yields D= wf ( w wcr ) w ( wf wcr ) wcr w wf (5)

(3)

For a 2-D model, only the rst two rows and columns of Equation 3 are used. Selection of the initial width of the cohesive zone and of the penalty stiffness, K, is largely based on prior experience with using the software, yet it can inuence the solution convergence signicantly. ABAQUS (15) recommends computing the penalty stiffness from Knn = E/T0, where E is the Youngs modulus of the intact (or uncracked) material. Similarly, it may be assumed that Kss = Ktt = G/T0, where G is the corresponding shear modulus of the intact material.

For bilinear softening, the location of the kink point is obviously important. ABAQUS incorporates only linear and exponential softening curves. Other kinds of curves (including the bilinear one), however, may be specied by the user in a tabular form.

Sensitivity Study for Proposed Discretization Previous investigators have examined in detail the effect of several variables inuencing numerical solutions analogous to that proposed in the present paper. Thus, Song et al. (11) studied the effect of total fracture energy, GF (dened as the area under the bilinear curve shown in Figure 1), of tensile strength, f t, and of cohesive zone mesh, on the fracture of asphalt concrete beams. Furthermore, Park (22) examined the sensitivity of the solution to the initial fracture energy, Gf (dened as the area under the rst two limbs of the softening curve shown in Figure 1), as well as of the location of the kink point, for PCC specimens. The latter was also investigated by Gaedicke and Roesler (14) by using built-in cohesive elements. In this section, the sensitivity of the proposed FE discretization to the analysis technique, mesh size, cohesive zone width for PCC, and type of softening curve is investigated. The beams are idealized by

Initiation of Crack and Postpeak Behavior

Crack initiation refers to the beginning of the degradation of the material. In PCC crack propagation studies, it is often assumed that the crack initiates when the stress reaches the tensile strength, f t, of the material (6, 19, 20). Once the crack initiates, material damage evolves on the basis of a predefined softening law. Park et al. (21) provided a comprehensive list of softening options proposed for concrete. First, Hillerborg et al. (4) used a linear softening curve. Today, it is more common to employ a bilinear curve characterized by three points, as shown in Figure 1: (a) the crack initiation point, defined by traction stress f t and separation wcr ; (b) the kink point,

Tractions, t ti (wi, ti)

ft Knn

(wi, ts) (wk, ft)

wcr

FIGURE 1

wi

w1 Separation, w

wf

Bilinear softening curve.

Aure and Ioannides

15

using 3-D elements, C3D27 for the intact material and COH3D8 for the cohesive zone, respectively.

Effect of Analysis Technique

For the purposes of this investigation, there are two analysis options in ABAQUS: the general (or default, which uses a NewtonRaphson method) and the modified Riks procedures (15). The latter is particularly suited for potentially unstable problems that occasionally exhibit negative stiffness values or present convergence difficulties (e.g., buckling and snap-back of the loaddisplacement curve). Because cohesive elements involve softening that results from progressive material damage, they may also experience such numerical problems. A possible solution when using the NewtonRaphson approach is to apply viscous regularization (15), but a preferable alternative is to employ the modied Riks procedure. For example, Song et al. (11, 23) encountered divergence problems when using the NewtonRaphson method, whereas the modied Riks approach produced convergence. For their part, Yang and Proverbs (24) studied the efficacy of various solution strategies for fracture and concluded that arc lengthbased solvers (such as that used in the modied Riks method) would capture the softening behavior in the snap-back type of loaddisplacement relations. To study the effect of the two analysis options in ABAQUS, Beam A in Table 1 was considered in an unnotched conguration. The cohesive zone width was set to 0.001 in. The penalty stiffnesses, Knn, Kss, and Ktt, were computed as noted earlier. Linear softening was used for simplicity. For the NewtonRaphson method, the loading parameters that need to be specied are initial time increment (ITI), time period of the step (TPS), minimum time increment (MnTI). and maximum time increment (MxTI). These were set to 6.E3, 1.0, 1.E9, and 3.E2, respectively, on the basis of previous work by Ioannides et al. (8). To alleviate convergence problems, viscous regularization is used

with viscosity set to 1E06, selected on the basis of several preliminary trials. The maximum number of time increments is set to 200. In contrast, the modied Riks approach requires four parameters to be defined: the initial increment in the arc length along the static equilibrium path, lin; the total arc length scale factor, lperiod; and the minimum and maximum arc length increments, lmin and lmax, respectively. A convenient way to assign numerical values for these parameters is to retain those specied above: 6.E3, 1.0, 1.E9, 3.E2, respectively. Moreover, the terminal increment is similarly set to 200. The results are plotted in Figure 2 as crack mouth opening displacement versus load (CMOD-P) and load line displacement versus load (LLD-P) curves. It is clear that the trends captured by the two methods are signicantly different; those in accordance with the modied Riks approach are considered more realistic because they reflect the snap-back behavior expected in the softening stage. It is recommended, therefore, that the modied Riks procedure be adopted for use with built-in cohesive elements.

Effect of Mesh Fineness

Beam B in Table 1 is considered for this set of runs, which involves both multiple mesh congurations for the intact region of the beam and a constant mesh for the cohesive zone. Linear softening was used for simplicity. The coarse mesh consisted of 24 6 2 elements in the length, depth, and width directions, whereas the fine mesh had 60 15 8 elements and the median mesh had 36 9 4 subdivisions. The cohesive zone mesh was set to be 10 times as ne as the median mesh in the depth and width directions and had one element in the length direction. In view of space limitations, no graph of results is presented here because the effect of fineness was surprisingly insignicant for the meshes adopted, especially for the CMOD response. Inasmuch as there were differences between the coarser and the ner meshes for the LLD response, it was observed that a ner mesh generally resulted in a slightly lower load before

1.80 1.60 1.40 1.20 Load (kips) 1.00 0.80 0.60 0.40 0.20 0.00 0.000

CMOD CMOD LLD LLD

NR Riks NR Riks

0.001

0.003 0.002 CMOD/2 or LLD (in.)

0.004

0.005

FIGURE 2 Effect of analysis technique (NewtonRaphson versus modified Riks) on Beam A.

16

Transportation Research Record 2154

the peak and a slightly higher load after the peak, but the differences did not exceed 5%.

and experimental results obtained by other researchers, as described in the following sections.

Effect of Cohesive-Zone Width

To investigate the inuence of the cohesive-zone width, three widths were considered: T0 = 1.0, 0.01, and 0.001 in. Three-dimensional FE discretization of Beam B with linear softening was carried out. Figure 3 shows that, as the cohesive zone width increased, the elastic deformation of the cohesive zone increased, contributing much to the elastic fracture energy until damage began. Once damage started, the responses were not sensitive to the cohesive-zone width. An increase in cohesive-zone width decreased the peak load that could be supported by the beam. The 0.01- and 0.001-in. widths, however, yielded almost the same result, which led to the decision to use 0.001 in. in all subsequent sections.

COMPARISON WITH PREVIOUS NUMERICAL MODELS In this section, comparison is made of simulation results obtained from this study with those from numerical studies conducted by other independent researchers. The purpose is to validate the proposed FE procedure by contributing evidence conrming its credibility.

GTSTRUDLCRACKIT by Sengupta In the earliest University of Cincinnati effort to simulate crack propagation in simply supported concrete beams, Sengupta (16) developed a combination approach that employed a commercial software FE package, GTSTRUDL, for the elastic response and the corresponding exibility matrix, in tandem with a specially coded FORTRAN computer program named CRACKIT for the ensuing fracture behavior, in accordance with a bilinear softening law and the FCM. To illustrate his approach, Sengupta (16) reproduced a beam that had rst been studied by Liu (19) and discretized it with four-node plane stress elements of size 0.2 0.5 in. Lius beam is Beam B in Table 1 and is considered in the present study with a 3-D idealization by using C3D27 elements of size 0.2 0.2 0.2 in. Results from the 2-D CRACKIT approach by Sengupta and the 3-D COH3D8 procedure employed for the cohesive fracture zone in this study are shown in Figure 4, in which the LLD-P curves appear to agree better than the CMOD-P curves. The difference between the LLD-P curves can be explained by the difference in the intact region elements used (2-D four-node element versus 3-D 27-node element), whereas the CMOD-P discrepancy is mainly due to the implicit assumption in CRACKIT that the notch remains undeformed until the crack begins to propagate.

Effect of Softening Curve

In the cases considered above, linear softening was used for its simplicity. A comparison between linear and bilinear curves employed in conjunction with Beam B indicated that linear softening would overpredict the peak load by about 11%. After the peak, however, the bilinear curve would eventually give a higher load than the linear one. The areas under CMOD-P curves for both softening models seemed to be approximately the same because the areas under both softening curves were also assumed to be the same. The sensitivity of the proposed fracture formulation to various parameters has been investigated. It can be concluded that careful attention should be given to the selection of the type of solver, the width of the cohesive zone, and the type of softening curve in modeling crack propagation by using cohesive elements. Once the effect of each parameter involved in the cohesive zone FE analysis is understood, the approach is then applied to reproducing numerical

0.45 0.40 0.35 0.30 Load (kips) 0.25 0.20 0.15 0.10 0.05 0.00 0.000

t=1.000 in. t=0.010 in. t=0.001 in.

0.001

0.002 0.003 CMOD/2 (in.)

0.004

0.005

FIGURE 3

Effect of cohesive zone width (Beam B).

Aure and Ioannides

17

0.18 0.16 0.14 0.12 Load (kips) 0.10 0.08 0.06 0.04 0.02 0.00 0.000 CMOD LLD CMOD LLD 2D CRACKIT 2D CRACKIT 3D COH3D8 3D COH3D8

0.001

0.001

0.002 0.002 CMOD/2 or LLD (in.)

0.003

0.003

0.004

FIGURE 4

Comparison of 2-D CRACKIT with 3-D cohesive elements (Beam B).

ABAQUSJOINTC by Ioannides et al. To model crack propagation in concrete beams with ABAQUS, Ioannides et al. (8) used CPS4 elements for the intact region and a JOINTC nonlinear spring element for the fracture zone, prescribing the same bilinear FCM curve as Sengupta (16). Beam A in Table 1 was considered and discretized with a coarse FE mesh consisting of elements of size 1 1 in. The notch-to-depth ratio was 13. An identical mesh pattern and element type were used in the present

2-D study, in which each intact zone element was a CPS4 and the cohesive zone was discretized by using COH2D4 instead of JOINTC elements. The results are shown in Figure 5. The cohesive model overpredicts the load for a given CMOD in the postpeak stage. In general, however, the two models are in good agreement for the particular mesh considered. Nonetheless, the wavy curves in Figure 5 suggest some convergence difficulties, which may easily be overcome when the mesh is rened. To complicate matters, however, mesh renement

0.70

0.60

CMOD LLD CMOD LLD

2D JOINTC 2D JOINTC 2D COH3D8 2D COH3D8

0.50 Load (kips)

0.40

0.30

0.20

0.10

0.00 0.000

0.001

0.002 CMOD/2 or LLD (in.)

0.003

0.004

FIGURE 5

Comparison between 2-D JOINTC and 2-D cohesive elements (Beam A).

18

Transportation Research Record 2154

is also found to increase the discrepancy between JOINTC and the cohesive elements. Further research is required to identify the source of this phenomenon, but the preliminary postulate is that it is related to differences in the assumptions of the two elements in regard to precrack behavior.

ABAQUS2-D UEL by Roesler et al. Roesler et al. (20) employed a UEL for the fracture zone and a four-node plane stress element for the intact material in a mesh that was signicantly ner near the cohesive zone than farther away. The geometry and material properties of their beam are shown in Table 1 in relation to Beam C. The following parameters were also adopted: T0 = 0.04 in., E = 4.6 Mpsi, Gf = 0.323 lbf/in., GF = 0.954 lbf/in., and = 0.25. To reproduce in the present study the results of the 2-D analysis presented by Roesler et al. (20), Beam C was meshed uniformly with 0.2- 0.2-in. elements in both directions for the intact material, whereas the mesh of the cohesive zone was made 5 times as ne. The penalty stiffnesses for the given E and T0 values were computed as Knn = 118 Mpsi/in. and Kss = 51 Mpsi/in. The CMOD-P curve obtained in the present study along with that presented by Roesler et al. (2007) is shown in Figure 6. As can be seen, good agreement is obtained between the two numerical simulations. The small difference in the elastic region may be due to the respective approaches followed in establishing the penalty stiffnesses.

of Beam C for a variety of kink point locations. Their mesh was similar to that used by Roesler et al. (20). Their CMOD-P curve for = 0.25 is plotted in Figure 7, along with the corresponding results from the present study. The peak load predictions differ by about 7%; Gaedicke and Roesler had reported that their model underpredicted the peak load by 12% and 7% with respect to the average and minimum experimental peak load, respectively (14). This may again be attributed to penalty stiffness differences. From the comparisons with previously reported results, it may be concluded that the proposed use of built-in ABAQUS cohesive elements is effective in simulating PCC fracture. Comparison with experimental measurements reported by other researchers appears in the following section.

COMPARISONS WITH EXPERIMENTAL RESULTS In this section, FE simulations conducted by means of the proposed procedure that implements cohesive elements in ABAQUS are compared with experimental measurements reported by various independent researchers. The simulations employ 3-D discretizations with bilinear softening curves in all cases.

Experimental Results by Liu Liu (19) tested notched-beam specimens under center-point loading. The pertinent geometry and average material properties reported are shown in Table 1, as Beam B. A comparison of the CMOD-P and LLD-P curves is shown in Figure 8. Good agreement is obtained between the numerical solution in the present study and Lius experimental results, especially for the CMOD-P curve. The small difference in the elastic portion of the LLD-P was explained by Liu as the result of support settlement, which can cause the measured

ABAQUS2-D COH2D4 by Gaedicke and Roesler Gaedicke and Roesler (14) were the first to use the built-in 2-D ABAQUS cohesive element COH2D4 to model the fracture process

1.60 Roesler et al. (2007) 2D UEL 1.40 This study 2D COH2D4

1.20

1.00 Load (kips)

0.80

0.60

0.40

0.20

0.00 0.000

0.005

0.010 CMOD (in.)

0.015

0.020

FIGURE 6 Comparison of Roesler et al. (20) numerical results with current studys results (Beam C).

Aure and Ioannides

19

1.60 Gaedicke and Roesler (2009) 2D COH2D4 1.40 This study 2D COH2D4

1.20

1.00 Load (kips)

0.80

0.60

0.40

0.20

0.00 0.000

0.005

0.010 CMOD (in.)

0.015

0.020

FIGURE 7 Comparison of Gaedicke and Roesler (14) numerical results with current studys results (Beam C).

0.18 CMOD 0.16 0.14 0.12 Load (kips) 0.10 0.08 0.06 0.04 0.02 0.00 0 0.001 0.003 0.002 CMOD or LLD (in.) 0.004 0.005 LLD CMOD LLD Experimental Experimental 3D COH3D8 3D COH3D8

FIGURE 8 Comparison of Lius (19) experimental results with current studys results (Beam B).

20

Transportation Research Record 2154

1.60 Roesler et al. (2007) 1.40 This study Experimental 3D COH3D8

1.20

1.00 Load (kips)

0.80

0.60

0.40

0.20

0.00 0.000

0.005

0.010 CMOD (in.)

0.015

0.020

FIGURE 9 Comparison of the Roesler et al. (20) experimental results with current studys results (Beam C).

load-point deflection [to be] larger than the actual one. As a result, the predicted curves are stiffer in comparison with the measured ones. A more sophisticated testing set-up is needed to overcome this problem (19).

Experimental Results by Roesler et al. Beam C of Table 1 is considered here. Good agreement is obtained between the experimental results by Roesler et al. (20) and the FE simulation conducted in the present study, as shown in Figure 9. In the elastic region, the idealization underpredicts the load for a given CMOD. This can be explained by the use of a low-penalty stiffness. The numerical procedure reproduced the peak load well. The postpeak behavior is accurately reproduced up to CMOD of 0.0063 in. If one keeps in mind the variability in the experimental results from replicate specimens reported by Roesler et al. (20), it can be concluded that the numerical simulation has reasonably captured the fracture process. The results shown in Figures 8 and 9 indicate the potential use of cohesive elements available in ABAQUS to simulate crack propagation in concrete on the basis of the FCM. The ndings from this study affirm the potential of the proposed numerical procedure when extended to PCC slabs-on-grade in the near future.

CONCLUSION This study focused on the use of 2-D and 3-D cohesive elements that have recently become available in the commercial FE software package ABAQUS for studying crack propagation in simply supported concrete beams. With reliance on Hillerborgs FCM, the input parameters needed for cohesive elements that are based on traction separation could be specied. These elements were then inserted at

the cohesive fracture zone with the top and bottom faces of the elements tied to beam elements at the right and left sides of the crack plane. Analyses examined the effect of solution techniques, mesh size, and thickness of cohesive zone. Comparison of this study with other numerical studies was presented. Good agreement was found with Senguptas GTSTRUDL CRACKIT combination. The small discrepancy observed can be ascribed to an expedient assumption implicit in CRACKIT. The proposed FE formulation also gave good agreement with the UEL created by Park (22). Results from the present study were also compared with experimental data reported by different researchers and good agreement was again found. The main advantages of cohesive elements over other numerical models presented can be summarized as (a) capability to be used in 3-D FE analysis, (b) ability to use different kind of softening curve assumptions, and (c) possibility to use other failure criteria. The use of cohesive elements, however, is computationally extremely intensive and requires signicant computer resources. Use of cohesive elements that are based on tractionseparation in tracking material damage introduces nonlinearity to the system, which results in convergence problems, especially if the NewtonRaphson solution algorithm is used. To avoid this problem, the modied Riks method (or the NewtonRaphson method with viscous regularization) can be used. From the findings in this study, it is anticipated that cohesive elements that are based on tractionseparation will be used in large problems with PCC pavement slabs resting on layered foundations. It is hoped that the use of fracture mechanics concepts will eventually lead to the definition of more reliable and realistic failure criteria, ones addressing the current weaknesses of statistical empirical transfer functions commonly employed in pavement design guides.

Aure and Ioannides

21

ACKNOWLEDGMENT This work was supported in part by an allocation of computing time from the Ohio Supercomputer Center.

12.

REFERENCES

1. Ioannides, A. M. Pavement Fatigue Concepts: A Historical Review. In Proc., 6th International Conference on Concrete Pavements, Vol. 3, Indianapolis, Ind., 1997, pp. 147159. 2. Khazanovich, L., and D. Tompkins. Singularities in Concrete Pavement Analysis. In Proc., Workshop on Fracture Mechanics for Concrete Pavements: Theory to Practice, International Society for Concrete Pavements, Copper Mountain, Colo., 2005, pp. 4958. 3. Miner, M. A. Cumulative Damage in Fatigue. Transactions of the American Society of Mechanical Engineers, Vol. 67, Sept. 1945, pp. A-159A-164. 4. Hillerborg, A., M. Modeer, and P. E. Petersson. Analysis of Crack Formation and Crack Growth in Concrete by Means of Fracture Mechanics and Finite Elements. Cement and Concrete Research, Vol. 6, No. 6, 1976, pp. 773782. 5. Ioannides, A. M. Fracture Mechanics in Pavement Engineering: The Specimen-Size Effect. In Transportation Research Record 1568, TRB, National Research Council, Washington, D.C., 1997, pp. 1016. 6. Ioannides, A. M., and S. Sengupta. Crack Propagation in Portland Cement Concrete Beams: Implications for Pavement Design. In Transportation Research Record: Journal of the Transportation Research Board, No. 1853, Transportation Research Board of the National Academies, Washington, D.C., 2003, pp. 110117. 7. GTSTRUDL: Finite Element Computer Software System for Structural Analysis and Design. Users Manual. Georgia Tech Research Corporation, Georgia Institute of Technology, Atlanta, 1993. 8. Ioannides, A. M., J. Peng, and J. R. Swindler. Simulation of Concrete Fracture Using ABAQUS. In Proc., 8th International Conference on Concrete Pavements, Vol. 3, Colorado Springs, Colo., Aug. 2005, pp. 11381154. 9. ABAQUS, v. 6.4-1. Abaqus, Inc., Providence, R.I., 2003. 10. Song, S. H. Fracture of Asphalt Concrete: A Cohesive Zone Modeling Approach Considering Viscoelastic Effects. PhD dissertation. University of Illinois at UrbanaChampaign, 2006. 11. Song, S. H., G. H. Paulino, and W. G. Buttlar. A Bilinear Cohesive Zone Model Tailored for Fracture of Asphalt Concrete Considering

13. 14.

15. 16.

17. 18. 19. 20.

21.

22.

23.

24.

Viscoelastic Bulk Material. Journal of Engineering Fracture Mechanics, Vol. 73, No. 18, 2006, pp. 28292848. Ioannides, A. M., and J. Peng. Finite Element Simulation of Crack Growth in Concrete Slabs: Implications for Pavement Design. In Proc., 5th International Workshop on Fundamental Modeling of Concrete Pavements, Istanbul, Turkey, International Society for Concrete Pavements, April 2004. What Is New in ABAQUS 6.5? Abaqus, Inc., Providence, R.I., 2004. www.pdfgeni.com. Accessed July 24, 2009. Gaedicke, C., and J. R. Roesler. Fracture-Based Method to Determine the Flexural Load Capacity of Concrete Slabs. FAA-05-C-AT-UIUC. University of Illinois at UrbanaChampaign, 2009. ABAQUS Analysis Users Manual, v. 6.7-1. Dassault Systmes, Providence, R.I., 2007. Sengupta, S. Finite Element Simulation of Crack Growth in PCC Beams: Implication for Concrete Pavement Design. MS thesis. University of Cincinnati, Ohio, 1998. Timoshenko, S. P., and J. N. Goodier. Theory of Elasticity. McGraw-Hill, New York, 1970. Shames, I. H., and C. L. Dym. Energy and Finite Element Methods in Structural Mechanics. Hemisphere Publishing, New York, 1985. Liu, P. Time-Dependent Fracture of Concrete. PhD dissertation. Ohio State University, Columbus, 1994. Roesler, J., G. H. Paulino, K. Park, and C. Gaedicke. Concrete Fracture Prediction Using Bilinear Softening. Cement and Concrete Composites, Vol. 9, No. 4, 2007, pp. 300312. Park, K., G. H. Paulino, and J. R. Roesler. Determination of the Kink Point in the Bilinear Softening Model for Concrete. Journal of Engineering Fracture Mechanics, Vol. 75, No. 13, 2008, pp. 38063818. Park, K. Concrete Fracture Mechanics and Size Effect Using a Specialized Cohesive Zone Model. MS thesis. University of Illinois at Urbana Champaign, 2005. Song, S. H., G. H. Paulino, and W. G. Buttlar. Simulation of Crack Propagation in Asphalt Concrete Using an Intrinsic Cohesive Zone Model. Journal of Engineering Mechanics, Vol. 132, No. 11, 2006, pp. 12151223. Yang, Z. J., and D. Proverbs. A Comparative Study of Numerical Solutions to Non-Linear Discrete Crack Modelling of Concrete Beams Involving Sharp Snap-Back. Journal of Engineering Fracture Mechanics, Vol. 71, No. 1, 2004, pp. 81105.

The Rigid Pavement Design Committee peer-reviewed this paper.

Você também pode gostar

- Abaqus Explicit VUMAT For HysteresisDocumento5 páginasAbaqus Explicit VUMAT For HysteresisAnastasios KarahaliosAinda não há avaliações

- 10-31-06 Python Scripting in ABAQUSDocumento17 páginas10-31-06 Python Scripting in ABAQUSSathian SuwannoAinda não há avaliações

- Defining ABAQUS Contact in Two StepsDocumento1 páginaDefining ABAQUS Contact in Two StepsAnastasios KarahaliosAinda não há avaliações

- Geotech BookDocumento306 páginasGeotech BookAnastasios Karahalios100% (1)

- Cohesive Zone Modelling Procedure in ABAQUSDocumento1 páginaCohesive Zone Modelling Procedure in ABAQUSAnastasios KarahaliosAinda não há avaliações

- Ae4131 Abaqus Lecture 1Documento28 páginasAe4131 Abaqus Lecture 1Anastasios KarahaliosAinda não há avaliações

- Tutorial 3: Plane Beam Frame Problems FEA DesignDocumento3 páginasTutorial 3: Plane Beam Frame Problems FEA DesignAnastasios KarahaliosAinda não há avaliações

- Steps Install of AbaqusDocumento1 páginaSteps Install of AbaqusAnastasios KarahaliosAinda não há avaliações

- FE Simulation Units GuideDocumento18 páginasFE Simulation Units Guideabegarza1Ainda não há avaliações

- Tutorial 3 Pre Processing of ABAQUSDocumento8 páginasTutorial 3 Pre Processing of ABAQUSselva_raj215414Ainda não há avaliações

- ABAQUS Basics and Input File Syntax OverviewDocumento18 páginasABAQUS Basics and Input File Syntax OverviewAnastasios KarahaliosAinda não há avaliações

- ABAQUS TutorialDocumento4 páginasABAQUS TutorialAnastasios KarahaliosAinda não há avaliações

- UMAT Superelastic Plastic PDFDocumento4 páginasUMAT Superelastic Plastic PDFAnastasios KarahaliosAinda não há avaliações

- Abaqus Truss TutorialDocumento4 páginasAbaqus Truss TutorialtoshugoAinda não há avaliações

- Con 5 HDocumento19 páginasCon 5 HAnastasios KarahaliosAinda não há avaliações

- Con 6 ADocumento20 páginasCon 6 AAnastasios KarahaliosAinda não há avaliações

- PresentationDocumento19 páginasPresentationAnastasios KarahaliosAinda não há avaliações

- ABAQUS TutorialDocumento10 páginasABAQUS Tutorialpetrus_lioe84Ainda não há avaliações

- Use of New Technology Single Wide-Base Tires Impact On PavementsDocumento24 páginasUse of New Technology Single Wide-Base Tires Impact On PavementsAnastasios KarahaliosAinda não há avaliações

- Softening of Concrete in Compression - Localization and Size EffectsDocumento7 páginasSoftening of Concrete in Compression - Localization and Size EffectsAnastasios KarahaliosAinda não há avaliações

- Stressing A Plate With A Circular or Elliptical HoleDocumento4 páginasStressing A Plate With A Circular or Elliptical HoleAlex da SilvaAinda não há avaliações

- LVRT2 CourseManual English SampleDocumento24 páginasLVRT2 CourseManual English SampleAnastasios KarahaliosAinda não há avaliações

- 05park MsthesisDocumento79 páginas05park MsthesisAnastasios KarahaliosAinda não há avaliações

- Continuously Reinforced Concrete PavementDocumento21 páginasContinuously Reinforced Concrete PavementAnastasios Karahalios100% (1)

- Mechanical Properties of Bituminous Aggregate Mixture Bns 22A Prepared With Fly Ash From Power Plant "Gacko" As A Filler ReplacementDocumento4 páginasMechanical Properties of Bituminous Aggregate Mixture Bns 22A Prepared With Fly Ash From Power Plant "Gacko" As A Filler ReplacementAnastasios KarahaliosAinda não há avaliações

- Roque HMA Fracture MechanicsDocumento42 páginasRoque HMA Fracture MechanicsAnastasios KarahaliosAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Monitoring and Supporting Data Conversion ExamDocumento2 páginasMonitoring and Supporting Data Conversion ExamAmanuel KassaAinda não há avaliações

- Sri Final Job SheetDocumento4 páginasSri Final Job SheetMohan LalAinda não há avaliações

- Secure Lock Manager Easy Quick Start GuideDocumento61 páginasSecure Lock Manager Easy Quick Start GuideEd ArenasAinda não há avaliações

- Enabling Web ConsoleDocumento2 páginasEnabling Web ConsolepmmanickAinda não há avaliações

- Electromagnetic Compatibility: Unit-1: Introduction To EmcDocumento28 páginasElectromagnetic Compatibility: Unit-1: Introduction To EmcShiva Prasad M100% (1)

- CAMWORKS Post Processor ReferenceDocumento372 páginasCAMWORKS Post Processor Referencevesilvar100% (2)

- SLHT Grade 7 CSS Week 2Documento6 páginasSLHT Grade 7 CSS Week 2princeyahweAinda não há avaliações

- Neltec Color MG CDocumento34 páginasNeltec Color MG CJavier Manuel IbanezAinda não há avaliações

- Computer PartsDocumento36 páginasComputer PartsJed SorollaAinda não há avaliações

- Online Resources, Educational Sites, and Portals PresentationDocumento32 páginasOnline Resources, Educational Sites, and Portals PresentationGian ReyesAinda não há avaliações

- UPS Package Tracking Systems & Business StrategiesDocumento6 páginasUPS Package Tracking Systems & Business StrategiesNgọc KhánhAinda não há avaliações

- Luxmeter: Downloaded From Manuals Search EngineDocumento12 páginasLuxmeter: Downloaded From Manuals Search Enginemetrologueha1Ainda não há avaliações

- Daa Lab Term Work - Pcs 409Documento13 páginasDaa Lab Term Work - Pcs 409Tem PAinda não há avaliações

- Historical Antecedents in The Course of Science and TechnologyDocumento2 páginasHistorical Antecedents in The Course of Science and TechnologyElboy Son DecanoAinda não há avaliações

- CV of Fairuz Areefin KhanDocumento2 páginasCV of Fairuz Areefin KhanAbu SaleahAinda não há avaliações

- Most Common Linux Root User PasswordsDocumento190 páginasMost Common Linux Root User PasswordsMihai-Antonio GarvanAinda não há avaliações

- Single Sign-On: Integrating Aws, Openldap, and Shibboleth: A Step-By-Step WalkthroughDocumento33 páginasSingle Sign-On: Integrating Aws, Openldap, and Shibboleth: A Step-By-Step WalkthroughSpit FireAinda não há avaliações

- Connecting Xilinx Fpgas To Texas Instruments Ads527X Series AdcsDocumento17 páginasConnecting Xilinx Fpgas To Texas Instruments Ads527X Series Adcsamrendra_kAinda não há avaliações

- WDV Dep MethodDocumento24 páginasWDV Dep Methodsudershan9Ainda não há avaliações

- OMEN by HP 17 Laptop PC: Maintenance and Service GuideDocumento99 páginasOMEN by HP 17 Laptop PC: Maintenance and Service GuideGustavo TorresAinda não há avaliações

- Apple Products TNCDocumento80 páginasApple Products TNCabhijit khaladkarAinda não há avaliações

- Signal To Interference Ratio & Signal To Noise Ratio: Lovely Professional University TopicDocumento7 páginasSignal To Interference Ratio & Signal To Noise Ratio: Lovely Professional University TopicRavi RajAinda não há avaliações

- Digital Public SpaceDocumento42 páginasDigital Public SpacesunnekoAinda não há avaliações

- List Operations in JavaDocumento4 páginasList Operations in Javamadhu jhaAinda não há avaliações

- I, Robot - Future (Will)Documento2 páginasI, Robot - Future (Will)CarolinaDeCastroCerviAinda não há avaliações

- Recurdyn Solver - Theoretical ManualDocumento325 páginasRecurdyn Solver - Theoretical ManualsawamurAinda não há avaliações

- Splunk 6.6.1 UpdatingDocumento70 páginasSplunk 6.6.1 UpdatingbobwillmoreAinda não há avaliações

- Panasonic KW1M HDocumento11 páginasPanasonic KW1M Hbole90Ainda não há avaliações

- Task Checklist Exhibition Re 2019Documento4 páginasTask Checklist Exhibition Re 2019zikrillah1Ainda não há avaliações

- SEC Form ICA-RRDocumento1 páginaSEC Form ICA-RRPatrick HarrisAinda não há avaliações