Escolar Documentos

Profissional Documentos

Cultura Documentos

Processaudit VDA 6.3 2010 en

Enviado por

Adilson DoboszDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Processaudit VDA 6.3 2010 en

Enviado por

Adilson DoboszDireitos autorais:

Formatos disponíveis

113854087.xls.

ms_office

Audit Contract VDA 6.3-2010

Client: (z.B. management,person responsible for the product, person responsible for the auditprogramme)

Audited Party: (z.B. internal department, supplier)

Reason for Audit:

Audit Objective:

Audit Variant:

Internal Audit External Audit Potential Analysis Special Audit external

Audit Location:

Internal Audit

Audit Team:

Lead Auditor: Auditors: Process Specialist(s):

Audit Extent:

Prosesses: Manufacturing Locations: Outside Processes: Products: Interfaces:

Audit Date

Desired Date: Auditperiod: Shifts:

Date of Contract Essential Documents (test/inspections regulations, contracts, important agreements, cost stipulations, etc.)

History (complaints, rejects, delivery performance, project status)

Remarks (background information)

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 1 von 38

113854087.xls.ms_office

VDA 6.3-2010 Audit Report: Assessment of Quality Cabability

Supplier:

Supplier No.: Location:

Client:

Reason for contract:

Date: Contract No.:

Process/Product

Overall Process P2 bis P7 befor SOP after SOP

Assess-ment index

Achieved nb nb nb nb nb nb nb nb

Classified

Findings / requirements

Highlights

EG ED EP

EPN EPN EPN EPN EPN

Product Group*

Product group 1 Product group 2 Product group 3 Product group 4 Product group 5

* Values automaticly taken from Assessment Matrix

Classification scale: A: 90-100% (Q-cabable); B: >= 80-90% (conditionally Q-cabable); C: <80% (not Q-capable)

Areas of improvement

Audit history / Certificates

Audit Basis Date Carried out Result

Participants:

Distribution to:

Timing for improvement plan:

For actions see 'Improvement program' and/or 'Immediate actions'

Lead Auditor

Co-Auditor

signed for Organisation

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 2 von 38

113854087.xls.ms_office

Explanations

Supplier: Client: Date:

The improvement program was discussed in the final meeting on site and handed over as a draft.. The audited Organisaion is asked to define sustainable corrective actions for the identified weak points and to implement them rapidly. We point out that within the audit the processes only can be checked randomly. Other weak points and / or potentials for imprevement may be possible. It is the responsibility of the audited parties to expand the investigation and necessary measures to similar areas / issues.

Participants:

Auditor:

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 3 von 38

113854087.xls.ms_office

VDA 6.3-2010 Audit Report: Assessment of Quality Cabability

Supplier: Client:

Assessment after Process Analysis

Target Minimum requirement per assessment element 60 Assignment to Product group 70 80 Erfllungsgrad preaudit actual P2 P3 Carrying out Product/Process Supplier Management Prozess Analysis P6 Customer Satisfaction P7 Process Name 1 Process Name 2 Process Name 3 Process Name 4 Process Name 5 Process Name 6 Process Name 7 Process Name 8 Process Name 9 Process Name 10 E1 E2 E3 E4 E5 E6 E7 E8 E9 E 10 nb nb nb nb nb nb nb nb nb nb nb Transport / parts handling / storage nb Process result EU 6 EU 7 nb nb P4 P5 nb Process sequence nb Personnel support nb Material resources nb Proces effectiveness level EU 5 nb EU 4 nb EU 3 nb EU 2 nb

80 90

Date:

(mean value, process stage E 1 - n) and generic baseline Target Minimum requirement 80 per assessment element 60 70 80 90 Erfllungsgrad pre audit actual EU 1 nb

Assessment Elements / Process Stages

90

90

100

100

Assessment elements / Process stages

Project Management Planning Product/Process

Assessment elements / Process stages

Process input

Produktgruppe 1

Produktgruppe 2

Produktgruppe 3

Produktgruppe 4

Produktgruppe 5

Generic Baseline

Process responsiblity Target orientation Communication Risk orientation PR TO CO RI nb nb nb nb

Overall Compliance Befor SOP After SOP

EG ED EP

nb nb nb

Comment: Please input values Pre-Audit yourself Values of actual audit will be automaticly entered

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 4 von 38

113854087.xls.ms_office

VDA 6.3-2010 Assessment Matrix including Product Groups

Supplier: A Development

P 2 Project Management

2.1 2.2* 2.3 2.4 2.5* 2.6 2.7*

Entry: only following values are allowed nb not assessed 10 Requirements fully satisfied 8 Requirements mainly satisfied 6 Requirements partly satisfied 4 Requirements inadequately satisfied 0 Requirements not satisfied

Notes: Client: Date: Achivement level %

Generic Baseline

G1 PR G2 TO G3 CO G4 RI

nb

nb

nb

nb

nb

nb

nb

EPM

nb

nb

nb

nb

nb

Note: Entry "n.b." = Question not answered Note: Entry "n.a." = Question not applicable

P 3 Planning Product/Process Development

Product 3.1 3.2* 3.3 3.4 3.5

Process 3.1 3.2*

3.3

3.4

3.5

nb

nb

nb

nb

nb

EPdP

nb

nb

nb

nb

nb

nb

EPzP

nb

EPP

nb

nb

nb

nb

nb

nb Green fields for entering Blue writing -> example entry

3.1.

P 4 Carrying out Product/Process Development

Product 4.1 4.2 4.3 4.4 4.5* 4.6 4.7 4.8 4.9 Process 4.1 4.2 4.3 4.4 4.5* 4.6 4.7 4.8 4.9

nb

nb

nb

nb

nb

nb

nb

nb

nb

EPdR

nb

nb

nb

nb

nb

nb

nb

nb

nb

nb

EPzR

nb

EPR

nb

nb

nb

nb

nb

nb

nb nb nb

Automatic Calculation of the

B Full Production

5.1* 5.2 5.3 5.4* 5.5* 5.6 5.7

grey, blue, yellow and red fields

P 5 Supplier Management P 6 Process Analysis Serial Production

1 Process Input 6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5 Process step 1: Process Name 1

nb

nb

nb

nb

nb

nb

nb

ELM

4 Material Ressources 6.4.1 6.4.2* 6.4.3 6.4.4 5 Process Effectiveness Level 6.5.1 6.5.2 6.5.3* 6.5.4* 6 Process Result / Output 6.6.1* 6.6.2 6.6.3 6.6.4

nb

nb

nb

nb

nb

2 Work Content / Process Sequences 6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support 6.3.1 6.3.2* 6.3.3

7 Transport and Part Handling

6.1.2 6.1.3 6.1.4 6.2.5 6.2.6 6.4.4 6.6.2 6.6.3

Generic Baseline

G1 PR G2 TO G3 CO G4 RI

nb

Process step 2:

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

E1 E2 E3 E4 E5 E6 E7 E8 E9 E10

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb nb nb nb

nb nb nb nb nb nb nb Farbcode Farbcode nb nb nb

Process Name 2

nb

Process step 3:

Process Name 3

nb

Process step 4:

Process Name 4

nb

Process step 5:

Reasons for downgrading

Down-grading from A to B despite an achievement level of EG>= 90% > At least one process elements P2-P7 or process stage E1-En assessed <80 %. > Level of achievement of the sub-elements of P6 (EU1-EU7) assessed <80 %. > At least one *-question awarded with 4 points. > At least one question from process audit awarded with 0 points. > Assessments from generic baseline assessed <70 %.

Process Name 5

nb

Process step 6:

Process Name 6

nb

Process step 7:

Process Name 7

nb

Process step 8:

Process Name 8

nb

Process step 9:

Process Name 9

nb

Process step 10:

Process Name 10

nb

Assessment of Subelements of the Process analysis (mean value step 1 - n) 1.1 1.2 1.3 1.4 1.5 2.1 2.2 2.3 2.4 nb nb nb nb nb nb nb nb nb

2.5 nb

2.6 nb

3.1 nb

3.2 nb

3.3 nb

4.1 nb

4.2 nb

4.3 nb

4.4 nb

5.1 nb

5.2 nb

5.3 nb

5.4 nb

6.1 nb

6.2 nb

6.3 nb

6.4 nb

6.1.2 6.1.3 6.1.4 6.2.5 6.2.6 6.4.4 6.6.2 6.6.3

EPG

nb

nb

nb

nb

nb

nb

nb

nb

nb

EU1

nb

EU2

nb

EU3

nb

7.1*

EU4

7.2

nb

7.3* 7.4 7.5 7.6

EU5

nb

EU6

nb

Transport, Part Handling

EU7

nb

G1 PR G2 TO G3 CO G4 RI

for down-grading to C despite an achievement level of 80 % > At least one process elements P2-P7 or process stage E1-En assessed <70 %. > Level of achievement of the sub-elements of P6 (EU1-EU7) assessed <70 %. > At least one *-question awarded with 0 points.

P 7 Customer Support / Customer Satisfaction / Services

nb

nb

nb

nb

nb

nb

EK

nb

nb

nb

TO

nb

Co

nb

RI

Achivement level EPG by Product Groups Element P6[%] (mean value Ex-En)

Product group 1

Product Group Process Steps

Product group 2

Product group 3

Product group 4

Product group 5

Overall Achivement Level EPN [%] by Product Groups

Product Group

Achivement level [%] for Generic Baseline

PR

nb

nb

nb

nb

EPN [%] Classification

nb

EPGN [%]

Achivement Level before SOP (Part A) Classification

Overall Achivement Level EG [%]:

Classified

Classification Achivement Level EG[%] Description of Classification

nb nb nb

ED [%]

nb

nb

A B C

EG > 90 80 EG 90 EG < 80

Quality cabable Conditionally qualitycapable Not quality-capable

after SOP

(Part B)

EP [%]

nb

nb

Classification results (A, B, C) must be entered manually, by taking into account the downgrading rule!

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 5 von 38

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

Question

Pionts

Comments / Assesment Remarks

A Development

P 2 Project Management

2.1 Is the project organisation (project management) established and are tasks & authorities specified for the team leader and team members? Are the resources required for the project development planned and available and are all changes displayed? Is there a project plan and has this been agreed with the customer? Is change management in the project ensured by the project organisation? Are the responsible personnel within the organisation and in the customer's company involved in the change control system? Is there a QM plan for the project? Is this implemented and monitored regularly for compliance? Is there an established escalation process and is this implemented effectively?

nb nb nb nb nb nb nb

2.2*

2.3 2.4 2.5*

2.6

2.7*

P 3 Planning Product/Process Development Product

3.1 3.2* Are the product-specific requirements laid down? Has manufacturing feasibility been assessed in a crossfunctional manner, based on the requirements which have been determined for product & process? Are there plans for the product and process development? Have the necessary resources been taken into account for the product and process development? Is QM planning arranged for sourcing bought-in products and services? Are the process-specific requirements laid down? Has manufacturing feasibility been assessed in a crossfunctional manner, based on the requirements which have been determined for product & process? Are there plans for the product and process development? Have the necessary resources been taken into account for the product and process development? Is QM planning arranged for sourcing bought-in products and services?

nb nb nb nb nb

3.3 3.4

3.5

Process

3.1 3.2*

nb nb nb nb nb

3.3 3.4

3.5

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 6 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Quest Question Nr. P 4 Carrying out Product/Process Development Product

4.1 Have the Product FMEA / Process FMEA been drawn up? Are they up-dated as the project progresses and are corrective actions laid down? Are the stipulations arising from the plans for product and process development put into effect? Are the personnel resources in place and qualified? Is the infrastructure in place and appropriate? Based on the requirements, are the necessary evidence and releases available for the various phases? Are the planning activities associated with sourcing outside products and services implemented effectively? Is the transfer of the project to production controlled in order to secure the product launch? Have the Product FMEA / Process FMEA been drawn up? Are they up-dated as the project progresses and are corrective actions laid down? Are the stipulations arising from the plans for product and process development put into effect? Are the personnel resources in place and qualified? Is the infrastructure in place and appropriate? Based on the requirements, are the necessary evidence and releases available for the various phases? Are the productions control plans used for the various phases and are production, test and inspection documents derived from them? Has a pre-production run been carried out under serial production conditions to obtain production approval / release? Are the planning activities associated with sourcing outside products and services implemented effectively? Is the transfer of the project to production controlled in order to secure the product launch?

Pos.

Pionts

Comments / Assesment Remarks

nb

4.2 4.3 4.4 4.5*

nb nb nb nb nb nb

4.8

4.9

Process

4.1

nb

4.2

nb nb nb nb nb nb nb nb

4.3 4.4 4.5*

4.6

4.7

4.8

4.9

B Full Production

P 5 Supplier Management Are only approved/released and quality-capable 5.1*

suppliers selected?

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 7 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr. 5.2 5.3 5.4* 5.5* 5.6 5.7

Question

Are the customer's requirements taken into account in the supply chain? Have target agreements for delivery performance been agreed with suppliers and put into operation? Are the necessary approvals/releases available for the out-sourced products and services? Is the quality of the out-sourced products and services ensured? Are incoming goods stored appropriately? Are personnel qualified for the various tasks and are responsibilities defined?

Pionts

nb nb nb nb nb nb

Comments / Assesment Remarks

P 6 Process Analysis Serial Production Process step 1: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 1 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 8 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.3.2*

Question

Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

Pionts

nb nb

Comments / Assesment Remarks

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb

6.6.4

nb

Process step 2: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials?

Process Name 2 nb nb

6.1.3

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 9 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.1.4

Question

Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Pionts

nb nb

Comments / Assesment Remarks

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of product and process?

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 10 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.6.2

Question

Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

Pionts

nb

Comments / Assesment Remarks

6.6.3

nb

6.6.4

nb

Process step 3: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 3 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/27.09.2011 Seite 11 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.4.1 6.4.2*

Question

How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

Pionts

nb nb nb nb

Comments / Assesment Remarks

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb

6.6.4

nb

Process step 4: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 4

nb

nb

6.1.3

nb

6.1.4

nb nb Seite 12 von 40

6.1.5

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Question Nr. 2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

Pionts

Comments / Assesment Remarks

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner?

nb nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 13 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.6.3

Question

Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

Pionts

Comments / Assesment Remarks

nb

6.6.4

nb

Process step 5: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 5 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production facilities / tools controlled?

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 14 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.4.2*

Question

Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

Pionts

nb nb nb

Comments / Assesment Remarks

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb

6.6.4

nb

Process step 6: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 6 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 15 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.2.1*

Question

Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

Pionts

nb nb nb nb nb nb

Comments / Assesment Remarks

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components?

nb nb

6.6.3

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 16 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.6.4

Question

Are the necessary records / releases carried out and stored appropriately?

Pionts

nb

Comments / Assesment Remarks

Process step 7: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 7 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements?

nb nb nb

6.4.3

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 17 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.4.4

Question

Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

Pionts

nb

Comments / Assesment Remarks

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb

6.6.4

nb

Process step 8: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 8 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged?

nb nb

6.2.2

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 18 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.2.3* 6.2.4* 6.2.5 6.2.6

Question

Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

Pionts

nb nb nb nb

Comments / Assesment Remarks

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb

6.6.4

nb

Process step 9: Erstellt: Rita Demmeler-Wirth

Process Name 9 Version/Stand: 2.6/27.09.2011 Seite 19 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Question Nr. 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Pionts

Comments / Assesment Remarks

nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1

nb Seite 20 von 40

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.5.2 6.5.3*

Question

Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

Pionts

nb nb nb

Comments / Assesment Remarks

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb

6.6.4

nb

Process step 10: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 10 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified?

nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 21 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.2.6

Question

Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

Pionts

nb

Comments / Assesment Remarks

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb

6.6.4

nb

P 7 Customer Support / Customer Satisfaction / Services 7.1* 7.2 7.3*

Are the customer's requirements satisfied regarding QM system, product (on delivery) and process? Is customer support ensured? Is the supply of parts ensured?

nb nb nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 22 von 40

113854087.xls.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr. 7.4

Question

If there are deviations from quality requirements, are failure analyses carried out and corrective actions implemented effectively? Is there a process which ensures that analysis of defective parts is carried out? Are personnel qualified for the various tasks and are responsibilities defined?

Pionts

nb nb nb

Comments / Assesment Remarks

7.5 7.6

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 23 von 40

113854087.xls.ms_office

Improvement Program VDA 6.3-2010

Supplier:

To be filled by auditor Quest No. to be filled by audited party

Date: Client:

Weaknesses, recommended actions, findings

Points

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

A Development

P 2 Project Management

2.1 2.2* 2.3 2.4 2.5* 2.6 2.7* nb nb nb nb nb nb nb

P 3 Planning Product/Process Development Product

3.1 3.2* 3.3 3.4 3.5 nb nb nb nb nb

Process

3.1 3.2* 3.3 3.4 3.5 nb nb nb nb nb

P 4 Carrying out Product/Process Development Product Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 24 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

4.1 4.2 4.3 4.4 4.5* 4.8 4.9

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

Process

4.1 4.2 4.3 4.4 4.5* 4.6 4.7 4.8 4.9

B Full Production

P 5 Supplier Management

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 25 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

5.1* 5.2 5.3 5.4* 5.5* 5.6 5.7

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

P 6 Process Analysis Serial Production Process step 1: 1 Process Input

6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5

Process Name 1

nb nb nb nb nb nb nb nb nb nb nb nb

2 Work Content / Process Sequences

6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 26 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

6.3.2* 6.3.3

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

4 Material Ressources

6.4.1 6.4.2* 6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3* 6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 6.6.3 6.6.4

Process step 2: 1 Process Input

6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5

Process Name 2

nb nb nb nb nb nb nb nb

2 Work Content / Process Sequences

6.2.1* 6.2.2 6.2.3*

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 27 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

6.2.4* 6.2.5 6.2.6

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

3 Personnel Support

6.3.1 6.3.2* 6.3.3

4 Material Ressources

6.4.1 6.4.2* 6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3* 6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 6.6.3 6.6.4

Process step 3: 1 Process Input

6.1.1* 6.1.2 6.1.3 6.1.4

Process Name 3

nb nb nb nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 28 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

6.1.5

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

2 Work Content / Process Sequences

6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2* 6.3.3

4 Material Ressources

6.4.1 6.4.2* 6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3* 6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 6.6.3 6.6.4

Process step 4: Erstellt: Rita Demmeler-Wirth

Process Name 4 Version/Stand: 2.6/27.09.2011 Seite 29 von 37

113854087.xls.ms_office

To be filled by auditor Quest No. 1 Process Input

6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

2 Work Content / Process Sequences

6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2* 6.3.3

4 Material Ressources

6.4.1 6.4.2* 6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3* 6.5.4*

6 Process Result / Output

6.6.1*

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 30 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

6.6.2 6.6.3 6.6.4

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

Process step 5: 1 Process Input

6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5

Process Name 5

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

2 Work Content / Process Sequences

6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2* 6.3.3

4 Material Ressources

6.4.1 6.4.2* 6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 31 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

6.5.2 6.5.3* y 6.5.4*

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

6 Process Result / Output

6.6.1* 6.6.2 6.6.3 6.6.4

Process step 6: 1 Process Input

6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5

Process Name 6

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

2 Work Content / Process Sequences

6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2* 6.3.3

4 Material Ressources

6.4.1

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 32 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

6.4.2* 6.4.3 6.4.4

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3* 6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 6.6.3 6.6.4

Process step 7: 1 Process Input

6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5

Process Name 7

nb nb nb nb nb nb nb nb nb nb nb

2 Work Content / Process Sequences

6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/27.09.2011 Seite 33 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

6.3.1 6.3.2* 6.3.3

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

4 Material Ressources

6.4.1 6.4.2* 6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3* 6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 6.6.3 6.6.4

Process step 8: 1 Process Input

6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5

Process Name 8

nb nb nb nb nb nb nb

2 Work Content / Process Sequences

6.2.1* 6.2.2

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 34 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

6.2.3* 6.2.4* 6.2.5 6.2.6

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

3 Personnel Support

6.3.1 6.3.2* 6.3.3

4 Material Ressources

6.4.1 6.4.2* 6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3* 6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 6.6.3 6.6.4

Process step 9: 1 Process Input

6.1.1* 6.1.2 6.1.3

Process Name 9

nb nb nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 35 von 37

113854087.xls.ms_office

To be filled by auditor Quest No.

6.1.4 6.1.5

to be filled by audited party

Weaknesses, recommended actions, findings

Points

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

2 Work Content / Process Sequences

6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2* 6.3.3

4 Material Ressources

6.4.1 6.4.2* 6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3* 6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 6.6.3 6.6.4

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 36 von 37

113854087.xls.ms_office

To be filled by auditor Quest No. Process step 10: 1 Process Input

6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5

to be filled by audited party

Weaknesses, recommended actions, findings

Points

Process Name 10

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Actions and cause analysis by the organisation

Timing

Responsibles

Pos.

Effectiveness

2 Work Content / Process Sequences

6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2* 6.3.3

4 Material Ressources

6.4.1 6.4.2* 6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3* 6.5.4*

6 Process Result / Output Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/27.09.2011 Seite 37 von 37

Você também pode gostar

- Vda63 Audit Report EnglishDocumento8 páginasVda63 Audit Report Englishjhmagagnin100% (1)

- Excel Tool Prozessaudit VDA 6.3 2010 enDocumento29 páginasExcel Tool Prozessaudit VDA 6.3 2010 enHokuto No KenAinda não há avaliações

- VDA 6.3 Volume 2010 9.1Documento6 páginasVDA 6.3 Volume 2010 9.1isbrabowAinda não há avaliações

- VDAqmc2014 Engl DownloadDocumento172 páginasVDAqmc2014 Engl DownloadLuis SosaAinda não há avaliações

- Send/Propose & General Releasing Tips: Version: IMDS Release 10.0Documento39 páginasSend/Propose & General Releasing Tips: Version: IMDS Release 10.0Vanessa Alves Moreira100% (1)

- Layer Process AuditDocumento8 páginasLayer Process AuditR JAinda não há avaliações

- QC 080000-2005 (2nd Ed) IECQ-HSPMDocumento16 páginasQC 080000-2005 (2nd Ed) IECQ-HSPMISO VintecomAinda não há avaliações

- VDA-RGA Questionaire V2.0Documento70 páginasVDA-RGA Questionaire V2.0docsenAinda não há avaliações

- Formel Q-Capability Version 6.0 Supplier Training - Product AuditDocumento11 páginasFormel Q-Capability Version 6.0 Supplier Training - Product AuditVijay LadAinda não há avaliações

- Redesigning Enterprise Process For E-BusinessDocumento211 páginasRedesigning Enterprise Process For E-BusinessMuarif AsdaAinda não há avaliações

- Histogram X-Bar Chart: Company NameDocumento1 páginaHistogram X-Bar Chart: Company NameSachin RamdurgAinda não há avaliações

- Requirements Comparison TS16949 VDA61Documento22 páginasRequirements Comparison TS16949 VDA61TarunaiAinda não há avaliações

- Training in MSA PQ Systems Training Material PDFDocumento109 páginasTraining in MSA PQ Systems Training Material PDFsaby aroraAinda não há avaliações

- Template Q-Offer v1 2Documento25 páginasTemplate Q-Offer v1 2Krishna Mohan T.R100% (1)

- Core Tools PDFDocumento3 páginasCore Tools PDFR.BalasubramaniAinda não há avaliações

- VDA6.3 - Engl06 04 04 PDFDocumento26 páginasVDA6.3 - Engl06 04 04 PDFjpenjerryAinda não há avaliações

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocumento3 páginasRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanAinda não há avaliações

- Reaction PlanDocumento14 páginasReaction PlanMariaNilaZaragozaPalacioAinda não há avaliações

- Vda 6-3Documento7 páginasVda 6-3julio_0489Ainda não há avaliações

- IATF 16949 Webinar Slides 3.7.17 Final PDFDocumento47 páginasIATF 16949 Webinar Slides 3.7.17 Final PDFwanphen kawnawanichAinda não há avaliações

- First Article Inspection Report: Purchase Order Number Supplier NameDocumento8 páginasFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityAinda não há avaliações

- Ppap Review ChecklistDocumento8 páginasPpap Review ChecklistVipin RanaAinda não há avaliações

- Prozessreadinessaudit FS - 01057-En Revision - 5Documento18 páginasProzessreadinessaudit FS - 01057-En Revision - 5truongngvAinda não há avaliações

- Tuv Rheinland Training Schedule 2017Documento19 páginasTuv Rheinland Training Schedule 2017ramnathAinda não há avaliações

- PPAP Checklist GenericDocumento9 páginasPPAP Checklist Genericamr ahmedAinda não há avaliações

- 8 D Report: 8 Discipline MethdologyDocumento14 páginas8 D Report: 8 Discipline MethdologyAshishkekreAinda não há avaliações

- MAstering IATFDocumento20 páginasMAstering IATFGyanesh_DBAinda não há avaliações

- IATF 16949 GM CSR Jan 2023Documento27 páginasIATF 16949 GM CSR Jan 2023Jesus Jay MedinaAinda não há avaliações

- Customer Specific Requirements - PPAP (2014!03!05)Documento7 páginasCustomer Specific Requirements - PPAP (2014!03!05)diablo2250Ainda não há avaliações

- Sensor KistlerDocumento2 páginasSensor KistlerFco JavierAinda não há avaliações

- Escalation Procedure Updated 020915Documento30 páginasEscalation Procedure Updated 020915Joezel Juaman Maglajos100% (1)

- APQP / PPAP Checklist - Suppliers: Responsiblility StepDocumento8 páginasAPQP / PPAP Checklist - Suppliers: Responsiblility Steprajesh sharmaAinda não há avaliações

- IPQC General FormatDocumento17 páginasIPQC General FormatMohd Isa HarunAinda não há avaliações

- PPAPDocumento7 páginasPPAPsunnysunsationAinda não há avaliações

- UntitledDocumento19 páginasUntitledSuresh KumarAinda não há avaliações

- Thyssenkrupp - Supplier Rating PDFDocumento18 páginasThyssenkrupp - Supplier Rating PDFmihaichfAinda não há avaliações

- Ppap Training PresentationDocumento166 páginasPpap Training PresentationSeismuxasAinda não há avaliações

- AUDITMANUALDocumento44 páginasAUDITMANUALRajula Gurva ReddyAinda não há avaliações

- VDA FMEA TemplateDocumento53 páginasVDA FMEA Templatewatna0% (2)

- VCC Phased PPAP Requirements Handbook - V2Documento14 páginasVCC Phased PPAP Requirements Handbook - V2medi38Ainda não há avaliações

- ISO IATF 16949 Gap Tool b70944Documento216 páginasISO IATF 16949 Gap Tool b70944SudhagarAinda não há avaliações

- GP-9 Process Control Plan Audit Summary SheetDocumento5 páginasGP-9 Process Control Plan Audit Summary SheetAsifAinda não há avaliações

- Stellantis Ex PSA Scorecard Quick Reference Guide July 2021Documento3 páginasStellantis Ex PSA Scorecard Quick Reference Guide July 2021白子健Ainda não há avaliações

- Core Tools: Measurement Systems Analysis (MSA)Documento6 páginasCore Tools: Measurement Systems Analysis (MSA)Salvador Hernandez ColoradoAinda não há avaliações

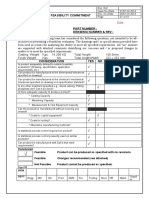

- 02-Team Feasibility CommittmentDocumento1 página02-Team Feasibility CommittmentVinod SaleAinda não há avaliações

- CPK & PPK CalculatorDocumento6 páginasCPK & PPK CalculatorAhmed TeranAinda não há avaliações

- Layered Audit ChecklistDocumento4 páginasLayered Audit ChecklistNavnath TamhaneAinda não há avaliações

- Summary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesDocumento8 páginasSummary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesStephen Lim Kean Jin100% (2)

- Attribute Gage R&RDocumento10 páginasAttribute Gage R&RCésar MezaAinda não há avaliações

- MMOG FinalDocumento26 páginasMMOG FinalSelvaraj SimiyonAinda não há avaliações

- CQI 9 3rd Edition Errata SheetDocumento2 páginasCQI 9 3rd Edition Errata SheetANONIMOAinda não há avaliações

- Training Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enDocumento3 páginasTraining Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enjpaulAinda não há avaliações

- GRR Study MSA TemplateDocumento21 páginasGRR Study MSA TemplaterajarajanAinda não há avaliações

- Dead Endclamp Failure AnalysisDocumento26 páginasDead Endclamp Failure AnalysisRK KumarAinda não há avaliações

- Gage R&R DetailsDocumento6 páginasGage R&R DetailssahilAinda não há avaliações

- TS 16949 Guidance DocumentDocumento6 páginasTS 16949 Guidance DocumentInnoviaAinda não há avaliações

- PMP Exam Preparation CourseDocumento132 páginasPMP Exam Preparation Courserasputin0780803494100% (5)

- Processaudit VDA 6.3 2010 enDocumento37 páginasProcessaudit VDA 6.3 2010 enAdilson DoboszAinda não há avaliações

- SCAP TrainingDocumento4 páginasSCAP TrainingParag ShindeAinda não há avaliações

- Implementation Rules For Compulsory Certification of Electrical and Electronic ProductsDocumento14 páginasImplementation Rules For Compulsory Certification of Electrical and Electronic ProductsJayamali ArambewelaAinda não há avaliações

- FSC Corp Quality ManualDocumento52 páginasFSC Corp Quality ManualMohamed AttiaAinda não há avaliações

- Saep 380 PDFDocumento14 páginasSaep 380 PDFmunnaAinda não há avaliações

- Using SSPC Coating Material Standards 1Documento18 páginasUsing SSPC Coating Material Standards 1achusanachu100% (1)

- Quality Assurance - Control PlanDocumento104 páginasQuality Assurance - Control PlanAhmed SamyAinda não há avaliações

- Manual of Environment Health & SafetyDocumento130 páginasManual of Environment Health & SafetyvalaypfbAinda não há avaliações

- CAPA Form ExampleDocumento1 páginaCAPA Form ExampleBharath71% (7)

- QA-QC - 15 System - Requirements FTADocumento15 páginasQA-QC - 15 System - Requirements FTAomislaAinda não há avaliações

- Iso 9001 1987Documento9 páginasIso 9001 1987siti sarahAinda não há avaliações

- K101-QC-PL.001 - Quality Plan - Rev 0 PDFDocumento85 páginasK101-QC-PL.001 - Quality Plan - Rev 0 PDFberthitasAinda não há avaliações

- ISO 14000 Quality StandardsDocumento4 páginasISO 14000 Quality Standardsmastercontroldotcom100% (1)

- QMS Internal External AuditDocumento5 páginasQMS Internal External AuditNesanAinda não há avaliações

- ISO 9001 2015 Internal Audit Tracker SampleDocumento42 páginasISO 9001 2015 Internal Audit Tracker SampleAhmad Yaseen50% (2)

- Quality Manual: ISO/TS 16949:2002 AS9100 Rev A ISO 9001:2000Documento20 páginasQuality Manual: ISO/TS 16949:2002 AS9100 Rev A ISO 9001:2000putu kusumaAinda não há avaliações

- B K Pandey Manual Revision 03Documento117 páginasB K Pandey Manual Revision 03syed aquibAinda não há avaliações

- (Insert Company Name) : Employee Safety & Injury Prevention ProgramDocumento33 páginas(Insert Company Name) : Employee Safety & Injury Prevention ProgramHenry Surya TengaraAinda não há avaliações

- Due Diligence QuestionnaireDocumento33 páginasDue Diligence QuestionnaireshyamchepurAinda não há avaliações

- Ebook A Systems Approach To Managing The Complexities of Process Industries PDF Full Chapter PDFDocumento67 páginasEbook A Systems Approach To Managing The Complexities of Process Industries PDF Full Chapter PDFwilbert.price951100% (24)

- (Use Separate Sheet If Required) : Corrective ActionDocumento2 páginas(Use Separate Sheet If Required) : Corrective ActionR AksathAinda não há avaliações

- Fta Checklist Group NV 7-6-09Documento7 páginasFta Checklist Group NV 7-6-09initiative1972Ainda não há avaliações

- Sgs Understanding The FSSC 22000 Food Safety System Certification Standard 2009 (PDF Library)Documento12 páginasSgs Understanding The FSSC 22000 Food Safety System Certification Standard 2009 (PDF Library)Víctor Manuel Pescorán DelfínAinda não há avaliações

- ORA-LAB.4.15 Management Review (v02)Documento6 páginasORA-LAB.4.15 Management Review (v02)Agus JatmikoAinda não há avaliações

- WWW Iso-9001-Checklist Co UkDocumento13 páginasWWW Iso-9001-Checklist Co UkAnonymous y7o7pjW8Ainda não há avaliações

- KCT Ims Ps 0002 Ims ManualDocumento41 páginasKCT Ims Ps 0002 Ims ManualMikku Katta100% (2)

- Quality Management SystemDocumento36 páginasQuality Management SystemAgung RiyadiAinda não há avaliações

- Salsa Audit Standard Issue 4 FinalDocumento9 páginasSalsa Audit Standard Issue 4 FinalFátima DuarteAinda não há avaliações