Escolar Documentos

Profissional Documentos

Cultura Documentos

QAP Format

Enviado por

Rajesh Kumar JhaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

QAP Format

Enviado por

Rajesh Kumar JhaDireitos autorais:

Formatos disponíveis

ISO9001:2008 Document No: QM-RF-7.

1-3 Document Title: Guidelines for preparing QAP during registration

Version No: 1.1

Date Effective: 21.10.2010

RESEARCH DESIGNS & STANDARDS ORGANIZATION

Manaknagar, Lucknow 226011 QM-RF-7.1-3

Guidelines for preparing QAP during registration

1.0 Amendment History:

S. No. 1 2 Amendment Date 28.09.2010 20.10.2010 Version 1.0 1.1 Reasons for Amendment Updation to ISO 9001:2008 Annexure (format) pages renumbered

AIE/QA(Mech) Prepared By:

Director/ QA(Mech) Issued By:

Printed: 2010/09/30 Page 1 of 2

ISO9001:2008 Document No: QM-RF-7.1-3 Document Title: Guidelines for preparing QAP during registration

Version No: 1.1

Date Effective: 21.10.2010

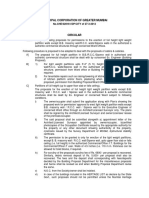

2.0 Purpose:

These are guidelines for preparing the QAP for product.

3.0 Scope of Application:

Applicable for all vendors registered with QA Mechanical Directorate.

4.0 Details:

Guidelines for preparing QAP during registration is attached as Annexure.

5.0 Referenced Documents:

None

6.0 Referenced Documents of External Origin:

None

7.0 Associated Records:

None

8.0 Responsibility and Authority:

Activity Creation, maintenance of this document Requirement of deviation from this form template. Responsible Director/I&L/ LKO Approver ED/QA(Mech) Supporting Staff of QA(Mech) Dte. Consulted Informed All Zonal office of QA(Mech) Dte.

Director/I&L/ LKO

ED/QA(Mech)

Respective AIE/I&L

MR/ISO Cell

All Zonal office of QA(Mech) Dte.

9.0 Abbreviations:

QA ED/QA (Mech) RDSO M&C ARO Quality Assurance Executive Director/ Quality Assurance (Mechanical) Research Designs & Standards Organisation Metallurgical & Chemical Assistant Research Officer

AIE/QA(Mech) Prepared By:

Director/ QA(Mech) Issued By:

Printed: 2010/09/30 Page 2 of 2

ISO9001:2008 Document No: QM-RF-7.1-3 Document Title: Guidelines for preparing QAP during registration

Version No: 1.1

Date Effective: 21.10.2010

Annexure

GUIDELINES FOR PREPARING QAP DURING REGISTRATION

The QAP to be submitted by the vendor in triplicate (along with the application form for registration) shall cover the following aspects

SECTION A ORGANISATION CHART

Organisational Chart, clearly indicating the Quality Control Set-up, role and responsibilities of key personal.

SECTION B QUALIFICATION / EXPERIENCE OF QC PERSONNEL

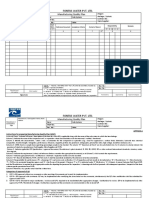

Part I: Details of qualification/experience of the quality control personnel specified in STR/Specification of RDSO of the items applied for approval/renewal Requirement as per STR/Spec. STR/Spec Experience Qualification Para No Specified in Specified in Spec. / STR/ Spec. / STR Para STR Spec Details of personnel employed Name Brief Technical scope of Dsgn. Experience Qualification responsi bilities the

SN

Part II: Qualification of other key personnel and the officials deployed in Quality Control Cell: SN Name Designation Technical Qualification Experience Brief scope of responsibilities

SECTION C PROCESS FLOW CHART/DESCRIPTION OF MANUFACTURING PROCESS

Part I: Process Flow Chart indicating process of manufacture for an individual product, with quality control points. Note: i Process flow chart shall indicate all the operation involving manufacturing & testing of product from raw material to finish product, including RDSO/RITES/Consignee inspection/dispatch. ii There should be separate flow chart for each item. Part II: Brief description of different manufacturing process mentioned in flow chart : a) Details of the manufacturing & testing process specially mentioned in the specification.

AIE/QA(Mech) Prepared By:

Director/ QA(Mech) Issued By:

Printed: 2010/09/30 Page 1 of 5

ISO9001:2008 Document No: QM-RF-7.1-3 Document Title: Guidelines for preparing QAP during registration

Version No: 1.1

Date Effective: 21.10.2010

SN

Para no of spec.

Requirement of manufacturing/testing process as per spec

Details of the process being installed/ follows

. ..

b) Brief details of the other manufacturing process. SN . .. Name of the manufacturing process Brief description

Part III: Brief description of ancillaries & additional units (if any): i Whether all the facilities are available at a single location (or) multiple location ii In case of multiple location give details in following formats : Whether unit is covered under factory license Whether unit is ISO certified

SN

units

Address

Mfg. processes details

SECTION D Details of Sub-assemblies / components manufactured inhouse and outsourced.

Part I: Details of in-house manufactured (Components/sub-assemblies) SN . .. Part II: Details of components/Sub-assemblies purchased from RDSO approved primary / sublet vendors SN . .. Part III : Details of items outsourced from other than RDSO approved items Frequency of review of the performance of sublet source Item Name Drawing No Is it a Primary Item of RDSO Is it a Sublet Item of RDSO Name of the source Item Name Drawing No

SN . ..

Item Name

Drawing No

Name of the source

AIE/QA(Mech) Prepared By:

Director/ QA(Mech) Issued By:

Printed: 2010/09/30 Page 2 of 5

ISO9001:2008 Document No: QM-RF-7.1-3 Document Title: Guidelines for preparing QAP during registration

Version No: 1.1

Date Effective: 21.10.2010

SECTION E INCOMING RAW MATERIAL & INPROCESS/FINAL INSPECTION

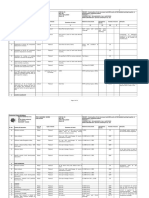

Stage inspection detailing inspection procedure, inspection parameters, method of testing/test procedure including sample sizes for destructive and non- destructive testing etc. Part I : Incoming raw materials/parts/sub-assemblies Acceptance Incoming Product/ assembly Sample Size & its Frequency of inspection Parameters for inspection Mode of inspection / equipmen t used limits/ Criteria /specified Value Reprocessed / Scrapped Rejection & Disposal Traceability register no

SN

. .. Part II: In process inspection (of the product) Acceptance Name of the process Sample Size & its Frequency of inspection Parameter s for inspection Mode of inspection / equipmen t used limits/ Criteria /specified Value Rejection / Disposal Correcti ve & preventi ve action Traceab ility register no

SN

. .. Part III: Final internal inspection of the product by the firm Acceptance Name of the test/ process Sample Size & its Frequency of inspection Parameters for inspection Mode of inspection / equipmen t used limits/ Criteria /specified Value Reprocessed / Scrapped Rejection disposal / Traceability register no

SN

. ..

AIE/QA(Mech) Prepared By:

Director/ QA(Mech) Issued By:

Printed: 2010/09/30 Page 3 of 5

ISO9001:2008 Document No: QM-RF-7.1-3 Document Title: Guidelines for preparing QAP during registration

Version No: 1.1

Date Effective: 21.10.2010

SECTION F CALIBRATION OF TESTING MEASURING EQUIPMENT

Part I : Inhouse Testing facilities available for calibration with the firm Frequency of calibration Traceability to national standard

SN

Name of Master

Make

Range

Part II : Personnel trained for inhouse calibration SN Name Qualification

Experience

Part III : Calibration plan for the items identified for specified calibration in STR/Specification Ref. para of Frequency Name of STR/Spec. Measuring Range/ Inhouse/ SN Specified in agency if Equipment STR/Spec./Para Accuracy Outsourced STR/Spec outsourced no. . .. Part IV : Calibration plan for other measuring equipment Measuring Inhouse/ SN Range/ Accuracy Frequency Equipment Outsourced . ..

Name of calibration agency

SECTION G SYSTEM OF MAINTAINING THE DATE OF CUSTOMER COMPLAINTS/WARRANTY FAILURES

Warranty failures/In-service failures reported from customers Brief details of complaint Complaint received from Failure analysis & cause of failure Date of joint inspection Whether any person deputed for collecting field sample Date of compliance in case of warranty Classification of failure Warranty failure/ In service failure/ Call for joint inspection / Consignee end rejection / General complaints

. .. * The firm shall maintain a complaint register in the above format and the summary required to be given during renewal

AIE/QA(Mech) Prepared By:

Director/ QA(Mech) Issued By:

Printed: 2010/09/30 Page 4 of 5

C & P action taken

Date of report of complaint

Letter no

SN

ISO9001:2008 Document No: QM-RF-7.1-3 Document Title: Guidelines for preparing QAP during registration

Version No: 1.1

Date Effective: 21.10.2010

SECTION - H ANY ADDITIONAL INFORMATION FIRM WISH TO SUBMIT

The firm can furnish any other information which they wish to submit on items other than furnished in annexure A to F.

Note :

1. QAP covering all the information as asked above under section A to F must be given in the form of single document indicating name of the firm and page no. x of y on each page. Each page should be signed by Quality Control in-charge. The approved QAP must be a controlled document and a quality record of ISO Quality Control System of the vendor. A certificate to this effect shall be provided along with the QAP by the vendor. In case of the QAP for sublet items, it is to be provisionally approved by the sponsor and final approval shall be given by the nominated officer for capability assessment. One copy of the QAP, after final approval will be given back to the vendor for implementation

2. 3.

___________

AIE/QA(Mech) Prepared By:

Director/ QA(Mech) Issued By:

Printed: 2010/09/30 Page 5 of 5

Você também pode gostar

- Manufacturing Quality Plan (MQP)Documento2 páginasManufacturing Quality Plan (MQP)Ranjit SinghAinda não há avaliações

- Quality InductionDocumento15 páginasQuality InductionaleemmurtazaAinda não há avaliações

- QSV 2 Product Release Procedure EN 01Documento6 páginasQSV 2 Product Release Procedure EN 01prashanthAinda não há avaliações

- Typical Quality Assurance Plans for ValvesDocumento6 páginasTypical Quality Assurance Plans for ValveskaustavAinda não há avaliações

- QAP Format - QA 01 F 01Documento1 páginaQAP Format - QA 01 F 01Murukan PadmanabhanAinda não há avaliações

- ITP-SV-M-FAN-CENTRIFUGAL&AXIALDocumento7 páginasITP-SV-M-FAN-CENTRIFUGAL&AXIALgauravamberkarAinda não há avaliações

- Quality Management PresentationDocumento8 páginasQuality Management PresentationLok SewaAinda não há avaliações

- PPAP Fourth Edition 2006Documento5 páginasPPAP Fourth Edition 2006Đại Hữu Tuấn MaiAinda não há avaliações

- Manufacturing Quality PlanDocumento4 páginasManufacturing Quality PlanDIENSHAinda não há avaliações

- Document Control ProcedureDocumento3 páginasDocument Control ProcedureHeny Kusumawati100% (1)

- ITP 63113 XX Stockpile ITP (Working)Documento6 páginasITP 63113 XX Stockpile ITP (Working)soni10483Ainda não há avaliações

- QC Engr CV PDFDocumento5 páginasQC Engr CV PDFMuthazhagan SaravananAinda não há avaliações

- Section 5 - Supplier Quality Surveillance: 1.0 GeneralDocumento3 páginasSection 5 - Supplier Quality Surveillance: 1.0 Generalanishgirme100% (1)

- DPT Report 02Documento2 páginasDPT Report 02Amit Hasan100% (1)

- SOP For DrawingDocumento2 páginasSOP For DrawingShashank DwivediAinda não há avaliações

- Inward Material Inspection Report: Project Name: Job Code: LocationDocumento2 páginasInward Material Inspection Report: Project Name: Job Code: LocationTarun GodiyalAinda não há avaliações

- Engineer Second Integrated Road Project Inspection RequestDocumento2 páginasEngineer Second Integrated Road Project Inspection Requesthovael laboratoryAinda não há avaliações

- VQA - PR.06 Customer Satisfaction ProcedureDocumento2 páginasVQA - PR.06 Customer Satisfaction ProcedureNyadroh Clement Mchammonds100% (1)

- F-Qa-03 Material Inspection ReportDocumento2 páginasF-Qa-03 Material Inspection ReportHilal mohamedAinda não há avaliações

- DD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateDocumento1 páginaDD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateWaqar SiddiqueAinda não há avaliações

- Umbrella Desander Contract Kick-Off Meeting MOM - IWSDocumento3 páginasUmbrella Desander Contract Kick-Off Meeting MOM - IWSFj JuniorAinda não há avaliações

- Larsen & Toubro underground piping inspection planDocumento4 páginasLarsen & Toubro underground piping inspection planBhavani PrasadAinda não há avaliações

- Hydraulic crash barriers ITPDocumento4 páginasHydraulic crash barriers ITPmoytabura96Ainda não há avaliações

- Controlled Quality ManualDocumento51 páginasControlled Quality ManualMoment BatureAinda não há avaliações

- Non-Conformance Report Form TemplateDocumento1 páginaNon-Conformance Report Form TemplateVIKASH PEERTHYAinda não há avaliações

- Inspection In Manufacturing A Complete Guide - 2020 EditionNo EverandInspection In Manufacturing A Complete Guide - 2020 EditionAinda não há avaliações

- QAPDocumento10 páginasQAPsheikmoinAinda não há avaliações

- Quality PlanDocumento40 páginasQuality PlanSakthi Kasi RajanAinda não há avaliações

- Painting RecordDocumento1 páginaPainting RecordHimawan SetyarsoAinda não há avaliações

- Inspection & Test Plan for Chilled Water Expansion TanksDocumento1 páginaInspection & Test Plan for Chilled Water Expansion TanksvictorAinda não há avaliações

- WFP 2-01 ASME B31 Piping Welding ProcedureDocumento8 páginasWFP 2-01 ASME B31 Piping Welding Procedureleodavid87Ainda não há avaliações

- 022 - Leak Test FormDocumento1 página022 - Leak Test FormAngela YumangAinda não há avaliações

- PQP Vs ISO 9001 Clauses List PDFDocumento1 páginaPQP Vs ISO 9001 Clauses List PDFVpln Sarma100% (1)

- QC Sample Manual GenericDocumento34 páginasQC Sample Manual GenericIan Stewart PorterAinda não há avaliações

- Quality ControlDocumento51 páginasQuality ControlOprisor CostinAinda não há avaliações

- QM501FA - Nonconformance ReportDocumento1 páginaQM501FA - Nonconformance ReportRio Handoko100% (1)

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDocumento53 páginasA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDan CosacAinda não há avaliações

- Saudi Aramco Inspection ChecklistDocumento3 páginasSaudi Aramco Inspection ChecklistZia ur RehmanAinda não há avaliações

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Documento2 páginasSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiAinda não há avaliações

- Quality Control Procedure Index) - Rev.2Documento3 páginasQuality Control Procedure Index) - Rev.2valent aviolandaAinda não há avaliações

- L&T GeoStructure casing inspection planDocumento2 páginasL&T GeoStructure casing inspection plansanil50% (2)

- AB-518b Quality Manual and Audit ChecklistDocumento24 páginasAB-518b Quality Manual and Audit ChecklistStan Lee PaulsonAinda não há avaliações

- Internal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksDocumento3 páginasInternal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksBihanChathurangaAinda não há avaliações

- FQP GeneralDocumento21 páginasFQP GeneralgaladrialAinda não há avaliações

- Procedure Progress ISO 3834 2 PDFDocumento3 páginasProcedure Progress ISO 3834 2 PDFKumar DAinda não há avaliações

- Quality Assuarance in WeldingDocumento150 páginasQuality Assuarance in WeldingMenad SalahAinda não há avaliações

- Quality Assurance and ControlDocumento55 páginasQuality Assurance and ControlACHESAinda não há avaliações

- Contractor Daily Quality Control ReportDocumento1 páginaContractor Daily Quality Control Reportpuivgi2012Ainda não há avaliações

- PRO-CAL-01 Measuring Equipment Calibration ProgramDocumento2 páginasPRO-CAL-01 Measuring Equipment Calibration ProgramChiekoi PasaoaAinda não há avaliações

- A#9 - Non Conformity Report Form Rev 2.Documento2 páginasA#9 - Non Conformity Report Form Rev 2.Mohammed AzizAinda não há avaliações

- 3.2 Develop The Material Control PlanDocumento9 páginas3.2 Develop The Material Control Planjesus_bs100% (1)

- 1.request For Inspection (HEMT FO QC 01)Documento1 página1.request For Inspection (HEMT FO QC 01)Balasai SabarinathAinda não há avaliações

- QIP of Boiler For ErectionDocumento6 páginasQIP of Boiler For ErectionUmair Awan100% (2)

- Research Designs & Standards Organization: 1.0 Amendment HistoryDocumento8 páginasResearch Designs & Standards Organization: 1.0 Amendment Historynvnrajesh123Ainda não há avaliações

- Final Inspection Report for Venturi Pin LinersDocumento1 páginaFinal Inspection Report for Venturi Pin LinersSenthil KumarAinda não há avaliações

- Invoice Cum Material Issue Voucher: Miv No. CWC No. CWC Date: Sap Material Document No. Posting DateDocumento1 páginaInvoice Cum Material Issue Voucher: Miv No. CWC No. CWC Date: Sap Material Document No. Posting Datehimanshu kalraAinda não há avaliações

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocumento2 páginasEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaAinda não há avaliações

- Supplier Pre-Qualification Document - September 2020Documento23 páginasSupplier Pre-Qualification Document - September 2020cephas ventures enterprisesAinda não há avaliações

- Quality Record Procedure Rev-JDocumento4 páginasQuality Record Procedure Rev-JherminAinda não há avaliações

- CorpDocumento3 páginasCorpMuskan KhatriAinda não há avaliações

- Pablico v. Master PabDocumento10 páginasPablico v. Master PabRaeAinda não há avaliações

- Dimensions of Global Administrative LowDocumento14 páginasDimensions of Global Administrative LowR. U. SinghAinda não há avaliações

- OmniClass 36 2012-05-16Documento20 páginasOmniClass 36 2012-05-16KelvinatorAinda não há avaliações

- Imp Questions To Be Referred - Module 2 & 3Documento2 páginasImp Questions To Be Referred - Module 2 & 3Akash NathwaniAinda não há avaliações

- IT Audit PowerpointDocumento87 páginasIT Audit Powerpointwang_vict100% (2)

- Chapter 11 PPT Perloff Microecon 1eDocumento33 páginasChapter 11 PPT Perloff Microecon 1edrgaan100% (2)

- 2 Republic Act No 3846Documento10 páginas2 Republic Act No 3846John Brix BalisterosAinda não há avaliações

- Case M.8087 - Smiths Group / Morpho Detection: REGULATION (EC) No 139/2004 Merger ProcedureDocumento95 páginasCase M.8087 - Smiths Group / Morpho Detection: REGULATION (EC) No 139/2004 Merger ProcedureAhmad.T Aldaajah92Ainda não há avaliações

- Do 53-03Documento6 páginasDo 53-03mefav7778520Ainda não há avaliações

- US Internal Revenue Service: Irb03-32Documento65 páginasUS Internal Revenue Service: Irb03-32IRSAinda não há avaliações

- Building SpecificationsDocumento6 páginasBuilding SpecificationsCarlAinda não há avaliações

- Art. 1468-1478Documento6 páginasArt. 1468-1478Ge Lato100% (1)

- Sonco, Et. Al. V NLRC G.R. No. 50999 Mar 23,1990 CASE DIGESTDocumento3 páginasSonco, Et. Al. V NLRC G.R. No. 50999 Mar 23,1990 CASE DIGESTAaron AristonAinda não há avaliações

- Policy For Dealing Proposals For PermissionDocumento3 páginasPolicy For Dealing Proposals For PermissionNeelesh PatilAinda não há avaliações

- RBI INWARD CLEARING REPORTDocumento194 páginasRBI INWARD CLEARING REPORTaaaAinda não há avaliações

- OUR LADY OF SNOWS ACADEMY ORGANIZATION AND MANAGEMENTDocumento3 páginasOUR LADY OF SNOWS ACADEMY ORGANIZATION AND MANAGEMENTvirginia taguiba0% (1)

- Observership ApplicationDocumento5 páginasObservership ApplicationPratiksha KapartiwarAinda não há avaliações

- HSE Laws and RegulationsDocumento22 páginasHSE Laws and Regulationsparadigman100% (3)

- Warehouse Supervisor, Warehouse Manager, Logistics CoordinatorDocumento4 páginasWarehouse Supervisor, Warehouse Manager, Logistics Coordinatorapi-121835777Ainda não há avaliações

- National Metrology System in AlbaniaDocumento15 páginasNational Metrology System in AlbaniaHenry MaedaAinda não há avaliações

- 2000-09 - Tangled Up in Blue - Corporate Partnerships at The United NationsDocumento20 páginas2000-09 - Tangled Up in Blue - Corporate Partnerships at The United NationsGlobal Compact CriticsAinda não há avaliações

- Ethics and Professional Practice Workshop ProblemsDocumento15 páginasEthics and Professional Practice Workshop ProblemsAkira ZamudioAinda não há avaliações

- IAS 37 Onerous ContractsDocumento7 páginasIAS 37 Onerous ContractsAnalou LopezAinda não há avaliações

- Safety Inspection Report by WillPoolDocumento5 páginasSafety Inspection Report by WillPoolRana Muhammad ZeeshanAinda não há avaliações

- #3 Dentech Vs NLRCDocumento2 páginas#3 Dentech Vs NLRCReina Anne JaymeAinda não há avaliações

- Implementing Rules and Regulations Governing The Imposition of An Anti-Dumping Duty Under Republic Act The Anti-Dumping Act of 1999Documento37 páginasImplementing Rules and Regulations Governing The Imposition of An Anti-Dumping Duty Under Republic Act The Anti-Dumping Act of 1999ALAJID, KIM EMMANUELAinda não há avaliações

- MAINCOTE™ AE-58 Emulsion: Regional Product Availability DescriptionDocumento2 páginasMAINCOTE™ AE-58 Emulsion: Regional Product Availability DescriptionHito Jimenez SalinasAinda não há avaliações

- Roles Functions Of: & SebiDocumento14 páginasRoles Functions Of: & SebiJeffry MahiAinda não há avaliações