Escolar Documentos

Profissional Documentos

Cultura Documentos

Welding Procedure Specification-1

Enviado por

Suresh RathodDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Welding Procedure Specification-1

Enviado por

Suresh RathodDireitos autorais:

Formatos disponíveis

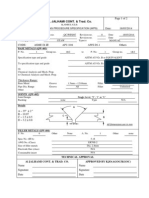

HEAVY FAB INDUSTRIES

COIMBATORE 641 006. WELDING PROCEDURE SPECIFICATION (WPS)

Sheet 01 of 02 Welding Procedure Specification No Revision No Welding Process : HFI/001 : 00 : SMAW Supporting P.Q.R. No : HFI/101 Date : Type : Manual

(Automatic, Manual, Machine or Semi Auto)

JOINTS (QW 402) Joint Design AS PER PRODUCTION DRAWING.

Backing (YES) For double side and backing strip joints : (NO) For single side welds Backing Material (Type) : Weld Metal / Base Metal Metal Yes Non fusing Metal : No Retainer No

BASE METALS (QW 403)

P. No. : 1 Group No. OR Specification Type and Grade To Specification Type and Grade OR Chemical Analysis and Mechanical properties : ___________ To Chemical Analysis and Mechanical Properties. : ___________ : 1&2 to P. No. : 1 Group No. : 1&2

: SA 516 GR 70 to : SA 516 GR 70

THICKNESS RANGE

Base Metal Pipe Dia. Range Others Groove Groove : 4.8mm to 200mm Fillet : All : All Dia Fillet : All : Root spacing for backing strip joints : 8 10mm For others 2 1mm

FILLER METALS (QW 404)

Specification No. (SFA) A.W.S. No (Class) F. No. A. No. Size of Filler Metals Deposited weld Metal Thickness Range Electrode Flux ( Class) Flux Trade Name Consumable Insert : 5.1 : E-7018 :4 :1 : 2.5, 3.15, 4.0, 5.0 & 6.3mm : Groove : 200mm Max Fillet : All : Basic : Not applicable : Not applicable Max bead thickness : 5mm

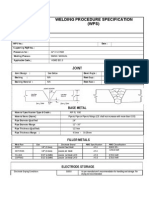

Sheet 02 of 02

POSITIONS (QW 405)

Position of Groove Welding Progression Position of Fillet : All : Uphill for Vertical : All

POST WELD HEAT TREATMENT (QW 407)

Temperature Range Time Range : 600 C - 620 C : 1 Hour/inch as per UCS .56

PRE-HEAT (QW 406)

Pre-heat Temperature Min. Pre-heat Maintenance Inter-pass Temp. Max. : 10 C Upto 30mm : 31-100mm - 100 C Above 100mm - 150 C : 350 C max.

GAS (QW 408)

Percent composition : NA Gas (es) Mixture Flow Rate Shielding : ------------------------------------------------------Trailing : -------------------------------------------------------Backing : --------------------------------------------------------

ELECTRICAL CHARACTERTISTICS (QW 409)

Current AC or DC : DC Polarity : DCEP Amperes (Range) 60 300 Volts(Range) : 22 26 Tungston Electrode Size and Type : Not applicable Mode of Metal Transfer for GMSW : Not applicable Electrode Wire Feed Speed Range : Not applicable

TECHNIQUE (QW 410)

String or Weave Bead Initial & Inter pass cleaning Method of Back Gouging Contact tube to work distance Multiple/ Single Electrode Peening Others Weld Layer(s) Process Filler Metal Class Root Run SMAW For Other SMAW Layers SMAW SMAW SMAW E 7018 E 7018 E 7018 E 7018 E 7018 Dia. 2.5 3.15 4.0 5.0 6.3 : String & Weave Orifice or Gas cup Size : Not applicable : Brushing/ Grinding / Chipping : By grinding Oscillation : Not applicable : Not applicable Multiple/ Single Pass : Multiple Pass : Single Travel Speed (Range) : Not applicable : Not applicable Electrode Spacing : Not applicable : Clean 25mm on either side of weld to remove oil, rust, grease, etc. Current Type of Polarity DC EP DC EP DC EP DC EP DC EP Ampere (Range) 60 90 90 140 140 180 180 240 240 300 22 26 22 26 22 26 22 26 22 26 Volts Wire Feed (IPM)

N.A. N.A. N.A. N.A. N. A

Travel Speed Range mm/min N.A. N.A. N.A. N.A. N.A

Others

Weave Max.3D Weave Max.3D. Weave Max.3D Weave Max.3D Weave Max.3D

Prepared by : R.PURUSHOTHAMAN Date : 19.04.05

Checked by : R.PURUSHOTHAMAN Date : 19.04.05

Approved by : Date :

HEAVY FAB INDUSTRIES

COIMBATORE 641 006. WELDING PROCEDURE SPECIFICATION (WPS)

Sheet 01 of 02 Welding Procedure Specification No Revision No Welding Process : HFI/002 : 00 : SMAW Supporting P.Q.R. No : HFI/102 Date : Type : Manual

(Automatic, Manual, Machine or Semi Auto)

JOINTS (QW 402) Joint Design AS PER PRODUCTION DRAWING.

Backing (YES) For double side and backing strip joints : (NO) For single side welds Backing Material (Type) : Weld Metal / Base Metal Metal Yes Non fusing Metal : No Retainer No

BASE METALS (QW 403)

P. No. : 1 Group No. OR Specification Type and Grade To Specification Type and Grade OR Chemical Analysis and Mechanical properties : ___________ To Chemical Analysis and Mechanical Properties. : ___________ : 1&2 to P. No. : 1 Group No. : 1&2

: SA 516 GR 70 to : SA 516 GR 70

THICKNESS RANGE

Base Metal Pipe Dia. Range Others Groove Groove : 4.8mm to 38mm Fillet : All : All Dia Fillet : All : Root spacing for backing strip joints : 8 10mm For others 2 1mm

FILLER METALS (QW 404)

Specification No. (SFA) A.W.S. No (Class) F. No. A. No. Size of Filler Metals Deposited weld Metal Thickness Range Electrode Flux ( Class) Flux Trade Name Consumable Insert : 5.1 : E-7018 :4 :1 : 2.5, 3.15, 4.0, 5.0 & 6.3mm : Groove : 200mm Max Fillet : All : Basic : Not applicable : Not applicable Max bead thickness : 5mm

Sheet 02 of 02

POSITIONS (QW 405)

Position of Groove Welding Progression Position of Fillet : All : Uphill for Vertical : All

POST WELD HEAT TREATMENT (QW 407)

Temperature Range Time Range : Not Applicable : Not Applicable

PRE-HEAT (QW 406)

Pre-heat Temperature Min. Pre-heat Maintenance Inter-pass Temp. Max. : 10 C Upto 30mm : 31-38mm - 100 C : 350 C max.

GAS (QW 408)

Percent composition : NA Gas (es) Mixture Flow Rate Shielding : ------------------------------------------------------Trailing : -------------------------------------------------------Backing : --------------------------------------------------------

ELECTRICAL CHARACTERTISTICS (QW 409)

Current AC or DC : DC Polarity : DCEP Amperes (Range) 60 300 Volts(Range) : 22 26 Tungston Electrode Size and Type : Not applicable Mode of Metal Transfer for GMSW : Not applicable Electrode Wire Feed Speed Range : Not applicable

TECHNIQUE (QW 410)

String or Weave Bead Initial & Inter pass cleaning Method of Back Gouging Contact tube to work distance Multiple/ Single Electrode Peening Others Weld Layer(s) Process Filler Metal Class Root Run SMAW For Other SMAW Layers SMAW SMAW SMAW E 7018 E 7018 E 7018 E 7018 E 7018 Dia. 2.5 3.15 4.0 5.0 6.3 : String & Weave Orifice or Gas cup Size : Not applicable : Brushing/ Grinding / Chipping : By grinding Oscillation : Not applicable : Not applicable Multiple/ Single Pass : Multiple Pass : Single Travel Speed (Range) : Not applicable : Not applicable Electrode Spacing : Not applicable : Clean 25mm on either side of weld to remove oil, rust, grease, etc. Current Type of Polarity DC EP DC EP DC EP DC EP DC EP Ampere (Range) 60 90 90 140 140 180 180 240 240 300 22 26 22 26 22 26 22 26 22 26 Volts Wire Feed (IPM)

N.A. N.A. N.A. N.A. N. A

Travel Speed Range mm/min N.A. N.A. N.A. N.A. N.A

Others

Weave Max.3D Weave Max.3D. Weave Max.3D Weave Max.3D Weave Max.3D

Prepared by : R.PURUSHOTHAMAN Date : 19.04.05

Checked by : R.PURUSHOTHAMAN Date : 19.04.05

Approved by : Date :

HEAVY FAB INDUSTRIES

COIMBATORE 641 006. WELDING PROCEDURE SPECIFICATION (WPS)

Sheet 01 of 02 Welding Procedure Specification No Revision No Welding Process : HFI/003 : 00 : SMAW Supporting P.Q.R. No : HFI/103 Date : Type : Manual

(Automatic, Manual, Machine or Semi Auto)

JOINTS (QW 402) Joint Design AS PER PRODUCTION DRAWING.

Backing (YES) For double side and backing strip joints : (NO) For single side welds Backing Material (Type) : Weld Metal / Base Metal Metal Yes Non fusing Metal : No Retainer No

BASE METALS (QW 403)

P. No. : 8 Group No. OR Specification Type and Grade To Specification Type and Grade OR Chemical Analysis and Mechanical properties : ___________ To Chemical Analysis and Mechanical Properties. : ___________ :1 to P. No. : 1 Group No. : 1&2

: SA 240 TP 304 to : SA 516 GR 70

THICKNESS RANGE

Base Metal Pipe Dia. Range Others Groove Groove : 4.8mm to 24mm Fillet : All : All Dia Fillet : All : Root spacing for backing strip joints : 8 10mm For others 2 1mm

FILLER METALS (QW 404)

Specification No. (SFA) A.W.S. No (Class) F. No. A. No. Size of Filler Metals Deposited weld Metal Thickness Range Electrode Flux ( Class) Flux Trade Name Consumable Insert : 5.4 : E-309-15 :5 :8 : 2.5 5mm : Groove : 24mm Max Fillet : All : Basic : Not applicable : Not applicable Max bead thickness : 5mm

Sheet 02 of 02

POSITIONS (QW 405)

Position of Groove Welding Progression Position of Fillet : All : Uphill for Vertical : All

POST WELD HEAT TREATMENT (QW 407)

Temperature Range Time Range : Not applicable : Not applicable

PRE-HEAT (QW 406)

Pre-heat Temperature Min. Pre-heat Maintenance Inter-pass Temp. Max. : 10 C : ----: 200 C max.

GAS (QW 408)

Percent composition : NA Gas (es) Mixture Flow Rate Shielding : ------------------------------------------------------Trailing : -------------------------------------------------------Backing : --------------------------------------------------------

ELECTRICAL CHARACTERTISTICS (QW 409)

Current AC or DC Amperes (Range) 60 180 Tungston Electrode Size and Type Mode of Metal Transfer for GMSW Electrode Wire Feed Speed Range : DC Polarity Volts(Range) : Not applicable : Not applicable : Not applicable : DCEP : 22 26

TECHNIQUE (QW 410)

String or Weave Bead Initial & Inter pass cleaning Method of Back Gouging Contact tube to work distance Multiple/ Single Electrode Peening Others Weld Layer(s) Proces s Filler Metal Class Root Run SMAW For Other SMAW Layers SMAW SMAW E 30915 E 30915 E 30915 E 30915 Dia. 2.5 3.15 4.0 5.0 : String Orifice or Gas cup Size : Not applicable : Brushing/ Grinding / Chipping : By grinding Oscillation : Not applicable : Not applicable Multiple/ Single Pass : Multiple Pass : Single Travel Speed (Range) : Not applicable : Not applicable Electrode Spacing : Not applicable : Clean 25mm on either side of weld to remove oil, rust, grease, etc. Current Type of Polarity DC EP DC EP DC EP DC EP Ampere (Range) 60 80 90 110 120 140 150 180 22 26 22 26 22 26 22 26 Volts Wire Feed (IPM)

N.A. N.A. N.A. N.A.

Travel Speed Range mm/min N.A. N.A. N.A. N.A.

Others

Weave Max.3D Weave Max.3D. Weave Max.3D Weave Max.3D

Prepared by : R.PURUSHOTHAMAN Date : 19.04.05

Checked by : R.PURUSHOTHAMAN Date : 19.04.05

Approved by : Date :

HEAVY FAB INDUSTRIES

COIMBATORE 641 006. WELDING PROCEDURE SPECIFICATION (WPS)

Sheet 01 of 02 Welding Procedure Specification No Revision No Welding Process : HFI/004 : 00 : SMAW Supporting P.Q.R. No : HFI/104 Date : Type : Manual

(Automatic, Manual, Machine or Semi Auto)

JOINTS (QW 402) Joint Design AS PER PRODUCTION DRAWING.

Backing (YES) For double side and backing strip joints : (NO) For single side welds Backing Material (Type) : Weld Metal / Base Metal Metal Yes Non fusing Metal : No Retainer No

BASE METALS (QW 403)

P. No. : 8 Group No. OR Specification Type and Grade To Specification Type and Grade OR Chemical Analysis and Mechanical properties : ___________ To Chemical Analysis and Mechanical Properties. : ___________ :1 to P. No. : 8 Group No. :1

: SA 240 TP 304L to : SA 516 GR 70

THICKNESS RANGE

Base Metal Pipe Dia. Range Others Groove Groove : 4.8mm to 24mm Fillet : All : All Dia Fillet : All : Root spacing for backing strip joints : 8 10mm For others 2 1mm

FILLER METALS (QW 404)

Specification No. (SFA) A.W.S. No (Class) F. No. A. No. Size of Filler Metals Deposited weld Metal Thickness Range Electrode Flux ( Class) Flux Trade Name Consumable Insert : 5.4 : E-308L 15 :5 :8 : 2.5 5mm : Groove : 24mm Max Fillet : All : Basic : Not applicable : Not applicable Max bead thickness : 5mm

Sheet 02 of 02

POSITIONS (QW 405)

Position of Groove Welding Progression Position of Fillet : All : Uphill for Vertical : All

POST WELD HEAT TREATMENT (QW 407)

Temperature Range Time Range : Not applicable : Not applicable

PRE-HEAT (QW 406)

Pre-heat Temperature Min. Pre-heat Maintenance Inter-pass Temp. Max. : 10 C : ----: 200 C max.

GAS (QW 408)

Percent composition : NA Gas (es) Mixture Flow Rate Shielding : ------------------------------------------------------Trailing : -------------------------------------------------------Backing : --------------------------------------------------------

ELECTRICAL CHARACTERTISTICS (QW 409)

Current AC or DC Amperes (Range) 60 180 Tungston Electrode Size and Type Mode of Metal Transfer for GMSW Electrode Wire Feed Speed Range : DC Polarity Volts(Range) : Not applicable : Not applicable : Not applicable : DCEP : 22 26

TECHNIQUE (QW 410)

String or Weave Bead Initial & Inter pass cleaning Method of Back Gouging Contact tube to work distance Multiple/ Single Electrode Peening Others Weld Layer(s) Proces s Filler Metal Class Root Run SMAW For Other SMAW Layers SMAW SMAW E 30915 E 30915 E 30915 E 30915 Dia. 2.5 3.15 4.0 5.0 : String Orifice or Gas cup Size : Not applicable : Brushing/ Grinding / Chipping : By grinding Oscillation : Not applicable : Not applicable Multiple/ Single Pass : Multiple Pass : Single Travel Speed (Range) : Not applicable : Not applicable Electrode Spacing : Not applicable : Clean 25mm on either side of weld to remove oil, rust, grease, etc. Current Type of Polarity DC EP DC EP DC EP DC EP Ampere (Range) 60 80 90 110 120 140 150 180 22 26 22 26 22 26 22 26 Volts Wire Feed (IPM)

N.A. N.A. N.A. N.A.

Travel Speed Range mm/min N.A. N.A. N.A. N.A.

Others

Weave Max.3D Weave Max.3D. Weave Max.3D Weave Max.3D

Prepared by : R.PURUSHOTHAMAN Date : 19.04.05

Checked by : R.PURUSHOTHAMAN Date : 19.04.05

Approved by : Date :

Você também pode gostar

- WPS 316 LDocumento4 páginasWPS 316 Llaz_k100% (2)

- Fcaw 16 THKDocumento5 páginasFcaw 16 THKparesh2387Ainda não há avaliações

- WPS FormatDocumento2 páginasWPS FormatAmit SarkarAinda não há avaliações

- Welding Proposed Pwps For Our Jubail WorkDocumento2 páginasWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDocumento2 páginasWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniAinda não há avaliações

- Wps A53 Gtaw R00Documento2 páginasWps A53 Gtaw R00Richard PeriyanayagamAinda não há avaliações

- 202 1sp 0 Saw Cs CsDocumento8 páginas202 1sp 0 Saw Cs CskrishimaAinda não há avaliações

- Weld Map & NDE Extent of Pressure VesselDocumento32 páginasWeld Map & NDE Extent of Pressure VesselMahesh Kumar100% (2)

- Weld Matrix Format 1Documento7 páginasWeld Matrix Format 1Arslan WaheedAinda não há avaliações

- WPS & PQRDocumento13 páginasWPS & PQRValentin RadulescuAinda não há avaliações

- Formato de ITP-estructuras Metalicas BOLT TORQUE TESTDocumento1 páginaFormato de ITP-estructuras Metalicas BOLT TORQUE TESTkrlitos24100% (1)

- Welding Procedure SpecificationDocumento3 páginasWelding Procedure SpecificationGodwin A.udo-akanAinda não há avaliações

- Wps (Gtaw & Smaw)Documento3 páginasWps (Gtaw & Smaw)Ramadhan AdityaAinda não há avaliações

- Welder Qualification Procedure PDFDocumento13 páginasWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- WPS Fcaw PDFDocumento1 páginaWPS Fcaw PDFErik Huang100% (3)

- Procedure Qualification RecordDocumento10 páginasProcedure Qualification Recordlamia97Ainda não há avaliações

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocumento3 páginasSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013Ainda não há avaliações

- WPS 03Documento2 páginasWPS 03mansoor_an100% (1)

- Piping WpsDocumento37 páginasPiping WpsZulfokar FahdawiAinda não há avaliações

- PQR Form (Welding)Documento2 páginasPQR Form (Welding)jasmineammaAinda não há avaliações

- Astm Equivalent ListDocumento1 páginaAstm Equivalent Listjojo_323Ainda não há avaliações

- Welding Coordination Activities and Responsibilities To ISO 14731 Task Allocation ListDocumento7 páginasWelding Coordination Activities and Responsibilities To ISO 14731 Task Allocation ListeliiiiiiAinda não há avaliações

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Documento14 páginasList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSAinda não há avaliações

- Wps 316L Gtaw R00Documento3 páginasWps 316L Gtaw R00Richard Periyanayagam100% (3)

- Welding Consumables Control RegisterDocumento5 páginasWelding Consumables Control RegisterAli Mhaskar100% (2)

- WPS-46 - Gtaw & Smaw Tig + SmawDocumento8 páginasWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaAinda não há avaliações

- Inter Office Memo: Sr. No. Material Specification Test Piece Size Welding ProcessDocumento1 páginaInter Office Memo: Sr. No. Material Specification Test Piece Size Welding Processg_sanchetiAinda não há avaliações

- Welding Traceability Record 1Documento1 páginaWelding Traceability Record 1Alfian Imaduddin100% (1)

- WPS Sitelca S002Documento2 páginasWPS Sitelca S002Jose Antonio GomezAinda não há avaliações

- Welding Procedure SpecificationsDocumento2 páginasWelding Procedure SpecificationsGerhard Kemp0% (1)

- Weld Map Pressure VesselDocumento32 páginasWeld Map Pressure Vesseljasmineamma100% (4)

- Mailam India Limited Qw-482: Welding Procedure Specification (WPS)Documento2 páginasMailam India Limited Qw-482: Welding Procedure Specification (WPS)Asad Bin Ala QatariAinda não há avaliações

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Documento5 páginasWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Reports - QAQC - R0Documento10 páginasReports - QAQC - R0talupurumAinda não há avaliações

- WPS (AsmeDocumento8 páginasWPS (AsmeMohammad Elhedaby100% (6)

- PWPS WPS CAP 039 PQR 035Documento15 páginasPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRAinda não há avaliações

- QW-483 BlankDocumento2 páginasQW-483 BlankCraftyBob100% (1)

- Electrode Baking RegisterDocumento1 páginaElectrode Baking RegisterSuresh Rathod100% (4)

- WPS PQR ProcedureDocumento31 páginasWPS PQR Proceduresudeesh kumarAinda não há avaliações

- SS WPSDocumento1 páginaSS WPSMOHAMEDABBASAinda não há avaliações

- Welders QualificationDocumento22 páginasWelders QualificationSreedhar Patnaik.M100% (2)

- Wqt-Visual-Mag - BS 2Documento24 páginasWqt-Visual-Mag - BS 2KyAinda não há avaliações

- WPS Format For ASME IX - PQR-AllDocumento3 páginasWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- PQR Sample PrintoutDocumento2 páginasPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Daily Welding Record LPDocumento27 páginasDaily Welding Record LProbby moneAinda não há avaliações

- Welding Procedure Specification For 24'' PipeDocumento2 páginasWelding Procedure Specification For 24'' Pipeenels77100% (1)

- ASME F and P Number Definitions..Documento9 páginasASME F and P Number Definitions..Sankar KrishnanAinda não há avaliações

- WPS 304L &316LDocumento2 páginasWPS 304L &316LShakeel Memon100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDocumento3 páginasWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadAinda não há avaliações

- Back Gouging ProcedureDocumento8 páginasBack Gouging Proceduremahi1437100% (1)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Documento6 páginasMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajAinda não há avaliações

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocumento5 páginasWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedAinda não há avaliações

- Weld MapDocumento1 páginaWeld MapvinothAinda não há avaliações

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Documento2 páginasWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- WPS PQRDocumento23 páginasWPS PQRHashim Khan88% (8)

- Nit 2019 20 56 Wps 1569579575Documento16 páginasNit 2019 20 56 Wps 1569579575vijayachiduAinda não há avaliações

- WPS GTAW Stainless SteelDocumento4 páginasWPS GTAW Stainless SteelAnand NarayananAinda não há avaliações

- PWPS For Piping-API 1104Documento6 páginasPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- P 91 - Welding WPSDocumento2 páginasP 91 - Welding WPSSuhailshah123475% (4)

- Inhouse NCR FormatDocumento2 páginasInhouse NCR FormatSuresh Rathod100% (1)

- Separator Top - Dimension ReportDocumento2 páginasSeparator Top - Dimension ReportSuresh RathodAinda não há avaliações

- WPS, PQR, WPQ (Si007)Documento5 páginasWPS, PQR, WPQ (Si007)Suresh RathodAinda não há avaliações

- Electrode Baking RegisterDocumento1 páginaElectrode Baking RegisterSuresh Rathod100% (4)

- Incoming Material RegisterDocumento2 páginasIncoming Material RegisterSuresh Rathod100% (2)

- Calibration Certificates and Maintenance ReportDocumento4 páginasCalibration Certificates and Maintenance ReportSuresh Rathod100% (1)

- AP Leave Rules 1933Documento42 páginasAP Leave Rules 1933Suresh RathodAinda não há avaliações

- How To Write A Joining Letter ReportDocumento1 páginaHow To Write A Joining Letter ReportSuresh Rathod100% (1)

- Basics of LPIDocumento21 páginasBasics of LPISuresh RathodAinda não há avaliações

- What Are They?: My Diabetes GoalsDocumento2 páginasWhat Are They?: My Diabetes GoalsSuresh RathodAinda não há avaliações

- SunPower Guideline For PVSyst Modeling - Oasis 3 - P-SeriesDocumento17 páginasSunPower Guideline For PVSyst Modeling - Oasis 3 - P-Seriesvineets058100% (1)

- SA08302002E - Control Panel Design GuideDocumento37 páginasSA08302002E - Control Panel Design GuideDennis Codis100% (1)

- Brochure - Main PDFDocumento28 páginasBrochure - Main PDFMahesh KorlapatiAinda não há avaliações

- Tower Wagon Manulas PDFDocumento165 páginasTower Wagon Manulas PDFkhan11k100% (1)

- Genius SW hf5.1 6000Documento36 páginasGenius SW hf5.1 6000A HAinda não há avaliações

- Physics - Reflection & Refraction: Sahil KhandareDocumento11 páginasPhysics - Reflection & Refraction: Sahil KhandaressskAinda não há avaliações

- P300 2Documento4 páginasP300 2Kevin LoayzaAinda não há avaliações

- Renewable Energy: Ahmed Djebli, Salah Hanini, Ouassila Badaoui, Brahim Haddad, Amina BenhamouDocumento13 páginasRenewable Energy: Ahmed Djebli, Salah Hanini, Ouassila Badaoui, Brahim Haddad, Amina Benhamou11751175Ainda não há avaliações

- Why I Must Attack ThriveDocumento6 páginasWhy I Must Attack ThriveMatthew EhretAinda não há avaliações

- N2 Thermostat Install GuideDocumento20 páginasN2 Thermostat Install Guideanon_601173652Ainda não há avaliações

- Progress in Electromagnetics Research, PIER 41, 307-335, 2003Documento29 páginasProgress in Electromagnetics Research, PIER 41, 307-335, 2003Vu Duc TuAinda não há avaliações

- The Starting SystemDocumento20 páginasThe Starting SystemRuth MwendaAinda não há avaliações

- Demand and Supply CurveDocumento3 páginasDemand and Supply CurveJanella Umieh De UngriaAinda não há avaliações

- Qualification of Compressed Air ProtocolDocumento18 páginasQualification of Compressed Air ProtocolBRIJENDRA KUMAR SINGH100% (2)

- SSR 2015-2016Documento42 páginasSSR 2015-2016RamkumarAinda não há avaliações

- LV Network Calculations and Use of AmtechDocumento38 páginasLV Network Calculations and Use of AmtechAbraham JyothimonAinda não há avaliações

- Static MixerDocumento2 páginasStatic Mixerjemakl1568Ainda não há avaliações

- AUGUST2007 REB500 LDocumento112 páginasAUGUST2007 REB500 LRK KAinda não há avaliações

- The World's First Industrial Gas Turbine Set at Neuchâtel (1939)Documento8 páginasThe World's First Industrial Gas Turbine Set at Neuchâtel (1939)boukhari39100% (1)

- AC Installation (Non-Inverter)Documento2 páginasAC Installation (Non-Inverter)winmyintzawAinda não há avaliações

- q1 m6 Heat Temperature Activity Sheet Summative TestDocumento5 páginasq1 m6 Heat Temperature Activity Sheet Summative TestALLYSA JANE SIAAinda não há avaliações

- Gait Analysis and Clinical ApplicationDocumento123 páginasGait Analysis and Clinical ApplicationKanhu Mallik100% (4)

- E3501 FPU KatalogversionDocumento12 páginasE3501 FPU KatalogversionRolando Jara YoungAinda não há avaliações

- TEP0011Documento2 páginasTEP0011slygerAinda não há avaliações

- Raku Kei Reiki MudrasDocumento4 páginasRaku Kei Reiki Mudrasmajadb100% (1)

- Pcr2019-14 PCR Construction Products v1.0Documento26 páginasPcr2019-14 PCR Construction Products v1.0marcoAinda não há avaliações

- LPI® Copper & Stainless Steel Earth Rods: o o o oDocumento3 páginasLPI® Copper & Stainless Steel Earth Rods: o o o oCecep NanuAinda não há avaliações

- Sustainable Performance in The Construction Industry: CEMEX STUDY 18/5/10 14:34 Page 1Documento4 páginasSustainable Performance in The Construction Industry: CEMEX STUDY 18/5/10 14:34 Page 1Nikhil SatavAinda não há avaliações

- 5.1.12 TRO Unit: Part Names of Each ComponentDocumento1 página5.1.12 TRO Unit: Part Names of Each ComponentMark Dominic FedericoAinda não há avaliações

- Dat P222leDocumento2 páginasDat P222lePowerTechAinda não há avaliações