Escolar Documentos

Profissional Documentos

Cultura Documentos

Commissioning of LP Dosing System of Boiler

Enviado por

deepakkesri26Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Commissioning of LP Dosing System of Boiler

Enviado por

deepakkesri26Direitos autorais:

Formatos disponíveis

Station: NTPC - Simhadri Plant Area: BOILER

BHEL Ref No. PS - DC - 186 - 500 0034 D NTPC Ref No. SIM / 1 / CS / 1 / 34 D

Sheet 1 of 11

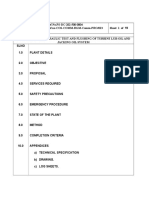

Procedure for: COMMISSIONING OF LP DOSING SYSTEM FOR BOILER SL. NO. CONTENTS

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.

PLANT DETAILS OBJECTIVE PROPOSAL SERVICES REQUIRED SAFETY PRECAUTIONS EMERGENCY PROCEDURE STATE OF THE PLANT METHOD COMPLETION CRITERIA APPENDICES a) DRAWINGS b) LOG SHEET

Signatures NTPC BHEL

Station: NTPC - Simhadri Plant Area: BOILER

BHEL Ref No. PS - DC - 186 - 500 0034 D NTPC Ref No. SIM / 1 / CS / 1 / 34 D

Sheet 2 of 11

Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER SL. NO. 1.0 PLANT DETAILS The LP Dosing System consists of the following: 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1 No. Mixing Tank with Agitator 1 No. Metering Tank 2 Nos. Pump with Motor (Positive Displacement pump) ( With stroke adjustment ) 2 Nos. Suction Filters 2 Nos. Relief Valve Inlet DM Water connection to Mixing and Metering Tank Level Gauges for Mixing and Metering Tank Local Instrumentation Plant Item Completion List for Mechanical, Electrical and C&I are to be prepared at site. 1.9 The Schematic of LP Dosing System is enclosed in Subsection 10.0 (Drawing No. 4: PS : TSX : 0066:00 Dt. 23.07.2001 STATUS

Signatures NTPC BHEL

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500 0034D NTPC Ref No. SIM / 1 /CS / 1 / 34 D

Sheet 3 of 11

Plant Area: BOILER Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER SL. NO. 2.0 2.1 OBJECTIVES To commission LP dosing system and make it available for unit operation. STATUS

3.0 3.1

PROPOSAL The Commissioning ofLP Dosing System is carried out as follows: a) Flushing of Mixing, Metering Tanks and upto Pump Station with DM Water. b) Pump trial run, Relief Valve setting and C&I System . c) To commission the remote stroke adjustment system

Signatures NTPC BHEL

Station: NTPC Simhadri

BHEL Ref No. PS - DC - 186 - 500 0034 D NTPC Ref No. SIM / 1 / CS / 1 / 34 D

Sheet 4 of 11

Plant Area: BOILER Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER SL. NO. 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 SERVICES REQUIRED Availability of manpower with required tools for attending to any leak, cleaning of filters. Availability of operating personal to co-ordinate the activities. Availability of lighting arrangement in and around the LP Dosing System. Availability of portable fire fighting equipment near the dosing system. Availability of sufficient quantity of DM Water. Availability of LT Power Supply. Availability of Chemicals. STATUS

Signatures NTPC BHEL

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500 0034 D NTPC Ref No. SIM / 1 / CS / 1 / 34 D

Sheet 5 of 11

Plant Area: BOILER Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER SL. NO. 5.0 5.1 5.2 5.3 SAFETY PRECAUTIONS Goggles, Apron, Hand-gloves for handling chemicals. Bunding & draining arrangements are properly done to take care of spillages. First aid kid is available at test area. STATUS

6.0 6.1

EMERGENCY PROCEDURE The operating staff should know about the normal operating procedure to be adopted in case of damage to machinery or injury to any person connected in the activity. The test team should be well aware of procedures to be adopted in case of any abnormality in the activity.

6.2

Signatures NTPC BHEL

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500 0034 D NTPC Ref No. SIM / 1 / CS / 1 / 34 D

Sheet 6 of 11

Plant Area: BOILER Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER SL. NO. 7.0 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 STATE OF THE PLANT LP Dosing Systems are erected as per recommended drawing. Mixing and Metering Tanks are cleaned with DM Water and filled upto normal operating level. LT power supply system for Pumps, are commissioned and available for operation. Required Local/Remote I&C Inputs are made available. DM Water connections to Mixing Tank, metering tank and to lines (for flushing) are ready. Lubricating oil is filled in the pump gear box up to its normal level / Indication. Suction filters are cleaned. Tank Drains and Pump Relief Valves are terminated as per scheme. STATUS

7.9 7.10

The test area is cleaned and proper approaches are available. LP dosing system are erected with proper bunding and draining facility to contain any spillage.

Signatures NTPC BHEL

Station: NTPC - Simhadri Plant Area: BOILER

BHEL Ref No. PS - DC - 186 - 500 34D NTPC Ref No. SIM / 1 / CS / 1 / 34D

Sheet 7 of 11

Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER SL. NO. 8.0 8.1 METHOD FLUSHING OPERATION The Mixing & Metering Tanks along with suction pipe upto pump to be flushed with DM Water so as to avoid the entry of dust into the pump. STATUS

8.2

PREPARATION: Disconnect the pump suction connection flange and connect the suction line with hose to nearby drain. Remove the suction filters and make the suction line through.

8.3 8.4 8.5

PROCESS Fill the Mixing and Metering Tank with DM Water. Open the pump suction valve and flush the system until clear water noticed in the temporary hose.

Signatures NTPC BHEL

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500 0034 D NTPC Ref No. SIM / 1 / CS / 1 / 34 D

Sheet 8 of 11

Plant Area: BOILER Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER SL. NO. 8.6 8.7 8.8 8.9 8.10 8.11 8.12 8.13 8.14 8.15 Normalise the suction connection to pump. Bump the motor (in decoupled condition) and check the direction of rotation. Trial run the motor for 2 hours and couple with the pump. Fill the Mixing and Metering Tank upto normal level. Open the Pumps Suction, Discharge and Recirculation valve. Close the valve in the line going to boiler. Ensure the suction & discharge gauges are installed and the respective valve cocks are opened. Keep pump stroke to minimum and start the pump and observe discharge pressure. Increase the pump stroke gradually to 100% and observe pump performance. Trial run the pump for 4 hours and maintain the tank level keeping the pump stroke around 50%. Commission the remote stroke adjustment system (if provided) and operate and observe its performance. STATUS

8.16

Signatures NTPC BHEL

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500 0034 D NTPC Ref No. SIM / 1 / CS / 1 / 34 D

Sheet 9 of 11

Plant Area: BOILER Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER SL. NO. 8.17 Set the relief valve by throttling the R/C Valve. (The set pressure to be around 10 KSC more than the working pressure of the system) Stop the pump. Ensure the Agitator is coupled with motor. Bump the Agitator and check the direction of rotation. Trial run the Agitator for 2 Hours. STATUS

8.18 8.19 8.20 8.21

9.0

COMPLETION CRITERIA Commissioning of LP dosing system completed with a) Flushing of the system from tanks to pump suction. b) Trial run of Pump and agitator for 4 Hours & 2 Hours respy. c) Setting of Relief valve around 10.0 KSC above working pressure of the system. d) Commg of remote stroke adjustment system

Signatures NTPC BHEL

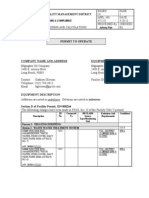

SHEET 11 OF 11 LOG SHEET

Date:

PROJECT : UNIT : ACTIVITY:

Sl. No.

Date / Time

Pump in service

Discharge Pressure Kg/cm2

Mixing/Meterin g Tank Level in Mn.

Gear Box Oil

Remark

Signatures NTPC BHEL

PROCEDURE FOR COMMISSIONING OF LP DOSING SYSTEM OF BOILER (Commissioning Schedule )

Você também pode gostar

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideNo EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideNota: 4 de 5 estrelas4/5 (8)

- Gen Air TightnessDocumento13 páginasGen Air TightnessSam100% (2)

- Advanced Temperature Measurement and Control, Second EditionNo EverandAdvanced Temperature Measurement and Control, Second EditionAinda não há avaliações

- BC Ii 800Documento38 páginasBC Ii 800Pop Ciprian100% (2)

- HP HeaterDocumento10 páginasHP HeateradehriyaAinda não há avaliações

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNo EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNota: 3.5 de 5 estrelas3.5/5 (3)

- Rankine CycleDocumento7 páginasRankine Cycledeepakkesri260% (1)

- Rankine CycleDocumento7 páginasRankine Cycledeepakkesri260% (1)

- Content Analysis in The Social Sciences From Manual To Automated ApproachesDocumento75 páginasContent Analysis in The Social Sciences From Manual To Automated Approachesdiablero999Ainda não há avaliações

- 015 VT PumpsDocumento32 páginas015 VT PumpsZainul Abdin100% (1)

- InfoWorks ICM Overview 60 Mins PDFDocumento31 páginasInfoWorks ICM Overview 60 Mins PDFAnonymous lyVIwA60% (2)

- Testing Schedule For Commissioning of Condensate Extraction PumpsDocumento13 páginasTesting Schedule For Commissioning of Condensate Extraction PumpsJackSparrow86100% (1)

- ACWDocumento9 páginasACWrohit_me083Ainda não há avaliações

- LPBP Commisiong GuideDocumento23 páginasLPBP Commisiong GuideBalaji AllupatiAinda não há avaliações

- Coal FeederDocumento8 páginasCoal FeedersanjeevchhabraAinda não há avaliações

- BFP TDDocumento22 páginasBFP TDJackSparrow8650% (2)

- HP by Pass System-ModifiedDocumento21 páginasHP by Pass System-Modifiedsrigirisetty208100% (1)

- Procedure For Governing Oil SystemDocumento29 páginasProcedure For Governing Oil SystemLakshmi NarayanAinda não há avaliações

- Procedure For Condenser Flood Test and Vacuum Tightness TestDocumento13 páginasProcedure For Condenser Flood Test and Vacuum Tightness TestJackSparrow86Ainda não há avaliações

- Aux HTDocumento11 páginasAux HTsanjeevchhabraAinda não há avaliações

- Procedure For Commissioning of Auxiliary Prds SystemDocumento14 páginasProcedure For Commissioning of Auxiliary Prds SystemJackSparrow86100% (1)

- BFP TDDocumento22 páginasBFP TDArvind ShuklaAinda não há avaliações

- F O Flushing and Steam BlowingDocumento8 páginasF O Flushing and Steam BlowingsprotkarAinda não há avaliações

- PRDSDocumento14 páginasPRDSSrinivas N GowdaAinda não há avaliações

- Fernando Shafier Alam - Procedure Commissioming Steam Turbine-BFWPDocumento20 páginasFernando Shafier Alam - Procedure Commissioming Steam Turbine-BFWPFershaalAinda não há avaliações

- Aux Steam SystemDocumento14 páginasAux Steam Systemsanjeevchhabra100% (1)

- Condenser Flood TestDocumento14 páginasCondenser Flood Testsrigirisetty208100% (1)

- F.O. Lines Steam BlowingDocumento9 páginasF.O. Lines Steam Blowingsrigirisetty208Ainda não há avaliações

- Aux Steam SystemDocumento14 páginasAux Steam SystemDipti BhanjaAinda não há avaliações

- Bhel VisDocumento11 páginasBhel VissanjeevchhabraAinda não há avaliações

- Clean Air Flow TestDocumento13 páginasClean Air Flow Testsrigirisetty20880% (5)

- Condenser Flood Test 8 of 11Documento14 páginasCondenser Flood Test 8 of 11Sara LopezAinda não há avaliações

- F O Flushing and Steam Blowing PDFDocumento8 páginasF O Flushing and Steam Blowing PDFSendal BodolAinda não há avaliações

- TG Lub Oil FlushingDocumento25 páginasTG Lub Oil Flushingsrigirisetty208Ainda não há avaliações

- Air Pre-Heater 600mwDocumento15 páginasAir Pre-Heater 600mwAmit BiswasAinda não há avaliações

- CDA Clean Dry AirDocumento15 páginasCDA Clean Dry AirJonAinda não há avaliações

- ID FD PA Fans StructuresDocumento17 páginasID FD PA Fans StructuresMohan RajAinda não há avaliações

- Chemical DosingDocumento24 páginasChemical DosingIskerAinda não há avaliações

- Seal Oil FlushingDocumento21 páginasSeal Oil FlushingSam50% (2)

- IACDocumento22 páginasIACSamAinda não há avaliações

- MDBFP Oil FlushingDocumento13 páginasMDBFP Oil Flushingsrigirisetty208Ainda não há avaliações

- Gen Seal Oil SysDocumento21 páginasGen Seal Oil SyslrpatraAinda não há avaliações

- Hfo & Oil FiringDocumento9 páginasHfo & Oil FiringSravan DasariAinda não há avaliações

- Detergent Flushing of Pre Boiler System-Procedure 250Documento11 páginasDetergent Flushing of Pre Boiler System-Procedure 250Sara LopezAinda não há avaliações

- List of Contents: Station: NTPC Simhadri BHEL REF NO: PS-DC-186-500-Ntpc Ref No: Sim/1/Ts/1Documento12 páginasList of Contents: Station: NTPC Simhadri BHEL REF NO: PS-DC-186-500-Ntpc Ref No: Sim/1/Ts/1Premkumar VasudevanAinda não há avaliações

- Unprotected TC8225 7 PDFDocumento428 páginasUnprotected TC8225 7 PDFVRV.RELATORIO.AVARIA RELATORIO.AVARIAAinda não há avaliações

- Chemical Cleaning of BoilerDocumento27 páginasChemical Cleaning of BoilerlrpatraAinda não há avaliações

- 2.va1 Gedi 00HTF M M5 PHL 0001 - 1Documento23 páginas2.va1 Gedi 00HTF M M5 PHL 0001 - 1hoangduythanhqbAinda não há avaliações

- Gdtest of EspDocumento13 páginasGdtest of Espsrigirisetty208Ainda não há avaliações

- Checklist - LDO-UnLoading PumpDocumento12 páginasChecklist - LDO-UnLoading PumpBandi Suryakanthareddy V G0% (1)

- 023 CepDocumento12 páginas023 Cepjp mishraAinda não há avaliações

- Id 800436 Tesoro Refining and Marketing Co - Engr Eval An 520668 520669 520670 520667Documento23 páginasId 800436 Tesoro Refining and Marketing Co - Engr Eval An 520668 520669 520670 520667api-242947664Ainda não há avaliações

- Dbplgoverning System FinalDocumento37 páginasDbplgoverning System FinaldavidAinda não há avaliações

- LDO Unloading PumpDocumento3 páginasLDO Unloading PumpSamAinda não há avaliações

- Soot BlowerDocumento6 páginasSoot BlowerSamAinda não há avaliações

- Edgington Oil Id 800264 An 471225 Eng EvalDocumento14 páginasEdgington Oil Id 800264 An 471225 Eng Evalapi-242947664Ainda não há avaliações

- Steam BlowingDocumento28 páginasSteam BlowingRajeshAinda não há avaliações

- Aux BLRDocumento28 páginasAux BLRrohit_me083Ainda não há avaliações

- 6 Fire Protection SystemDocumento1.320 páginas6 Fire Protection SystemedmondevangelistacorpuzAinda não há avaliações

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNo EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNota: 5 de 5 estrelas5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1No EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Nota: 3.5 de 5 estrelas3.5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGAinda não há avaliações

- DiodeDocumento16 páginasDiodedeepakkesri26Ainda não há avaliações

- Data InterpretationDocumento12 páginasData InterpretationAbhayMenonAinda não há avaliações

- G KDocumento30 páginasG Kdeepakkesri2650% (2)

- Viola - David Tudor - The Delicate Art of FallingDocumento9 páginasViola - David Tudor - The Delicate Art of FallingRobin ParmarAinda não há avaliações

- Role of Technology in AdvertisementtDocumento29 páginasRole of Technology in AdvertisementtShalini ChatterjeeAinda não há avaliações

- Operation and Maintenance Manual: Mux-2200E Integrated Service MultiplexerDocumento82 páginasOperation and Maintenance Manual: Mux-2200E Integrated Service Multiplexerlee.tetleie1675Ainda não há avaliações

- Kevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterDocumento37 páginasKevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterRejinAinda não há avaliações

- Dodge Journey 2017 - Owner's ManualDocumento510 páginasDodge Journey 2017 - Owner's Manualandres camachin100% (1)

- Ram Concrete AnalysisDocumento94 páginasRam Concrete AnalysisTom CurryAinda não há avaliações

- CRCCDocumento13 páginasCRCCGalih SantanaAinda não há avaliações

- Fis-Opf Ach PaymentsDocumento5 páginasFis-Opf Ach PaymentscrazytrainAinda não há avaliações

- 990 Vibration Transmitter Datasheet-141612mDocumento14 páginas990 Vibration Transmitter Datasheet-141612mloopkkAinda não há avaliações

- Career Development PlanDocumento5 páginasCareer Development Planapi-317247630Ainda não há avaliações

- Lec 1 - SuperelevationDocumento24 páginasLec 1 - SuperelevationMohamedAinda não há avaliações

- Memory QVL 3rd Gen AMD Ryzen Processors PDFDocumento14 páginasMemory QVL 3rd Gen AMD Ryzen Processors PDFნიკო ქარცივაძეAinda não há avaliações

- Communication With Energy Meter and Field Devices Using PLCDocumento3 páginasCommunication With Energy Meter and Field Devices Using PLCIJRASETPublicationsAinda não há avaliações

- ORF Issue Brief 309 SpaceLawDocumento12 páginasORF Issue Brief 309 SpaceLawNitish KumarAinda não há avaliações

- BOQ For Interior WorkDocumento2 páginasBOQ For Interior WorkSudhanshu MandlikAinda não há avaliações

- Parts List: 8108.010 MagnumDocumento16 páginasParts List: 8108.010 MagnumRoque LlamoccaAinda não há avaliações

- Solution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Documento10 páginasSolution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Shroyon100% (2)

- Switch v7LAB StudentDocumento206 páginasSwitch v7LAB Studentkcf4scribdAinda não há avaliações

- Quality Related QuestionsDocumento22 páginasQuality Related QuestionsHotPriyu OnlyforgalsAinda não há avaliações

- Presentation On Optical Signal To Noise RatioDocumento6 páginasPresentation On Optical Signal To Noise RatioReg NdhlovuAinda não há avaliações

- Revised Runway Length Discussion (20171206) - 201712211212022318Documento3 páginasRevised Runway Length Discussion (20171206) - 201712211212022318Ilham RaffiAinda não há avaliações

- LC 2539Documento16 páginasLC 2539Kelly JonesAinda não há avaliações

- Richard Feynman BiographyDocumento5 páginasRichard Feynman Biographyapi-284725456100% (1)

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocumento1 página4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFRonald ValenciaAinda não há avaliações

- Lista Preturi Linhai 300 2014 PDFDocumento25 páginasLista Preturi Linhai 300 2014 PDFSimonaVătafuAinda não há avaliações

- Catalogo de Oleohidraulica AGVDocumento73 páginasCatalogo de Oleohidraulica AGVadjime3Ainda não há avaliações