Escolar Documentos

Profissional Documentos

Cultura Documentos

Failure Analysis Case Studies by Using Vibration Analysis T

Enviado por

Valéria Lima Antônio FilhoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Failure Analysis Case Studies by Using Vibration Analysis T

Enviado por

Valéria Lima Antônio FilhoDireitos autorais:

Formatos disponíveis

Failure Analysis Case Studies by using Vibration Analysis Technique 1- Bearing Premature Fatigue Problem Initiation and definition :

The problem was initiated by the operator. He noticed that high vibration level was sensed by human sense. Vibration measurements were carried out by condition monitoring engineer as he received the order.

Measuring procedures and used instrumentations :

The condition monitoring engineer select the measuring point which is near to the expected fault. An axial vibration data ware collected using piezoelectric accelerometer mounted with magnet. The accelerometer have the following characteristics ( natural frequency F= 200 order 0f the machine rotational speed, the accelerometer sensitivity = 100 mV/g) The accelerometer signal was sent to the CSI model 2120 equipped condition monitoring and diagnosis programs.

Analysis:

Bearing outer race defect was detected in the 4th mode as indicated from the time signal and FFT plot where BPFO was presented at 12.21 order according the bearing type and it needs to be changed As Soon As possible. This defect resulted from excessive axial load causes edge loading and overstressing of the raceway and result in premature fatigue. This is easily recognized as the damage is clearly restricted to one side..

Follow Up:

After changing the bearing and revising the assembly . the problem was disappeared where vibration measurements identical to that described in Measuring procedures and used instrumentations were carried out.

18 16 PK Velocity in mm/Sec 14 12 10 8 6 4 2 0 0 20 15 10 Acceleration in G-s 5 0 -5 -10 -15 -20 -25 0

SPIN - FINISHING HOLDER HOLDER#16 -IHA INNER BRG.HOLDER AXIAL(HIGH FRQ) E E E E E E E ROUTE SPECTRUM 15-Jul-99 10:03:42 OVRALL= 36.75 V-DG PK = 36.51 LOAD = 100.0 RPM = 507. RPS = 8.44 >SKF 61836M A E=BPFO : 102.5

100

200

300

400 500 Frequency in Hz CF ALARM

600

700

800

PK ALARM PK ALARM

WAVEFORM DISPLAY 15-Jul-99 10:03:42 RM S = 4.89 PK(+) = 14.75 PK(-) = 18.71 CRESTF= 3.83

CF ALARM

100

200

300 Tim e in m Secs

400

500

600

Label: Before changing the bearing

SPIN - FINISHING HOLDER HOLDER#16 -IHA INNER BRG.HOLDER AXIAL(HIGH FRQ)

Freq: 103.13 Ordr: 12.21 Spec: 3.648

PK Velocity in mm/Sec

18 16 14 12 10 8 6 4 2 0 0 2.0 1.5 100

ROUTE SPECTRUM 22-Jul-99 08:49:03 OVRALL= 6.73 V-DG PK = 6.70 LOAD = 100.0 RPM = 430. RPS = 7.16

200

300 Frequency in Hz PK ALARM CF ALARM

400

500

600

Acceleration in G-s

1.0 0.5 0 -0.5 -1.0 -1.5 -2.0 0 100 200

WAVEFORM DISPLAY 22-Jul-99 08:49:03 RMS = .3284 PK(+) = 1.39 PK(-) = 1.16 CRESTF= 4.23

CF ALARM PK ALARM 300 400 Time in mSecs 500 600 700 Freq: Ordr: Spec: 7.125 .995 5.086

Label: After changing the bearing

2- Bearing Fatigue Problem Initiation and definition :

The problem was initiated by the PM Craw. They noticed that high vibration level was sensed by human sense. Vibration measurements were carried out by condition monitoring engineer as he received the order.

Measuring procedures and used instrumentations :

The condition monitoring engineer select the measuring point which is near to the expected fault. An axial vibration data ware collected using piezoelectric accelerometer mounted with magnet. The accelerometer have the following characteristics ( natural frequency F= 200 order 0f the machine rotational speed, the accelerometer sensitivity = 100 mV/g) The accelerometer signal was sent to the CSI model 2120 equipped condition monitoring and diagnosis programs.

Analysis:

Bearing outer race defect was detected in the 4th mode as indicated from the time signal and FFT plot where BPFO was presented at 12.1order according the bearing type and it needs to be changed As Soon As possible. This defect resulted from excessive axial load due to severe looseness causes general outer race annular damage. ..

Follow Up:

After changing the bearing and revising the assembly . the problem was disappeared where vibration measurements identical to that described in Measuring procedures and used instrumentations were carried out.

18 16 PK Velocity in mm/Sec 14 12 10 8 6 4 2 0 0 20 15 10 Acceleration in G-s 5 0 -5 -10 -15 -20 -25 0

SPIN - FINISHING HOLDER HOLDER#16 -IHA INNER BRG.HOLDER AXIAL(HIGH FRQ) E E E E E E E ROUTE SPECTRUM 15-Jul-99 10:03:42 OVRALL= 36.75 V-DG PK = 36.51 LOAD = 100.0 RPM = 507. RPS = 8.44 >SKF 61836M A E=BPFO : 102.5

100

200

300

400 500 Frequency in Hz CF ALARM

600

700

800

PK ALARM PK ALARM

WAVEFORM DISPLAY 15-Jul-99 10:03:42 RM S = 4.89 PK(+) = 14.75 PK(-) = 18.71 CRESTF= 3.83

CF ALARM

100

200

300 Tim e in m Secs

400

500

600

Label: Before changing the bearing

Freq: 103.13 Ordr: 12.21 Spec: 3.648

Spin - FINSHING HOLDER HOLDER#17 -UOA UPPER BRG.HOLDER AXIAL(HIGH FRQ) 30 27 24 21 18 15 12 9 6 3 0 0 E E E E E E E ROUTE SPECTRUM 29-Jun-02 11:51:45 OV RALL= 38.49 V-DG PK = 38.38 LOAD = 100.0 RPM = 626. RPS = 10.44 >SKF 61836M A E=BPFO : 126.6

PK Velocity in mm/Sec

200

400

600 Fre que ncy in Hz CF ALARM

800

1000

20 15 Acceleration in G-s 10 5 0 -5 -10 -15 -20 -25 0 50 100 150

PK ALARM PK ALARM

WAV EFORM DISPLAY 29-Jun-02 11:51:45 RM S = 7.27 PK(+) = 19.50 PK(-) = 20.49 CRESTF= 2.82

CF ALARM 200 250 Tim e in m Se cs Labe l: BEFORE CHANGING THE BEARING 300 350 400 Fre q: 126.25 Ordr : 12.10 Spe c: 4.069

Spin - FINSHING HOLDER HOLDER#17 -UOA UPPER BRG.HOLDER AXIAL(HIGH FRQ) PK Velocity in mm/Sec 27 BBBBBBBBBBBB 24 21 18 15 12 9 6 3 0 0 8 6 Acceleration in G-s 4 2 0 -2 -4 -6 -8 0 100 200 300 Tim e in m Secs 400 500 600 Freq: Ordr: Spec: 9.375 .995 5.998 CF ALARM PK ALARM PK ALARM CF ALARM 100 200 300 400 500 Frequency in Hz 600 700 800 ROUTE SPECTRUM 30-Jun-02 16:13:32 OVRALL= 20.01 V-DG PK = 19.92 LOAD = 100.0 RPM = 565. RPS = 9.42 B=1X HARM ONIC : 9.42

WAVEFORM DISPLAY 30-Jun-02 16:13:32 RMS = 1.11 PK(+) = 6.42 PK(-) = 6.42 CRESTF= 5.77

Label: AFTER CHANGING THE BEARING

3- Coupling Fatigue Problem Initiation and definition :

The problem was initiated by the maintenance groupe. They noticed that high vibration level was sensed by human sense. Vibration measurements were carried out by condition monitoring engineer as he received the order.

Measuring procedures and used instrumentations :

The condition monitoring engineer select the measuring point which is near to the expected fault. An axial vibration data ware collected using piezoelectric accelerometer mounted with magnet. The accelerometer have the following characteristics ( natural frequency F= 200 order 0f the machine rotational speed, the accelerometer sensitivity = 100 mV/g) The accelerometer signal was sent to the CSI model 2120 equipped condition monitoring and diagnosis programs.

Analysis:

Coupling defect was detected in the 4th mode as indicated from the time signal and FFT plot where it was presented at 8order and 1 order in the axial direction in the radial direction according the coupling type where the coupling have 8 jaws and it needs to be changed As Soon As possible. This defect can be attributed to misalignment of coupling jaws causes edge loading and overstressing of the coupling jaws and result in premature fatigue. Coupling defect frequency exists with rotating speed modulation due to coupling excessive wear. Action must be taken is to adjust the alignment and change the coupling.

Follow Up:

After adjusting the alignment and changing the coupling . the problem was disappeared .

8 L 7 L

VWP - VERTICAL WATER PUMP PUMP#B -P1V INPUT SHAFT INB.BRG.VER. L L L L Route Spectrum 29-Jan-03 14:17:35 OVRALL= 12.70 V-DG PK = 12.65 LOAD = 100.0 RPM = 1488. RPS = 24.79 L=Coupling frq : 198.3

6 PK Velocity in mm/Sec

0 0 400 800 1200 Frequency in Hz 1600 2000 Freq: 198.36 Ordr: 8.000 Spec: 6.221

Label: Before changing the coupling

8 L 7 L

VWP - VERTICAL WATER PUMP PUMP#B -P1V INPUT SHAFT INB.BRG.VER. L L L L Route Spectrum 05-Feb-03 11:45:27 OVRALL= 5.80 V-DG PK = 5.80 LOAD = 100.0 RPM = 1493. RPS = 24.89 L=Coupling frq : 199.1

PK Velocity in mm/Sec

0 0 400 800 1200 Frequency in Hz 1600 2000 Freq: 199.11 Ordr: 8.000 Spec: .275

Label: After changing the coupling

4- Impeller Wear Problem Initiation and definition :

The problem was initiated by the operator and from the pump performance. They noticed that high vibration level was sensed by human sense. Vibration measurements were carried out by condition monitoring engineer as he received the order.

Measuring procedures and used instrumentations :

The condition monitoring engineer select the measuring point which is near to the expected fault. An radial vibration data ware collected using piezoelectric accelerometer mounted with magnet. The accelerometer have the following characteristics ( natural frequency F= 200 order 0f the machine rotational speed, the accelerometer sensitivity = 100 mV/g) The accelerometer signal was sent to the CSI model 2120 equipped condition monitoring and diagnosis programs. .

Analysis:

The defect was detected in the 4th mode as indicated from the time signal and FFT plot . It was presented at 1order in the radial direction and it needs to be changed As Soon As possible. This defect can be attributed to Severe pitting on the pump impeller due to corrosion erosion and chemical water effect. Action must be taken is to adjust the alignment and change the coupling. Sub-synchronous vibrations due to impeller wear which exits structure resonance. Change the pump impeller and recoat it with the ceramic coating.

Follow Up:

The lifetime of the impeller was extended and the Sub-synchronous vibration was disappeared after changing the impeller.

12

VWP - VERTICAL WATER PUM P PUMP#A -MOH AC M OTOR OUTB.BRG.HOR. Route Spectrum 18-Oct-01 12:08:35 OVRALL= 15.59 V-DG PK = 15.56 LOAD = 100.0 RPM = 1493. RPS = 24.88

10

8 PK Velocity in mm/Sec

0 0 50 100 150 200 250 Frequency in Hz 300 350 400 Freq: Ordr: Spec: 25.00 1.005 8.558

Label: Before changing the im pe ller

Você também pode gostar

- RBMWizardDocumento286 páginasRBMWizardJesus EspinozaAinda não há avaliações

- Rotating Machinery Reliability for Technicians and EngineersNo EverandRotating Machinery Reliability for Technicians and EngineersAinda não há avaliações

- VibrationDocumento4 páginasVibrationzhyhh100% (1)

- ISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-Shurafa PDFDocumento1 páginaISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-Shurafa PDFMohammed Kamel TonyAinda não há avaliações

- Machinery Malfunction Diagnosis and Correction - Constant ContactDocumento2 páginasMachinery Malfunction Diagnosis and Correction - Constant ContactLisan YanAinda não há avaliações

- Creating PeakVue Measurement PointsDocumento2 páginasCreating PeakVue Measurement PointsNewman RiosAinda não há avaliações

- Test (With Ans)Documento25 páginasTest (With Ans)B V ManoharAinda não há avaliações

- Vibration Sample Template PDFDocumento1 páginaVibration Sample Template PDFnumanfawzal50% (2)

- Cooling System, Service MP7 EPA2004, EPA2007Documento150 páginasCooling System, Service MP7 EPA2004, EPA2007Hamilton MirandaAinda não há avaliações

- Pelton WheelDocumento5 páginasPelton WheelMuhammedShafiAinda não há avaliações

- TD-SILENT Series: In-Line Mixed Flow Duct Fans Ultra-QuietDocumento13 páginasTD-SILENT Series: In-Line Mixed Flow Duct Fans Ultra-QuietJustin ReyesAinda não há avaliações

- Vibration Analysis Reports of RM ChemicalsDocumento25 páginasVibration Analysis Reports of RM ChemicalsAnant Jain100% (1)

- Vibration Analysis of Gear Box.5-MilosprokoDocumento3 páginasVibration Analysis of Gear Box.5-MilosprokoRavikiran Hegde100% (2)

- Autocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookDocumento8 páginasAutocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookLe Thanh Hai100% (2)

- Phase MeasurementDocumento5 páginasPhase Measurementuak107080Ainda não há avaliações

- Bypass Screw Conveyor Drive:: MotorDocumento2 páginasBypass Screw Conveyor Drive:: MotorHosam Abd ElkhalekAinda não há avaliações

- VIBXPERT II Balancing Manual en 052012Documento46 páginasVIBXPERT II Balancing Manual en 052012luismariogallego50% (2)

- Vibration Analysis For CBM: Basic Concepts - Unit 2Documento16 páginasVibration Analysis For CBM: Basic Concepts - Unit 2Mehboob ulHaqAinda não há avaliações

- Training Cat III Practice Exam Asset Optimization en 39842Documento3 páginasTraining Cat III Practice Exam Asset Optimization en 39842Mohammadreza Galeban100% (1)

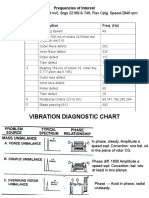

- Vibration Diagonistic ChartDocumento1 páginaVibration Diagonistic ChartsamiAinda não há avaliações

- Phase Analysis: Making Vibration Analysis Easier: SearchDocumento4 páginasPhase Analysis: Making Vibration Analysis Easier: Searchdillipsh123Ainda não há avaliações

- ISO 18436 Category IVDocumento2 páginasISO 18436 Category IVzona amrullohAinda não há avaliações

- Monitoring and Analysis of Machine VibrationDocumento6 páginasMonitoring and Analysis of Machine VibrationAvinashAinda não há avaliações

- VibMatters Current IssueDocumento19 páginasVibMatters Current IssueUsman JabbarAinda não há avaliações

- Vibration AnalysisDocumento22 páginasVibration Analysisvenkat chakAinda não há avaliações

- Monitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005Documento60 páginasMonitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005eko bagus sunaryo100% (2)

- Vibration SeverityDocumento19 páginasVibration Severityanon_900141394Ainda não há avaliações

- Detect Machinery Faults by Using Peak VueDocumento13 páginasDetect Machinery Faults by Using Peak VueHarold Alconz100% (2)

- AMPLITUDE MODULATION Versus BEATSDocumento5 páginasAMPLITUDE MODULATION Versus BEATSHaitham YoussefAinda não há avaliações

- Omni Trend Getting StartedDocumento32 páginasOmni Trend Getting Startedtgrtrtqwreyt0% (1)

- CGL02 Blowers Report May 2009Documento9 páginasCGL02 Blowers Report May 2009Hosam Abd Elkhalek100% (1)

- 20 - Sample Machinery Vibration Analysis ReportDocumento12 páginas20 - Sample Machinery Vibration Analysis ReportBawaInspectorAinda não há avaliações

- VA1901SOGT-01 - OGC Cooler Fan Vibration Analysis Report PDFDocumento3 páginasVA1901SOGT-01 - OGC Cooler Fan Vibration Analysis Report PDFfazzlieAinda não há avaliações

- Advanced Turbomachinery Diagnostics - Online Course W2Documento8 páginasAdvanced Turbomachinery Diagnostics - Online Course W2ali shetaAinda não há avaliações

- Sample Questions: Category IDocumento6 páginasSample Questions: Category IALEJANDRO MELENDEZAinda não há avaliações

- Methodical Phase AnalysisDocumento31 páginasMethodical Phase Analysisturboconch100% (1)

- Vibration ChartDocumento1 páginaVibration Chartairframer1981Ainda não há avaliações

- Solving Motor Vibration Problems On Vertical Pumps ResonanceDocumento5 páginasSolving Motor Vibration Problems On Vertical Pumps Resonancejameel babooramAinda não há avaliações

- Basics of VibrationDocumento6 páginasBasics of VibrationChetan PrajapatiAinda não há avaliações

- Basic Training Program On Vibration AnalysisDocumento24 páginasBasic Training Program On Vibration AnalysisMohamed Al-OdatAinda não há avaliações

- Bearing Vibration Analysis in Labview PDFDocumento11 páginasBearing Vibration Analysis in Labview PDFAli ShanAinda não há avaliações

- Welcome To Modal Testing and Analysis: From Brüel & KjærDocumento20 páginasWelcome To Modal Testing and Analysis: From Brüel & KjærAhmed AymanAinda não há avaliações

- Cuaderno Curso - CAT I Activity Book Spanish With CoverDocumento34 páginasCuaderno Curso - CAT I Activity Book Spanish With CoverJose Raul Reyes Dominguez100% (1)

- Vibration Quiz #1Documento2 páginasVibration Quiz #1Jose Luis RattiaAinda não há avaliações

- Pre-Assessment of Vibration AnalysisDocumento6 páginasPre-Assessment of Vibration AnalysisIrfan Uz ZamanAinda não há avaliações

- Bumptest 180410120817Documento13 páginasBumptest 180410120817Daniel SolaresAinda não há avaliações

- ISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-ShurafaDocumento1 páginaISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-ShurafaMohammed Kamel Tony100% (1)

- Vibration Quiz #2Documento2 páginasVibration Quiz #2Jose Luis RattiaAinda não há avaliações

- 2130 PPT PeakVueCaseDocumento98 páginas2130 PPT PeakVueCasesebastian100% (1)

- How To Bump Test With MicrologDocumento2 páginasHow To Bump Test With MicrologYuda SatriaAinda não há avaliações

- Rev.8 RBMviewDocumento216 páginasRev.8 RBMviewdford8583Ainda não há avaliações

- A Review of Enveloping and Demodulation TechniquesDocumento6 páginasA Review of Enveloping and Demodulation TechniquesMohamed WahidAinda não há avaliações

- Vibration Acceptance Test ReportDocumento20 páginasVibration Acceptance Test ReportfazzlieAinda não há avaliações

- Introduction To PeakvueDocumento55 páginasIntroduction To PeakvuesebastianAinda não há avaliações

- Examen Vibraciones Nivel IIDocumento41 páginasExamen Vibraciones Nivel IIJim Morrison67% (3)

- Order Analysis ToolkitDocumento16 páginasOrder Analysis ToolkitManuel Enrique Salas FernándezAinda não há avaliações

- Boralign TRG PPT - 2k3 Aug019Documento65 páginasBoralign TRG PPT - 2k3 Aug019propulzi100% (2)

- Vibration Diagnostic Chart1Documento16 páginasVibration Diagnostic Chart1Anand KumarAinda não há avaliações

- Rev.13 VibViewDocumento466 páginasRev.13 VibViewdford8583Ainda não há avaliações

- ORBIT AnalysisDocumento4 páginasORBIT AnalysisManoj PaneriAinda não há avaliações

- Spectrum Interpretation & Vibration AnalysisDocumento1 páginaSpectrum Interpretation & Vibration AnalysisAhmad DanielAinda não há avaliações

- Structural Health MonitoringNo EverandStructural Health MonitoringDaniel BalageasAinda não há avaliações

- Idemitsu - Mechanic Oil SeriesDocumento2 páginasIdemitsu - Mechanic Oil SeriesarieprachmanAinda não há avaliações

- SolutionDocumento2 páginasSolutionBOTU ROHITHAinda não há avaliações

- AIATS First Step JEE (Main & Advanced) 2022-24 - Group 1Documento2 páginasAIATS First Step JEE (Main & Advanced) 2022-24 - Group 1Deepak LimbaAinda não há avaliações

- Lesson No.6.Lecture - Physics For Engineers - Friction.may2023-1Documento1 páginaLesson No.6.Lecture - Physics For Engineers - Friction.may2023-1Lloyd Christian PorlajeAinda não há avaliações

- BHI Enamel Coating Technology - Power Gen PTDocumento42 páginasBHI Enamel Coating Technology - Power Gen PTJacoboAinda não há avaliações

- Rotomac Progressive Cavity Pumps: Installation, Operation and Maintenance Manual 'LDocumento14 páginasRotomac Progressive Cavity Pumps: Installation, Operation and Maintenance Manual 'Lkallappa naikAinda não há avaliações

- 4 Forced VibrationDocumento108 páginas4 Forced Vibrationsolomonrajar100% (2)

- ME320 Professor John M. Cimbala: Water Draining From A TankDocumento6 páginasME320 Professor John M. Cimbala: Water Draining From A TankShohag HossainAinda não há avaliações

- Poly (Vinylidene Fluoride) Clay Nanocomposites Prepared byDocumento8 páginasPoly (Vinylidene Fluoride) Clay Nanocomposites Prepared byPrapto PraptAinda não há avaliações

- ME463 Plate3 CapulDocumento9 páginasME463 Plate3 CapulJuvy Lyka CapulAinda não há avaliações

- Analysis of Failure Criteria Applied To Woo - 2013 - Engineering Failure AnalysiDocumento10 páginasAnalysis of Failure Criteria Applied To Woo - 2013 - Engineering Failure AnalysiArimateia SoaresAinda não há avaliações

- DN To ReflectanceDocumento9 páginasDN To ReflectanceManoharamRipeshMAinda não há avaliações

- Header&pipe Sizes - 00361Documento9 páginasHeader&pipe Sizes - 00361JKKAinda não há avaliações

- S2-3 - PT Transfer - Almila UzelDocumento25 páginasS2-3 - PT Transfer - Almila UzelChien KsAinda não há avaliações

- Shielding Gases ACM Vs CO2Documento34 páginasShielding Gases ACM Vs CO2ukavathekar100% (2)

- ExtrusionDocumento15 páginasExtrusionSaad Ur RehmanAinda não há avaliações

- Datasheet Anemometro Extech An100Documento1 páginaDatasheet Anemometro Extech An100Juan Carlos Lavado JuarezAinda não há avaliações

- 420118-Hydraulic Pump SettimaDocumento9 páginas420118-Hydraulic Pump SettimaAndreyOsyaninAinda não há avaliações

- Chapter 12 STSDocumento7 páginasChapter 12 STSCute kittyAinda não há avaliações

- A Completely Algebraic Solution of The Simple Harmonic OscillatorDocumento11 páginasA Completely Algebraic Solution of The Simple Harmonic OscillatorDiego Alejandro Rasero CausilAinda não há avaliações

- Thermal ConductivityDocumento5 páginasThermal ConductivitySiva Kumar SalumuriAinda não há avaliações

- Thermodynamics 1 Thermodynamics 1Documento73 páginasThermodynamics 1 Thermodynamics 1Dinesh Pandian67% (3)

- Module 2 - Rectilinear MotionDocumento33 páginasModule 2 - Rectilinear MotionRozel100% (2)

- 10c-Electrostatics MC Practice Problems-ANSWERSDocumento10 páginas10c-Electrostatics MC Practice Problems-ANSWERSJanel EdwardsAinda não há avaliações

- Unit 4Documento68 páginasUnit 4priyata debAinda não há avaliações

- Final ResearchDocumento29 páginasFinal Researchshubham dhakulkarAinda não há avaliações