Escolar Documentos

Profissional Documentos

Cultura Documentos

Project Standards and Specifications Piping Materials Rev01web

Enviado por

Nguyen Anh TungDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Project Standards and Specifications Piping Materials Rev01web

Enviado por

Nguyen Anh TungDireitos autorais:

Formatos disponíveis

Page : 1 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

TABLE OF CONTENTS

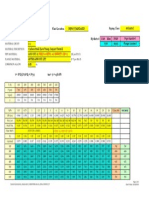

1 GENERAL 1.1 Scope 1.2 Code and Standards 1.3 Pressure-Temperature Design 1.4 Pipe Wall Thickness Allowance 1.5 Ends 1.6 Units 1.7 Language 2 MATERIAL 2.1 General 2.2 Chemical Composition 3 PIPING COMPONENTS 3.1 Pipes 3.2 Fittings 3.3 Flanges 3.4 Gaskets 3.5 Bolts and Nuts 3.6 Branches 3.7 Valves 3.8 Vents and Drains 3.9 Seal Welding and Thread Sealant 3.10 Hub Connectors 3.11 Post Weld Heat Treatment (PWHT) and NDE 3.12 Impact Test Requirement 3.13 Sour Service Requirement 3.14 Hydrogen Service Requirement 3.15 Caustic Service Requirement 3.16 Production Ferrite Determination 4 MATERIAL SUBSTITUTION Appendix-A Appendix-B Appendix-C Appendix-D : : : : ABBREVIATIONS PIPING MATERIALS SERVICE INDEX PIPING MATERIAL CLASS REDUCINGTABLE 2 2 2 6 7 8 8 9 9 9 12 12 12 15 19 23 25 27 28 53 53 54 54 58 60 61 63 63 64

Page : 2 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

1. GENERAL

1.1 1.1.1 1.1.2 SCOPE This specification covers the requirements of materials selected for piping to be used for Company Project. This specification covers specific requirements for the selection of materials to be used in the construction and fabrication of all process and utility piping systems except the following items; 1) 2) 3) 1.1.3 Fabrication ducts, square ducts and other special piping Heating, plumbing, ventilation and similar piping inside buildings Instrumentation tubing

Instrument Piping This specification does not apply to instrument piping with the exception of the first isolation valve which isolates the instrument from the general piping, or the first two isolation valves when dual isolation valves are specified.

1.1.4 1.1.5

This specification shall be applied to piping materials indicated on piping & instrument diagram (P & ID) and utility flow diagram (UFD). Limits of the Piping System This specification applies to the following items when connected to a nozzle located on a piece of equipment: 1) 2) 3) Flanges, gaskets, bolts, and nuts at the equipment nozzle Any valves or blinds connected to the equipment nozzle Piping between the equipment nozzle and the first isolation valve going to an instrument (or second valve if dual isolation is specified)

Page : 3 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

2.2 1.2.1 1.2.2

CODE AND STANDARDS All codes and standards specified in this document refer to the latest revision at the time of signing the contract for this project unless otherwise specified. This specification is based on the American Society of Mechanical Engineers (ASME) Code for Pressure Piping, ASME B31.3, "Process Piping" or ASME B31.1 Power Piping (ASME Section I). Design, fabrication, testing, and inspection of piping materials shall be accomplished in accordance with the applicable codes and standards, which are in effect as of the date contract signed. Where conflicts between the specification and other drawings, documents, codes, standards and specifications, etc., the most stringent shall be applied. The code and standards shall be applied below lists, but not limited to the following;

AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) ASME B31.1 ASME B31.3 ASME B1.1 ASME B1.20.1 ASME B16.5 ASME B16.9 ASME B16.10 ASME B16.11 ASME B16.20 ASME B16.21 ASME B16.25 ASME B16.34 ASME B16.47 ASME B16.48 ASME B18.2.1 ASME B18.2.2 ASME B36.10 ASME B36.19 ASME B46.1 Power Piping Process Piping Unified Inch Screw Threads Pipe Threads, General Purpose (Inch) Piping Flanges and Flanged Fittings Factory-Made Wrought Steel Buttwelding Fittings Face-to-Face and End-to-End dimensions of Valves Forged Fittings, Socket-Welding and Threaded Metallic Gaskets for Pipe Flanges-Ring Joint, Spiral Wounds and Jacketed Nonmetallic Flat Gaskets for Pipe Flanges Buttwelding Ends Valves-Flanged, Threaded, and Welding End Large Diameter Steel Flanges, NPS 26 through NPS 60 Line Blanks Square and Hex Bolts and Screws (Inch Series) Square and Hex Nuts (Inch Series) Welded and Seamless Wrought Steel Pipe Stainless Steel Pipe Surface Texture (Surface Roughness, Waviness, and Lay)

1.2.3

1.2.4 1.2.5

Page : 4 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

AMERICAN BOILER AND PRESSURE VESSEL CODE ASME Section I ASME Section II ASME Section V ASME Section VIII ASME Section IX Rules for Construction of Power Boilers Materials Nondestructive Examination Rules for Construction of Pressure Vessels Qualification Standard for Welding and Brazing Procedures, Welders, Brazers, and Welding and Brazing Operators AMERICAN PETROLEUM INSTITUTE (API) ANSI/API SPEC.5L API 594 API 598 API 599 API 600 API 602 API 603 API 607 API 608 API 609 Specification for Line Pipe Check Valves : Flanged, Lug, Wafer and Butt-Welding Valve Inspection and Test Metal Plug Valves - Flanged and Welding Ends Steel Gate Valves Flanged and Butt-Welding Ends, Bolted Bonnets Steel Gate,Globe and Check Valves for Size NPS 4(DN100) and Smaller for the Petroleum and Natural Gas Inustries Corrosion-Resistant, Bolted Bonnet Gate Valves-Flanged and Buttwelding Ends Fire Test for Soft-seated Quarter-turn Valves Metal Ball Valves-Flanged, Threaded, and Welding End Butterfly Valves: Double Flanged, Lug- and Wafer-Type

AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM) ASTM For materials of regular piping part BRITISH STANDARD (BS) BS 1868 Steel Check Valves(Flanged and Butt-Welding Ends) for the Petroleum, Petrochemical and Allied Industies BS 1873 Steel Globe and Globe Stop and Check Valves(Flanged and ButtWelding Ends) for the Petroleum, Petrochemical and Allied Industies BS 6364 Valve for Cryogenic Service BS EN ISO 17292 Metal Ball Valves for Petroleum, Petrochemical and allied industries BS EN ISO 12266-1 Industrial Valves Testing of Valves BS EN ISO 12266-2 Industrial Valves Testing of Valves

Page : 5 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

MANUFACTURERS STANDARD SOCIETY (MSS) MSS-SP-25 MSS-SP-44 MSS-SP-75 MSS-SP-80 MSS-SP-97 MSS-SP-110 MSS-SP-53 MSS-SP-54 MSS-SP-93 Standard Marking System for Valves, Fittings, Flanges and Unions Steel Pipeline Flanges Specification for High Test Wrought Butt Welding Fittings Bronze Gate, Globe, Angle and Check Valves Integrally Reinforced Forged Branch Outlet Fittings-Socket Weldings, Threaded and Buttwelding Ends Ball Valves, Threaded, Socket Welding, Solder Joint, Grooved and Flanged Ends Quality Standard for Steel Castings and Forgings for Valves, Flanges,and Fittings and Other Piping Component - Magnetic Particle Examination Method Quality Standard for Steel Castings and Forgings for Valves, Flanges, and Fittings and Other Piping Component - Radiographic Examination Method Quality Standard for Steel Castings and Forgings for Valves, Flanges, and Fittings and Other Piping Component Liquid Penetrant Examination Method DEUTSCHE NORM (DIN) DIN 30670 Polyethylene Coating for Steel Pipe and Fittings OTHERS ISO NACE PFI International Organization for Standardization National Association of Corrosion Engineers Pipe Fabrication Institute

Page : 6 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

1.3 1.3.1

PRESSURE-TEMPERATURE DESIGN The design pressure-temperature to be used as a basis for the design of piping system and selection of standard piping material components shall be in accordance with the requirements of the ASME B31.3 Process Piping or ASME B31.1 Power Piping (ASME Section I) or other governing codes. Design pressure-temperature limitations are in general based on the flange ratings ASME B16.5, ASME B16.47 and are shown on individual line class specifications, unless otherwise noted. These design conditions shall not be less than the most severe conditions of coincident internal and external pressure and temperature expected during service including start-up, shutdowns, and possible emergency situations (e.g. emergency depressurization, etc). Unless otherwise specified, piping component wall thickness, specified in the pipe classes are based only on design consideration of pressure, temperature, and allowances for corrosion and minus tolerance according to ASME B31.3 Process Piping or ASME B31.1 Power Piping (ASME Section I). Piping component wall thickness do not include additional thickness required to compensate for design considerations such as thermal loads due to restrains, live load, hydraulic shock or load and sources from other caused all of which must be considered in the design of piping systems. Pipe classes intended for vacuum service or steam service and some pipe classes, especially requested for vacuum design condition, must be verified for vacuum design condition. PIPE WALL THICKNESS ALLOWANCE Wall thickness as determined by design formulas shall be increased to provide for: 1) Corrosion allowance 2) Tolerances for threading and machining, thinning allowance when pipe is to be bent 3) Pipe manufacturer's manufacturing tolerances

1.3.2

1.3.3

1.3.4

1.3.5

1.3.6

1.4 1.4.1

Page : 7 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

1.4.2

Corrosion and erosion allowances are not set forth in the code, but are left to the discretion of the designer. The following corrosion allowances are specified as minimum requirement: Material Carbon steel and alloy up to 9 Cr-Mo in dry service Carbon steel and alloy up to 9 Cr-Mo in wet service Galvanized steel Stainless steel Non-Metal such as GRP, HDPE, PVC, Non-metal lined, etc. Corrosion Allowance 1.6 mm 3.2 mm 1.6 mm 0 mm 0 mm Remarks

In special cases a greater corrosion allowance may be required. If a higher corrosion allowance for a specific service is specified in any of the specifications, then that corrosion allowance will govern for that service. Likewise, if the Licensor specifies a greater corrosion allowance than that specified in this paragraph or one of the other specifications, then the Licensors corrosion allowance will govern for that service. 1.4.3 Threading and Machining Tolerances 1) Pipe which is to be threaded shall have an allowance equal to the thread depth added to the calculated wall thickness. 2) For machine surfaces or grooves where the tolerance is not specified, the tolerance shall be assumed to be 0.5 mm in addition to the specified depth cut. Manufacturing Tolerances The manufacturers minus tolerance for wall thickness must be added to the calculated wall thickness in accordance with applicable ASTM or API.

1.4.4

Page : 8 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

1.4.5

Dual Grade Materials Where dual grade materials i.e 316/316L or 304/304L Stainless steel is available, they shall be used. The corresponding allowable stresses of the higher strength material shall be used in calculating wall thicknesses and the pressure limits of the class.

1.5

ENDS Unless otherwise specified, the ends shall be to the following standard: Ends Type SW / SCRD BW Flanged Threaded Standard ASME B16.11 ASME B16.25 ASME B 16.5 and ASME B16.47 Series B7 Taylor Forge/AWWA ASME B1.20.1 (NPT, Taper Threads) Remarks

1.6

UNITS All units are expressed in the international SI system, except for nominal bore sizes of pipes, which are in inches. Pressures are gauge pressures (in bars), unless otherwise stated. Temperatures are in degrees Celsius. Pressure/Temperature ratings of flanges are based on the latest version of the ASME B 16.5 and ASME B16.47.

1.7

LANGUAGE The language used in drawings, correspondence and other technical document shall be English.

Page : 9 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

2.

2.1 2.1.1 2.1.2

MATERIAL

GENERAL Piping materials shall be in accordance with ASME B31.3 or where applicable. Metallic piping shall be used temperature limitation as follows ;

Material Carbon Steel P11 (1 Cr- Mo) Steel P12 (1Cr- Mo) Steel P22 (2 Cr-1Mo) Steel P91 (9Cr-1Mo-V) Steel Type 304/304L/316/316L/321/347 Stainless Steel Type H Stainless Steel (304H, 316H, etc.) 800H (Incoloy) Maximum Design Temperature 427oC 550oC 550oC 550 C 600oC 538oC 800oC 950oC

o

Remarks

2.1.3

The following pipe sizes shall not be allowed: , 1 , 2 , 3 , 5, 7, and 9 inches. However, in cases where the use of these sizes cannot be avoided, the required piping material, fittings, flanges, valves and gaskets shall be the same material as next larger sizes in the applicable piping class. Material used in the fabrication of piping and piping components shall be new, clean and free from rust, pits and obvious defects. For 50 and larger pipes and fittings, two longitudinal welding seam (double seam) 180 degree apart shall be acceptable. The use of 3.5% nickel material for either piping components or equipment is prohibited. 304 SS shall be used in place of or 3.5% nickel.

2.1.4 2.1.5 2.1.6

Page : 10 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

2.1.7 2.1.8

All underground piping components shall be coated or cold tape wrapping except non-metal such as HDPE, FRP, etc. Several common materials are now produced as dual certified or are multiple marked, meaning that these materials conform to more than one material specification or grade. Any material so marked may be used interchangeably for any or all of the corresponding materials called out in the standard. The most common example is quad-stenciled seamless steel pipe, which is marked A(SA)53B/A(SA)106-B/API-5L-B/API-5L-X42. This pipe may be used anywhere that A(SA)53 Gr.B Type S or A(SA)106 Gr.B or API 5L-B or API 5L-X42 is specified. Another is dual-stenciled304/304L stainless which may be used wherever either 304 or 304L is specified, or dual-stenciled316/316L stainless which may be used wherever either 316 or 316L is specified. Material that are not multiple or dualmarked may not be used in this manner. Material used in the piping systems shall comply with ASTM standards. During the engineering and procurement stage the Company will consider allowing other internationally recognized standards to be used for limited application in the piping system. Galvanized pipes and fittings and flanges, etc. shall be only hot dip galvanized to ASTM A153. Threads for galvanized items shall be clean and free from any galvanizing. External surfaces where galvanizing has been burned-off during field welding, etc., shall be wire brushed and zinc coated or cold galvanized using proper paint only for external surfaces. Low Temperature Carbon Steel (LTCS) is defined for this project as Charpy V-notch impact-tested carbon steel. The minimum low design temperature where LTCS may be used is -46 . Carbon steel piping and components requiring welding or heat cutting (torch) shall have carbon content less than 0.33% wt%. Austenitic stainless steel material (pipe, fitting, flange, plate, forging, casting, etc.) shall be furnished in the solution annealed condition.

2.1.9

2.1.10

2.1.11

2.1.12 2.1.13

Page : 11 of 216

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

PIPING MATERIAL SPECIFICATION (PROJECT STANDARDS AND SPECIFICATIONS)

2.1.14 2.1.15 2.1.16

Structural grade steel is prohibited from being used in any piping system except for structural support. Undressed flame cut weld bevels on butt-welding ends are not permitted. Material marking methods shall be in accordance with applicable product specifications, except that hard stamping using other than "low stress" (round nose) dies is prohibited. Low alloy 2 Cr- Mo steels (A335-P22, A691-2 Cr, A234-WP22, A182-F22, A387 Gr.22, etc.) are used in piping material, the carbon content of the base material, weld metal and weld filler metal shall have greater than 0.05%. When piping components shall be required 100% Radiography Test to weld area, the piping components shall be provided a weld joint efficiency of 1.00. All forgings shall be supplied in normalized condition except designated other heat treatment in related code and standard, and weld repair are not acceptable. Positive Material Identification (PMI) test shall be applied in accordance with specification for Positive Material Identification. Piping material shall be color marked in accordance with specification for Color Marking for Piping Material Identification.

2.1.17

2.1.18 2.1.19 2.1.20 2.1.21

Você também pode gostar

- PROJECT STANDARDS and SPECIFICATIONS Offshore Piping Fabrication and Installation Rev01Documento8 páginasPROJECT STANDARDS and SPECIFICATIONS Offshore Piping Fabrication and Installation Rev01totongopAinda não há avaliações

- Offshore Skid Piping DesignDocumento7 páginasOffshore Skid Piping DesignmihahudeaAinda não há avaliações

- GEN-L-XXX-SP-0001 - 5 - Specification For Piping and Valve MaterialsDocumento107 páginasGEN-L-XXX-SP-0001 - 5 - Specification For Piping and Valve MaterialsWilliam Smith100% (3)

- Chemical Injection Package SpecificationDocumento21 páginasChemical Injection Package SpecificationAnonymous ygQUvDK100% (2)

- Hydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1Documento1 páginaHydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1rakeshsundaramurthyAinda não há avaliações

- Data Sheet Sight GlassDocumento5 páginasData Sheet Sight GlassAdhya RazanAinda não há avaliações

- L&T Double Block and Bleed Plug ValvesDocumento12 páginasL&T Double Block and Bleed Plug Valvesvijay10484Ainda não há avaliações

- Dye Injection Skid Process DatasheetDocumento7 páginasDye Injection Skid Process Datasheetjibran42Ainda não há avaliações

- Submerged Motor LNG Pumps Used in Send-Out SystemsDocumento6 páginasSubmerged Motor LNG Pumps Used in Send-Out SystemscsAinda não há avaliações

- Mechanical Data Sheet V-001 PDFDocumento3 páginasMechanical Data Sheet V-001 PDFdharwin ap100% (1)

- Checklist for Pre-FEED Project ActivitiesDocumento2 páginasChecklist for Pre-FEED Project ActivitiesPappu JaniAinda não há avaliações

- Amec SpecDocumento32 páginasAmec Specshinojbaby4148Ainda não há avaliações

- Cover LetterDocumento6 páginasCover LetterselvarajvijayakumarAinda não há avaliações

- Specification For Valves P-09-1001 Rev0Documento29 páginasSpecification For Valves P-09-1001 Rev0Anonymous H8EsgFCXjWAinda não há avaliações

- Flame ArresterDocumento16 páginasFlame Arresteriran1362Ainda não há avaliações

- Unloading Arm Datasheet: Crude Oil Unloading and Pumping ProjectDocumento2 páginasUnloading Arm Datasheet: Crude Oil Unloading and Pumping Projectbecpavan0% (1)

- Loading Arms SpecificationDocumento9 páginasLoading Arms Specificationm.shehreyar.khanAinda não há avaliações

- Offshore Process Design StandardsDocumento10 páginasOffshore Process Design Standardssri9987Ainda não há avaliações

- Fpso OtcDocumento7 páginasFpso OtcMartinus LuckyantoAinda não há avaliações

- Equipment List Including Long Lead ItemsDocumento6 páginasEquipment List Including Long Lead Itemspapilolo2008Ainda não há avaliações

- Piping Material SpecificationDocumento91 páginasPiping Material SpecificationDashan WangAinda não há avaliações

- Valve Specification Document SummaryDocumento32 páginasValve Specification Document SummaryJohn MechAinda não há avaliações

- API & Asme PSV, PZV Orifice AreaDocumento2 páginasAPI & Asme PSV, PZV Orifice AreaUmmer BavaAinda não há avaliações

- Wake Frequency Calculation ThermowellDocumento1 páginaWake Frequency Calculation ThermowellSusheel WankhedeAinda não há avaliações

- SK-A-YCC-021 Sales Gas Filtration System FSDDocumento30 páginasSK-A-YCC-021 Sales Gas Filtration System FSDtouseef88Ainda não há avaliações

- PSV Sizing and Reaction Force Modelling Rev 1.1Documento11 páginasPSV Sizing and Reaction Force Modelling Rev 1.1Hoang-Vu BuiAinda não há avaliações

- WHP - Equipment Layout DrawingDocumento8 páginasWHP - Equipment Layout DrawingharrisAinda não há avaliações

- Datasheet For Nitrogen Bottle Rack 4B.4300 SAI S0003 ISGP U48000 MS 2105...Documento10 páginasDatasheet For Nitrogen Bottle Rack 4B.4300 SAI S0003 ISGP U48000 MS 2105...vydaniAinda não há avaliações

- Project Manager Oversees 21 Deliverables for Pipeline EngineeringDocumento2 páginasProject Manager Oversees 21 Deliverables for Pipeline EngineeringJosua100% (2)

- Volime II of II Mechanical Piping PDFDocumento245 páginasVolime II of II Mechanical Piping PDFkamleshyadavmoneyAinda não há avaliações

- Branch Reinforcement Pad Requirement Calculation PDFDocumento1 páginaBranch Reinforcement Pad Requirement Calculation PDFdeua2004Ainda não há avaliações

- 1515 020 SPC 0001Documento15 páginas1515 020 SPC 0001Lakshmi NarasimhanAinda não há avaliações

- Total Pms Scope of Work: Days Start Date End DateDocumento6 páginasTotal Pms Scope of Work: Days Start Date End DateElhamy M. SobhyAinda não há avaliações

- Design of PipingDocumento51 páginasDesign of PipingLuisRiosQAinda não há avaliações

- SGP Stress Analysis ReportDocumento14 páginasSGP Stress Analysis ReportDenstar Ricardo Silalahi100% (2)

- Piping Class P-T RatingDocumento1 páginaPiping Class P-T Ratingcyno21Ainda não há avaliações

- 020-GN-BK-101AB, Rev.1 PDFDocumento1 página020-GN-BK-101AB, Rev.1 PDFVeena S VAinda não há avaliações

- FPM1300 Layout and SpacingDocumento15 páginasFPM1300 Layout and SpacingdxlongAinda não há avaliações

- DBB Datasheet WHRP PDFDocumento48 páginasDBB Datasheet WHRP PDFRajendraAinda não há avaliações

- 4.6 Full System Leak Detection PhilosophyDocumento6 páginas4.6 Full System Leak Detection PhilosophyPaidar Engineering and Energy Development Co.Ainda não há avaliações

- BV Gate Valve DS 15111Documento2 páginasBV Gate Valve DS 15111yulianus_srAinda não há avaliações

- Aviation Refuelling Equipment CatalogueDocumento180 páginasAviation Refuelling Equipment Catalogueviktor_gligorovAinda não há avaliações

- PipingDocumento267 páginasPipingNurcahyo Djati W100% (1)

- 16-02 - Fuel-Gas Filter SeparatorsDocumento8 páginas16-02 - Fuel-Gas Filter SeparatorsFolayemiAinda não há avaliações

- Gate Valve Specification for Fuel Gas Supply ProjectDocumento14 páginasGate Valve Specification for Fuel Gas Supply Projectmoonstar_dme100% (1)

- Piping Class B31Documento142 páginasPiping Class B31interx00Ainda não há avaliações

- H 002 CRDocumento12 páginasH 002 CRmra1982Ainda não há avaliações

- L&T GateGlobe&CheckValves-API 600Documento31 páginasL&T GateGlobe&CheckValves-API 600vsvineesh100% (1)

- Final MSR Rev (1) - CDocumento104 páginasFinal MSR Rev (1) - CDeepak Goyal100% (1)

- Technical Evaluation Criteria For Chemical Injection PackageDocumento5 páginasTechnical Evaluation Criteria For Chemical Injection Packagefarazhussainkhan100% (1)

- API 676 pump nozzle load increaseDocumento2 páginasAPI 676 pump nozzle load increaseAshok KumarAinda não há avaliações

- Project Standards and Specifications Metallic Expansion Joint Rev01Documento4 páginasProject Standards and Specifications Metallic Expansion Joint Rev01hiyeonAinda não há avaliações

- Project Standards and Specifications Pipeline Construction Rev01Documento15 páginasProject Standards and Specifications Pipeline Construction Rev01hiyeonAinda não há avaliações

- Project Standards and Specifications Mechanical Design Rev01Documento11 páginasProject Standards and Specifications Mechanical Design Rev01cvssbvAinda não há avaliações

- Piping fabrication standardsDocumento10 páginasPiping fabrication standardsGabrielPantilicaAinda não há avaliações

- SS Weld SpecificationDocumento39 páginasSS Weld SpecificationmurugesanAinda não há avaliações

- PROJECT STANDARDS and SPECIFICATIONS Pipeline Functional Specification For Piping Special Items Rev01Documento8 páginasPROJECT STANDARDS and SPECIFICATIONS Pipeline Functional Specification For Piping Special Items Rev01hiyeonAinda não há avaliações

- Piping Chevron OffDocumento44 páginasPiping Chevron OffdfdflkAinda não há avaliações

- Project Standards and Specifications Shell and Tube Heat Exchangers Rev01Documento9 páginasProject Standards and Specifications Shell and Tube Heat Exchangers Rev01amitgoel1989Ainda não há avaliações

- All-in-One Manual of Industrial Piping Practice and MaintenanceNo EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceNota: 5 de 5 estrelas5/5 (1)

- PML Course IranpipingDocumento150 páginasPML Course IranpipingNguyen Anh TungAinda não há avaliações

- Training Program On Basic Process Engineering PracticesDocumento14 páginasTraining Program On Basic Process Engineering PracticesNguyen Anh TungAinda não há avaliações

- Presentationonasmesec 191101032115Documento121 páginasPresentationonasmesec 191101032115shahqazwsxAinda não há avaliações

- Materials and Corrosion Design GuideDocumento34 páginasMaterials and Corrosion Design GuideNguyen Anh TungAinda não há avaliações

- Pig Launching & Receiving SystemsDocumento4 páginasPig Launching & Receiving SystemssilvanopipeAinda não há avaliações

- Process Design QuestionnaireDocumento30 páginasProcess Design QuestionnaireNguyen Anh TungAinda não há avaliações

- P&ID Preparation ProcedureDocumento38 páginasP&ID Preparation ProcedureNguyen Anh Tung100% (1)

- Manual of Process Economic EvaluationDocumento480 páginasManual of Process Economic EvaluationNguyen Anh Tung100% (2)

- Process Engineering Design GuideDocumento296 páginasProcess Engineering Design GuideNguyen Anh TungAinda não há avaliações

- Technip-Process-Manual For P&IDDocumento62 páginasTechnip-Process-Manual For P&IDNguyen Anh Tung67% (3)

- Basic process design requirements and criteriaDocumento23 páginasBasic process design requirements and criteriaNguyen Anh Tung100% (1)

- 10 Items To Include in Supplier Audit Checklists TemplateDocumento3 páginas10 Items To Include in Supplier Audit Checklists TemplateNguyen Anh TungAinda não há avaliações

- Norsok P-002 Ac-2017Documento4 páginasNorsok P-002 Ac-2017Nguyen Anh Tung0% (2)

- NDT Method SummaryDocumento3 páginasNDT Method SummaryNguyen Anh TungAinda não há avaliações

- Classification of Hazardous AreasDocumento26 páginasClassification of Hazardous AreasNaveen ReddyAinda não há avaliações

- Flange Data ComparisonDocumento21 páginasFlange Data ComparisonRiki FernandesAinda não há avaliações

- Determining Piggability of Pipelines For Inline ToolDocumento7 páginasDetermining Piggability of Pipelines For Inline ToolNguyen Anh TungAinda não há avaliações

- Allowable Stress ForUnlisted MaterialsDocumento3 páginasAllowable Stress ForUnlisted MaterialsNguyen Anh TungAinda não há avaliações

- Over Pressure Protection For Pressure Vessel & Pressure PipingDocumento41 páginasOver Pressure Protection For Pressure Vessel & Pressure PipingNguyen Anh TungAinda não há avaliações

- CSWIP 3.2 Course Material 2016Documento418 páginasCSWIP 3.2 Course Material 2016skychurch97% (29)

- Asme PTC 22-2014Documento112 páginasAsme PTC 22-2014zafarusmani100% (4)

- ASME B31.1 Vs B31.3 Vs B31.8Documento9 páginasASME B31.1 Vs B31.3 Vs B31.8Nguyen Anh Tung67% (3)

- Asme B16.28Documento20 páginasAsme B16.28Nguyen Anh Tung100% (1)

- Insulation Thickness Heat Transfer Pipe CalculationsDocumento2 páginasInsulation Thickness Heat Transfer Pipe Calculationsrajpal14667% (6)

- Asme B16.44 2012Documento24 páginasAsme B16.44 2012Nguyen Anh TungAinda não há avaliações

- FireSeal Catalouge - InbundenDocumento36 páginasFireSeal Catalouge - InbundenNguyen Anh TungAinda não há avaliações

- A790a790m 17Documento10 páginasA790a790m 17Nguyen Anh TungAinda não há avaliações

- PFI ES-7 Min Spacing For WeldingDocumento6 páginasPFI ES-7 Min Spacing For WeldingNguyen Anh TungAinda não há avaliações

- Pig Traps Launcher 2016428 CriDocumento7 páginasPig Traps Launcher 2016428 CriKrishna KusumaAinda não há avaliações

- KG-DWN-98/2 Piping Installation DrawingsDocumento51 páginasKG-DWN-98/2 Piping Installation DrawingsNguyen Anh Tung100% (3)

- On Hereditary Italian WitchcraftDocumento79 páginasOn Hereditary Italian WitchcraftAlbion JamesAinda não há avaliações

- Dimensions of Comparative EducationDocumento5 páginasDimensions of Comparative Educationeminentsurvivor9Ainda não há avaliações

- Keyence cv700 - Man2Documento232 páginasKeyence cv700 - Man2kamaleon85Ainda não há avaliações

- VRLA Instruction ManualDocumento11 páginasVRLA Instruction Manualashja batteryAinda não há avaliações

- Rediscovering Ecotorism - : Poaching, A Major Challenge in Liwonde National Park Cashing in On TourismDocumento28 páginasRediscovering Ecotorism - : Poaching, A Major Challenge in Liwonde National Park Cashing in On TourismJohn Richard KasalikaAinda não há avaliações

- 1703 - Facility Perspectives v502 LOWRESDocumento84 páginas1703 - Facility Perspectives v502 LOWRESdavid_haratsisAinda não há avaliações

- DGS Mock Exam - Full AnswerDocumento11 páginasDGS Mock Exam - Full AnswerSofia NicoriciAinda não há avaliações

- Emily Act 3 GraficoDocumento13 páginasEmily Act 3 Graficoemily lopezAinda não há avaliações

- Semi Detailed Lesson Format BEEd 1Documento2 páginasSemi Detailed Lesson Format BEEd 1Kristine BuenaventuraAinda não há avaliações

- 2021.01 - Key-Findings - Green Bond Premium - ENDocumento6 páginas2021.01 - Key-Findings - Green Bond Premium - ENlypozAinda não há avaliações

- Horses To Follow: Ten To Follow From Timeform'S Team of ExpertsDocumento12 páginasHorses To Follow: Ten To Follow From Timeform'S Team of ExpertsNita naAinda não há avaliações

- Physical GEOGRAPHY - TIEDocumento432 páginasPhysical GEOGRAPHY - TIEnassorussi9Ainda não há avaliações

- Ec010 505 Applied Electromagnetic TheoryDocumento2 páginasEc010 505 Applied Electromagnetic Theorywalternampimadom100% (1)

- rfg040208 PDFDocumento2.372 páginasrfg040208 PDFMr DungAinda não há avaliações

- Louise Bedford Trading InsightsDocumento80 páginasLouise Bedford Trading Insightsartendu100% (3)

- High Performance, Low Cost Microprocessor (US Patent 5530890)Documento49 páginasHigh Performance, Low Cost Microprocessor (US Patent 5530890)PriorSmartAinda não há avaliações

- Ratio, Proportion, and Percent: Presented By: John Darryl M. Genio Bocobo #3Documento18 páginasRatio, Proportion, and Percent: Presented By: John Darryl M. Genio Bocobo #3John Darryl GenioAinda não há avaliações

- Lahore School of Economics Operations Management Final Group Project Outline (Weightage 15%) Bba - Iv Instructor: Dr. Saba Fazal FirdousiDocumento3 páginasLahore School of Economics Operations Management Final Group Project Outline (Weightage 15%) Bba - Iv Instructor: Dr. Saba Fazal FirdousiAshir HassanAinda não há avaliações

- Urinary: Rachel Neto, DVM, MS, DACVP May 28 2020Documento15 páginasUrinary: Rachel Neto, DVM, MS, DACVP May 28 2020Rachel AutranAinda não há avaliações

- Xbox - RGH E Ltu: Jogo 3.0 4.0 HD NºDocumento11 páginasXbox - RGH E Ltu: Jogo 3.0 4.0 HD NºGabriel DinhaAinda não há avaliações

- Mercado - 10 Fabrikam Investments SolutionDocumento3 páginasMercado - 10 Fabrikam Investments SolutionMila MercadoAinda não há avaliações

- Bid Document Vol. II Attachment BOQDocumento6 páginasBid Document Vol. II Attachment BOQHrityush ShivamAinda não há avaliações

- Build A Tunnel: What You NeedDocumento2 páginasBuild A Tunnel: What You NeedManila Business ShopsAinda não há avaliações

- History of Architecture in Relation To Interior Period Styles and Furniture DesignDocumento138 páginasHistory of Architecture in Relation To Interior Period Styles and Furniture DesignHan WuAinda não há avaliações

- ISO 22301 Mandatory DocumentDocumento2 páginasISO 22301 Mandatory Documenttrackuse100% (1)

- CH 9 - Spontaneity, Entropy, and Free EnergyDocumento65 páginasCH 9 - Spontaneity, Entropy, and Free EnergyCharbel RahmeAinda não há avaliações

- Joou No Gohoubi - Tate No Yuusha No Nariagari 288869 Doujin - EdoujinDocumento25 páginasJoou No Gohoubi - Tate No Yuusha No Nariagari 288869 Doujin - Edoujinaura.nazhifa10020% (1)

- C15 DiagranmaDocumento2 páginasC15 Diagranmajose manuel100% (1)

- Moral Agent - Developing Virtue As HabitDocumento2 páginasMoral Agent - Developing Virtue As HabitCesar Jr Ornedo OrillaAinda não há avaliações

- Plastic RecyclingDocumento14 páginasPlastic RecyclingLevitaAinda não há avaliações