Escolar Documentos

Profissional Documentos

Cultura Documentos

PLC of Servo

Enviado por

hzq1eDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PLC of Servo

Enviado por

hzq1eDireitos autorais:

Formatos disponíveis

PROGRAMMABLE SERVO CONTROL - A NEW APPROACH

I M Whiting, BSc(Hons), PhD and N P Cottell, CEng, MIMechE Moog Controls Limited, Tewkesbury, Glos, UK.

First presented at the I.MechE, Seminar S268, 'Digital Control in Fluid Power Systems', Wednesday 22 June 1994, Clarendon Suites,Birmingham, UK.

SYNOPSIS Closing the loop is often one of the least considered aspects of machine automation, seldom exploring beyond the bounds of the widely used PID approach. This may reflect directly as a loss of performance or over-sizing of the actuation components - both of which can be expensive. A more flexible and often more appropriate solution to loop closure is offered by the Programmable Servo Control (PSC) approach to loop closure design and motion control. This paper outlines PSC concepts, operation and applications in the field.

1. INTRODUCTION Closed loop servo drive technology is increasingly becoming the norm in machine automation, where machine operators are demanding greater precision, faster operation, simpler adjustment and shorter down times. At the same time there is an expectation that the price of increasing the level of automation should be contained within acceptable limits. The machine builder has a bewildering number of options in responding to these demands in all aspects of closed loop automation, whether it be in the choice of actuation device, sensor, valve, or control system. This is especially true in the area of controller electronics and software. Whilst the mass-produced machine builder may be able to invest in purpose designed hardware platforms and customised software, this approach is often too expensive where specialised machines are being built in smaller volumes. A solution here is provided by the so-called 'Axis Control' or 'Motion Control' products offered on the market. A good motion control product uses a high level motion control oriented programming language where the machine sequences can be programmed with speed and only basic programming skills. It has all the I/O needed for the machine application integrated into a single unit, reducing the amount of wiring and interfacing. It should also be flexible enough to enable the standard software to be configured for a large variety of applications. There is another element in the selection of a motion control product which is often over-looked. This is in the area of the closed loop control capability, where in the main the industry standard PID approach (maybe enhanced by velocity feed-forward) is the only option. This is in spite of well known text book control theory [1] and R&D work [2]

which demonstrates that other control strategies may improve performance and/or result in lower cost actuation hardware. In this paper a new approach to closed loop control is described where the flexibility and ease of programming extends beyond the normal motion control (sequencing) language to also include the structure of the closed loop servo controller and associated real-time tasks. This is referred to as the 'Programmable Servo Control' (PSC) approach to axis control [3]. The paper provides an overview of PSC operation and programming, focuses on the real-time 'Function Block' approach to loop configuration and overviews a number of applications where PSC concepts have been exploited in the field.

2. THE PSC CONCEPT - AN OVERVIEW The PSC uses a 'Function Block' approach to closed loop control, where each of the loop functions are declared explicitly. Take for example the widely used PID position loop structure shown in Figure 1(a).

Position Demand

P I Limit

Valve Demand

Sig. Gen.r

D/A

Position Feedback

A/D

1(a)

Typical PID Position Control Structure

Velocity Demand

P Limit I

Valve Demand

PROCESS CONTROL Enable

Sig. Gen.r

D/A

Mode Flag Latch

Velocity Feedback

PROCESS INPUT Input LIMITER PROCESS

PROCESS OUTPUT Output Flag

A/D

1(b)

Re-structured for Velocity Control with Feed Forward PSC Re-Structurable Control Concept

Max Output Min Output Max Rate Min Rate

Fig.1

The loop structure is made up of 3 filter functions (P, I and D), 2 summing junction functions, analog input and output functions, a limiting function and a demand signal generation function. The parameter values for each of these are set in software by the user. This also includes the input/output connections between Function Blocks, i.e. the controller structure definition. The benefit of being able to change the controller structure is seen in Figure 1(b) where the same elements are now used to create a velocity control system. Re-connection of the P and D elements and re-positioning of the Limiter is all that is required to produce the new controller. Each of the PSC Function Blocks is a simple preprogrammed process which is executed every sample period. The characteristics of the process may be adjusted by the user to achieve specific objectives. This is achieved via Control, Data, Input and Output parameters. For example details of the Limiter Function Block are shown in Figure 2(a). In this particular case the limiting process includes both rate and/or output level limiting, selected using the Mode parameter. The Max/Min Output level and Max/Min Rate parameters are defined in the process via the data parameters, producing the effect shown in Figure 2(b). The process also produces a latchable flag which goes TRUE when limiting of the process input occurs. A similar approach is used to define all of the other Function Block processes used in the PSC concept, a full list of which is given in Appendix 1 of this paper. Some of the more notable ones include the Filter Function Block whereby PID, High/Low Pass Filters or any discrete filter up to 3rd order transfer function may be defined in the control structure. The Nonlinear Table Function Block allows any input signal to be mapped to the output via a table of points defined by the user. Another powerful Function Block is the so called 'Flag Handler' which allows real-time switching of the control loop structure. The use of these and other Function Blocks to produce some powerful control algorithms are described in the following sections.

PROCESS DATA

2(a)

Limiter Function Block Definition

INPUT OUTPUT Max Rate INPUT OUTPUT

Max Output

TIME Min Output Min Rate

2(b) Fig.2

Limiter Function Block Characteristic Example Function Block - The Limiter

3. POSICUT WOOD CUTTING MACHINE 3.1 Overview The POSICUT Machine [a] demonstrates interaction between Function Blocks and the PSC's Motion Control Language (MCL). The objective is to lift (vertical axis) and re-position (horizontal axis) the machine saw blade between cuts, see Figure 3. The uncut planks of wood are measured for length via a laser system whilst being conveyed towards the blade. Position demand data derived from the measurement is fed into the PSC controller (see Appendix 1). The horizontal axis is called upon to move the demanded distance prior to the blade being lowered and the next cut taking place. The PSC concept enhances the cutting sequence by the use of:

Real-time Sequence Logic Move Time Motion Generation with Velocity and Acceleration Limiting

The latter function allows the horizontal axis to move the specified distance (which is different from plank to plank) in a fixed time frame. This reduces the axis accelerations to the minimum needed to achieve the motion, thereby reducing machine loads.

3.2 Real-Time Sequencing Logic The interaction between MCL program and Function Blocks is shown in Figure 4. At the PLC strobe command a 'Blade Up' instruction is issued to the Up/Down Motion Generator. The Flag Generator Function Block is loaded with a value of Up/Down Axis position which represents the blade clearance level above the wood. When the blade reaches this point, the Flag Generator produces a TRUE flag and the Traverse Motion Generator starts moving to the new horizontal axis demand position. The PSC Motion Generator Function Block may be operated in any one of several modes which produce absolute or relative motions. The 'Move Time' mode constrains the motion as shown in Figure 5. The move position and maximum velocity and acceleration parameters are defined as normal, but in addition a time parameter is specified.

OUTPUT VELOCITY

Max Vel

Max Acc

A3 A2

A3

A4

A1

TIME Pos A1,A2,A3,A4 A1 - Small Move A2 - Large Move A3 - Largest Move Time A4 - Move Time Exceeded Time

Fig.5

Move Time Motion Generator Function Block

Fig.3

Ahlstrm POSICUT Wood Cutting Machine

If the distance moved is small, the motion is described by area A1 in Figure 5, where the minimum acceleration and deceleration is used. If the distance moved is larger, then the maximum velocity may be reached (A2). If the maximum distance (A3) is exceeded, then a flag is raised and the move continues at the maximum acceleration and velocity, but exceeding the defined time frame (A4).

The Motion Generator Function Block raises a flag at the end of the motion which triggers the blade down instruction to the Up/Down Axis. The POSICUT Machine repeats the cycle over and over for as many times as is necessary.

4. INJECTION MOULDING MACHINE 4.1 Overview Another commonly occurring process is where the servo axis is required to switch between 2 control strategies at a particular point in the machine cycle. For example injection moulding machines include a velocity profile as the material is entered into the die. This is followed by a pressure cycle which commences when the injection pressure (which is monitored during the velocity profile) exceeds the trigger value. A simplified representation of this process is shown in Figure 6. In this application the PSC concept is used to ensure that the switch over point is as smooth (bumpless) as possible, even when the transition point occurs at high speed. This is achieved by:

REPEAT Logic From PLC

MCL - A

Strobe Blade Up B - Ready Blade Down Max = Clearance Level

Valve Demand

Motion Gen.r

P

AXIS - A UP/DOWN

D/A

A/D

Position Feedback Motion Done Flag Valve Demand

Clearance Flag

Flag Gen.r

REPEAT

MCL - B

Blade Up Data From PLC Move Time New Position

Motion Gen.r

P

AXIS - B TRAVERSE

D/A

A/D

Position Feedback

Pressure/Position Control Real-Time Triggering Pressure Loop Output Tracking (Bumpless Transfer) at the X to P Switch Over

Fig 4. Ahlstrm POSICUT Axis Sequencing 3.3 Move Time Motion Generation

Pb A/D

Pa A/D

TRACKING CONTROLLER

Compliant Load

Flag Handler Function Blocks Valve Demand

X A/D POSITION

Pressure Demand

F I T D PRESSURE CONTROL D

T D/A F A/D Pa Ratio A/D Pb TRIGGER DETECTION Max/Min Error Window Flag Gen.r Effective (Actual) Pressure Feedback I

Velocity Profile

Ps I PRESSURE D/A PSC Position and Pressure Control Set Pressure

TIME Trigger

Pressure Trigger Latched TRUE (T) when Pressure High

Position Demand

TIME

Max Rate Limit P POSITION CONTROL Position Feedback A/D X

Fig.6

Position/Pressure Control with Smooth Transition Fig.7

Position/Pressure Control Scheme

4.2 Pressure/Position Control Triggering The PSC Function Block construction for the position and pressure loop structures are shown in Figure 7. The two loops run in parallel, one or the other being used as valve demand. The pressure loop derives an effective pressure feedback using the Ratio Function Block which corrects for the unequal area effect in the cylinder drive. The use of appropriately placed I and D filters gives good static accuracy and dynamic response. The trigger detection circuit is built up using standard Function Blocks and set to produce a TRUE flag when the difference in demanded and actual pressure is within the pressure error window (defined via the Flag Generator). The trigger point is also user adjustable (via the D term) and may be advanced in time (pre-triggered) depending on the rate of change of pressure at impact. This helps to reduce the overshoot of pressure at the switching point. The path switching action in this example introduces the Flag Handler Function Block which is the key to real-time control structure switching. In this case the Flag Handler is triggered from the Flag Generator and is set up to connect the output from either the Pressure Controller or the Position Controller to the valve drive D/A output. Path switching is one of several modes of operation of the Flag Handler [3]. 4.3 Bumpless Transfer

PSC 1

5. LARGE MANIPULATOR (LAMA) 5.1 Overview Hydraulic manipulators which have long reach (over 15m) and substantial payload (over 250 kg) exhibit large scale structural and hydraulic flexibility. The resulting low overall natural frequencies - combined with very little damping present difficulties when it comes to closed loop control. In addition to this, the large variation in cylinder load (which may be up to 95% of the stall pressure) and the use of kinematic (4 bar chain) linkages at each joint (converting linear to rotary motion), exhibit severe nonlinearities. If not corrected these cause further deterioration in servo performance. The LAMA manipulator [b], (having 20m reach and 450 kg payload), suffers from all of the effects described above (see Figure 8).

Serial Communications RS-485

PSC 3 PSC 5 3 5

Host - Path Planning PSC - Axis Control

PSC 6 PSC 2 PSC 4 7 2 4 6 z HOST SYSTEM 1 450kg (Max) PSC 7 PSC 8 PSC 9 y x

The smoothness of the transfer between position and pressure control may be improved by the inclusion of a Tracking Controller. This is produced in PSC Function Blocks as shown in Figure 7. The Tracking Controller is active during position control mode (via a second Flag Handler) and is designed to ensure that the valve demand output of the pressure control loop tracks the position loop output. This minimises transients at the trigger point.

20m Reach (Max)

Fig.8

LArge MAnipulator (LAMA) Distributed PSC Control System

In this particular case PSC concepts are implemented using distributed control hardware platforms (as in Appendix 1) mounted locally at each of the 6 main and 3 wrist axes. Each controller receives demand data in real-time via the serial communication link established between the base mounted Host Control System and each distributed hardware platform. The PSC sensor system utilises a high precision angular resolver for position feedback from which velocity feedback is also derived. Active structural and hydraulic damping is achieved via the additional feedback of cylinder pressures Pa and Pb (see Figure 9). Each servo cylinder is fitted with a pressure compensated servo valve designed to include 10% overlap for safety reasons. The pressure compensator (enhanced by PSC control strategies) is used to maintain a constant servo valve flow gain (via control of valve pressure drop) in the face of changing cylinder load conditions.

5.2 Nonlinear Correction The key Function Blocks used in creating nonlinear algorithms are Limiters, Tables, Flag Generators and Flag Handlers. The Limiter Function Block for example is used as part of the valve overlap and cylinder area ratio corrector, (see Figure 11).

D Tracking Control P

Incremental Demand (Velocity)

+ +

Gen

Valve Control

D/A

Valve Demand

Effective Inertia

Gain Schedule HP K.Matic Control P

P.Comp Control

A/D

Pressure Pa

Gen

AR

A/D

Pressure Pb

Incremental Position (Velocity) Feedback A/D Absolute

A/D

Angular Position Arm 4

Resolver Angle

A/D Pa

A/D Pb

Fig.10

LAMA Overall (Incremental) Position Control Loop Structure

Kinematic (4 bar) Linkage Arm 3

Pa

Pb

Pv Pm Shuttle Valve 15 Bar Pm = Pa or Pb (Whichever is highest) Pv - Pm = 15 Bar D/A Ps Pressure Compensator

The Table Function Block allows a number of points to be defined which describe a single input/output function. For example the LAMA kinematic linkage nonlinearity causes a gain change which can be corrected by defining the d/dx characteristic in the table. The measured angle is the table input and d/dx the table output, which is used to correct the P gain prior to the valve output (see Figure 10).

VALVE CONTROL

PSC Incremental Pos.n Loop with Damping Adaptive and Nonlinear Control

P =32000 P Input

P=0.05 OUTPUT P Output Flag1 Flag2 (Output) INPUT

Fig.9

LAMA Servo System Hydraulic and Sensor Schematic

P P=0.65

Limit Max=0 Min=-100%

The same overall control scheme is used for all of the LAMA axes (see Figure 10), having the following characteristics built from PSC Function Blocks: Nonlinear correction for; Valve Overlap and Cylinder Area Ratio Kinematic Linkage Correction Load Pressure Compensation Adaptive Control Correction for; Effective Inertia Variation High Precision Tracking

Flag1 TRUE for +ve Input Flag2 FALSE for +ve Input (See Fig.12(b))

Fig.11

Valve Control Correction for Overlap and Cylinder Area Ratio

Flag Generators, Limiters, Tables and Flag Handlers may also be used together to provide more complex nonlinear functions. The Pressure Compensator Controller (P.Comp in Figure 10) is a good example. The hydromechanical compensator is intended to maintain 15 bar pressure drop across the in-flowing metering edge of the servo valve. However there are cases (depending on which of Pa or Pb is the higher and whether the valve is open +ve or -ve) when

the compensator fails to operate as required (see Figure 12(a)). A gain adjustment parameter correcting for the compensator error (depending on Pa-Pb) is contained in a Table Function Block. Real-time logic, based on Flag Generator and Handler (switching) Function Blocks is configured as shown in Figure 12(b). At the appropriate operating points (determined by the logic) the P gain may be adjusted in real-time by a factor up to 5 times. This example shows in particular the power of switching Flag Handler Function Blocks which may be combined to produce more complex logic functions or configured to directly change controller gain values.

of some performance criteria, usually related to controller performance [4]. The LAMA controller utilises both of these processes as indicated in Figure 10. The effective inertia adaptation gain schedule is based on 3 input parameters. These are; calculated effective inertia (information supplied directly from the Host Controller over the serial link), the locally measured angular position and the locally tabulated kinematic gains (see Figure 10). The 3 input parameters are manipulated using a combination of Table Function Blocks and arithmetic functions available in the PSC background Motion Control Language (MCL). In total the gain schedule allows for the correction of 3 controller gains, these are; position gain, velocity feedback gain and pressure damping gain as shown in Figure 10. The LAMA also makes good use of the PSC Filter Design Tool Box, which in addition to the classic P, I and D constructions, allows high pass and low pass (HP/LP) filters to be defined up to 3rd order. The Tool Box also allows discrete (Generic) transfer functions up to 3rd order to be created (see Figure 10). In the case of the LAMA these are used to improve the overall control behaviour.

EXTEND VELOCITY Linear (Correct) Characteristic Nonlinear Characteristic for Constant +ve Valve Opening Pa - Pb (LOAD)

Nonlinear Characteristic for Constant -ve Valve Opening

Linear (Correct) Characteristic

RETRACT VELOCITY

Max Adapt Speed

12(a)

Pressure Compensator Characteristic for Constant Valve Opening

From Position Controller

DIRECTIONAL AND MIN.SPEED LOGIC Flag Gen.r T Min Adapt Speed Gain=1 T F Max=0 Gain=-1 F Flag Gain=0 Gen.r

Valve Control

D/A Valve Demand

Demanded Control Error (=0)

Max Gain Min Gain Ps Pr Limit Integrator ADAPTATION LOOP Control Error Feedback Feed forward (Fixed Gain)

T F

Gain Selection Logic

T F

Flag 1 - Extend (See Fig.11) Flag 2 - Retract

F 100% T Gain Reduced Gain From Kinematic Controller Correction Table

Max=0 Flag Gen.r A/D Pressure Pa

Incremental Position (Velocity) Demand

Adapt On/Off Flag

P Velocity Feed Forward Gain P

ADAPTIVE TRACKING CONTROLLER To Valve Control

A/D

Pressure Pb

INCREMENTAL POSITION Incremental LOOP (See Fig.10) Feedback

PRESSURE COMPENSATOR (P.COMP) CONTROLLER

Reduced Gain as a Function of Pa-Pb

A/D

Fig.13 12(b) Fig.12 Correction using PSC Function Blocks Load Pressure Compensation Gain Adjustment Controller

Adaptive Feed forward Tracking Controller

5.3 Adaptive Control Adaptive control mechanisms allow gain values to be adjusted to correct for time variable changes in servo behaviour. The adaptation process may be based on the direct or indirect measurement of parameters as they change (Gain Scheduling), or on the observation and minimisation

Another example of adaptive control using the PSC Function Block concept is illustrated in Figure 13. Once more the control structure is built up using Flag Handler, Flag Generator and Limiter Function Blocks. The adaptation criteria used here is to adjust the velocity feed forward gain so that the tracking error is forced to zero during motion. The PSC Function Block implementation of the adaptive tracking controller utilises 2 mechanisms which work together to generate appropriate gain values. These are the

'Adaptation Loop' itself and the 'Directional and Minimum Speed Logic' as shown in Figure 13. The adaptation loop uses position control error as a basis for determining the rate of change of the velocity gain. Note the use of a Limiter with feedback to provide a limited output integrating effect (thereby controlling the range of adaptation of the velocity gain). The adaptation loop also provides a means of trading off gain adaptation rate against robustness (via the Pr gain in Figure 13) and a means of switching to a fixed velocity gain depending on the state of the Adapt On/Off Flag. The adaptation logic mechanism determines the state of the Ps gain in Figure 13 which may be one of 3 values; +1 or -1 depending on the direction of motion or 0 depending on the speed of motion. The latter is important to prevent adaptation at low or zero speed where noise and nonlinearities may distort velocity gain values.

[1] Franklin G. F, Powell J. D., 'Digital Control of Dyn-amic Systems'', Addison Wesley World Student Series, 1980. [2] Whiting I. M., 'Closed Loop Digital Control of Electrohydraulic Systems'', Ph.D Thesis, School of Mechanical Engineering, University of Bath, UK, 1987. [3] Moog Controls Limited, M2000-PSC User's Manual, April 1993, Part No B75432. [4] strm K. J., Wittenmark B., 'Adaptive Control', Addison Wesley, 1989.

6. CONCLUSIONS PSC real-time Function Block concepts are demonstrated as being a powerful tool in control engineering, where advanced control concepts can be implemented and adjusted with ease in real industrial situations. Significant performance improvements may be achieved by the use of Logic Function Blocks in combination with flexible control structures. PSC concepts may be used in providing correction for actuation system and load nonlinearities. Further to this, time variable nonlinearities may be corrected by on-line gain adaptation. Smooth transition between control modes may be achieved using PSC high speed logic functions. Above all, the industrial application of PSC concepts presented in this paper demonstrate the benefits in giving careful consideration to closed loop requirements when choosing a Motion Control product (See Appendix 1).

ACKNOWLEDGEMENTS [a] The authors wish to thank Lars Stenstrm of Ahlstrm Machinery AB, for allowing the use of POSICUT Machine details in this paper. [b] The authors acknowledge financial support provided to Moog Controls Limited by the European Commission (DG III) via Esprit II project EP2280 - LAMA (completed January 94). Technical support given by the participating companies is also recognised.

REFERENCES

APPENDIX 1 - PSC HARDWARE PLATFORM (1 or 2 AXES) Moog Controls Limited Model No E122-211

DESCRIPTION Function The Programmable Servo Controller (PSC) is a microprocessor based loop closure and motion sequencing card available in 'Single Eurocard' (DIN 41612 connector) format. The unit provides extensive I/O capability, a high level Motion Control Programming Language and real-time Function Block Programming according to the following specification: Analog Output: Details

FUNCTION BLOCK PROGRAMMING Description Summing Junction (4 input) Limiter/Summing (3 input) Filter (up to 3rd order) Ratio Block (2 input) Signal Generator Trajectory Generator Control Error Monitor Flag Generator (Comparator) Flag Handler (Logic Switch) Nonlinear Table Scale Data Logging Channel Timer No Off 4 6 24 4 2 2 4 16 16 4 2 3 16

2off, 12bit, +/-10V or +/-10, 30, 50, 100mA Analog Input: 6off, 12bit, +/-10V plus options Digital Input: 4 off opto-isolated 24V Digital Output: 4 off opto-isolated 24V Serial Transducer: 2off SSI Protocol, Rs-422 Serial Com.s: Rs-232 Set-Up Link Rs-485 Sync Link Can Bus I/O Expansion: Dual Encoder Logic I/O Analog Conditioning Parallel Input

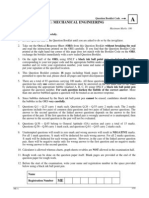

PSC PICTORIAL VIEW

MOTION CONTROL LANGUAGE PROGRAMMING Command Type Move Abs./Rel. Move Time, Jog Stop/Quick Stop Programming: Assign/Set Comment If/Then/Else GoTo Repeat Units Wait True/False Expressions: Arithmetic Bitwise Logic Boolean Logic Set Connection Greater/Less Than HARDWARE (I/O) SPECIFICATION Motion:

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Statics and Strength of Materials Formula SheetDocumento1 páginaStatics and Strength of Materials Formula SheetRichard TsengAinda não há avaliações

- Syllabus PDFDocumento15 páginasSyllabus PDFJatin SharmaAinda não há avaliações

- SofmandsolidDocumento51 páginasSofmandsolidroylmechAinda não há avaliações

- Statics and Strength of Materials Formula SheetDocumento1 páginaStatics and Strength of Materials Formula SheetRichard TsengAinda não há avaliações

- ONGC Mechanical QuestionDocumento27 páginasONGC Mechanical QuestionNavlesh SharmaAinda não há avaliações

- Keyboard Shortcuts For Microsoft Office Word - WordDocumento14 páginasKeyboard Shortcuts For Microsoft Office Word - Wordraj08101990Ainda não há avaliações

- N123 134electronicsDocumento4 páginasN123 134electronicsraj08101990Ainda não há avaliações

- Articles: What Do Productivity Shocks Tell Us About The Saving-Investment Relationship?Documento14 páginasArticles: What Do Productivity Shocks Tell Us About The Saving-Investment Relationship?raj08101990Ainda não há avaliações

- Income Tax of India Section 192Documento2 páginasIncome Tax of India Section 192raj08101990Ainda não há avaliações

- Moog Controller N121-132electronicsDocumento6 páginasMoog Controller N121-132electronicsnm2007kAinda não há avaliações

- Servo ControlDocumento8 páginasServo Controlraj08101990Ainda não há avaliações

- 89s52 DatasheetDocumento30 páginas89s52 DatasheetAnkit TakleAinda não há avaliações

- Servo ControlDocumento8 páginasServo Controlraj08101990Ainda não há avaliações

- QpmeDocumento16 páginasQpmeSandeep PandeyAinda não há avaliações

- Mechanical Engineering ExamDocumento16 páginasMechanical Engineering ExamantonoxfordAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)