Escolar Documentos

Profissional Documentos

Cultura Documentos

1938 - 3043

Enviado por

seafire47Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1938 - 3043

Enviado por

seafire47Direitos autorais:

Formatos disponíveis

NOVEMBER

3, 1938.

FLIGHT.

387

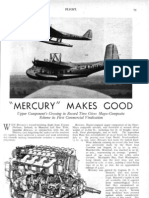

From top to bottom are detail views of the Bristol Hercules, Perseus and Aquila sleeve-valve engines. The Perseus is the first of the sleevevalve series to go into large-scale production. It is specified for some interesting new military and civil types. layshaft, which also carries the fan layshaft gear. From the pinion, power is transmitted to the fan layshaft gear through a centrifugal friction clutch consisting of six phosphorbronze clutch pads in a steel housing, the latter being incorporated in the gear which in turn drives a spur gear on the fan spindle. Drives for the auxiliaries are enclosed in a box on top of the rear cover, the generator on the Cheetah X being mounted on top of the box. There are two current models of the fourteen-cylinuer two-row Tigerthe Mark VII1 and the Mark IXthe former having the distinction of being the first aero engine with two-speed supercharger to go into production in this country. The medium supercharged Tiger I X powers the A'.W. Ensign.

* I * :P, W>'-***

Two'Speed

Supercharging

The two-speed supercharger of the Tiger VIII, combined with the v.p. airscrew, provides great- advantages in take-off power and output at altitude, together with great fuel economy under cruising conditions. The twospeed supercharger is assembled direct to a support plate, bolted and enclosed within the induction casing. The supercharger rotor is driven from the crankshaft by a countershaft drive in high gear and a planetary drive iii low gear. The gearing comprises a set of three balanced compound planets comprising a small and a large pinion housed in a: carrier which is allowed to rotate in low gear position and is held stationary in high gear. There is also an internally toothed annulus which meshes with the smaller pinions. This has a flange which, when held stationary, gives the planetary drive. Driving gear, which is integral with the spring drive on the rear end of the crankshaft, is coupled by means of an internally and externally toothed sleeve to the small planet pinions which, in-turn, <lrive the larger pinions. The smaller pinion is keyed to the spindles driving the centrifugally operated clutch within the larger planet pinion which drives the rotor shaft. The planet carrier is Held stationary when required by means of an internally toothed clutch plate having toothed engagement with the outer diameter of the carrier. This plate forms the high-gear clutch plate, and the annulus gear already mentioned forms the clutch plate for low gear. Either of these can be held stationary by a clutch which takes the form of two annular members. These members mesh with a stationary housing, and a small rotational movement will cause sufficient axial movement to lock either clutch plate, according to the direction ol rotation. Rotation of the clutch actuating members is by two toggles, each having one link mounted on a pivot on the stationary member and the other link mounted on a pivot on the control member. The centre pivot points are connected to a hydraulically actuated piston in each end of a double-acting cylinder. This cylinder is connected to the oil pressure system of the engine controlled by a handoperated piston valve. When this valve is pulled outward, oil is forced through a passage in the cylinder wall to the ends of the cylinder and forces the pistons inwards, the oil between them being exhausted through a port behind the valve (low gear). In the other extreme position of the piston valve, pressure oil is carried to the heads of the pistons, forcing them away from each other, the oil at each end of the cylinder being exhausted through ports in the cylinder (high gear). MAKERS: Armstrong Siddeley Motors. Ltd., Coventry.

ASPIN

HTHE salient feature in the unconventional Aspin engine -*- is the .rotary combustion chamber, which takes the form of an inverted hollow cone rotated by gearing over the top of the cylinder. As this cone revolves, a port in its side moves over the inlet and exhaust ports, thus providing communication with the combustion chamber. The sparking plugs are cut off from the contents of the cylinder except at the actual moment of ignition. Rapid and complete combustion is claimed, and the engine can be run at very high speeds and very high compression ratios. Modifications lately made are said to improve performance considerably. Interesting developments are expected before very long. MAKERS : F. M. Aspin, Ltd., Egyptian Mills, Elton, Bury, Lanes. ..

BRISTOL

' P H E current Bristol range of air-cooled radials comprises -*- the Mercury and Pegasus poppet-valve engines and the Aquila, Perseus, and Hercules sleeve-valve models. The Mercury (now giving 920 h.p. for take-off with 100octane fuel) was developed primarily for installation in

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Ford 350 Navistar 6.0 Diesel Diagnostic PDFDocumento83 páginasFord 350 Navistar 6.0 Diesel Diagnostic PDFChristopher Ramos93% (14)

- PC210LC-8 SPC 18-12-2012Documento442 páginasPC210LC-8 SPC 18-12-2012veeresh83% (6)

- Service.: AUDI A2 - Engine and GearboxDocumento44 páginasService.: AUDI A2 - Engine and GearboxAlex StirbuAinda não há avaliações

- Internal Combustion Engine Parts: 1.crankshaft-Is 8.wrist Pin - 15.exhaustDocumento3 páginasInternal Combustion Engine Parts: 1.crankshaft-Is 8.wrist Pin - 15.exhaustAngelika Pangilinan100% (1)

- Shor BRQS.: of RochesterDocumento1 páginaShor BRQS.: of Rochesterseafire47Ainda não há avaliações

- "Mercury" Makes GoodDocumento1 página"Mercury" Makes Goodseafire47Ainda não há avaliações

- Gtsac : Flight Engineering SectionDocumento1 páginaGtsac : Flight Engineering Sectionseafire47100% (1)

- 598 Flight.: DECEMBER I 6, 1937Documento1 página598 Flight.: DECEMBER I 6, 1937seafire47Ainda não há avaliações

- 203 Sample ArticleDocumento8 páginas203 Sample Articleseafire47Ainda não há avaliações

- SB2U VindicatorDocumento11 páginasSB2U Vindicatorseafire47100% (1)

- 7 Moundsville Lone Eagle 94Documento9 páginas7 Moundsville Lone Eagle 94seafire47Ainda não há avaliações

- Modeller's Guide To Early P-51 Mustang VariantsDocumento10 páginasModeller's Guide To Early P-51 Mustang Variantsseafire47100% (3)

- Splash 1Documento4 páginasSplash 1seafire47100% (1)

- Seversky P-35 in DetailDocumento10 páginasSeversky P-35 in Detailseafire47100% (1)

- North American P-51D in Detail (Revisited) - Wings and TailsDocumento10 páginasNorth American P-51D in Detail (Revisited) - Wings and Tailsseafire47100% (2)

- North American P-51D in Detail (Revisited) - FuselagesDocumento10 páginasNorth American P-51D in Detail (Revisited) - Fuselagesseafire47Ainda não há avaliações

- Modeller's Guide To Late P-51 Mustang VariantsDocumento17 páginasModeller's Guide To Late P-51 Mustang Variantsseafire47100% (1)

- Rockforo Round-Up: UhmnmmrkitDocumento1 páginaRockforo Round-Up: Uhmnmmrkitseafire47Ainda não há avaliações

- Big Deal From BEDEDocumento1 páginaBig Deal From BEDEseafire47Ainda não há avaliações

- Grumman f3f 2Documento14 páginasGrumman f3f 2seafire47100% (1)

- Nene Jet Engines of The Two XF9F-2 Prototypes Were Replaced in Production F9F-2s by PrattDocumento8 páginasNene Jet Engines of The Two XF9F-2 Prototypes Were Replaced in Production F9F-2s by Prattseafire47Ainda não há avaliações

- Timin Chain CaravanDocumento9 páginasTimin Chain Caravanfrancisco AlbaAinda não há avaliações

- Dellorto Manual A Guide 1.1Documento22 páginasDellorto Manual A Guide 1.1viktormotoAinda não há avaliações

- Manual Skoda Octavia 1,4 44kWDocumento96 páginasManual Skoda Octavia 1,4 44kWCornea Horatiu SebastianAinda não há avaliações

- Gas Force Analysis With Considering Connecting Rod WeightDocumento12 páginasGas Force Analysis With Considering Connecting Rod WeightBoovendra VarmanAinda não há avaliações

- Mini-Striker Hoja de DatosDocumento4 páginasMini-Striker Hoja de DatosAlvaro Neisa LopezAinda não há avaliações

- CHAPTER 7 Combustion in SI and CI EnginesDocumento47 páginasCHAPTER 7 Combustion in SI and CI EnginesRushabh PatelAinda não há avaliações

- RX-K Rx-King Electrical 1Documento1 páginaRX-K Rx-King Electrical 1TwinFlatfourAinda não há avaliações

- 5HP Ingersoll Rand SHT2Documento23 páginas5HP Ingersoll Rand SHT2David GaciaAinda não há avaliações

- SSP 921703 20l Chain Driven Tfsi EngineDocumento58 páginasSSP 921703 20l Chain Driven Tfsi EngineJose Ramón Orenes ClementeAinda não há avaliações

- Low Compression, Fault TracingDocumento8 páginasLow Compression, Fault TracingIzz Bahar100% (2)

- 2 MS41-1 MS41-2Documento111 páginas2 MS41-1 MS41-2danielAinda não há avaliações

- Toro 38180 Snowthrower Parts CatalogDocumento16 páginasToro 38180 Snowthrower Parts CatalogDanAinda não há avaliações

- AIM Loggers ECU Connection EFI Euro 2 V006-V009Documento8 páginasAIM Loggers ECU Connection EFI Euro 2 V006-V009GiuseppeAinda não há avaliações

- Husky Preassure Washer - Manual-Owner ManualDocumento8 páginasHusky Preassure Washer - Manual-Owner ManualLeonel RodriguezAinda não há avaliações

- LAV35-40616M Page 1 of 8 Engine Parts List #1Documento8 páginasLAV35-40616M Page 1 of 8 Engine Parts List #1LUCAPRATAinda não há avaliações

- SSP 604 - Audi 30l v6 Tdi Biturbo Engine EngDocumento23 páginasSSP 604 - Audi 30l v6 Tdi Biturbo Engine Engfrancois.garcia31100% (1)

- Turning Moment DiagramsDocumento3 páginasTurning Moment DiagramsDhinesh3693Ainda não há avaliações

- SAMPLE PROBLEM of Otto CycleDocumento19 páginasSAMPLE PROBLEM of Otto CycleBenedict ReductoAinda não há avaliações

- Main Parts List For Cummins QSK60 EngineDocumento4 páginasMain Parts List For Cummins QSK60 EngineMamadou lyAinda não há avaliações

- CRDi Engine DiagnosisDocumento5 páginasCRDi Engine DiagnosisAhmad Nashrullah0% (2)

- Nissan TD27 Engine DataDocumento1 páginaNissan TD27 Engine Datasageis2fast4uAinda não há avaliações

- Small Biogas Engine Conversion Kit Rural ApplicationDocumento43 páginasSmall Biogas Engine Conversion Kit Rural Applicationgkarthikeyan100% (1)

- Especificaciones de valvulasDIDocumento4 páginasEspecificaciones de valvulasDIAlejandro ValenzuelaAinda não há avaliações

- Engine Ct3-44Tv Spare Parts ManualDocumento57 páginasEngine Ct3-44Tv Spare Parts ManualCircle ChanAinda não há avaliações

- Electrice Generator PerkinsDocumento2 páginasElectrice Generator Perkinsveverita3030Ainda não há avaliações

- Repair Instructions - Off Vehicle Aveo 1.6Documento32 páginasRepair Instructions - Off Vehicle Aveo 1.6rectificamos100% (1)