Escolar Documentos

Profissional Documentos

Cultura Documentos

Core Loss Tester

Enviado por

Kastury RNDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Core Loss Tester

Enviado por

Kastury RNDireitos autorais:

Formatos disponíveis

CORE LOSS TESTING IN THE PRACTICAL MOTOR REPAIR ENVIRONMENT

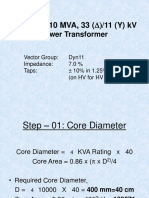

ABSTRACT Lexseco developed the first commercial Core Loss Tester fifteen years ago. Over the years, Lexseco performed thousands of core loss tests in a motor repair shop environment. Hundreds of Lexseco testers are in use around the world. Until now, the only real source of guidance for performing core loss tests has been several articles published in the last decade. This publication will present the mathematical foundations of the toroidal transformer type core loss test and discuss the application of this test procedure to the motor repair environment including common core repair techniques. INTRODUCTION TO LOSSES Before any test procedure for determining core losses and core degradation can be explained, the nature of steel properties should be understood. Ferrous materials have various electrical, magnetic, and mechanical properties that are taken into consideration during the design of an electrical apparatus. The object of the design is typically to maximize output while minimizing the associated electrical and mechanical losses. By design, the motor is known to have a certain level of I2R copper loss, windage and friction, and stray load losses which accompany the specific design parameters of the motor. Similarly, designers choose the grade of core steel, the desired thickness of the steel, and the processing techniques in an attempt to minimize the steel losses without incurring a substantial increase in material costs. These losses are divided into two categories: 1. 2. Hysteresis losses Eddy current losses expended to change the magnetic polarity of the steel in conjunction with the changing polarity of the alternating current waveform. This portion of the total core loss is represented by the shaded portion of the hysteresis curve shown in Figure 1. Ideally, the voltage (VS) to magnetization current (IM) graph would be represented by a single path from A to B equal to the path from B to A. However, due to this increase in expended energy, the path from A to B is not equal to the path from B to A, and a hysteresis loop is developed. The area between the two paths is identically equal to the hysteresis loss. Hysteresis loss will be dissipated in the form of heat. Eddy currents are circulating currents resulting from the magnetic fields generated in the electric motor. Normal eddy current flow is shown in Figure 2.

Figure 2 Normal Eddy Current Flow

When any electrical conductor is placed within a magnetic field, a current proportional to the crosssection of the conductor and the strength of the field is known to flow perpendicular to that field. For this reason, steel lamination thickness is minimized to reduce the amount of eddy current flow.

Figure 1 - Hysteresis Loss Curve

Hysteresis loss is the amount of input energy

When the insulation between laminations breaks down, there is an associated increase in the eddy current flow. At the point of degradation, currents

Copyright 1991. All Rights Reserved Page 1

flow between the laminations as shown in Figure 3. Eddy current loss is the total input power lost to these circulating currents. Like hysteresis loss, eddy current losses are dissipated in the form of heat.

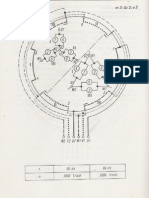

segregated loss method for determining the condition of the core is very impractical. The other method, which is extremely well suited to the motor repair industry, is commonly referred to as the Toroidal Transformer Test or loop test as shown in Figure 4.

Figure 3 - Interlaminar Eddy Current Flow

Summing the eddy current and hysteresis losses will provide the total core losses for any given motor.

Figure 4 - Toroidal Transformer Test

CORE LOSS TEST PROCEDURES Today, there exist two types of tests for determining the total core loss of an electric motor. The first of these is known as the segregated loss method described in the Institute of Electrical and Electronics Engineers (IEEE) Standard 112 and the Canadian Standards Association Standard 390. Using linear regression analysis and various percentage loading characteristics, this test method determines each component of the total losses as well as the subject motor efficiency. When the exact nature of core losses in the complete motor system are required, this type of test is much more effective than any other test of its type. However, the subject motor must be in complete working order. This limits its usage to motor repairs which can be classified as preventive maintenance repairs. Second, the testing procedure must be performed in laboratory controlled environments. Subletting core loss testing to laboratories specifically devoted to motor testing is a costly and time consuming venture. Conservative estimates of the time and cost of segregated loss testing is approximately one day per motor at upwards of $1000 per day. This further reduces the set of motors to non-emergency breakdowns. Obviously, for the motor repair industry, the

While there exist several variations on the toroidal transformer test procedure, they all share the same basic mathematical foundations. The principles underlying the traditional "loop test," and the commercial Core Loss Tester, are based upon an electromagnetic equation known as Faraday's Law. This application of Faraday's Law (1) holds that any laminated steel core assembly, regardless of size or design, can be used as the core of a toroidal transformer. Once excited to a selected backiron flux density, the power lost to the core steel can be measured. More specifically,

v = n(

d ) dt

(1)

where v is the induced voltage, n is the number of turns in the transformer, and is the flux in the core. Given that = BM c (2) where BM is the flux density and c is the crosssectional area of the toroid, we can directly incorporate the flux density (2) into Faraday's Equation (3). i.e.

v = n(

d( B M c) ) dt

(3)

Copyright 1991. All Rights Reserved Page 2

With the loop test, the voltage (v) in Faraday's equation is held constant at the value supplied by the fixed power source. With a known target back iron flux density (BM), this equation can be solved for the number of turns (n). By wrapping the calculated number of turns around the core, the target flux density is achieved. Being both labor intensive and applicable to only stator cores, the loop test is often omitted from the repair procedure of most repair shops. For the commercial core loss tester, the number of turns (n) is held constant at one turn, and the voltage source is varied. This achieves the same goal while simplifying the test procedure. To further enhance the accuracy of the test flux density level, the equation can be further simplified to solve for the flux ( ) instead of the voltage (v). This solution, while proprietary to Lexseco, Inc., is both waveshape and frequency independent, thus removing the effects of inherent transformer harmonics from the equation. Once the target back iron flux density has been reached, the excitation current, induced voltage, and the excitation and resultant power levels are measured. By taking the difference between the excitation power on the primary and the resultant power on the secondary of the toroidal transformer, the loss to the core steel is determined. Copper loss to the transformer winding is assumed negligible due to the size of the conductor used. APPLYING THE CORE LOSS TEST While the theory behind the toroidal transformer test is relatively simple, the application of this theory to various motor designs is complicated and requires further explanation. The watts loss is divided by the weight of the steel to yield an industry accepted standard value of watts-per-pound (kilogram). This value removes one of the remaining variables in the cores under test which is the size of the core. Now, a 500 HP stator core with a known watt loss can be compared to that of a 5 HP stator. Key to evaluating the results of core loss testing is

taking a large random sample of stator core tests. With the aid of statistical analysis, the average core loss and distinct marginal and maximum rejection limits can be calculated. The average core loss (x) is given by

x=

i=1 xi n

n n 2

(4)

and the standard deviation ( ) of the statistical population is defined as

(x -x ) = i=1 i n 2

(5)

After careful examination of the graphical results, it is seen that the lower limit (L1) can be equated as

L1 = x -

(6)

and the upper limit (L2) can be equated as

L2 = x +

(7)

Assuming that the average stator core is marginal and would require some repair, the three bands created by the addition of the lower and upper limits can now be classified. Motor cores in the region defined from 0 watts-per-pound to the lower limit (L1), named the marginal limit, are classified as good stator cores requiring little or no repair. From the marginal limit to the upper limit (L2), named the maximum limit, are marginal cores requiring more extensive repairs. The outer band, with watts-perpound greater than the maximum limit, is considered to contain bad cores. These cores are usually known to have significant damage to the core iron and interlaminar insulation system and cannot always be satisfactorily repaired. As with any statistical calculation, the size of the sample (n) determines the accuracy or the confidence level of the calculations. A sample statistical population (n = 1006) is shown in Figure 5.

Copyright 1991. All Rights Reserved Page 3

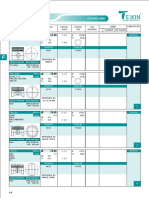

frame into the industrial sector can be easily analyzed and incorporated into the multiparameter testing environment in a relatively short amount of time. BEYOND STATOR TESTING One distinct advantage of the commercial core loss tester over the multiple turn loop test is the ability to achieve excitation in the rotating member of both AC (wound and squirrel cage rotors) and DC (armatures) machines. For wound rotors and armatures, the methods already described are easily adapted. For squirrel cage rotors, however, a slightly different approach must be adopted. Except during startup or in the instance of variable speed applications such as wound rotor motors or inverter duty, the frequency in a squirrel cage rotor approaches zero as the machine approaches synchronous speed. Provided the rotor is operating at nearly full speed and does not experience frequent start/stops, rotor losses caused solely by steel degradation can usually be ignored. For those rotors excluded in the above description, the answers provided by testing rotors for losses, bar/endring integrity, and hot spots can be quite helpful in determining the operational integrity of almost any rotor, but the watts-per-pound calculation can be ignored. Because the rotor is not typically driven by a 60 Hz AC waveform as supplied by the core loss tester, the losses determined by the 60 Hz test will contain hysteresis and eddy components that are greatly amplified from the original design criterion. REPAIR OR REPLACE? Once a core loss test has been performed, and the damaged core steel areas have been identified, they must be repaired, the core must be restacked, or the core must be replaced. From an economic standpoint, this decision must be made with both the repair facility's and the end user's best interests in mind. Specialty stator cores and above 50 horsepower stator cores can usually be repaired and rewound for considerably less than the replacement core cost. Below 50 horsepower, however, it is usually more cost effective for the end user to replace the motor than repair/rewind the core.

Figure 5 - Sample Watts per lb Statistical Population

The second key realization is that these rejection limits are dynamic. Original-NEMA frame motors, constructed of thicker laminations and lower grades of core steel, have an average core loss greater than the maximum rejection limit of the T-Frame motor, regardless of horsepower. Since Original-NEMA frames have been replaced by U-Frames and subsequently by T-Frames, whose averages are respectively 25% and 50% less than Original-NEMA, the general test average has trended downward. For this reason, test comparisons should be performed against a sample of similar motors, and hence the creation of multiparameter testing. In multiparameter testing, distinct marginal and maximum rejection limits for each of the various frame classifications (including Pre-NEMA, OriginalNEMA, T-Frame, U-Frame, High Efficiency, AboveNEMA and IEC frames) are generated. This insures that the subject test core is being compared to cores of similar type and design. With the Above-NEMA frames, making a similar comparison requires that the nameplate rated efficiency and the manufacture date be within the same period. Similarly, a statistical sample of nearly identical special purpose motors must be made to provide any useful information regarding the condition of the core steel. Collecting a sample population large enough to perform statistical analysis is not an easy task. A single motor shop assembling data may spend a year or more before achieving any level of confidence. To expedite this procedure, the results obtained by more than one motor repair facility should be collected. If statistically analyzed on a regular basis, this information will dynamically track the trends in the motor industry. The introduction of a new motor

Copyright 1991. All Rights Reserved Page 4

Beyond the economic factors, rewinding a damaged stator core with satisfactory results depends on the repair techniques used. The following list of common repair techniques are provided, but are by no means exclusive. Without exception, the object of the repair is the reduction or elimination of the damaged areas while minimizing the deformation of the core steel. CRACKING: (Also referred to as bumping or pounding.) Of the most common repair practices for reducing watts-per-pound loss and clearing hot spot areas, cracking will usually provide the best results without removing core iron or deforming the core. Since the process can be performed in a relatively short period of time with standard shop tools, it should be performed before attempting any other techniques. This technique may be applied to the stator, wound rotor, or armature. By striking the back iron section of the outside lamination with a mallet (or hit pin and hammer), the shorted laminations will vibrate and often separate. SPREADING: Like cracking, this technique does not remove steel from the test core, but it does require that the laminations be spread apart. In many cases, spreading of the laminations can clear up hot spot areas which remain after cracking. Using a screwdriver or similar tool and dragging the surface of the affected tooth area will provide sufficient interlaminar separation for insulation to be applied. GRINDING: Grinding is typically used to remove shorted iron caused by mechanical failures. (i.e. Copper blown in the slot or rotor dragging the stator tooth surface). When handled properly, areas can be cleared without the removal of excessive amounts of steel. Filing or grinding the affected areas may produce a significant reduction in the watts-perpound. Once the desired results have been achieved, the final and most critical step in the repair process is reinsulating the core. When the improvement in core condition is substantial enough to warrant the rewind of the core, the core stack must be reinsulated to prevent the return of the damaged areas. The core should be returned to its original form before the rewind. An optional step in this procedure is a final core loss test to verify that the core condition has not returned to its original state (Some change is acceptable). CONCLUSIONS Several methods for determining the core losses in an electric motor exist, and each has advantages and disadvantages over its counterparts. When utilized properly, the commercial core loss tester is effective for determining the condition of motor core steel in a practical motor repair environment. Combined with an aggressive data collection and evaluation strategy and the proper repair techniques, it can adapt to changing motor designs and insure that the repaired motor, which is generally more economically gratifying to the end user than a new replacement, will provide an adequate return on investment. Warranty repairs due to bad core iron will be greatly reduced. For motor repair facilities and end users alike, this is a win-win situation.

Copyright 1991. All Rights Reserved Page 5

Você também pode gostar

- Fault Code 195 Coolant Level Sensor Circuit - Voltage Above Normal or Shorted To High SourceDocumento13 páginasFault Code 195 Coolant Level Sensor Circuit - Voltage Above Normal or Shorted To High SourceAhmedmah100% (1)

- Green Tea ExtractDocumento28 páginasGreen Tea ExtractNikhil TribhuwanAinda não há avaliações

- Inspection and Test Plan For Power Transformer PDFDocumento6 páginasInspection and Test Plan For Power Transformer PDFSiva Kumar100% (1)

- Synchronous Generator Transient AnalysisDocumento11 páginasSynchronous Generator Transient AnalysisSBNSSenanayakeAinda não há avaliações

- Calculating Motor Start TimeDocumento8 páginasCalculating Motor Start TimeRaj SekharAinda não há avaliações

- Calculating Motor Start TimeDocumento8 páginasCalculating Motor Start TimeRaj SekharAinda não há avaliações

- Gen Write UpDocumento11 páginasGen Write Upsarirag100% (1)

- El Cid Handout PP v1Documento66 páginasEl Cid Handout PP v1Carlos MolinaAinda não há avaliações

- Case StudiesDocumento32 páginasCase StudiesSE Electrical100% (1)

- Electrical Safety and Protection of Ehv Substation Including The Effects of Power System TransientsDocumento62 páginasElectrical Safety and Protection of Ehv Substation Including The Effects of Power System TransientsMuhammad Asif IqbalAinda não há avaliações

- Field Inspection and Test ReportDocumento19 páginasField Inspection and Test ReportAe SuwaphanAinda não há avaliações

- Machine Protection PDFDocumento14 páginasMachine Protection PDFAbdelsalam ElhaffarAinda não há avaliações

- Instruction Manual FOR Large Vertical A.C. Motors: Bharat Heavy Electricals Limited, Bhopal (M.P.)Documento40 páginasInstruction Manual FOR Large Vertical A.C. Motors: Bharat Heavy Electricals Limited, Bhopal (M.P.)PraveenKvAinda não há avaliações

- 5 - Tank Itp - Inspection & Test Plan For TanksDocumento10 páginas5 - Tank Itp - Inspection & Test Plan For TanksAhmed Hassan100% (2)

- Motors and GeneratorsDocumento8 páginasMotors and GeneratorsHealthyCut FarmsAinda não há avaliações

- Transformer Protection and Transformer FaultDocumento3 páginasTransformer Protection and Transformer FaultThirumalAinda não há avaliações

- 35MW Generator Test ReportDocumento10 páginas35MW Generator Test ReportAshok KumarAinda não há avaliações

- 4.various Tests Part 1Documento69 páginas4.various Tests Part 1Rohit JoshiAinda não há avaliações

- Testing of InsulationDocumento27 páginasTesting of Insulationகவி பாரதி முத்துசாமிAinda não há avaliações

- FAQ QuantaDocumento11 páginasFAQ Quantarss56Ainda não há avaliações

- Motor Selection 1Documento22 páginasMotor Selection 1abhishek_918Ainda não há avaliações

- Circuit Breaker Types and TestingDocumento30 páginasCircuit Breaker Types and TestingAnuj GuptaAinda não há avaliações

- Electric Motors: By: Muhammad Azhar HussainDocumento28 páginasElectric Motors: By: Muhammad Azhar HussainShaami AtmAinda não há avaliações

- Manufacturing of Turbo Generators in BHELDocumento8 páginasManufacturing of Turbo Generators in BHELPraveen KumarAinda não há avaliações

- ABB-DMI Type DC Machines Operating and Maintenance InstructionsDocumento48 páginasABB-DMI Type DC Machines Operating and Maintenance InstructionsElafanAinda não há avaliações

- Generator Electrical Test #3Documento2 páginasGenerator Electrical Test #3Santoshkumar GuptaAinda não há avaliações

- Stator Earth Fault in 200MW Generator-A Case StudyDocumento5 páginasStator Earth Fault in 200MW Generator-A Case StudylrpatraAinda não há avaliações

- Instrument Data Sheets FormatsDocumento165 páginasInstrument Data Sheets Formatsrathnam.pm100% (1)

- Sizing Generators For Leading Power FactorDocumento9 páginasSizing Generators For Leading Power Factor최형식Ainda não há avaliações

- Alternator TestingDocumento40 páginasAlternator TestingAmit BiswasAinda não há avaliações

- Test On TransformerDocumento13 páginasTest On TransformerGurvinder Singh Virdi100% (2)

- IS 2026-2 (2010) - Power Transformers, Part 2 - Temperature-RiseDocumento17 páginasIS 2026-2 (2010) - Power Transformers, Part 2 - Temperature-Riserajiv71Ainda não há avaliações

- GVPI Assessment-EASA 2014 v2Documento7 páginasGVPI Assessment-EASA 2014 v2mersiumAinda não há avaliações

- Chapter 2-2 - Induction MotorDocumento33 páginasChapter 2-2 - Induction MotorHanis SyafiqAinda não há avaliações

- Micadur Compact Industry Insulation System For RotatingDocumento8 páginasMicadur Compact Industry Insulation System For Rotatingreygrant3900100% (2)

- Core Loss Testing in The Practical Motor Repair EnvironmentDocumento5 páginasCore Loss Testing in The Practical Motor Repair EnvironmentPradeep KumarAinda não há avaliações

- Circuit BreakerDocumento70 páginasCircuit BreakerBADAL CHOUDHARYAinda não há avaliações

- 3606&3608 Mar PRJ Guide - LEBM0600Documento124 páginas3606&3608 Mar PRJ Guide - LEBM0600della alAinda não há avaliações

- Beckwith-Optimizing Performance of Fast Bus Transfer Scheme PDFDocumento5 páginasBeckwith-Optimizing Performance of Fast Bus Transfer Scheme PDFKrishna VenkataramanAinda não há avaliações

- Induction MotorDocumento45 páginasInduction Motorjigar_gajjar_9Ainda não há avaliações

- Design Case StudyDocumento14 páginasDesign Case Studyp m yadavAinda não há avaliações

- Basics of Steel MakingDocumento26 páginasBasics of Steel MakingakshukAinda não há avaliações

- Avoiding Flashover in Medium-Voltage SwitchgearDocumento7 páginasAvoiding Flashover in Medium-Voltage SwitchgearJuvencio MolinaAinda não há avaliações

- Catalogue SGF Eng PDFDocumento8 páginasCatalogue SGF Eng PDFrimce77Ainda não há avaliações

- Introduction To Process Plant Layout & Piping DesignDocumento91 páginasIntroduction To Process Plant Layout & Piping DesignRaj Kamal0% (1)

- Auma Button Type Manual PDFDocumento80 páginasAuma Button Type Manual PDFMotorola AndroidAinda não há avaliações

- R&i - Generator, GT, UatDocumento46 páginasR&i - Generator, GT, UatPradeep SinghAinda não há avaliações

- Transformer MaintenancDocumento13 páginasTransformer MaintenancAnonymous m4MF1gAinda não há avaliações

- Maintenance of TrafoDocumento4 páginasMaintenance of TrafoNauval Bangbang Dwi PutraAinda não há avaliações

- Insulation ResistanceDocumento22 páginasInsulation Resistancewikyarif100% (5)

- VCBDocumento3 páginasVCBMitesh GandhiAinda não há avaliações

- Bearing HeaterDocumento5 páginasBearing HeaterAnand KatariyaAinda não há avaliações

- Arcing HornDocumento2 páginasArcing HornSureshraja9977100% (1)

- Seminar Topic On: Circuit Breaker-IDocumento25 páginasSeminar Topic On: Circuit Breaker-IParameshwar TummetiAinda não há avaliações

- Insulators: Submitted byDocumento18 páginasInsulators: Submitted byGurpreet UppalAinda não há avaliações

- Testing of Turbo Generator: Chapter-1IntroductionDocumento4 páginasTesting of Turbo Generator: Chapter-1Introductionemmanuel akaAinda não há avaliações

- AC Motor Name Plate - Terms & MeaningsDocumento2 páginasAC Motor Name Plate - Terms & Meaningsavandetq15Ainda não há avaliações

- Power TransformerDocumento55 páginasPower TransformerPrakash KumarAinda não há avaliações

- CB76 3261Documento7 páginasCB76 3261rodruren01Ainda não há avaliações

- IE RulesDocumento35 páginasIE Rulessubho100% (1)

- Battery Charging ProcedureDocumento3 páginasBattery Charging ProceduremuthakkerAinda não há avaliações

- Testing & Commissioning of Electrical EquipmentDocumento16 páginasTesting & Commissioning of Electrical EquipmentAnkit YadavAinda não há avaliações

- Circuit BreakerDocumento18 páginasCircuit Breakersrinu247Ainda não há avaliações

- HT TransformerDocumento6 páginasHT TransformerMaintenance CircleAinda não há avaliações

- Is 3842 2 1966Documento21 páginasIs 3842 2 1966Ramesh AnanthanarayananAinda não há avaliações

- Difference Between AC and DC Hi PotDocumento1 páginaDifference Between AC and DC Hi Potunnikrish05Ainda não há avaliações

- Controlled Switching of High-Voltage Circuit-BreakersDocumento8 páginasControlled Switching of High-Voltage Circuit-BreakersBaris GurbuzAinda não há avaliações

- In Situ Testing of Large MachinesDocumento1 páginaIn Situ Testing of Large MachinesKastury RNAinda não há avaliações

- Document Details: United States Dollars (USD)Documento1 páginaDocument Details: United States Dollars (USD)Kastury RNAinda não há avaliações

- Automotive Emc StandardsDocumento1 páginaAutomotive Emc StandardsKastury RNAinda não há avaliações

- 4P BrushDocumento1 página4P BrushKastury RNAinda não há avaliações

- 2 Pole 2 Parallel ConnectionsDocumento1 página2 Pole 2 Parallel ConnectionsKastury RNAinda não há avaliações

- Eriks - VR Shaft Seals enDocumento7 páginasEriks - VR Shaft Seals enKastury RNAinda não há avaliações

- ABB Motor Efficiency EasierDocumento1 páginaABB Motor Efficiency EasierKastury RNAinda não há avaliações

- TESTMETHDocumento4 páginasTESTMETHKastury RNAinda não há avaliações

- 03 Energy Efficient Electric Motor Selection Handbook PDFDocumento65 páginas03 Energy Efficient Electric Motor Selection Handbook PDFnicu_psiAinda não há avaliações

- Fact Sheet ThreeDocumento4 páginasFact Sheet ThreeRodrigo VargasAinda não há avaliações

- Leyte Geothermal Power Progressive Employees UnionDocumento3 páginasLeyte Geothermal Power Progressive Employees Unionaags_06Ainda não há avaliações

- DISCOVER DTS I SRR PDFDocumento24 páginasDISCOVER DTS I SRR PDFLunatikus EklectikusAinda não há avaliações

- 487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing TransformersDocumento55 páginas487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing Transformersjose eduardo mejia sanchezAinda não há avaliações

- JSW SteelDocumento44 páginasJSW Steelauttyhubli100% (1)

- Agc Structure For Smart GridsDocumento14 páginasAgc Structure For Smart GridsAkash NaiduAinda não há avaliações

- Turret & Installation Challenges: Espirito Santo FPSODocumento26 páginasTurret & Installation Challenges: Espirito Santo FPSOUthanmalliah NagarajanAinda não há avaliações

- 2007 Oprema Za Gole I Izolirane Nadzemne Elektromagnetske Mreze HR PDFDocumento212 páginas2007 Oprema Za Gole I Izolirane Nadzemne Elektromagnetske Mreze HR PDFTarik KrivokapaAinda não há avaliações

- Fuel, Lubricants and Fluids: en-GBDocumento59 páginasFuel, Lubricants and Fluids: en-GBRuanAinda não há avaliações

- Vijay Singh CVDocumento2 páginasVijay Singh CVVijay ChauhanAinda não há avaliações

- Waterjet 2008 CondensedDocumento12 páginasWaterjet 2008 Condensedkaniappan sakthivelAinda não há avaliações

- Cloud Point of Diesel Fuel: Application NoteDocumento2 páginasCloud Point of Diesel Fuel: Application Noteanilkumar995472Ainda não há avaliações

- Lam 101-11Documento240 páginasLam 101-11mrcdtsAinda não há avaliações

- Iadc Dull Grading: Cutting StructureDocumento2 páginasIadc Dull Grading: Cutting StructuredayanaAinda não há avaliações

- Catalog - Regent RSV Ed 3Documento14 páginasCatalog - Regent RSV Ed 3Nyu123456Ainda não há avaliações

- Arts NPSH TutorialDocumento3 páginasArts NPSH TutorialDidier SanonAinda não há avaliações

- Urban - Visions - SUP2ER Project 8 - PlannerDocumento14 páginasUrban - Visions - SUP2ER Project 8 - Plannersamanisbest553Ainda não há avaliações

- ChemiTek SOLARWASHPROTECT DATASHEETDocumento2 páginasChemiTek SOLARWASHPROTECT DATASHEETPhani ArvapalliAinda não há avaliações

- Issue 3 Battery Talk Exploding BatteriesDocumento2 páginasIssue 3 Battery Talk Exploding BatterieseigersumarlyAinda não há avaliações

- Teikin Catalog Vol 18-Automotive FiatDocumento6 páginasTeikin Catalog Vol 18-Automotive FiatJuan Esteban Ordoñez BonillaAinda não há avaliações

- MR-E-A-QW003 MR-E - AG-QW003: General-Purpose AC Servo Ezmotion Mr-E Super General-Purpose InterfaceDocumento326 páginasMR-E-A-QW003 MR-E - AG-QW003: General-Purpose AC Servo Ezmotion Mr-E Super General-Purpose InterfaceKailas PardeshiAinda não há avaliações

- Hydrocracking Unit PDFDocumento9 páginasHydrocracking Unit PDFcrili69Ainda não há avaliações

- Load Flow - CompleteDocumento24 páginasLoad Flow - CompleteJohn Cristouv CortezAinda não há avaliações