Escolar Documentos

Profissional Documentos

Cultura Documentos

Basic Transformer

Enviado por

Pin SantosDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Basic Transformer

Enviado por

Pin SantosDireitos autorais:

Formatos disponíveis

Contents

Contents

Foreword ...................................................................................................................iv

Principles of Transformers

Chapter 1 Basic Electrical Theories and Principles ..................................................................1 Chapter 2 Alternating Current and Induction Principles ......................................................17 Chapter 3 Transformers............................................................................................................27 Chapter 4 Transformer Construction......................................................................................35 Chapter 5 Transformer Information, Characteristics.............................................................51 Chapter 6 Transformer Operation...........................................................................................69 Chapter 7 Polarity of Transformers .........................................................................................87 Chapter 8 Tap Changers and Operation .................................................................................95

Single-Phase Transformers

Chapter 9 Install Transformers to Company Standards.......................................................105 Chapter 10 Single-Phase Transformer Connections...............................................................119 Chapter 11 Conduct Transformer Load Checks .....................................................................133 Chapter 12 Energize Transformers Safely................................................................................143

Three-Phase Transformers

Chapter 13 Characteristics of Delta and Wye Systems ...........................................................151 Chapter 14 Three-Phase Transformer Connections ...............................................................161 Chapter 15 Apply Vector Principles for Three-Phase Transformer Connections.................193 Chapter 16 Build Three-Phase Banks to Standard .................................................................217 Chapter 17 Apply Transformer Connections..........................................................................225 Chapter 18 Calculate Load Checks on Delta and Wye Banks................................................247 Chapter 19 Describe Phasing and Paralleling Procedures for Three-Phase Circuits............257 Chapter 20 Ferroresonance .......................................................................................................267 Appendices.............................................................................................................279

iii

Transformation for Lineworkers

Describe Transformer Construction

Figure 4-1 illustrates a distribution transformer with the tank partly cut away to show the internal equipment.

HIGH-VOLTAGE TERMINALS HIGH-VOLTAGE COVER BUSHINGS

FLUIDIZED-BED COATING ONE-PIECE COVER BAND TAP CHANGER

INSPECTION PLATE LOW-VOLTAGE TERMINALS LOW-VOLTAGE BUSHING

SECONDARY LEADS

CORE CLAMP BRACKETS

CORE AND COIL ASSEMBLY

Figure 4-1. Distribution transformer construction.

Basically, a transformer consists of the primary and secondary coils, iron core, insulation, and the container or tank. Other features may be added, such as tap changing mechanisms, internal secondary breakers, internal primary fuses, or lightning arrestors. The larger power transformers have many more features, such as oil conservator tanks, oil-filled bushings, cooling tubes, cooling fans, and heat indicating equipment.

Primary and Secondary Coils

It is customary to use copper wire in the manufacture of transformer windings. Before the introduction of modern insulation materials, the copper conductor was wrapped with a thin cotton cover which added significantly to the bulk of the overall winding. Todays transformer uses enamel insulated copper wire, and because the insulation is of a better grade and is much thinner than the cotton insulation, improved electrical characteristics as well as compactness are obtained. Round wire is used in some of the smaller transformers, while square or rectangular wire is normally used in medium-sized and larger-sized transformers. Square and rectangular wires form a more compact and solidly built coil, and also provide better conductivity for the heat to flow out of the windings.

36

Chapter 5: Transformer Information, Characteristics

Identify Internal and External Leads

For the connection of a distribution transformer to primary and secondary distribution circuits, it is important that: Each lead that emerges from the winding be correctly identified. Correct connection of each lead to the bushings match the external connection required.

The primary leads usually present no problem because the manufacturer connects the leads to the designated bushings at the time of assembly. Similarly, the high voltage taps are permanently connected to the tap changing switch or terminal board. Connection of the secondary leads is a different matter. While the normal secondary connection is a series connection of the two secondary coils, the same coils may be placed in parallel operation in the following instances: Where the intention is to establish a 120/208 volt three-phase fourwire wye connected secondary using three transformers. For parallel-series operation of two transformers used to temporarily replace one larger transformer. In specific cases, where 120 volts two-wire single phase is required, using the total capacity of the transformer.

The secondary winding of a distribution transformer normally consists of two separate windings, and each of the two windings is designed to produce one-half of the secondary output voltage. The two windings connected in series would produce the total secondary output voltage. Figure 5-6 illustrates the internal winding leads for additive and subtractive distribution transformers.

H1 ADDITIVE A A X3 B C X2 C B D D X1 D D X1 H2 H1 H2

SUBTRACTIVE C B X2 B C A A X3

Figure 5-6. Internal winding leads for additive and subtractive distribution transformers.

The letters on the secondary leads indicate that A and B designate the leads of one coil, while C and D designate the leads of the other coil. The center leads B and C cross over at a point near the core and windings and emerge above the oil in the crossed position.

57

Chapter 6: Transformer Operation

Transformers are tapped up one tap at a time if required, but only after the voltage conditions have been checked on a 24 hour basis. Recording voltmeters and other instruments are used for this purpose. On-load tap changers differ in design and purpose from off-load tap switches. These may be found on the large power transformers and on regulators. As the name implies, the on-load tap changer is designed to tap the winding up or down, as voltage conditions require, without interrupting the load circuit. At some point in the transition from one tap to another, both taps must be joined together; and as the two taps will be at different voltages with respect to the end of the transformer winding, a circulating current will flow in the (bridge) circuit. This circulating current is limited to a safe value by using either a center-tapped reactor or a preventative autotransformer in the bridge circuit.

Describe Transformer Winding Taps

Older double-bushing distribution transformers were usually built with three percentage taps below full winding. Figure 6-2 illustrates an elementary primary winding with tap percentages shown.

FULL WINDING

(F.W.) - 4 1/2% (F.W.) - 9% (F.W.) - 13 1/2%

Figure 6-2. Elementary primary winding.

The taps are provided to permit changes in the voltage ratio. Changing the number of primary turns in use will change the ratio of the transformer, and in this way we can either raise or lower the secondary voltage when the primary (applied) voltage is consistently high or low. Examination of Figure 6-2 will show that placing the transformer on 4.5%, 9%, or 13.5% tap actually means we are cutting out this percentage of the primary winding or, full winding minus 4.5%, full winding minus 9%, etc. The following table (see Figure 6-3) shows what the primary voltage setting will need to match a corresponding drop in primary line voltage and in order to produce 120/240 volts at the secondary terminals of the transformer.

75

Chapter 9: Install Transformers to Company Standards

Self Test Answers

Note: Answers to the fill-in-the-blank questions are italicized. 1. 2. All transformer tanks must be grounded during installation and before energization. You would find the information that identifies secondary drop lead sizes in the company standards manual. See also, Figure 9-1. You would select a 2/0 AWG copper for a 50 kVA 120/240 volt transformer installation. Pre-installation checks that you would make before installing a transformer include checking 5. Primary voltage rating Secondary voltage rating kVA capacity Internal connections to ensure that they are tight Loose or cracked bushings and terminals The dual voltage switch and placing it in the correct position for the installation The case ground to ensure it is intact

3. 4.

A CSP transformer means that it is completely self-protected. It is equipped with lightning arresters, a secondary breaker and internal primary fuse links. When the red light of the CSP transformer is on, it means that that transformer is slightly overloaded. You would obtain information regarding correct fuse sizes for transformer installations in the company standard fuse charts. For a 50 kVA, 14,400 - 120/240 volt transformer installation, you would select a 5H fuse.

6.

7.

8.

117

Transformation for Lineworkers

9.

Following are the differences between a conventional transformer and a CSP: A CSP transformer is completely self-protected and is equipped with lightning arresters, a secondary breaker and internal primary fuse links. A conventional transformer is fused externally at a disconnect and is only protected by lightning arresters when a utility chooses to do so because of a high frequency lightning area.

10. Secondary leads are sized to at least 100% of currents shown for a given transformer size and voltage that the drop lead is used for.

If you had any problems with this Self Test, please review the material and, if necessary, see your sponsor before proceeding.

118

CHAPTER 12

Energize Transformers Safely

Introduction

Before energizing a transformer, checks must be done to ensure that everything is in order. After energizing a transformer more checks must be done to ensure that it is operating as required. The topics covered in this chapter are: Inspect and troubleshoot Energize transformers safely Perform post-energization checks

143

Transformation for Lineworkers

As discussed earlier, the line-to-line voltage is equal to the winding voltage of the transformers. In this case, the secondary winding voltage is 240 volts, therefore, the line-to-line voltage will also be 240 volts. In a four-wire delta secondary, the neutral or mid point of one of the secondary windings is grounded so that singlephase 120/240 volt service can also be supplied from the same bank. Voltages to ground are established as soon as this ground connection is made to one transformer. By referring to Figure 14-10 and 14-11 it is easy to establish the a - N voltage is 120 volts and the b - N voltage as 120 volts. What then, is the voltage from c to neutral (c - N)? This phase is what is commonly referred to as the high or wild leg, or bastard phase and its voltage to neutral will always be 1.73 times the phase to neutral voltage of the grounded transformer. In this example, the c - N voltage is 1.73 120 = 208 volts. This can be easily seen in a simple vector diagram of the connections. Figure 1412 illustrates a vector diagram of the connection shown in Figure 14-10.

b 120 V C PHASE IS THE FARTHEST DISPLACEMENT FROM THE NEUTRAL POINT 120 V 240 V 208 V b

240 V

Figure 14-12. Vector diagram of the connections.

Note: The c - N is a voltage through a full transformer winding and a half. The full winding is 120 displaced from the half winding. By referring to the vector representation of the secondary in Figure 14-12, it should be easy to establish the following voltages: a - b = 240 volts b - c = 240 volts a - c = 240 volts a - N = 120 volts b - N = 120 volts c - N = 208 volts

As stated before, the c - N voltage will be 1.73 times the phase to neutral voltage of the grounded transformer. In this case, the voltage c - N = 208 volts. If the secondary diagram in Figure 14-12 is drawn to scale with each angle 60 degrees, a measurement from c - N will also indicate 208 volts. Always remember that the phase which is not connected to the grounded transformer is the bastard phase or phase which will measure approximately 208 volts to neutral. Common delta three phase service voltages are 240 volts and 480 volts.

168

Transformation for Lineworkers

Self Test Answers

1. Standard three phase wye-wye 120/208V connection diagram using 3 x 75 kVA 120/240V transformers.

H1

H2

H1

H2

H1

H2

X4 X3 X2

X1

X4 X3 X2

X1

X4 X3 X2

X1

2.

Standard three phase wye-delta 240V connection diagram using 3 x 75 kVA 120/240V transformers.

H1

H2

H1

H2

H1

H2

X3 X2

X1

X3 X2

X1

X3 X2

X1

222

Chapter 20: Ferroresonance

I= E R

I=

E X+R

XL = 0

XC = XL

XL

Figure 20-2. AC circuit response curve.

Now consider the typical case of a three-phase pad or pole mounted floating neutral wye/delta connected transformer installation, fed via an overhead tap or underground cable run from pole mounted cutouts, switching kiosk or other supply point (Figure 20-3).

POLE MOUNTED CUTOUTS, SWITCHING KIOSK, ETC. TO MAIN LINE (SOURCE) 2 CUTOUTS CLOSED 1 CUTOUT OPEN 3 PHASE TRANSFORMER BANK (PADMOUNT OR OVERHEAD) 3 PHASE INSULATED (FLOATING) NEUTRAL

2 CONDUCTORS OR CABLES ENERGIZED AT LINE VOLTAGE

CAPACITIVE REACTANCE (XC) TO GROUND OF OPEN CONDUCTOR(S) OR CABLE(S) IS IN SERIES WITH INDUCTIVE REACTANCE (XI) OF TRANSFORMER(S)

Figure 20-3. Three-phase pad mounted installation.

Under switching conditions with one (or two) cutouts open and the other two (or one) cutouts closed, Figure 20-3 can be represented by the same circuit configuration as Figure 20-1, except that the capacitive reactance (XC) is provided by those conductors or cables that are not connected to the source, and the inductive reactance (XL) by the iron core primary winding of the energized transformers.

269

Você também pode gostar

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesNo EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesAinda não há avaliações

- M.Tech Power System PDFDocumento30 páginasM.Tech Power System PDFRaja RamachandranAinda não há avaliações

- 2-Contractors and RelaysDocumento13 páginas2-Contractors and RelaysMais AlsharifAinda não há avaliações

- TransformerDocumento9 páginasTransformerSamPolancosAinda não há avaliações

- Linear SolenoidsDocumento20 páginasLinear SolenoidsAndrei ReventAinda não há avaliações

- Power Control Devices Report Ni SottoDocumento61 páginasPower Control Devices Report Ni SottoLEONEL SOTTOAinda não há avaliações

- Lecture 5 Power Factor ImprovementDocumento54 páginasLecture 5 Power Factor ImprovementMohammed ShifulAinda não há avaliações

- 1 Tutorial Handouts 150Documento80 páginas1 Tutorial Handouts 150GokulGopiAinda não há avaliações

- Alternative Gas To SF6 For Use in High Voltage Switchgears - g3 PDFDocumento5 páginasAlternative Gas To SF6 For Use in High Voltage Switchgears - g3 PDFNoé Rafael Colorado SósolAinda não há avaliações

- Construction of Three Phase Induction MotorDocumento6 páginasConstruction of Three Phase Induction MotorMuhammadZaydArattKhanAinda não há avaliações

- 01 Transformer ConstructionDocumento32 páginas01 Transformer Constructionedin_huseinbegovicAinda não há avaliações

- Automatic Battery ChargerDocumento2 páginasAutomatic Battery ChargervipincktyAinda não há avaliações

- How Electricity Works Book 4Documento9 páginasHow Electricity Works Book 4mrshong5bAinda não há avaliações

- Ansi/Ashrae/Iesna Standard 90.1-1999/2001/2004Documento13 páginasAnsi/Ashrae/Iesna Standard 90.1-1999/2001/2004Win San HtweAinda não há avaliações

- How To Select A Variable Frequency DriveDocumento6 páginasHow To Select A Variable Frequency Drivedavid_diaz_sAinda não há avaliações

- Smartplant ElectricalDocumento1 páginaSmartplant ElectricalGEETHA PUSHKARANAinda não há avaliações

- IE Rules For DP Structure - Electrical Notes & ArticlesDocumento10 páginasIE Rules For DP Structure - Electrical Notes & Articleshemant kumarAinda não há avaliações

- Bus Bar Schemes-NewDocumento41 páginasBus Bar Schemes-Newbedilu770% (1)

- What Is The Difference Between MCB MCCB ELCB and RCCBDocumento5 páginasWhat Is The Difference Between MCB MCCB ELCB and RCCBSebastianCicognaAinda não há avaliações

- Voltage Drop and Load Flow AnalysisDocumento77 páginasVoltage Drop and Load Flow Analysisrfactor0976Ainda não há avaliações

- Electrical Components in A SubstationDocumento8 páginasElectrical Components in A SubstationpantherAinda não há avaliações

- Electrical Installations and Systems EI449362 NVQ2 C14 P331 388Documento58 páginasElectrical Installations and Systems EI449362 NVQ2 C14 P331 388robpeter2425Ainda não há avaliações

- Effects of Harmonics On Induction MotorsDocumento5 páginasEffects of Harmonics On Induction Motorsrbargallo0Ainda não há avaliações

- Electrical Power DistributionDocumento3 páginasElectrical Power DistributionRustha123Ainda não há avaliações

- Relay and Contactor in DetailDocumento12 páginasRelay and Contactor in DetailSafen Bakr SiwailyAinda não há avaliações

- Contactors and Motor StartersDocumento5 páginasContactors and Motor StartersZdan AhmadAinda não há avaliações

- Electrical DesignDocumento50 páginasElectrical DesignNethajiAinda não há avaliações

- Introduction To TransformersDocumento186 páginasIntroduction To TransformerscaplukAinda não há avaliações

- Power SystemDocumento155 páginasPower SystemMELVINAinda não há avaliações

- Construction and Working of 3 Phase Induction MotorDocumento3 páginasConstruction and Working of 3 Phase Induction MotorArdyas Wisnu BaskoroAinda não há avaliações

- What Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPDocumento5 páginasWhat Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPcurazaq100% (1)

- Stability of Power SystemDocumento11 páginasStability of Power Systemhasbi fadliAinda não há avaliações

- Practical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsNo EverandPractical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsAinda não há avaliações

- Electric Motors and GeneratorsDocumento30 páginasElectric Motors and GeneratorshafizrahimmitAinda não há avaliações

- English M21 Inverter, UPS and Battery (SSEE4)Documento12 páginasEnglish M21 Inverter, UPS and Battery (SSEE4)john power100% (1)

- Dokumen - Tips - Free Download Here Wiring Estimating and Costing by Uppalpdf Free Download Here PDFDocumento2 páginasDokumen - Tips - Free Download Here Wiring Estimating and Costing by Uppalpdf Free Download Here PDFKanav Mahajan100% (1)

- Circuit Breakers Lecture Notes 3Documento124 páginasCircuit Breakers Lecture Notes 3Varun NarisettyAinda não há avaliações

- HVE Course FileDocumento51 páginasHVE Course Fileprathap kumarAinda não há avaliações

- Enerlin'X FDM128: Ethernet Display For Eight Devices User GuideDocumento76 páginasEnerlin'X FDM128: Ethernet Display For Eight Devices User GuideShailesh ChettyAinda não há avaliações

- Bus Riser - CouplerDocumento3 páginasBus Riser - CouplerMarey MorsyAinda não há avaliações

- Electrical Interview QuestionsDocumento3 páginasElectrical Interview QuestionsAndile CeleAinda não há avaliações

- BL0683 6EJ517 Electronic Devices and SystemsDocumento19 páginasBL0683 6EJ517 Electronic Devices and Systemskhan aliAinda não há avaliações

- Motor Control: Case Study: MIT Handy BoardDocumento6 páginasMotor Control: Case Study: MIT Handy BoardIsuru Pasan DasanayakeAinda não há avaliações

- Latest Updated Electrical ENGINEERING & DESIGNDocumento92 páginasLatest Updated Electrical ENGINEERING & DESIGNShivani GuptaAinda não há avaliações

- Load CalculationDocumento6 páginasLoad CalculationBharathi100% (1)

- Circuit BreakerDocumento15 páginasCircuit BreakerYamasani Dileep KumarReddyAinda não há avaliações

- Knowledge is "Real Power": Introduction to Power QualityNo EverandKnowledge is "Real Power": Introduction to Power QualityAinda não há avaliações

- Absolyte Engineering PDFDocumento110 páginasAbsolyte Engineering PDFwizlishAinda não há avaliações

- BEE Assignment Unit 4Documento13 páginasBEE Assignment Unit 4Abhishek RaoAinda não há avaliações

- LEC # 08 Distribution System Voltage RegulationDocumento61 páginasLEC # 08 Distribution System Voltage RegulationSaddam jatt786Ainda não há avaliações

- Study of Different Components and Their Functions of An Air Circuit Braker (ACB)Documento5 páginasStudy of Different Components and Their Functions of An Air Circuit Braker (ACB)Zahid Hasan KhokaAinda não há avaliações

- Basics of SubstationDocumento53 páginasBasics of Substationraza239Ainda não há avaliações

- Power AC Transmission Lines: 3.4 Chapter ConclusionsDocumento49 páginasPower AC Transmission Lines: 3.4 Chapter ConclusionsHassenAinda não há avaliações

- MCB or MCCBDocumento4 páginasMCB or MCCBKurnia FajarAinda não há avaliações

- Current-Limiting Inductors Used inDocumento7 páginasCurrent-Limiting Inductors Used inkgskgmAinda não há avaliações

- Simulation and Analysis of LLC Resonant Converter Using Closed Loop PI ControllerDocumento3 páginasSimulation and Analysis of LLC Resonant Converter Using Closed Loop PI ControllerijaertAinda não há avaliações

- Energy Audit of A 400-220 KV Substation - A Case Study PDFDocumento8 páginasEnergy Audit of A 400-220 KV Substation - A Case Study PDFRajuAinda não há avaliações

- Leak Testing MethodologiesDocumento9 páginasLeak Testing MethodologiesPin SantosAinda não há avaliações

- Bus Bar 1Documento33 páginasBus Bar 1Pin Santos100% (3)

- Maintenance EvaluationDocumento28 páginasMaintenance EvaluationPin Santos100% (1)

- Equipment Breakdown KitDocumento9 páginasEquipment Breakdown KitPin SantosAinda não há avaliações

- Equipment BreakdownDocumento1 páginaEquipment BreakdownPin SantosAinda não há avaliações

- Pfeiffer P3 MSDSDocumento7 páginasPfeiffer P3 MSDSPin SantosAinda não há avaliações

- Materials System SpecificationDocumento10 páginasMaterials System SpecificationHatemS.MashaGbehAinda não há avaliações

- Transmission Line BOQ VIMPDocumento72 páginasTransmission Line BOQ VIMPkajale_shrikant2325Ainda não há avaliações

- Espesificacion de PostesDocumento76 páginasEspesificacion de PostesFlaKo Man La AmeNazaAinda não há avaliações

- Transformer CatalogueDocumento51 páginasTransformer CatalogueFathy RamadanAinda não há avaliações

- TESAR - TransformersDocumento4 páginasTESAR - TransformersIvan HandjievAinda não há avaliações

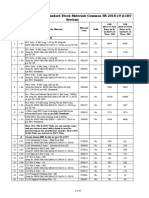

- Schedule of Rate For Standard Stock Materials Common SR 2018-19 (11KV System)Documento33 páginasSchedule of Rate For Standard Stock Materials Common SR 2018-19 (11KV System)Nagaraju NayakAinda não há avaliações

- Compact Sub Station BrochureDocumento8 páginasCompact Sub Station BrochureAnimesh SahaAinda não há avaliações

- Application Information For Busway Rated 600 Volts or Less: NEMA Standards Publication BU 1.2-2002Documento17 páginasApplication Information For Busway Rated 600 Volts or Less: NEMA Standards Publication BU 1.2-2002Nestor-leoAinda não há avaliações

- Last Mile Connectivity Project Kenya: African Development FundDocumento29 páginasLast Mile Connectivity Project Kenya: African Development FundEfosaUwaifoAinda não há avaliações

- IEEE STD C37.101-1985Documento43 páginasIEEE STD C37.101-1985NghiaAinda não há avaliações

- IEEE STD C57.12.32-2002-Standard For Submersible Equipment-Enclosure IntegrityDocumento16 páginasIEEE STD C57.12.32-2002-Standard For Submersible Equipment-Enclosure Integrityjaimito=)Ainda não há avaliações

- Distribution TransformarsDocumento6 páginasDistribution TransformarsBanupriya Balasubramanian100% (1)

- Mahadiscom Dry TypeDocumento22 páginasMahadiscom Dry TypeSANJAY BHATTACHARYAAinda não há avaliações

- 24kV Distribution TransformerDocumento37 páginas24kV Distribution TransformermrhomAinda não há avaliações

- 2 Winding Transformer LongDocumento58 páginas2 Winding Transformer Longnaveendevi13Ainda não há avaliações

- 11kv Packaged Substation-Specification Nit 063Documento54 páginas11kv Packaged Substation-Specification Nit 063M.Senthil Velavan100% (1)

- Dry-Type Transformers: Codes and Standards Enhancement (CASE) StudyDocumento22 páginasDry-Type Transformers: Codes and Standards Enhancement (CASE) StudyAnonymous DJrec2Ainda não há avaliações

- Materials System SpecificationDocumento10 páginasMaterials System Specificationnadeem shaikhAinda não há avaliações

- KEL Transformer DivisionDocumento2 páginasKEL Transformer DivisionRishma RamachandranAinda não há avaliações

- 20 BLDocumento14 páginas20 BLAisah El ArinalAinda não há avaliações

- Rex Power Magnetics CatalogDocumento72 páginasRex Power Magnetics CatalogBrajesh SharmaAinda não há avaliações

- TF TestingDocumento25 páginasTF Testingask4vinod100% (1)

- Switchgear Application Guide 12E3Documento135 páginasSwitchgear Application Guide 12E3andrademaxAinda não há avaliações

- Transformer: Oil ImmersedDocumento16 páginasTransformer: Oil ImmersedEngineerOmarAinda não há avaliações

- BOM For Transformer at Playa LaiyaDocumento3 páginasBOM For Transformer at Playa LaiyaHarold de MesaAinda não há avaliações

- EDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFDocumento14 páginasEDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFLimuel EspirituAinda não há avaliações

- Ieee C57.12.38-2014Documento36 páginasIeee C57.12.38-2014User PcAinda não há avaliações

- Liquid-Filled Medium-Voltage TransformersDocumento5 páginasLiquid-Filled Medium-Voltage Transformersmilner12Ainda não há avaliações

- Transformers Buyer's GuideFinal10-16-17Documento6 páginasTransformers Buyer's GuideFinal10-16-17SachinAinda não há avaliações

- Technical Data Sheet - Distribution TransformerDocumento1 páginaTechnical Data Sheet - Distribution Transformertelogix559Ainda não há avaliações