Escolar Documentos

Profissional Documentos

Cultura Documentos

Tricast Sales Data Sheet en

Enviado por

Duy NguyenDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tricast Sales Data Sheet en

Enviado por

Duy NguyenDireitos autorais:

Formatos disponíveis

Tricast

Cast resin dry type transformer up to 25 MVA - 52 kV

PM102297

01

Tricast Key transformer features

Around the world, customers are demanding eco-friendly solutions for their transmission networks that are not only safe for their personnel but that are also safe for the environment. With todays focus on improving environmental impact and preserving the earths natural resources, Schneider Electrics contribution is to manufacture safe and environmentally friendly equipment : Tricast

PM102289

CUSTOMER BENEFITS

Self-extinguishing Designed for wet or highly polluted environments and areas with high electrical disturbance Excellent load and short-circuit performance Low noise level Space optimization Environmentally friendly E2, C2, F1 Almost zero maintenance (occasional cleaning and recommended checks only)

High quality and reliability make Tricast cast resin transformers the perfect solution for infrastructure projects such as transmission and distribution substations, public buildings and high-rise developments. As Tricast is self-extinguishing, it provides an effective solution for use in industrial installations susceptible to fire hazards. In addition, it meets the needs of special applications such as wind farms and it is the perfect replacement for PCB transformers.

Tricast, the safe eco-friendly solution

Our Tricast range of dry type cast resin transformers complies with all your distribution transformer requirements. Tricast is available as single and three-phase units. With ratings up to 25MVA and 52 kV, 50/60 Hz, it offers AN cooling for continuous indoor service (with AF and outdoor options), and normal or reduced losses.

Tricast meets the following standards:

IEC 60076-11 EN 60726 NF EN 60076-11 and NF C 52-115 VDE 0532 part 6 DIN 42523 ANSI C57.12.01

Quality assurance

All our transformer production sites are certified ISO 9001 or ISO 14001.

02

Tricast Key transformer features

(continued)

Safety & reliability first

To ensure total compliance with the most relevant national and international standards, Tricast transformers have been put through the most stringent series of tests. Tricast is one of few transformers having successfully passed these tests and is characterized by the following features: C2 Insensitive to thermal shocks. Withstands overloads and frequent changes in loading. Dielectric tests of standard. Very resistant to polluted environments and humidity. E2; Immune to corrosive environments. Reduced flammability and self-extinguishing. Excellent classification according to IEC 60076-11 standard: F1 Fire behaviour. Tricast is your best solution for public safety. Whether for industrial plants susceptible to fire hazards or use in public buildings and high rise developments that are occupied or visited by thousands of people per day.

Tricast

Eco-friendly

Because preserving the environment is one of the most important issues today, we have designed our products to help you meet the latest environmental protection guidelines and regulations introduced by national and international governments and institutions. Tricast dry-type cast resin transformers are not only self-extinguishing, they are also free of any risk of leakage of flammable or contaminating substances. Using non-toxic high quality materials, Tricast components are designed to enable the maximum amount to be recycled. Tricast is the best solution to replace existing PCB transformers.

PM102290

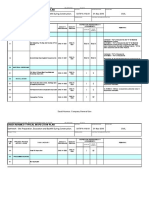

Tricast tests

Electrical and routine tests Winding resistance Voltage ratio and coupling No-load losses and no-load current Short circuit impedance Load losses Dielectric tests Partial discharge testing (acceptable level: 10 pC at 1.30 Ur) Type tests

In addition to the routine tests, the following type tests can be performed on request in Schneider Electric laboratories: Impulse voltage test and temperature rise test.

Specific tests

Noise level test (this test can be performed on request in our laboratories). Short circuit withstand test.

Tests in accordance with IEC 60076-11

The tests to prove compliance with class E2 - C2 - F1 shall be performed on the same unit.

Tricast for a modern world

Minimizing space requirements and associated civil work costs is a major factor in most building projects today. Whether it is for a new city center office block, an expansion in the capacity of an industrial process or a wind farm project, the compact design of Tricast provides a costeffective solution. The exclusive casting system and advanced technology used in its HV windings give Tricast transformers the reliability and operating characteristics needed in the high-technology applications which demand maximum availability and maximum quality of electrical supplies.

Smoke classification

During a fire, the smoke alone can have considerable impact on people, property and the environment. The effect of smoke may include: Opacity: no orientation. Emission of corrosive gases which produces damage far from he fire zone and increases repair costs and downtime. Emission of noxious gases which present a health and safety hazard.

03

Tricast Specifications

Tricast

with hot polymerized resin. If necessary,

PM102292

developed in our laboratories. This system comprises 2 main components: Epoxy resin, A hydrid hardener. When polymerized, the epoxy resins

ventilation ducts can be added. A choice of copper coils and casting is also available depending on the specific application requirement.

HV winding

The HV winding is an insulated aluminium

PM102291

associated with the hardener forms a stable three-dimensional network. These systems have better properties than most of plastics. Their use in transformers is justified owing to their: Excellent resistance to thermal aging, Remarkable adherence to almost all known materials. Exceptional performance renders the windings resistant to many chemicals. Mechanical strength and high-thermal conductivity are achieved by incorporating selected mineral fillers, thus enabling heat to be evacuated during use, improved fire resistance and a dramatically reduced quantity of combustible materials. The solid insulation is obtained by vacuum casting in pre-heated moulds, followed by a hardening period under controlled temperature. After hardening by polymerization, this casting system becomes permanent. It offers excellent fire behavior and immediate self-extinction well beyond rated conditions of use.

(or copper) conductor cast under vacuum in moulds. Strong fiber glass reinforcement dramatically improves and enhances the mechanical stability and shock with standability during thermal overload.

HV/LV column assembly

The columns are assembled concentrically. The LV winding is secured directly to the core. The HV winding is blocked between

Magnetic core

The magnetic core consists of oblique cut, grain- oriented steel sheets insulated by carlite, made for low losses. It is protected on the surface with a flash-proof varnish (non-static insulation) in order to prevent the sheet from corroding and to improve the noise level.

two frames by wedges with rubber cushions that also serve as expansion absor bers. This arrangement ensure minimal movement during handling.

Exclusive casting system

In the face of increasingly strict regulations with regard to the risk of fire and pollution, Schneider Electric practices a policy of permanent research on the fire behavior of insulating materials. This has led to the exclusive class F casting system (temperature of insulation system: 155C)

LV winding

The LV winding generally consists of aluminium foils isolated between layers by a pre-impregnated insulating material

Schneider Electric Industries SAS

35, rue Joseph Monier CS 30323 F - 92506 Rueil Malmaison Cedex (France) Tl. : +33 (0)1 41 29 70 00 RCS Nanterre 954 503 439 Capital social 896 313 776 www.schneider-electric.com NRJED111053EN As standards, specifications and designs change from time to time, please ask for confirmation of the information given in this publication. Design: Schneider Electric Industries SAS Photos: Schneider Electric Industries SAS

This document has been printed on recycled paper

05-2011

2011 Schneider Electric. All rights reserved.

Você também pode gostar

- Tri CastDocumento2 páginasTri CastyoongleiAinda não há avaliações

- Resimold Resiglas CRT DryType CommercialBrochure enDocumento12 páginasResimold Resiglas CRT DryType CommercialBrochure engreyllom9791Ainda não há avaliações

- Resimold Resiglas enDocumento12 páginasResimold Resiglas enAngeloAinda não há avaliações

- Trihal Catalogue EN - 04062015Documento29 páginasTrihal Catalogue EN - 04062015César Luis Castillo Chilet100% (1)

- Hollow Core BushingDocumento4 páginasHollow Core BushingAkhileshkumar PandeyAinda não há avaliações

- Enclosure Form of SegregationDocumento18 páginasEnclosure Form of Segregationkkn1234Ainda não há avaliações

- GE Wavecast Dry Type TransformerDocumento16 páginasGE Wavecast Dry Type Transformeranindya19879479Ainda não há avaliações

- SLIM®TransformerDocumento6 páginasSLIM®TransformerJayadevDamodaranAinda não há avaliações

- Powerfullstop Katalog 2017 02Documento18 páginasPowerfullstop Katalog 2017 02PredragPeđaMarkovićAinda não há avaliações

- Surge Arresters: Best Solutions and Best QualityDocumento12 páginasSurge Arresters: Best Solutions and Best QualitySatadal DashAinda não há avaliações

- Gas-Insulated Medium-Voltage Switchgear: Answers For EnergyDocumento8 páginasGas-Insulated Medium-Voltage Switchgear: Answers For Energymilekitic2005Ainda não há avaliações

- History and Emerging of The Industry: Industrial Training at Industry PremisesDocumento21 páginasHistory and Emerging of The Industry: Industrial Training at Industry PremisesDharam PatelAinda não há avaliações

- Siemens Power Engineering Guide 7E 83Documento1 páginaSiemens Power Engineering Guide 7E 83mydearteacherAinda não há avaliações

- TRIHALDocumento32 páginasTRIHALangelcepedasantosAinda não há avaliações

- Rip Bushing PDFDocumento38 páginasRip Bushing PDFTravis Wood100% (1)

- Catalogue Nxplus C enDocumento72 páginasCatalogue Nxplus C enSheik HussainAinda não há avaliações

- Tumetic Tunorma Oil Distribution TransformersDocumento10 páginasTumetic Tunorma Oil Distribution Transformerscojo_drAinda não há avaliações

- 3M-EMD High Voltage CableAss PBDocumento8 páginas3M-EMD High Voltage CableAss PBLiz Vilela ArízagaAinda não há avaliações

- High VoltageDocumento56 páginasHigh VoltageMarcos Casanova LopezAinda não há avaliações

- Dry Type TransformerDocumento28 páginasDry Type TransformerKCFUNG50% (2)

- Dry Type BrochureDocumento16 páginasDry Type BrochurekannuAinda não há avaliações

- Damival en 20120516Documento8 páginasDamival en 20120516ssingaram1965Ainda não há avaliações

- Catalog Celule Siemens 8DJHDocumento80 páginasCatalog Celule Siemens 8DJHAlexandru HalauAinda não há avaliações

- Solutions For Internal Arc Protection According To IEC 62271-200 in MV SwitchgearDocumento5 páginasSolutions For Internal Arc Protection According To IEC 62271-200 in MV Switchgearkyawswarpm100% (1)

- Cast Resin TransformersDocumento7 páginasCast Resin TransformersNandkumar Chinai100% (1)

- ABB VD4 Catalogue EngDocumento56 páginasABB VD4 Catalogue EngPuiu TiganasuAinda não há avaliações

- The Switchboard That Your Installation Deserves: BloksetDocumento12 páginasThe Switchboard That Your Installation Deserves: Bloksetmumi87Ainda não há avaliações

- Ca Unisafe (En) A 1vcp000250-1003Documento32 páginasCa Unisafe (En) A 1vcp000250-1003boukhaadraAinda não há avaliações

- Sihf-C-Si: Silicon Multicore Cable, Halogen-Free, Cu-Screened, Emc-Preferred Type, Meter MarkingDocumento1 páginaSihf-C-Si: Silicon Multicore Cable, Halogen-Free, Cu-Screened, Emc-Preferred Type, Meter Markingbaguspermana7Ainda não há avaliações

- Alstom Gis Up To 800kvDocumento12 páginasAlstom Gis Up To 800kvgovindarulAinda não há avaliações

- Tyco HV Cable and Arresters Ans InsulatorDocumento104 páginasTyco HV Cable and Arresters Ans InsulatorRazvan MaresAinda não há avaliações

- Bushing Instllation Manual-ABB Type AIRRIP-RTKFDocumento13 páginasBushing Instllation Manual-ABB Type AIRRIP-RTKFariel celaAinda não há avaliações

- Solid Core En-Ankara Seramik PDFDocumento32 páginasSolid Core En-Ankara Seramik PDFtholgasenelAinda não há avaliações

- Catalogo Resina IngleseDocumento9 páginasCatalogo Resina IngleseLevi Franco CarvalhoAinda não há avaliações

- Energizing A More Sustainable Future.: 3M Electrical Solutions - Renewable EnergyDocumento12 páginasEnergizing A More Sustainable Future.: 3M Electrical Solutions - Renewable EnergyYohanes Dimas PriambodhoAinda não há avaliações

- Catalogue 8djh enDocumento92 páginasCatalogue 8djh enbajricaAinda não há avaliações

- Transformer Database ReserchDocumento8 páginasTransformer Database ReserchJignesh100% (1)

- Catalogue Nxplus C enDocumento68 páginasCatalogue Nxplus C enAnonymous 2feRXsn30Ainda não há avaliações

- High Voltage Products Reliable Products - EN PDFDocumento102 páginasHigh Voltage Products Reliable Products - EN PDFSiva ReddyAinda não há avaliações

- Gas Insulated Switchgear For High Voltage Substations SiemensDocumento10 páginasGas Insulated Switchgear For High Voltage Substations SiemenspcelisAinda não há avaliações

- Power and Distribution TransformersDocumento32 páginasPower and Distribution TransformersŽeljkoMarković50% (2)

- KoolDuct Technical Data Sheet UKDocumento2 páginasKoolDuct Technical Data Sheet UKsiva_nagesh_2Ainda não há avaliações

- L&T Henikwon BBTDocumento25 páginasL&T Henikwon BBTraghuveeranush50% (2)

- Industrial VisitDocumento20 páginasIndustrial VisitKanchan kumarAinda não há avaliações

- Dry-Type Transformers For Railways Brochure A4 - vFINALDocumento18 páginasDry-Type Transformers For Railways Brochure A4 - vFINALYusuke Okudaira100% (1)

- Canalis KTA 800 - 4000ADocumento205 páginasCanalis KTA 800 - 4000ACatalin NeaguAinda não há avaliações

- 3M MV Termination KitsDocumento20 páginas3M MV Termination Kitsomh129Ainda não há avaliações

- H-93498 NOMEX Setting The Standard BrochureDocumento24 páginasH-93498 NOMEX Setting The Standard BrochureJemal MusaAinda não há avaliações

- Brochure VD4Documento8 páginasBrochure VD4Can PoonsawatAinda não há avaliações

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNo Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNota: 4 de 5 estrelas4/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesNo EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesNota: 3.5 de 5 estrelas3.5/5 (3)

- Insulation Co-ordination in High-voltage Electric Power SystemsNo EverandInsulation Co-ordination in High-voltage Electric Power SystemsNota: 4.5 de 5 estrelas4.5/5 (5)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionNo EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionNota: 4.5 de 5 estrelas4.5/5 (3)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNo EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNota: 5 de 5 estrelas5/5 (1)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsAinda não há avaliações

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNo EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyAinda não há avaliações

- Ruggedcom Rx1000 User ManualDocumento284 páginasRuggedcom Rx1000 User ManualHector Fabio Florez LondoñoAinda não há avaliações

- Multisens Picture Error in Rlink 2: Ddt4AllDocumento16 páginasMultisens Picture Error in Rlink 2: Ddt4AllAriana ScheiderAinda não há avaliações

- Brochure B1500 All Fire PumpsDocumento4 páginasBrochure B1500 All Fire Pumpseng_elbarbaryAinda não há avaliações

- Author Instructions For Publication in IOSR JournalDocumento2 páginasAuthor Instructions For Publication in IOSR JournalSwati Shahi100% (1)

- General Specifications: GS 33K05H40-50EDocumento3 páginasGeneral Specifications: GS 33K05H40-50ETheNewHetfieldAinda não há avaliações

- Sika Galvashield XP XPT XP2 XP4Documento5 páginasSika Galvashield XP XPT XP2 XP4dimitrios25Ainda não há avaliações

- 5.DEMADEM AV10859650 enDocumento6 páginas5.DEMADEM AV10859650 enEngineering TFIAinda não há avaliações

- Net CoolDocumento32 páginasNet Coolsandey16585Ainda não há avaliações

- DIN EN ISO 2409-2020英文Documento22 páginasDIN EN ISO 2409-2020英文김종원Ainda não há avaliações

- Chapter - 20: Effective ControlDocumento32 páginasChapter - 20: Effective Controlcooldude690Ainda não há avaliações

- LTE Event Analysis - Case StudiesDocumento15 páginasLTE Event Analysis - Case Studiesranjan100% (2)

- Standards Publication: DOC NO: QP-GDL-S-031 Revision 1Documento10 páginasStandards Publication: DOC NO: QP-GDL-S-031 Revision 1Deepak Kannan100% (1)

- Free 3 of 9Documento1 páginaFree 3 of 9yspn2006Ainda não há avaliações

- SRS Hostel Management System (HMS)Documento19 páginasSRS Hostel Management System (HMS)sona_meet200243% (7)

- Model Sim UserDocumento412 páginasModel Sim UserjubidownAinda não há avaliações

- Marina TCDocumento5 páginasMarina TCJeff KabigtingAinda não há avaliações

- Metadata Extraction Tool ChangesDocumento4 páginasMetadata Extraction Tool ChangesHotland SitorusAinda não há avaliações

- HEV Emissions TestingDocumento18 páginasHEV Emissions TestingSashi VelnatiAinda não há avaliações

- Anaconda SS 304 Standard Fittings and Locknuts PDFDocumento4 páginasAnaconda SS 304 Standard Fittings and Locknuts PDFBoiaflinAinda não há avaliações

- Ravens APM Item Banked FAQsDocumento5 páginasRavens APM Item Banked FAQsCH KarimAinda não há avaliações

- Reverse Engineering Serial ProtocolDocumento19 páginasReverse Engineering Serial ProtocolRichardmsiska100% (1)

- Material Handling Control Procedure PDF FreeDocumento9 páginasMaterial Handling Control Procedure PDF FreeAli KayaAinda não há avaliações

- Proposal Request: Issued By: Jason Breyer, Project Manager Date: 03.29.2021Documento1 páginaProposal Request: Issued By: Jason Breyer, Project Manager Date: 03.29.2021Deepak MasaunAinda não há avaliações

- Bosch Rexroth S 6 S 10 S 20 S 30 Inline Check ValveDocumento4 páginasBosch Rexroth S 6 S 10 S 20 S 30 Inline Check ValveOARIASCOAinda não há avaliações

- Zinc-Coated (Galvanized) Steel Pipe Winding Mesh: Standard Specification ForDocumento3 páginasZinc-Coated (Galvanized) Steel Pipe Winding Mesh: Standard Specification ForNarendrasinhAinda não há avaliações

- Installation Manual VRV III BSVQ - PVJU - DaikinDocumento17 páginasInstallation Manual VRV III BSVQ - PVJU - Daikinvineeth8624Ainda não há avaliações

- 12 - Network Devices or ComponentsDocumento3 páginas12 - Network Devices or ComponentsOmer107100% (1)

- Descargar ArchivoDocumento851 páginasDescargar ArchivoAnder RacingAinda não há avaliações

- Satip A 114 01 Earth WorkDocumento11 páginasSatip A 114 01 Earth WorkZia ur RehmanAinda não há avaliações

- NES 304 Part 2 Shafting Systems and PropulsorsDocumento36 páginasNES 304 Part 2 Shafting Systems and PropulsorsJEORJEAinda não há avaliações