Escolar Documentos

Profissional Documentos

Cultura Documentos

DSS Valve

Enviado por

Shankar RajDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

DSS Valve

Enviado por

Shankar RajDireitos autorais:

Formatos disponíveis

RIZZIO S PA

www.rizzio.it info@rizzio.it ITALY 13018 Valduggia (VC) - via Circonvallazione, 37 Ph. 0039 0163 438 911 Fax +39 0163 48 181

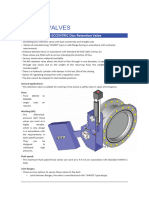

DSS DOUBLE SAFE SHUT VALVES TECHNICAL MANUAL

DSS TECHNICAL MANUAL

RIZZIO Spa

Contents

Page

1. GENERAL DESCRIPTION 2. DSS - MAIN FEATURES 3. LINE BLIND AND DOUBLE SAFE SHUT COMPARISON 4. ATTACHED DOCUMENTS

3 3 4 4

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PARTY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. VALDUGGIA (VC) ITALY

G.M.

P.M.

DATE OF ISSUE

LAST REVISION

DATE OF LAST REV.

PAGES

Masso Paolo

28/05/09

04

2/8

DSS TECHNICAL MANUAL

RIZZIO Spa

1. GENERAL DESCRIPTION

DSS valves satisfy IBC code par. 1.3.24 and solve the uncertainty leaking risks and all the very complex and delicate tightening procedures typical of the Line Blind valves.

2. DSS - MAIN FEATURES

Auto emptying and very sturdy body, bonnet and cover entirely bolted to protect the trim, to grant internal discs movement on specific guides and to reduce any type of maintenance. DSS can be used in any possible position. Double, independent, symmetrical, bi-directional and no floating blinded discs with a central no floating cast wedge that segregates pipelines in two independent isolate parts. The discs are realized from flat stainless steel to prevent any possible passing leakage from the parts. Capacity to segregate two different fluids at difference pressures. Tightness recovering having pipelines in pressure. Double primary metallic seat on the discs also for propylene oxide. Double secondary dynamic and energized PTFE seat for bubble tightness. Rising shaft for a distant visual indication of the valve position. Lockable hand wheel or lockable hydraulic actuator. Lateral inspection door for ambient air communication with the internal body and maintenance procedure inspections. No dismantling procedures are required to segregate the valves and so very low operating costs. One or two option draining valves will make possible the recovering of the internal mixing of cargo product on a return tank. Moreover DSS valves can be used according to the DEMO C 2002_05 rev 0 drawing and so with only one butterfly valve on condition that it is provided with the additional metal seat according to Fire Safe Design. The segregation can be identified from the group valves composed by one DSS and one 2D Butterfly. The two draining valves can be used to check the two independent chambers and to control any possible leak between them. The segregation is grant from several factors : the DSS is protected in order to avoid any big loss leakage. Also in case of damaged seat the valve will never allow the passage of big flow but only of few drops; anyway there will be 2 + 2 seats to protect. The opposite side on butterfly valve will have moreover 2 seats, which avoids the fluid contact towards the DSS valve. The chambers can be inspected in differential mode, in order to verify any possible leakage and its location. Also in case of two non-miscible fluids in pressure one against the other there will be the possibility to collect them from the two draining valves in two independent lines.

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PARTY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. VALDUGGIA (VC) ITALY

G.M.

P.M.

DATE OF ISSUE

LAST REVISION

DATE OF LAST REV.

PAGES

Masso Paolo

28/05/09

04

3/8

DSS TECHNICAL MANUAL

RIZZIO Spa

3. LINE BLIND AND DOUBLE SAFE SHUT COMPARISON

Valve location LINE BLIND FLANGE VALVES DSS - Double Safe Shut Valves For safety reason, its correct to never DSS valves can be placed in any locate a Blind valve under a cargo location also under a cargo tank. tank column like a tunnel or in the pump room. The only safe place is the deck on the cargo product column. Independently from the location, in There are no possibilities of case that a seat leakage is bigger overflow because the conical then the drain plug capacity, the metallic seats are self-cleaning cargo product will be poured out of during the valve closing and so the valve with all the possible risks. able to reduce any leak also in This is due to the absence of the case of dirtiness. The valve body cover that cannot be placed when the is only one piece and it is entirely discs are inside of the body. close so no external overflow is possible. In case of water hammer the disc and The cast body is so sturdy that it body structure will never grant any cannot be affected by water sure protection when the valve is hammer problems. closed. The too thin shaft is not able We have built over 500 cargo to contrast any lateral water hammer. ships with such body type withMostly on our competitor valves out any problem. where bodies and discs are welding constructions. Blind valve can be placed only in ver- DSS can be placed in all positical position. tions. These must be decided in advance for the drain plugs positioning in the bottom place. For a safe segregation procedure, af- All the closing procedures are toter the discs introduction and their tally safe. This is because the closing in the body, it would be correct tightness is done simply operata tightness air test in order to avoid ing by a hand wheel or in a recargo products losses in case of seat mote way by an actuator. leakage. This preventive action is No spanners are required and no rarely done because too long and preventive actions are to be complex. taken to tight the valves. The tightness recovering is never One big advantage of DSS is possible. The internal screw is not that the recovering of the tightable to tight the discs under pressure ness is always possible. due to a high torque request. 10 bar of pressure corresponds to a force of 1767 Kg on DN 150, of 3142 Kg on DN 200 and of 4909 Kg on DN 250.

Overflow risk

Water hammer

Positioning

Preventive Air test procedure

Tightness recovering when lines are in pressure

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PARTY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. VALDUGGIA (VC) ITALY

G.M.

P.M.

DATE OF ISSUE

LAST REVISION

DATE OF LAST REV.

PAGES

Masso Paolo

28/05/09

04

4/8

DSS TECHNICAL MANUAL

RIZZIO Spa

When the Blind has to be closed its No preventive actions to control necessary to inspect carefully the me- the seats are foreseen. tallic body seat surfaces. They have The internal wedge is moving in to be like mirrors. Scratches, sedi- internal body tracks that do not ments or any form of scale will never allow any contact between the give a perfect disc support or o-ring components. grip. In case of damages its necessary to dismount the body from the flanges and to grind it on a machine. Preventive me- In the same way the two metallic disc For the same reasons the intertallic disc seats seat surfaces have to be inspected. In nal discs cant be damaged durcase of damages its necessary to ing their stroke and so no inspect inspection. dismount them from the flanges and actions are required. to grind them on a machine. Preventive disc The two soft o-rings must be checked, The two soft seats are totally simply passing a finger on them to protected in their stroke. The insoft seats inverify the scratches absence. It's spection door will leave the posspection. preferable to change them at any sibility to inspect them during the closing operation. periodical but very rare maintenance procedures. The competitors valves without me- DSS are built to have a primary Soft seat detallic seats are provided with only flat metallic seat for each side plus formations gaskets that, working statically, suffer additional soft rings for bubble of permanent deformations. The main tightness. The two soft seats gaskets have to be changed at any have to be changed only during closing operation. the programmed and very rare maintenance procedures. External disc The two discs, when are not used, are No components are to be placed to be placed in vertical, safety and out of the valve. fixing fixed position on a special support in order to avoid any collision or dragging with other external elements. Disc introduc- The two discs have to be introduced Vertical and guided movement carefully, avoiding any metallic con- protects all the mechanical contion tact with the internal body. A contact tact. can create permanent damage on the machined surfaces. Help of a crane In the biggest sizes is necessary to Not required. use a crane in order to avoid big efforts that would increase all the possible mechanical contact of the parts. Preventive metallic body seats inspection.

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PARTY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. VALDUGGIA (VC) ITALY

G.M.

P.M.

DATE OF ISSUE

LAST REVISION

DATE OF LAST REV.

PAGES

Masso Paolo

28/05/09

04

5/8

DSS TECHNICAL MANUAL

RIZZIO Spa

The valve has to be closed, rotating The shaft and yoke threaded, the the internal tightening screw by dimensioning of the hand wheel means of a spanner in a very reduced plus a perfect respect of the rotation angle. An extra force has to conical angle of body and disc be applied when the discs are in con- seats, by means of CNC machintact against the body seats applying a ing centre, will grant a very simresolute and constant force in only ple closing operations where the one step in the last degrees rotation. use of two arms is enough to Any hesitation of this will not assure tight the valve. the reaching of the tightness end po- No spanners or special tools are sition and it will require to repeat this required. procedure after the pressure test. Cover and his In the same way the cover and the We have only a lateral inspection gasket inspec- top cover o-ring have to be inspected doors corresponding to the closin advance. ing of a small flange. tion Cover gasket In case of competitor valve the top Please see the previous item. cover seal is a flat gasket that, working statically, suffers of permanent deformation. It has to be changed during all closing operations. In our valves the gasket is dimensioned for a dynamic tightness and it grants a capacity to adapt itself to the external profile of the groove when the pressure will move it against it. This requires very rare replacement. Cover closing The cover must be positioned and Please see the previous item. tight in a perfect parallel way to the procedure top valve body. The two nuts have to be screwed down simultaneously, operating with a correspondent number of turns and torque for every nut. A wrong closing procedure of the cover will surely involve external fluid losses. So its once more preferable to test the line with air before the pipeline is in use with cargo products. The opening of cover and disc risk to DSS let you open the discs when Cargo gas have external pouring of cargo gas the valve body is closed. The inproduct surely hazardous for the op- ternal gas can be drained out by erator. its valve and recovering pipe. No risks for the operators. Closing procedure, hesitation and external tools.

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PARTY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. VALDUGGIA (VC) ITALY

G.M.

P.M.

DATE OF ISSUE

LAST REVISION

DATE OF LAST REV.

PAGES

Masso Paolo

28/05/09

04

6/8

DSS TECHNICAL MANUAL

RIZZIO Spa

4. ATTACHED DOCUMENTS

RINA Approval MAC/FSC/36060 date 6/7/2005 DSS Segregation functionality P24100-00010-Functional Views Segregation with one DSS valve and one 2D Butterfly valve DEMO C 2002_05 rev.0 DSS dimensional drawing P24100 5 DSS ISO 5752 S3 Manual Operated 02 P24100 7 DSS ISO 5752 S3 with LDD Actuator 02 P24200 5 DSS ISO 5752 S15 Manual Operated 02 P24200 7 DSS ISO 5752 S15 with LDD Actuator 02

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PARTY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. VALDUGGIA (VC) ITALY

G.M.

P.M.

DATE OF ISSUE

LAST REVISION

DATE OF LAST REV.

PAGES

Masso Paolo

28/05/09

04

7/8

DSS TECHNICAL MANUAL

RIZZIO Spa

5. REVISIONS HISTORY

Author PM PM GM Date Revision 28/05/2009 04 03/05/2009 23/10/2007 02 01 Comments Renamed file, annexed and dwg update New format

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PARTY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. VALDUGGIA (VC) ITALY

G.M.

P.M.

DATE OF ISSUE

LAST REVISION

DATE OF LAST REV.

PAGES

Masso Paolo

28/05/09

04

8/8

BLIND DISC Nr.1 FLUID 1

BLIND DISC Nr 2 FLUID 2

VALVE OPEN EXPANSION WEDGE

OPTIONAL DRAINING VALVE

INTERNAL SEGREGATION AIR

FLUID 1 FLUID 2 VALVE CLOSED

03 02 01 REV. 00

---DATE 09/09/2004

---DESIGNER GS

---REVISION DESCRIPTION

DWG FILE TITLE

GENERAL TOLERANCES

LENGHT : DIAMETER : ANGLE :

`0.100 `0.100 `0.25

ONLY FOR QUOTA WITHOUT SPECIFIC INDICATION

RIZZIO Valvole spa

P24100-00010

P24100-00010-Functional Views r 01

DOUBLE SAFE SHUT VALVE 2103 OS&Y HAND OPERATED ISO 5752 S3 FUNCTIONAL VIEWS --

FOR INTERNAL USE ONLY

Via Circonvallazione, 37 - 13018 Valduggia (VC) ITALY Ph. +39 0163 47 107 - Fax +39 0163 48 181

www.rizziovalvole.com

THE COPYRIGHT/OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PARTY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO VALVOLE S.p.A. VALDUGGIA (VC) ITALY

Você também pode gostar

- Orbinox VG08 Knife Gate ValveDocumento8 páginasOrbinox VG08 Knife Gate ValveYorkistAinda não há avaliações

- TL TL TL TL: Installation, Operation & Maintenance Manual ModelDocumento12 páginasTL TL TL TL: Installation, Operation & Maintenance Manual ModelSamet BabaAinda não há avaliações

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDocumento20 páginasFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalAinda não há avaliações

- M60DSW6 1463X Man 001 PDFDocumento15 páginasM60DSW6 1463X Man 001 PDFOswaldo VillarroelAinda não há avaliações

- SC Fepa Sa Bârlad: Installation, Operation&Maintenance Ball Valve Type RSD-BBDocumento15 páginasSC Fepa Sa Bârlad: Installation, Operation&Maintenance Ball Valve Type RSD-BBtoader56Ainda não há avaliações

- 120 Volt Electric Single Ybss ManualDocumento17 páginas120 Volt Electric Single Ybss ManualSal TargarienAinda não há avaliações

- 1 - Operation Instruction SSC15Documento6 páginas1 - Operation Instruction SSC15sumanta_2008dredifmaAinda não há avaliações

- Atmospheric Relief Valve ManualDocumento12 páginasAtmospheric Relief Valve ManualTarun ChandraAinda não há avaliações

- Mooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasDocumento12 páginasMooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasCarlos TarquinoAinda não há avaliações

- JC Ball Valves Fig 6000fb 7000rb Iom Rev 4 1Documento39 páginasJC Ball Valves Fig 6000fb 7000rb Iom Rev 4 1Inspection Engineer100% (1)

- Va18 Va19Documento59 páginasVa18 Va19joymotiAinda não há avaliações

- Iom (202306023-A)Documento12 páginasIom (202306023-A)Batara SinagaAinda não há avaliações

- 101C and 20-10C Sluice Gate Multi-PageDocumento12 páginas101C and 20-10C Sluice Gate Multi-PageWalterHuAinda não há avaliações

- Febco DCD and DC 850 856 870 and 876Documento12 páginasFebco DCD and DC 850 856 870 and 876Brandon TrocAinda não há avaliações

- Safety Relief Valves Operation ManualDocumento21 páginasSafety Relief Valves Operation ManualSumit JadhavAinda não há avaliações

- Rupture Disc Vs Safety ValvesDocumento3 páginasRupture Disc Vs Safety ValvesOsama Nabil KashkoushAinda não há avaliações

- SolenoidDocumento2 páginasSolenoidStelios KonstantinidesAinda não há avaliações

- кабельный барабан Operator's manualDocumento34 páginasкабельный барабан Operator's manualВасяAinda não há avaliações

- General Twin Seal 06Documento24 páginasGeneral Twin Seal 06Gk GaneshAinda não há avaliações

- Rofi Operation and Maintenance ManualDocumento3 páginasRofi Operation and Maintenance ManualSteve NewmanAinda não há avaliações

- W W W WG G G G: Installation, Operation & Maintenance Manual ModelDocumento15 páginasW W W WG G G G: Installation, Operation & Maintenance Manual ModelAngelSuarezAinda não há avaliações

- EEX e Handbook 247404Documento25 páginasEEX e Handbook 247404www.otomasyonegitimi.comAinda não há avaliações

- User Manual SaladetteDocumento94 páginasUser Manual SaladettepippoAinda não há avaliações

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDocumento14 páginasFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalAinda não há avaliações

- Maintenance and Use ManualDocumento1 páginaMaintenance and Use ManualSebastian GanciAinda não há avaliações

- Manual Fold Door 8920PLDocumento40 páginasManual Fold Door 8920PLCristian Luis Mansilla SilvaAinda não há avaliações

- Codeline Drawing 80S45 Non CodedDocumento2 páginasCodeline Drawing 80S45 Non CodedoctavioAinda não há avaliações

- Enerpac Hydraulic ManifoldDocumento33 páginasEnerpac Hydraulic ManifoldZeckAinda não há avaliações

- 6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValveDocumento20 páginas6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValvePilar HernandezAinda não há avaliações

- PrimeRoyal Metallic LE IOMDocumento19 páginasPrimeRoyal Metallic LE IOMTadeo FajardoAinda não há avaliações

- C Protec Arisawa Users Manual - en PDFDocumento39 páginasC Protec Arisawa Users Manual - en PDFBassemAinda não há avaliações

- CV Valvulas Twin SealDocumento20 páginasCV Valvulas Twin Sealprocesossictec100% (1)

- BVM Corporation Maintenance Manual: Pneumatic / Hydraulic Tubing SpiderDocumento17 páginasBVM Corporation Maintenance Manual: Pneumatic / Hydraulic Tubing SpiderDean ReinAinda não há avaliações

- 2003 Nissan Altima 2.5 Serivce Manual EIDocumento36 páginas2003 Nissan Altima 2.5 Serivce Manual EIAndy DellingerAinda não há avaliações

- Viscossus Fan DriveDocumento16 páginasViscossus Fan DriveaaronAinda não há avaliações

- STASTO RT Series enDocumento10 páginasSTASTO RT Series envinston.s1949Ainda não há avaliações

- p077 02 PDFDocumento8 páginasp077 02 PDFJuan ZamoraAinda não há avaliações

- DHV API 600 Gate ValveDocumento21 páginasDHV API 600 Gate ValveBakheit LayliAinda não há avaliações

- IOM Wastewater Air Valves SCF 2Documento9 páginasIOM Wastewater Air Valves SCF 2adamaso09Ainda não há avaliações

- Manuales Válv y Actuador Válv SeccionamientoDocumento114 páginasManuales Válv y Actuador Válv Seccionamientodiuska13Ainda não há avaliações

- Installation, Operation and Maintenance Manual: Date: October 2006 Supersedes: 806 C - 05/10 CDocumento28 páginasInstallation, Operation and Maintenance Manual: Date: October 2006 Supersedes: 806 C - 05/10 Cmohamed ibrahimAinda não há avaliações

- 2005 - 2009 Water Leak RepairsDocumento5 páginas2005 - 2009 Water Leak RepairsJuan CandiaAinda não há avaliações

- Equipos RouseelDocumento28 páginasEquipos RouseeljorgeAinda não há avaliações

- Operating Instructions: N - R 472C en 05.12Documento42 páginasOperating Instructions: N - R 472C en 05.12Long HuynhAinda não há avaliações

- C45db97118a2Documento85 páginasC45db97118a2anilr008100% (1)

- MANUAL016Documento8 páginasMANUAL016kim johnAinda não há avaliações

- 2006 Radium - Metal Shock Service ManualDocumento16 páginas2006 Radium - Metal Shock Service ManualJesus Francisco MorenoAinda não há avaliações

- SC 15TW-Stainless Steel 13Documento44 páginasSC 15TW-Stainless Steel 13roherneville100% (1)

- s05 Boom b14nvDocumento20 páginass05 Boom b14nvAnonymous iu95trpxNAinda não há avaliações

- Iom WKM 310FDocumento4 páginasIom WKM 310FNasir NaqviAinda não há avaliações

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDocumento7 páginas52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeAinda não há avaliações

- Dome ValveDocumento6 páginasDome Valvesaisssms9116Ainda não há avaliações

- Consolidated: Consolidated Safety Relief Valve Type 1900Documento8 páginasConsolidated: Consolidated Safety Relief Valve Type 1900Peerasak ArunAinda não há avaliações

- Bal Ektg 04eDocumento18 páginasBal Ektg 04eAbdullah GhannamAinda não há avaliações

- Rei Vol IiDocumento142 páginasRei Vol IiDineshAinda não há avaliações

- Assembly Instructions For Sandwich Panels - RuukkiDocumento32 páginasAssembly Instructions For Sandwich Panels - RuukkiRui GarciaAinda não há avaliações

- BuWa SZF Manual Globe-Valves EN-1Documento11 páginasBuWa SZF Manual Globe-Valves EN-1Diego VerlyAinda não há avaliações

- Installation, Operation & Maintenance Manual - Original VersionDocumento11 páginasInstallation, Operation & Maintenance Manual - Original VersionAli AafaaqAinda não há avaliações

- Rubber Expansion Joints Installation GuideDocumento3 páginasRubber Expansion Joints Installation GuideLudi D. LunarAinda não há avaliações

- Low Pressure SW Series Compression FittingsDocumento20 páginasLow Pressure SW Series Compression FittingsShankar RajAinda não há avaliações

- Legal Metrology Act, Act 9 of 2014: Compiled By: Legricon Legal Register Version June 2015 Page 1 of 5Documento5 páginasLegal Metrology Act, Act 9 of 2014: Compiled By: Legricon Legal Register Version June 2015 Page 1 of 5Shankar RajAinda não há avaliações

- Additional Rights & Obligations (Voluntary)Documento17 páginasAdditional Rights & Obligations (Voluntary)Shankar RajAinda não há avaliações

- IRS - Pan India Training CalenderDocumento2 páginasIRS - Pan India Training CalenderShankar RajAinda não há avaliações

- JT Catalogue 2012 WebDocumento228 páginasJT Catalogue 2012 WebShankar RajAinda não há avaliações

- PDO ScopeDocumento34 páginasPDO ScopeShankar Raj100% (1)

- Alagappa University,: Directorate of Distance EducationDocumento1 páginaAlagappa University,: Directorate of Distance EducationShankar RajAinda não há avaliações

- How To Write A Risk AssessmentDocumento8 páginasHow To Write A Risk AssessmentbranikAinda não há avaliações

- Excavation Work GuidelinesDocumento9 páginasExcavation Work GuidelinesShankar RajAinda não há avaliações

- Master of Business Administration (Mba) Master of Business Administration (Mba)Documento1 páginaMaster of Business Administration (Mba) Master of Business Administration (Mba)Shankar RajAinda não há avaliações

- List of Management System ProcedureDocumento1 páginaList of Management System ProcedureShankar RajAinda não há avaliações

- Cable DetailsDocumento30 páginasCable DetailsShankar RajAinda não há avaliações

- Bking Process SopDocumento4 páginasBking Process Sopjoly67% (6)

- Resume (Salim Ahmed) MEPDocumento3 páginasResume (Salim Ahmed) MEPSalim AhmedAinda não há avaliações

- Rahul ResumeDocumento7 páginasRahul ResumeMohit GautamAinda não há avaliações

- Design and Selection of Materials Project UCF Formula Car Exhaust HeadersDocumento13 páginasDesign and Selection of Materials Project UCF Formula Car Exhaust HeadersNathan WendrickAinda não há avaliações

- UNIT I 1.2 Process Planning and Production PlanningDocumento52 páginasUNIT I 1.2 Process Planning and Production Planningprof_panneerAinda não há avaliações

- Bulks PDFDocumento44 páginasBulks PDFmihai085Ainda não há avaliações

- Catálogo de Pruebas Estándar IEEE para Transformadores Tipo SecoDocumento83 páginasCatálogo de Pruebas Estándar IEEE para Transformadores Tipo SecoBanner Ruano100% (2)

- SimaPro PHDDocumento1 páginaSimaPro PHDAnonymous zYW2HQlezdAinda não há avaliações

- SCA121T-D09 Product Specification 8270700A0Documento5 páginasSCA121T-D09 Product Specification 8270700A0Crystal KingAinda não há avaliações

- Circular Logs vs. Linear LogsDocumento9 páginasCircular Logs vs. Linear LogsManish100% (1)

- Zenith Cooling FanDocumento2 páginasZenith Cooling Fanraza239Ainda não há avaliações

- Edu Toy Descriptive AnalyticsDocumento2 páginasEdu Toy Descriptive AnalyticsKiran MishraAinda não há avaliações

- Dbms FileDocumento31 páginasDbms FileAdam MooreAinda não há avaliações

- CODEMagazine 2019 SeptemberOctoberDocumento76 páginasCODEMagazine 2019 SeptemberOctoberAnonymous ze7rq2QKyAinda não há avaliações

- Er. Shivam KR CVDocumento6 páginasEr. Shivam KR CVBulk WeighingAinda não há avaliações

- Receiving and Inspection of Incoming Direct MaterialsDocumento1 páginaReceiving and Inspection of Incoming Direct MaterialssigmasundarAinda não há avaliações

- Percona Server 5.5.34-32.0Documento195 páginasPercona Server 5.5.34-32.0Mas KliwonAinda não há avaliações

- Review - Module I - Understanding ValueDocumento72 páginasReview - Module I - Understanding ValueRavi RakeshAinda não há avaliações

- HP Compaq A Failure or SuccessDocumento19 páginasHP Compaq A Failure or SuccessPooja Kaul100% (1)

- BS 5588 Part 4 1978Documento46 páginasBS 5588 Part 4 1978Kirsty Elliston0% (1)

- Chapter 1 - Introduction To Production ManagementDocumento12 páginasChapter 1 - Introduction To Production ManagementRohit BadgujarAinda não há avaliações

- NE 364 Engineering Economy: Introduction To The Basic Cost Concepts and Economic EnvironmentDocumento11 páginasNE 364 Engineering Economy: Introduction To The Basic Cost Concepts and Economic Environmentyoussef hossamAinda não há avaliações

- Lead Workplace Communication PDFDocumento26 páginasLead Workplace Communication PDFrommel minorAinda não há avaliações

- "Agricultural Equipment Repair & Motor Repair'': A Powerpoint Presentation OnDocumento17 páginas"Agricultural Equipment Repair & Motor Repair'': A Powerpoint Presentation OnAniruddha MAinda não há avaliações

- Republic Technical Data ManualDocumento110 páginasRepublic Technical Data ManualAbu AlAnda Gate for metal industries and Equipment.Ainda não há avaliações

- UC001 - IM Use Case 1Documento15 páginasUC001 - IM Use Case 1dedie29Ainda não há avaliações

- Infographic Tetra RecartDocumento1 páginaInfographic Tetra RecartvizmarghAinda não há avaliações

- Project Status Report v2.4Documento9 páginasProject Status Report v2.4Tan Nguyen100% (1)

- SamsungDocumento10 páginasSamsungGrosaru FlorinAinda não há avaliações

- Oracle UnifierDocumento16 páginasOracle UnifierahhanyAinda não há avaliações

- University of Chicago Press Fall 2009 Distributed TitlesNo EverandUniversity of Chicago Press Fall 2009 Distributed TitlesNota: 1 de 5 estrelas1/5 (1)