Escolar Documentos

Profissional Documentos

Cultura Documentos

USACE Manual 32

Enviado por

Rizwan MirzaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

USACE Manual 32

Enviado por

Rizwan MirzaDireitos autorais:

Formatos disponíveis

************************************************************************** USACE / NAVFAC / AFCESA / NASA UFGS-01 33 23.

33 (February 2010) -------------------------------Preparing Activity: USACE UNIFIED FACILITIES GUIDE SPECIFICATIONS References are in agreement with UMRL dated April 2011 ************************************************************************** SECTION TABLE OF CONTENTS DIVISION 01 - GENERAL REQUIREMENTS SECTION 01 33 23.33 AVIATION FUEL SYSTEM SPECIFIC SUBMITTAL REQUIREMENTS 02/10 PART 1 GENERAL

1.1 SUBMITTALS 1.1.1 SD-02 Shop Drawings 1.1.2 SD-03 Product Data 1.1.2.1 Standards Compliance 1.1.2.2 Manufacturer's Installation Instructions 1.2 STANDARD PRODUCTS/SERVICE AVAILABILITY 1.2.1 Materials and Equipment 1.2.1.1 Experience Required 1.2.1.2 Alternative Service Record 1.2.2 Service Support 1.2.3 Manufacturer's Nameplate PART 2 PRODUCTS

PART 3

EXECUTION

-- End of Section Table of Contents --

SECTION 01 33 23.33

Page 1

************************************************************************** USACE / NAVFAC / AFCESA / NASA UFGS-01 33 23.33 (February 2010) -------------------------------Preparing Activity: USACE UNIFIED FACILITIES GUIDE SPECIFICATIONS References are in agreement with UMRL dated April 2011 ************************************************************************** SECTION 01 33 23.33 AVIATION FUEL SYSTEM SPECIFIC SUBMITTAL REQUIREMENTS 02/10 ************************************************************************** NOTE: This guide specification covers the requirements for specific contract requirements for aircraft refueling systems constructed to the requirements of the DoD Type III/IV/V, and Cut'n Cover Hydrant Refueling System Standards Adhere to UFC 1-300-02 Unified Facilities Guide Specifications (UFGS) Format Standard when editing this guide specification or preparing new project specification sections. Edit this guide specification for project specific requirements by adding, deleting, or revising text. For bracketed items, choose applicable items(s) or insert appropriate information. Remove information and requirements not required in respective project, whether or not brackets are present. Comments, suggestions and recommended changes for this guide specification are welcome and should be submitted as a Criteria Change Request (CCR). ************************************************************************** PART 1 GENERAL

************************************************************************** NOTE: Use this Section in conjunction with UFGS 01 33 00 SUBMITTAL PROCEDURES. DoD Type III systems shall conform to Standard Design 078-24-28 PRESSURIZED HYDRANT FUELING SYSTEM (TYPE III). DoD Type IV/V systems shall conform to Standard Design 078-24-29 AIRCRAFT DIRECT FUELING SYSTEM (TYPE IV) DESIGN. ************************************************************************** 1.1 SUBMITTALS

Provide submittals as specified in each individual section and obtain approval as specified before procurement, fabrication, or delivery to the job site. Partial submittals are not acceptable and will be returned SECTION 01 33 23.33 Page 2

without review. In addition to the definitions in Section 01 33 00 SUBMITTAL PROCEDURES, the following provisions apply: 1.1.1 SD-02 Shop Drawings

Drawings shall be a minimum of A3 sheet[ANSI B][11 inches by 17 inches] in size, with a minimum scale of 1:1001/8 inch per foot, except as specified otherwise. Include floor plans, sectional views, wiring diagrams, and installation details of equipment; and equipment spaces identifying and indicating proposed location, layout and arrangement of items of equipment, control panels, accessories, piping, ductwork, and other items that must be shown to assure a coordinated installation. Wiring diagrams shall identify circuit terminals, and indicate the internal wiring for each item of equipment and the interconnection between each item of equipment. Drawings shall indicate adequate clearance for operation, maintenance, and replacement of operating equipment devices. If equipment is disapproved, drawings shall be revised to show acceptable equipment and be resubmitted. (Prior to the completion of the contract, on A1 sheet size[ANSI D][22 x 34 inch] reproducible drawings, for each system, wiring/control diagram and approved system layout drawing shall be provided to the Contracting Officer with the operation and maintenance manuals specified herein). 1.1.2 SD-03 Product Data

Submittals for each manufactured item shall be manufacturer's descriptive literature of cataloged products, equipment drawings, diagrams, performance and characteristic curves, and catalog cuts. The submittals shall also include the manufacturer's name, trade name, catalog model or number, nameplate data, size, layout dimensions, capacity, project specification and paragraph reference, applicable Government, industry, and technical society publication references, years of satisfactory service, and other information necessary to establish contract compliance of each item the Contractor proposes to provide. Photographs of existing installations and data submitted in lieu of catalog data are not acceptable and will be returned without approval. 1.1.2.1 Standards Compliance

When materials or equipment are required to conform to the standards of organizations such as the American National Standards Institute (ANSI), ASTM International (ASTM) , National Electrical Manufacturers Association (NEMA), ASME International (ASME), American Gas Association (AGA), American Petroleum Institute (API), Air-Conditioning and Refrigeration Institute (ARI), and Underwriters Laboratories (UL) or equivalent, submit proof of such conformance to the Contracting Officer. Factory Mutual (FM) listing or CSA International (CSA) listing will be acceptable in lieu of any UL listing requirements. If an organization uses a label or listing to indicate compliance with a particular standard, the label or listing will be acceptable evidence, unless otherwise specified in the individual sections. In lieu of the label or listing, submit a certificate from an independent testing organization, which is competent to perform acceptable test and is approved by the Contracting Officer. The certificate shall state that the item has been tested in accordance with the specified organization's test methods and that the item conforms to the specified organization's standard. For materials and equipment whose compliance with organizational - standards or specifications is not regulated by an organization using its own listing or label as proof of compliance, submit a certificate of compliance from the manufacturer. The certificate shall identify the manufacturer, the product, and the referenced standard and SECTION 01 33 23.33 Page 3

shall simply state that the manufacturer certifies that the product conforms to all requirements of the project specification and of the referenced standards listed. 1.1.2.2 Manufacturer's Installation Instructions

Where installation procedures or any part thereof are required to be in accordance with the recommendations of the manufacturer of the material being installed, furnish printed copies of these recommendations prior to installation. Installation of the item will not be allowed to proceed until the recommendations are received. Failure to furnish these recommendations can be cause for rejection of the material. 1.2 1.2.1 STANDARD PRODUCTS/SERVICE AVAILABILITY Materials and Equipment

Provide materials and equipment that are standard products of a manufacturer regularly engaged in the manufacturer of such products, which are of a similar material, design and workmanship. The standard products shall have been in satisfactory commercial or industrial use for two years prior to [bid opening][proposal]. The two-year use shall include applications of equipment and materials under similar circumstances and of similar size. Contracting Officer approval of materials with less than two years experience is allowed if acceptable by the design agency, [COE/NAVFAC,] and MAJCOM Fuels Engineer. 1.2.1.1 Experience Required

The two-year experience requirement must be satisfactorily completed for a product which has been sold or is offered for sale on the commercial market through advertisements, manufacturer's catalogs, or brochures. 1.2.1.2 Alternative Service Record

Products having less than a two-year field service record will be acceptable if a certified record of satisfactory field operation for not less than 6000 hours, exclusive of the manufacturer's factory or laboratory test, can be shown. Contracting Officer approval of materials with less than two years experience is allowed if acceptable by the design agency, [COE/NAVFAC,] and MAJCOM Fuels Engineer. 1.2.2 Service Support

The equipment items shall be supported by service organizations. Submit a certified list of qualified permanent service organizations for support of the equipment which includes their addresses and qualifications. These service organizations shall be reasonably convenient to the equipment installation and able to render satisfactory service to the equipment on a regular and emergency basis during the warranty period of the contract. 1.2.3 Manufacturer's Nameplate

Provide a nameplate, on each item of equipment, bearing the manufacturer's name, address, model number, and serial number securely permanently affixed in a conspicuous place; the nameplate of the distributing agent will not be acceptable.

SECTION 01 33 23.33

Page 4

PART 2

PRODUCTS

Not Used PART 3 EXECUTION

Not Used -- End of Section --

SECTION 01 33 23.33

Page 5

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- SAP ACH ConfigurationDocumento49 páginasSAP ACH ConfigurationMohammadGhouse100% (4)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Code of Practice For Mandatory Building Inspection Scheme and Mandatory Window Inspection SchemeDocumento104 páginasCode of Practice For Mandatory Building Inspection Scheme and Mandatory Window Inspection SchemeRizwan MirzaAinda não há avaliações

- Condition Assessment of Timber BridgesDocumento14 páginasCondition Assessment of Timber BridgesRizwan MirzaAinda não há avaliações

- Guide For InteriorsDocumento6 páginasGuide For InteriorsRizwan MirzaAinda não há avaliações

- Disbursement VoucherDocumento5 páginasDisbursement VoucherFonzy RoneAinda não há avaliações

- Performance Based Seismic DesignDocumento154 páginasPerformance Based Seismic DesignIp Siu Hei100% (5)

- RC Column Design (ACI318-05)Documento5 páginasRC Column Design (ACI318-05)Rizwan MirzaAinda não há avaliações

- HVAC - Geothermal Heat Pump ManualDocumento211 páginasHVAC - Geothermal Heat Pump ManualJoão Vaz100% (1)

- Coca-Cola VS CaDocumento6 páginasCoca-Cola VS CaporeoticsarmyAinda não há avaliações

- Miners Association of The Philippines v. FactoranDocumento2 páginasMiners Association of The Philippines v. FactoranRoger Pascual Cuaresma100% (1)

- Easy IntentionsDocumento10 páginasEasy IntentionsUmmahTechnology100% (1)

- Friction Factors For Large Conduits Flowing FullDocumento77 páginasFriction Factors For Large Conduits Flowing FullJean BattellAinda não há avaliações

- (Defamation) Cassidy V Daily Mirror NewspapersDocumento4 páginas(Defamation) Cassidy V Daily Mirror NewspapersHoey Lee100% (4)

- VHACADApp GuideDocumento21 páginasVHACADApp GuideRizwan MirzaAinda não há avaliações

- VHACADApp GuideDocumento21 páginasVHACADApp GuideRizwan MirzaAinda não há avaliações

- Welded Steel PenstockDocumento63 páginasWelded Steel PenstockIfnu Setyadi100% (1)

- PPL Law R13Documento13 páginasPPL Law R13Dhruv JoshiAinda não há avaliações

- Cavitation in Chutes and SpillwaysDocumento164 páginasCavitation in Chutes and SpillwaysjamesnyamaiAinda não há avaliações

- Stress Analysis of Concrete PipeDocumento17 páginasStress Analysis of Concrete PipeAli ÖztürkAinda não há avaliações

- Hydraulic and Excavation TablesDocumento352 páginasHydraulic and Excavation TablesRizwan MirzaAinda não há avaliações

- Guidelines On The Design and Construction of Bamboo ScaffoldsDocumento24 páginasGuidelines On The Design and Construction of Bamboo ScaffoldsRizwan MirzaAinda não há avaliações

- EM 1110-1-4006 - Removal of Underground Storage Tanks (USTs) - WebDocumento253 páginasEM 1110-1-4006 - Removal of Underground Storage Tanks (USTs) - WebPDHLibraryAinda não há avaliações

- Hydrodynamic C.N.Zanger PDFDocumento20 páginasHydrodynamic C.N.Zanger PDFnizamanizaAinda não há avaliações

- Seismic Retrofit RCBridge ColumnsDocumento20 páginasSeismic Retrofit RCBridge Columnsyoungc71Ainda não há avaliações

- Itl TR 02 9Documento225 páginasItl TR 02 9Felipe ToledoAinda não há avaliações

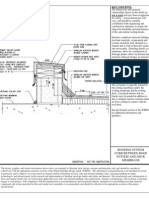

- USACE Standard Detail For Roof at Curb.Documento1 páginaUSACE Standard Detail For Roof at Curb.Rizwan MirzaAinda não há avaliações

- Ufgs 01 57 19.02Documento21 páginasUfgs 01 57 19.02Rizwan MirzaAinda não há avaliações

- Pakistan Engineering Council Profile Consulting Firms ServicesDocumento162 páginasPakistan Engineering Council Profile Consulting Firms ServicesRizwan MirzaAinda não há avaliações

- Reliability and Risk Assessment For Seepage and Slope Stability Modes For Embankment DamsDocumento129 páginasReliability and Risk Assessment For Seepage and Slope Stability Modes For Embankment DamsRizwan MirzaAinda não há avaliações

- Usace Ufgs01-32Documento5 páginasUsace Ufgs01-32Rizwan MirzaAinda não há avaliações

- CE All ListDocumento37 páginasCE All ListRizwan Mirza100% (1)

- USACE Standard Detail For Roof at Curb.Documento1 páginaUSACE Standard Detail For Roof at Curb.Rizwan MirzaAinda não há avaliações

- Va 00 01 10Documento9 páginasVa 00 01 10Rizwan MirzaAinda não há avaliações

- UFGS00015Documento4 páginasUFGS00015Rizwan MirzaAinda não há avaliações

- 69 - Civil Engineering & Architecture E-Books ListDocumento70 páginas69 - Civil Engineering & Architecture E-Books ListRizwan MirzaAinda não há avaliações

- Exposition TextDocumento5 páginasExposition TextImam YusaAinda não há avaliações

- ABL Internship ReportDocumento36 páginasABL Internship ReportMubasher Ciit100% (2)

- NBCUniversal Trademark LawsuitDocumento44 páginasNBCUniversal Trademark LawsuitTHROnlineAinda não há avaliações

- Flores Cruz Vs Goli-Cruz DigestDocumento2 páginasFlores Cruz Vs Goli-Cruz DigestRyan SuaverdezAinda não há avaliações

- Philippines Supreme Court Upholds Murder ConvictionDocumento4 páginasPhilippines Supreme Court Upholds Murder ConvictionJoy NavalesAinda não há avaliações

- D.A.V. College Trust case analysisDocumento9 páginasD.A.V. College Trust case analysisBHAVYA GUPTAAinda não há avaliações

- Bill - 2014 01 01Documento4 páginasBill - 2014 01 01Nor Hidayah0% (1)

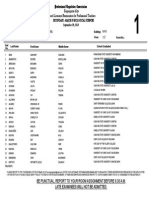

- Biological Science - September 2013 Licensure Examination For Teachers (LET) - TuguegaraoDocumento8 páginasBiological Science - September 2013 Licensure Examination For Teachers (LET) - TuguegaraoScoopBoyAinda não há avaliações

- Code-Sebi Insider TradingDocumento58 páginasCode-Sebi Insider Tradingpradeep936Ainda não há avaliações

- Occupational Health Safety Quiz 1Documento2 páginasOccupational Health Safety Quiz 1Al-juffrey Luis AmilhamjaAinda não há avaliações

- Bezza SST 010722Documento1 páginaBezza SST 010722Rachel LeeAinda não há avaliações

- LASC Case SummaryDocumento3 páginasLASC Case SummaryLuisa Elena HernandezAinda não há avaliações

- V2150 Mexico CAB MU920 MU610Documento2 páginasV2150 Mexico CAB MU920 MU610RubenL MartinezAinda não há avaliações

- Court Rules Criminal Charges Not Covered by Stay OrderDocumento6 páginasCourt Rules Criminal Charges Not Covered by Stay OrderSharon BakerAinda não há avaliações

- Derbes, Program of Giotto's ArenaDocumento19 páginasDerbes, Program of Giotto's ArenaMarka Tomic DjuricAinda não há avaliações

- Case StudyDocumento6 páginasCase StudyGreen Tree0% (1)

- CAGAYAN STATE UNIVERSITY TECHNOLOGY LIVELIHOOD EDUCATION CLUB CONSTITUTIONDocumento7 páginasCAGAYAN STATE UNIVERSITY TECHNOLOGY LIVELIHOOD EDUCATION CLUB CONSTITUTIONjohnlloyd delarosaAinda não há avaliações

- 2019 Ford Ranger Owners Manual Version 2 - Om - EN US - 12 - 2018Documento499 páginas2019 Ford Ranger Owners Manual Version 2 - Om - EN US - 12 - 2018Charles MutetwaAinda não há avaliações

- Ad Intelligence BDocumento67 páginasAd Intelligence BSyed IqbalAinda não há avaliações

- Genetically Modified Foods: The Public Health Association of Australia Notes ThatDocumento4 páginasGenetically Modified Foods: The Public Health Association of Australia Notes ThatLe HuyAinda não há avaliações

- Online Dog RegistrationDocumento2 páginasOnline Dog RegistrationtonyAinda não há avaliações

- MediamintDocumento1 páginaMediamintKaparthi GujjarAinda não há avaliações

- Test 3 - Part 5Documento4 páginasTest 3 - Part 5hiếu võ100% (1)