Escolar Documentos

Profissional Documentos

Cultura Documentos

Simba

Enviado por

Cesar SarmientoDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Simba

Enviado por

Cesar SarmientoDireitos autorais:

Formatos disponíveis

Atlas Copco Production drilling rigs

Simba 157

Technical specification

SIMBA H157

Production drilling rig adapted for narrow-vein mining. Production

drilling with tophammer rock drill in the hole range 5176 (89) mm.

Boom-mounted drilling unit for optimized reach and flexibility in

small drifts.

Standard features

Rock drill

Atlas Copco COP 1800-series

Dual-damping system for shock wave absorption and

continuous rock contact for high penetration

Lubricated and pressurized mating surfaces giving long

service intervals

Shank adapters suitable for the given hole range

Drilling unit

BMH 2000-series heavy-duty aluminium hydraulic feed

Rear-mounted stinger

Drill steel support for guidance during collaring and

as support during manual rod handling

Positioning unit

BUT 4 boom with mine-adapted, sturdy components

Boom mounted drilling unit

Accurate and smooth movements

Control system

Direct Control System (DCS)

Rotation Pressure Controlled feed (RPCF)

Anti-jamming system

Angle reading instrument, ARI 157

Carrier

Mine-adapted carrier for narrow drifts with articulated

steering and four-wheel drive

General

Operator panel mounted under canopy

Swingable control panel for manual rod handling

FOPS-approved protective roof

Electrical cable reel

Working lights on protective roof

Simba 157

Specifications

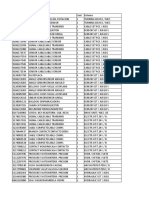

ROCK DRILL

Electrical system

COP 1838ME

Shank adapter

Hole diameter

Impact power

Impact rate

Hydraulic pressure, max.

Rotation motors

Rotation speed

Lub. air consump. (at 3 bar)

Water consumption

Weight

Total installed power......................................................60 kW

Main motors...............................................................1x55 kW

Voltage.................................................................3801,000 V

Frequency. ................................................................5060 Hz

Starting method..................................... star/delta (380-690 V)

Thermal overload protection for electric motors

Digital volt/amperage meter in electric cabinet

Phase sequence indicator

Earth fault indicator

Battery charger

Transformer. ................................................................1.8 kVA

Working lights, mounted on roof......................2x200 W, 24 V

Cable reel

R32, T38, T45

5176 (89) mm

18 kW

54 Hz

230 bar

Separate rotation

0210 rpm

6 l/s

50 l/min

171 kg

Air system

FEED

BMH 2800

BMH 2812

3,205 mm

Total length

1,220 mm

Drill rod length

Total length with extractor 3,410 mm

BMH 2815

BMH 2818

3,529 mm

1,525 mm

3,730 mm

3,756 mm

1,830 mm

3,960 mm

Positioning system

Boom extension.......................................................... 900 mm

Feed extension 4, 5, 6.............................. 600/750/1,200 mm

Stinger extension. .................................................... 1,000 mm

Feed roll-over.................................................................... 360

Feed rotation................................................................... 114

Feed dump cylinder. ................................................+18/100

Max. swinging angle.........................................................30

Weight, boom only......................................................1,000 kg

Control system

Direct Control System, DCS

Power pack

Variable pump for percussion, positioning, feed

Fixed pump for rotation, and water pump drive

Pumps unloaded at start

System pressure, max. ................................................. 230 bar

Hydraulic oil tank, volume max/min............................... 124 l

Low oil level indicator and shut-down

Oil temperature gauge on oil tank

Electric oil filling pump

Filtration, absolute......................................................... 16 m

Oil filter indicator

Water/oil cooler, shell and tube type

Mineral hydraulic oil

Compressor...................................................Atlas Copco LE3

Capacity at 1,500 rpm and 7 bar.....................................4.4 l/s

Hole blowing kit, external air supply

Water system

Hydraulic driven water booster pump

Capacity at 8 bar boost. ...................................... max 66 l/min

Min water inlet pressure. ................................................. 2 bar

Water pressure gauge

Water flow guard

Carrier

Engine......Deutz 4-cylinder, F4L 912W, 4-stroke prechamber

Power rating at 2,300 rpm. ............................................42 kW

Torque at 1,500 rpm.....................................................198 Nm

Fixed seat for tramming, including safety belt

Articulated steering................................... 40 steering angle

Four-wheel drive

FOPS-approved protective roof

Hydrostatic power steering system

Hydrodynamic transmission

Front axle .............................................................. DANA 171

Rear axle..............................................DANA, 7 oscillation

Automatic differential lock on front axle, limited slip

Tyres. .......................................................................8.25 Rx15

Clearence outside axles....................................................... 15

Hydraulic jacks, front. ......................................... 2 extendable

Hydraulic jacks, rear...............................................................2

Service brakes............................................. 2 separate circuits

Emergency and parking brakes......................................SAHR

Fuel tank, volume. ............................................................. 40 l

Electric system..................................................................24 V

Batteries..............................................................2x12V, 75 Ah

Tramming lights........................................................... 4x70 W

Brake lights

Central lubrication system

Silencer

Fire extinguisher

Spirit levels

Gradeability at max load on drive wheels. ......................... 1:4

Tramming speed on flat ground................................... 8 km/h

Tramming speed on incline 1:8. ................................... 5 km/h

Shelf for bits and tools

Horn

Beacon warning lamp

Reverse alarm

Simba 157

Specifications

DRILL STEEL

Rock drill

Hole diameter, mm

Drill rod

Shank adapter

Guide tube

COP 1838ME

5164

R32 Speedrod

R32

TDS 45

COP 1838ME

6476

T38 Speedrod

T38

TDS 56

COP 1838HE

7689

T45 Speedrod

T45

TDS 64

Optional equipment

Drilling system

Water mist flushing, water oil cooler, external air supply

Rock drill lubrication surveillance system

Big hole drilling kit

COP 1638, COP 1838MEX,

COP 1838HE, COP 1838HEX

Positioning system

Feed BMHS 2000

Rig alignment laser RAL 650

Central lubrication, rear part of boom

Power pack

Heater kit

Carrier

Fire suppression system, manual

Catalyser

Electrical system

Soft start for 400700 V

Electrical cable on reel, H07RN-F

Electrical cable on reel, Buflex

Plug PC4

Socket PC4

Switch gear

Electrics according to local standards

CE-approved working lights, 2x500 W, 230 V

Miscellaneous

Rod holder for extra drill rods

Ni-Cr piston rods

Manual spotlight

Simba 157

Measurements

side view

900

20o

COVERAGE AREA DRIFTING

3766

4910

17,5m

6500

360

114

1990

1100

1800

2000

2635

1150

7435

Coverage area

Dimensions

in mm

1500

Feed extension

(24)

900

370

40

R32

4910

R2340

20 o

55

2635

900

175

20

114

360

1380

Stinger extension

TURNING RADIUS

RECOMMENDED CABLE SIZE AND LENGTH

depending on surface

Voltage

mm

Outer

4,400

Inner

2,485

DIMENSIONS

mm

Width

1,220

Height tramming

1,990

Height roof up

2,875

Length tramming

9,460

Ground clearance

270

WEIGHT

gross weight

kg

Total

9,600

Type

Dimension, mm2

Diameter,

mm

Length,

m

380400 V

Buflex

3x50+3x10

33

85

440700 V

RDOT

4x35

38

85

1,000 V

Buflex

3x25+3x6

26

140

Recommendations are given for surrounding temperature of 40oC.

Copyright 2008, Atlas Copco Rock Drills AB, rebro, Sweden. All product names in this publication are trademarks of Atlas Copco. Any unauthorized use or copying of the contents or any part thereof is prohibited.

Illustrations and photos in this brochure may show equipment with optional extras. Specifications and equipment are subject to change without notice. Consult your Atlas Copco Customer Center for specific information.

1150

9851 2289 01 a 06/2008

1535

225

270

965

1380

46

17

175

SIMBA H157

1520

2690

55

18 o (T

ilt)

20o

79 (Tilt)

1500

(24)

Você também pode gostar

- Hydrogen Cooled GeneratorsDocumento4 páginasHydrogen Cooled GeneratorsRigoberto UrrutiaAinda não há avaliações

- Uae Oil & Gas DirectoryDocumento1.586 páginasUae Oil & Gas DirectoryChristopher Robin Richardson87% (23)

- 10 - Front End ModuleDocumento71 páginas10 - Front End ModuleBlue BlueyAinda não há avaliações

- Diagramas Hidraulicos - ElectricosDocumento80 páginasDiagramas Hidraulicos - ElectricosMilu Borja CabelloAinda não há avaliações

- Debottlenecking A Delayed Coker To Improve Overall Liquid Yield and Selectivity Towards Diesel PDFDocumento20 páginasDebottlenecking A Delayed Coker To Improve Overall Liquid Yield and Selectivity Towards Diesel PDFmujeebtalibAinda não há avaliações

- General HydraulicsDocumento30 páginasGeneral HydraulicsFernandoAinda não há avaliações

- Truck Load-Out ChecklistDocumento3 páginasTruck Load-Out ChecklistIsaac Anthony100% (2)

- Paver SUPER 1800-3 BrochureDocumento22 páginasPaver SUPER 1800-3 BrochureMohammad Younes100% (1)

- TM 9-1750G General Motors Twin Diesel 6-71 Power Plant For Medium Tanks M3A3, M3A5, and M4A2 1942Documento369 páginasTM 9-1750G General Motors Twin Diesel 6-71 Power Plant For Medium Tanks M3A3, M3A5, and M4A2 1942beppefranz100% (2)

- Minetruck mt42Documento4 páginasMinetruck mt42Miguel Angel Cortes Quintrel100% (1)

- Atlas High RotationDocumento2 páginasAtlas High RotationOnur AlpayAinda não há avaliações

- Atlas Copco CatalogDocumento110 páginasAtlas Copco Catalog381tutAinda não há avaliações

- Diamec U6: Service Kits ForDocumento47 páginasDiamec U6: Service Kits Forpeter_157608700Ainda não há avaliações

- Anglo American Fire Protection Manual-2010 Issue 0Documento343 páginasAnglo American Fire Protection Manual-2010 Issue 0LouisAucamp100% (3)

- PneumaticsDocumento52 páginasPneumaticsESRAAinda não há avaliações

- ContentsDocumento5 páginasContentsEloisa Ribeiro0% (1)

- 101 Hydraulic Rock Drills PDFDocumento2 páginas101 Hydraulic Rock Drills PDFKenny CasillaAinda não há avaliações

- Week 44 Weekly ScheduleDocumento4 páginasWeek 44 Weekly ScheduleAaron HortonAinda não há avaliações

- Manual Del OperadorDocumento146 páginasManual Del OperadorFernando NunezAinda não há avaliações

- Partes Viga Retráctil 3128 1036 80Documento2 páginasPartes Viga Retráctil 3128 1036 80JavierAinda não há avaliações

- Combustion Engineering Issues For Solid Fuel Systems PDFDocumento2 páginasCombustion Engineering Issues For Solid Fuel Systems PDFAmy0% (1)

- Manual de Taller: Principios de Funcionamiento (Sistema Common Rail) DDGX131 (E)Documento35 páginasManual de Taller: Principios de Funcionamiento (Sistema Common Rail) DDGX131 (E)Juan Pablo Duque Rodríguez100% (1)

- Simba L6 CDocumento4 páginasSimba L6 CKoko ElrAinda não há avaliações

- Marine Engine Genset Product Guide PDFDocumento104 páginasMarine Engine Genset Product Guide PDFHendriyana RizkyAinda não há avaliações

- Mil DTL 5593dDocumento13 páginasMil DTL 5593dSenthil KumarAinda não há avaliações

- Docmine: Spare Parts ListDocumento98 páginasDocmine: Spare Parts ListJH Miguel AngelAinda não há avaliações

- ActiveFaults 7cyl GeneralDocumento8 páginasActiveFaults 7cyl GeneralCalin Silviu100% (1)

- Sandvick LH201 - 9900sbDocumento4 páginasSandvick LH201 - 9900sbMario AlonsoAinda não há avaliações

- Caboltec Atlas PDFDocumento40 páginasCaboltec Atlas PDFNeilAinda não há avaliações

- Simba E7-SeriesDocumento8 páginasSimba E7-SeriesVictor BalboaAinda não há avaliações

- Normas para Pruebas en Mantenimientos de SubestacionesDocumento4 páginasNormas para Pruebas en Mantenimientos de SubestacionesCristianMedinaAinda não há avaliações

- Epiroc SR T45Documento5 páginasEpiroc SR T45RAFTAMA JAYA ABADIAinda não há avaliações

- Technical Specification Simba w6 C - 9851 2635 01 - tcm835-1537599Documento4 páginasTechnical Specification Simba w6 C - 9851 2635 01 - tcm835-1537599Cecitafex2014Ainda não há avaliações

- Simba Atlas Copco PDFDocumento4 páginasSimba Atlas Copco PDFdiego0% (1)

- Simba M4 C PDFDocumento4 páginasSimba M4 C PDFTamara MonsalveAinda não há avaliações

- ST 710 PDFDocumento3 páginasST 710 PDFIvanAinda não há avaliações

- Boomer104 SpecDocumento4 páginasBoomer104 SpecLucho MoraAinda não há avaliações

- IHT Global CatalogDocumento153 páginasIHT Global CatalogIsabel ChoqueAinda não há avaliações

- 9851 3302 01 - LDocumento4 páginas9851 3302 01 - Llourdes calderonAinda não há avaliações

- L PDFDocumento5 páginasL PDFYuri Urquizo RiveraAinda não há avaliações

- Tiger DG700 Operator's ManualDocumento202 páginasTiger DG700 Operator's ManualJame SmithAinda não há avaliações

- RR11 Brochure PDFDocumento4 páginasRR11 Brochure PDFel.runitaAinda não há avaliações

- Raise Boring Product Catalogue 2007Documento16 páginasRaise Boring Product Catalogue 2007Alexandre Moreira100% (1)

- Atlas 9851 3497 01 - LDocumento4 páginasAtlas 9851 3497 01 - LYiğit ErpakAinda não há avaliações

- Spec ST2D 9851 2251 01f - tcm795-1539250 PDFDocumento4 páginasSpec ST2D 9851 2251 01f - tcm795-1539250 PDFRizky AsharyAinda não há avaliações

- LF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Documento2 páginasLF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Max RojasAinda não há avaliações

- 9852 1466 01h Safety Boomer 281 - 282 DC15Documento47 páginas9852 1466 01h Safety Boomer 281 - 282 DC15lidoAinda não há avaliações

- Boltec 235Documento4 páginasBoltec 235Ronald Osorio100% (1)

- Perforadora Montabert HC 50: ReseminDocumento12 páginasPerforadora Montabert HC 50: ReseminAdolfo MarcosAinda não há avaliações

- 13.atlas Copco ROCKET BOOMER E1-E2 SerijaDocumento8 páginas13.atlas Copco ROCKET BOOMER E1-E2 Serijaadamajaks1985Ainda não há avaliações

- Boomer E3/E4 Series: Hydraulic Face Drilling Rigs For Medium To Large Drifts and Tunnels With Cross Sections Up To 205 MDocumento8 páginasBoomer E3/E4 Series: Hydraulic Face Drilling Rigs For Medium To Large Drifts and Tunnels With Cross Sections Up To 205 MTOLEDO GARVIZO JAIRO GERM�NAinda não há avaliações

- ScopTramp 1030Documento89 páginasScopTramp 1030Nelson GonzalezAinda não há avaliações

- Operating InstructionsDocumento270 páginasOperating InstructionsCarlos Juarez ChungaAinda não há avaliações

- Simba M4 02Documento4 páginasSimba M4 02Raphael Ruiz RamosAinda não há avaliações

- Minetruck MT436B 9851 2249 01N tcm833-1540890 PDFDocumento4 páginasMinetruck MT436B 9851 2249 01N tcm833-1540890 PDFLuis Hernández BarrazaAinda não há avaliações

- Spec ST3.5 9851 2254 01 G - tcm836-1532853Documento4 páginasSpec ST3.5 9851 2254 01 G - tcm836-1532853IoannisVourdounisAinda não há avaliações

- FrontPage Spare Parts 4147Documento42 páginasFrontPage Spare Parts 4147Liliana Rebeca Santos santosAinda não há avaliações

- 6 TransmissionDocumento79 páginas6 TransmissionDiego BernalAinda não há avaliações

- Tunneling SandvikDocumento148 páginasTunneling SandvikYebrail Mojica RuizAinda não há avaliações

- List of Proposed Spare Parts - Boyles C5CDocumento8 páginasList of Proposed Spare Parts - Boyles C5CRafael Castillo LimachiAinda não há avaliações

- Boltec S: Start The EngineDocumento2 páginasBoltec S: Start The EngineerwinAinda não há avaliações

- GENDocumento117 páginasGENdevgahlotAinda não há avaliações

- CatalogoDocumento5 páginasCatalogoDiego Alonso Velez Villegas0% (1)

- Sandvik Dt1231 Tunneling Drills: Technical SpecificationDocumento4 páginasSandvik Dt1231 Tunneling Drills: Technical SpecificationKevin QFAinda não há avaliações

- Production427 PDFDocumento35 páginasProduction427 PDFAlex Darkami Castro MelendezAinda não há avaliações

- Bolting Unit: Docmine Drill Steel Sup - 200X200 Plates 8999361000-001 Boltec SDocumento10 páginasBolting Unit: Docmine Drill Steel Sup - 200X200 Plates 8999361000-001 Boltec Scristian nahuelcuraAinda não há avaliações

- 8999 2398 00Documento12 páginas8999 2398 00Miguel Paez NoeAinda não há avaliações

- 08 ST1030 Dump and Hoist - enDocumento25 páginas08 ST1030 Dump and Hoist - enGerardo HuertaAinda não há avaliações

- Cubex Mining Products 2006Documento10 páginasCubex Mining Products 2006Diogo Cordova100% (1)

- D245S 734046 Om enDocumento90 páginasD245S 734046 Om enEndro Accoustic100% (1)

- Technical Specification Simba S7 D Atlas CopcopDocumento4 páginasTechnical Specification Simba S7 D Atlas CopcopPedro Espinoza HuahuacondoriAinda não há avaliações

- Boomer S1 L-M PDFDocumento4 páginasBoomer S1 L-M PDFArturo Pedro Salgado MedinaAinda não há avaliações

- Technical Specification Boomer m2 C With Cop 3038 9851 2774 01 Tcm835-1533267Documento4 páginasTechnical Specification Boomer m2 C With Cop 3038 9851 2774 01 Tcm835-1533267death666darkAinda não há avaliações

- Boomer T1D PDFDocumento4 páginasBoomer T1D PDFArturo Pedro Salgado MedinaAinda não há avaliações

- Urban Problems Related To EnergyDocumento33 páginasUrban Problems Related To Energyvinsree1996100% (8)

- Oxysystems 2v3x 172 4.1 ManualDocumento21 páginasOxysystems 2v3x 172 4.1 ManualDavid GarciaAinda não há avaliações

- C7 and C9 On-HighwayDocumento4 páginasC7 and C9 On-HighwaykrisornAinda não há avaliações

- Microporous and Mesoporous MaterialsDocumento9 páginasMicroporous and Mesoporous MaterialsIka SulistyaningtiyasAinda não há avaliações

- Cambridge Ordinary LevelDocumento20 páginasCambridge Ordinary LevelNeen NaazAinda não há avaliações

- Hydraulic Pumps TypesDocumento2 páginasHydraulic Pumps TypesNezar AminAinda não há avaliações

- Handheld FireballDocumento4 páginasHandheld FireballShay NoblesAinda não há avaliações

- Enviro GearDocumento4 páginasEnviro GearrasottoAinda não há avaliações

- 002 42 L PM 1102 2 Pipeline Manufacturing ITPDocumento5 páginas002 42 L PM 1102 2 Pipeline Manufacturing ITPrizalbasoAinda não há avaliações

- Fm64r1hb GBR EngDocumento7 páginasFm64r1hb GBR EngariwibowoAinda não há avaliações

- 08a PPIA Styropor Recycling TechnologyDocumento71 páginas08a PPIA Styropor Recycling TechnologyThe Outer Marker100% (1)

- DGCA PaperDocumento24 páginasDGCA PaperHardik Tank0% (1)

- Geology & GeophysicsDocumento25 páginasGeology & GeophysicsMuhammad Ikhsan HadisaputraAinda não há avaliações

- Project Title: Solar Rechargeable Electric ScooterDocumento23 páginasProject Title: Solar Rechargeable Electric ScooterArsh 837Ainda não há avaliações

- Joint Agreement On Readiness To DischargeDocumento2 páginasJoint Agreement On Readiness To DischargeOlink Achmad KafaillahAinda não há avaliações

- Economizer Tubing Chemical Plot PlanDocumento1 páginaEconomizer Tubing Chemical Plot Planmuhammad85Ainda não há avaliações