Escolar Documentos

Profissional Documentos

Cultura Documentos

Digital Control Using Both Conventional Control Algorithms For Level-Control of Dual Water Tank System

Enviado por

అయ్యలసోమయాజుల సాయి శివTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Digital Control Using Both Conventional Control Algorithms For Level-Control of Dual Water Tank System

Enviado por

అయ్యలసోమయాజుల సాయి శివDireitos autorais:

Formatos disponíveis

Digital control using both conventional control algorithms for level-control of dual water tank system

Introduction:

While modern control theory has made modest inroad into practice, fuzzy Logic control has been rapidly gaining popularity among practicing engineers. This increased popularity can be attributed to the fact that fuzzy logic provides a powerful vehicle that allows engineers to incorporate human reasoning in the control algorithm. As opposed to the modern control theory, fuzzy logic design is not based on the mathematical model of the process. The controller designed using fuzzy logic implements human reasoning that has been programmed into fuzzy logic language (membership functions, rules and the rules interpretation)It is interesting to note that the success of fuzzy logic control is largely due to the awareness to its many industrial applications.

The system consists of two small water-tanks one on top of the other and a water reservoir at the bottom of the lower tank. Each tank has an outlet valve which can be opened or closed to various orifice diameters. Water flows from the top tank into the bottom tank. Both tanks have calibration marks on them for visual determination of the water level in the tanks. Each tank is also provided with a pressure sensor at the base which can be appropriately calibrated to determine the level of the water in each tank for feedback control purposes. The input to the system is via a water pump which feeds water to the top tank. The flow rate is controlled by speed of a direct current motor that drives the pump using input from a digital computer running an appropriate feedback control algorithm for various water level control tasks. Working: A continuous square wave is applied at the I/P to the controller for creating continuous disturbance.Another I/P to the controller comes from feedback. The controller takes the action according to the error generated. This error and its derivative is applied to the controller which then takes the necessaryaction and decides the position of the valve which gives the desired flow of the liquid into the tank.The positioning of the valve is decided by PID Controller or by the rules written in the Fuzzy Logic Controller Rule Editor. If the liquid level in the tank is low then the valve open completely and if then liquid level is high in the tank then the valve closes or opens upto an extent. When the level is full then the valve closes completely. The designing of the PID controller can be changed by changing thevalues of Proportional Gain, Integral Gain & Derivative Gain . Control of dual water tank system: i : Simulink Block Diagram Description:

A*dh/dt=qin a*sqrt(2gh)-----------------------------------------(1) A=2300 a=7.1 g=9.81m/s2 Linearization The model of the water tank is non-linear. The non-linear model can be approximated by a linear model for small deviations around an operating point. The actuator is a pump which pumps water into the water tank. The relationship between the rate of flow in q and the controller output u is q in = ku, where k = 3.9 106 m3 /(s V) . The pump saturates at an input voltage of 10 V. The pumpcannot draw water from the tank, so there is also saturation at zero input voltage. The water level is measured by a sensor whose sensitivity is 40 V/m. PI Controller: The below figure is a screenshot of Simulink code of PI (Proportional + Integral) control implemented for the level control of Dual-Water tank system. The desired level of water in the upper tank is set by the user using a Simulink constant block. As a variation the desired level can be superimposed with a square, sinusoidal or other suitably shaped pulse with a small amplitude and frequency so as to require the water level to vary around a set point according to the shape of the pulse. This can be conveniently achieved using pre-defined blocks in Simulink. The error in level is computed using a comparator block which finds the difference between actual level measured with a pressure sensor and the desired level set by the user. The error signal is used in conjunction with appropriately tuned proportional and integral gains to achieve the level control by varying the speed of a DC motor connected to a water pump. The raw reading of the level sensor is very noisy due to bubbles, inflow of water from the pump etc. and is appropriately filtered using a suitable low-pass filter block in Simulink.

Simulink code for PI control of Dual Water Tank system

As in the PI controller the user sets the desired level using a constant block and the error is computed by comparing the actual level measured by the level sensor. Level error and change in error level is fuzzified using three overlapping membership functions similar to the fuzzification described for the DC motor fuzzy control.

Simulation result using PID controller

It is seen that PID controllers drives the system unstable due to mismatch error generated by the inaccurate time delay parameter used in the plant model. Transients & overshoots are present when PID controller is used to control the liquid level. Applications Classification of Liquid Level Controllers: There are several types of level controllers. Some of these are: A) Level Controllers: Level controllers are devices that operate automatically to regulate liquid or dry material level values. There are three basic types of control functions that level controllers can use, limit control, linear control and advanced or nonlinear control .

B) Integrated motion controllers: Integrated motion control systems contain matched components such as controllers, motor drives, motors, encoders, user interfaces and software. The manufacturer optimally matches components in these systems. They are frequently customized for specific applications. C)Pump Controllers: Pump controllers manage pump flow and pressure output. D)Flow controllers: Flow controllers allow metered flow of fluid in one or both directions. Many of them allow for free flow in one direction and reduced or metered flow in the reverse direction. Industrial Uses: We consider level control a fundamental control technique . Level controls are used in all types of applications: Tank farms Boilers Waste treatment Plants Reactors

Você também pode gostar

- PID Control of Water Level in A Coupled Tank SystemDocumento9 páginasPID Control of Water Level in A Coupled Tank SystemEioAsan100% (1)

- DEN5200 CONTROL SYSTEMS ANLAYSIS AND DESIGN ReportDocumento15 páginasDEN5200 CONTROL SYSTEMS ANLAYSIS AND DESIGN Reportsilvia100% (1)

- Lab ReportDocumento13 páginasLab ReportHemal MenukaAinda não há avaliações

- Simulation of ZN Tuning Method-2319Documento10 páginasSimulation of ZN Tuning Method-2319Rumana AliAinda não há avaliações

- TminDocumento17 páginasTminhanaAinda não há avaliações

- اخررررر تعديلDocumento10 páginasاخررررر تعديلAhmed nawfalAinda não há avaliações

- Implementation of Electronic Governor & Control System of A Mini-Hydro Power PlantDocumento6 páginasImplementation of Electronic Governor & Control System of A Mini-Hydro Power PlantbagastcAinda não há avaliações

- Designing of Fuzzy Logic Controller For Liquid Level ControllingDocumento10 páginasDesigning of Fuzzy Logic Controller For Liquid Level ControllingSkr KhanAinda não há avaliações

- Final Year ProjectDocumento4 páginasFinal Year ProjectZain RiazAinda não há avaliações

- Project Proposal LCSDocumento3 páginasProject Proposal LCSShameen MazharAinda não há avaliações

- amr.945 949.2559Documento5 páginasamr.945 949.2559Huynh Trung HieuAinda não há avaliações

- Water Flow Control System V2 PDFDocumento12 páginasWater Flow Control System V2 PDFAayushSrivastava100% (1)

- Control Lab Project ReportDocumento28 páginasControl Lab Project ReportDanyal QamarAinda não há avaliações

- (IV) Water Level Control SystemDocumento9 páginas(IV) Water Level Control Systemnasamohd17Ainda não há avaliações

- The PROCON PH Process Control System Is Based Around The PH Rig and Is A SelfDocumento10 páginasThe PROCON PH Process Control System Is Based Around The PH Rig and Is A Selfmiantahir89Ainda não há avaliações

- Design and Implementation of Fuzzy Controller On Embedded Computer For Water Level ControlDocumento5 páginasDesign and Implementation of Fuzzy Controller On Embedded Computer For Water Level ControlGopinathbl100% (1)

- Liquid Level Control System V2Documento14 páginasLiquid Level Control System V2Shisanu SenAinda não há avaliações

- PLC Based Sequential Batch Process Control SystemDocumento11 páginasPLC Based Sequential Batch Process Control SystemAmol PawarAinda não há avaliações

- PHD Research Plannin2Documento7 páginasPHD Research Plannin2CharlesAinda não há avaliações

- Don Bosco Technological Institiute: RationaleDocumento19 páginasDon Bosco Technological Institiute: RationaleRegina WayiAinda não há avaliações

- Ijetae 0712 19Documento5 páginasIjetae 0712 19SathisKumaarAinda não há avaliações

- Control of An Industrial Process Using PID Control Blocks PDFDocumento9 páginasControl of An Industrial Process Using PID Control Blocks PDFarnisiAinda não há avaliações

- PCVLDocumento16 páginasPCVLabmuqeet2Ainda não há avaliações

- HMPP Norsok Brochure V1-FinalDocumento5 páginasHMPP Norsok Brochure V1-FinalVidur ShibnauthAinda não há avaliações

- Scada Etp ReportDocumento12 páginasScada Etp ReportTahir DonAinda não há avaliações

- Level Control TrainerDocumento1 páginaLevel Control TrainerVirender RanaAinda não há avaliações

- Iceece Formatting TemplateDocumento6 páginasIceece Formatting TemplateVaibbhav GodseAinda não há avaliações

- College of Engineering Process Control Lab.: Basrah UniversityDocumento11 páginasCollege of Engineering Process Control Lab.: Basrah UniversityhanaAinda não há avaliações

- Project Proposal PI ControllerDocumento10 páginasProject Proposal PI ControllerMuhammad ArsalAinda não há avaliações

- Automatic Irrigation System Using AURDINO Uno (Mine)Documento41 páginasAutomatic Irrigation System Using AURDINO Uno (Mine)Shobha HebballiAinda não há avaliações

- Automatic Switching On and Off of Water PumpsDocumento15 páginasAutomatic Switching On and Off of Water PumpssravaniAinda não há avaliações

- Smart Valve Flow ConditionersDocumento4 páginasSmart Valve Flow ConditionersMuzammil HussainAinda não há avaliações

- Sir C.R.Reddy College of Engineering: PLC Based Sequential Batch Process Control SystemDocumento11 páginasSir C.R.Reddy College of Engineering: PLC Based Sequential Batch Process Control SystemParag RekhiAinda não há avaliações

- PID Theory From WikipediaDocumento7 páginasPID Theory From Wikipediaputra-tzuAinda não há avaliações

- Industrial Automation: AnswerDocumento10 páginasIndustrial Automation: AnswershachihataAinda não há avaliações

- AnswersDocumento22 páginasAnswersVAIBHAV KESHAV MANGARAinda não há avaliações

- Automation With PLCDocumento26 páginasAutomation With PLCKannan S100% (2)

- Mesb333 Pid ControlDocumento13 páginasMesb333 Pid ControlMohd KhairiAinda não há avaliações

- Chapter10 (Governors)Documento10 páginasChapter10 (Governors)Zohaib Anser100% (1)

- Automatic Liquid Level Control of Tank SystemDocumento9 páginasAutomatic Liquid Level Control of Tank SystemFatahillah AtaAinda não há avaliações

- Process Control System, Open Loop System (Automatic) and Closed Loop System (Manual)Documento3 páginasProcess Control System, Open Loop System (Automatic) and Closed Loop System (Manual)DanialAzimAinda não há avaliações

- UNIT-8 Elements of Control SystemsDocumento8 páginasUNIT-8 Elements of Control SystemsVenkateshYadavCivarlaAinda não há avaliações

- UNIT-8 Elements of Control SystemsDocumento8 páginasUNIT-8 Elements of Control SystemsVenkateshYadavCivarlaAinda não há avaliações

- UNIT-8 Elements of Control SystemsDocumento8 páginasUNIT-8 Elements of Control Systemsgkk001Ainda não há avaliações

- ECNG3004 Control System ApplicationsDocumento7 páginasECNG3004 Control System ApplicationsMarlon BoucaudAinda não há avaliações

- Streamlining Water Management Operations:: Moving Beyond Mechanical To Automated Electronic ControlDocumento3 páginasStreamlining Water Management Operations:: Moving Beyond Mechanical To Automated Electronic ControlHuy VuAinda não há avaliações

- General EK (Control)Documento22 páginasGeneral EK (Control)Maneesh100% (1)

- Water LevellingDocumento4 páginasWater Levellingshresth.gupta.ug22Ainda não há avaliações

- Flow Control Trainer: Experiment No: 03Documento3 páginasFlow Control Trainer: Experiment No: 03Musa KhanAinda não há avaliações

- Remote Aquarium Monitor and Control System: Project DescriptionDocumento7 páginasRemote Aquarium Monitor and Control System: Project DescriptionVrushali KhatpeAinda não há avaliações

- Introduction To Hydraulics, Servo Drive and PLCDocumento5 páginasIntroduction To Hydraulics, Servo Drive and PLCHeather Reyes100% (1)

- PID ControllersDocumento9 páginasPID Controllerszs94qjqcx7Ainda não há avaliações

- Ladder LogicDocumento7 páginasLadder LogicCesar ChangAinda não há avaliações

- Juice Flow Stabilization Using PLC and Simulating With ScadaDocumento3 páginasJuice Flow Stabilization Using PLC and Simulating With ScadaerpublicationAinda não há avaliações

- Paper Multivariable Tank 0405131Documento17 páginasPaper Multivariable Tank 0405131Vaghela ChintanAinda não há avaliações

- Control System NotesDocumento179 páginasControl System NotesChandrashekarAinda não há avaliações

- Control of DC Motor Using Different Control StrategiesNo EverandControl of DC Motor Using Different Control StrategiesAinda não há avaliações

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceAinda não há avaliações

- Introduction to the simulation of power plants for EBSILON®Professional Version 15No EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Ainda não há avaliações

- Electromagnetic Transients and FaultsDocumento1 páginaElectromagnetic Transients and Faultsఅయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- Install GuideDocumento159 páginasInstall GuideKandimalla Divyabramhendra ChowdaryAinda não há avaliações

- Adm1602k Nsa Fbs 3.3vDocumento22 páginasAdm1602k Nsa Fbs 3.3vHer ManTokAinda não há avaliações

- AccelerometersDocumento4 páginasAccelerometersఅయ్యలసోమయాజుల సాయి శివ100% (1)

- Am 23226231Documento6 páginasAm 23226231అయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- InstallDocumento6 páginasInstallAndrew DugganAinda não há avaliações

- 3b XCBDocumento8 páginas3b XCBఅయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- 4F7Examples06 07Documento22 páginas4F7Examples06 07అయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- 3 NDMA VinodDocumento22 páginas3 NDMA VinodShruti GaurAinda não há avaliações

- Grade Card: Course Code Course Name Credits Grade ResultDocumento1 páginaGrade Card: Course Code Course Name Credits Grade Resultఅయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- Universal ATM Card: Anjanaa. J, Devi Priyal. V & Prathiba. MDocumento4 páginasUniversal ATM Card: Anjanaa. J, Devi Priyal. V & Prathiba. Mఅయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- BiblioDocumento6 páginasBiblioఅయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- Real-Time Control Implementation of Simple Mechatronic Devices Using MATLAB/Simulink/RTW PlatformDocumento12 páginasReal-Time Control Implementation of Simple Mechatronic Devices Using MATLAB/Simulink/RTW Platformఅయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- Analog and Digital ElectronicsDocumento10 páginasAnalog and Digital Electronicsఅయ్యలసోమయాజుల సాయి శివ100% (1)

- ASIO4ALL v2 Instruction ManualDocumento11 páginasASIO4ALL v2 Instruction ManualDanny_Grafix_1728Ainda não há avaliações

- ASIO4ALL v2 Instruction ManualDocumento11 páginasASIO4ALL v2 Instruction ManualDanny_Grafix_1728Ainda não há avaliações

- Analysis of Digital Modulation Techniques Meeting Low Power Requirements For Microwave Link Satellite SystemsDocumento1 páginaAnalysis of Digital Modulation Techniques Meeting Low Power Requirements For Microwave Link Satellite Systemsఅయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- Frew Space Q CryptographyDocumento6 páginasFrew Space Q Cryptographyఅయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- MP 8051Documento15 páginasMP 8051api-19757160Ainda não há avaliações

- Programming Methods For Robots: Apurva Joshi M.Tech (RE)Documento21 páginasProgramming Methods For Robots: Apurva Joshi M.Tech (RE)అయ్యలసోమయాజుల సాయి శివAinda não há avaliações

- TACCP Risk Assessment Template Checklist - SafetyCultureDocumento4 páginasTACCP Risk Assessment Template Checklist - SafetyCultureNaeemaAinda não há avaliações

- An2292 PDFDocumento9 páginasAn2292 PDFMarcel BlinduAinda não há avaliações

- IBM Tivoli Storage Manager Version 6.4 Problem Determination GuideDocumento294 páginasIBM Tivoli Storage Manager Version 6.4 Problem Determination GuideBogdanAinda não há avaliações

- Fazlur KhanDocumento19 páginasFazlur KhanyisauAinda não há avaliações

- Dewa Asset ManagemntDocumento7 páginasDewa Asset ManagemntDC VashistAinda não há avaliações

- Open Source Whitebox Router PDFDocumento13 páginasOpen Source Whitebox Router PDFtobecaAinda não há avaliações

- Windows 8.1 Error.Documento2 páginasWindows 8.1 Error.comenbabyAinda não há avaliações

- Introduction To GDPRDocumento107 páginasIntroduction To GDPRHarkirat Vasir0% (1)

- 1PH EswfDocumento9 páginas1PH EswfSomaraju PitchikaAinda não há avaliações

- DLKDocumento144 páginasDLKJUAN CARLOS PAZAinda não há avaliações

- Paddy Leaf Disease DetectionDocumento48 páginasPaddy Leaf Disease DetectionAkula SandeepAinda não há avaliações

- Installation of TransformerDocumento24 páginasInstallation of TransformerMariel A. ReyesAinda não há avaliações

- Graphic Design Assignment 1Documento4 páginasGraphic Design Assignment 1Amita MaddhesiyaAinda não há avaliações

- HON-FIN4000xxK-10K - User Guide V1.3 (EN)Documento63 páginasHON-FIN4000xxK-10K - User Guide V1.3 (EN)RantiAinda não há avaliações

- Spec Sheet Potato Peeler Pi 20Documento2 páginasSpec Sheet Potato Peeler Pi 20voldemort.bilalAinda não há avaliações

- APEX Connector S 187EO 132 2Documento67 páginasAPEX Connector S 187EO 132 2sunhuynhAinda não há avaliações

- CONTENTS Hyundai Excavator - R35Z 7 - Parts Catalog 280pagesDocumento15 páginasCONTENTS Hyundai Excavator - R35Z 7 - Parts Catalog 280pagesKen LeeAinda não há avaliações

- AssetDocumento13 páginasAssetrageendrathasAinda não há avaliações

- Bulk Sms End User GuideDocumento46 páginasBulk Sms End User GuideMutiara HatiAinda não há avaliações

- A Framework For Web Based Student Record Management System Using PHPDocumento5 páginasA Framework For Web Based Student Record Management System Using PHPDrey Drey IIAinda não há avaliações

- Electric Circuits Analysis 1 - With Page NumbersDocumento15 páginasElectric Circuits Analysis 1 - With Page Numberskenneth1195Ainda não há avaliações

- Canalta Meter Run Info SheetDocumento3 páginasCanalta Meter Run Info Sheetautrol100% (1)

- Makalah Bahasa InggrisDocumento6 páginasMakalah Bahasa InggrisIRFANAinda não há avaliações

- Topaz User Manual (Eng)Documento418 páginasTopaz User Manual (Eng)mohanraj100% (5)

- Handbook For Sap PP in S/4HANADocumento477 páginasHandbook For Sap PP in S/4HANArahmani83% (6)

- B.tech - CSE - AI & ML - 2020 - 2021 - Curriculum and Syllabus V4Documento263 páginasB.tech - CSE - AI & ML - 2020 - 2021 - Curriculum and Syllabus V4Yash UtrejaAinda não há avaliações

- Virtualinstrumentation2 150506100543 Conversion Gate01Documento177 páginasVirtualinstrumentation2 150506100543 Conversion Gate01vvipmembersAinda não há avaliações

- Brand PerceptionDocumento105 páginasBrand Perceptionlekshmi517100% (1)

- ANA Content Marketing Maturity ModelDocumento2 páginasANA Content Marketing Maturity ModelDemand Metric100% (1)

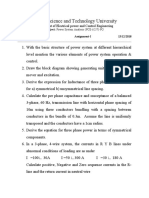

- Adama Science and Technology University: Department of Electrical Power and Control EngineeringDocumento2 páginasAdama Science and Technology University: Department of Electrical Power and Control EngineeringOkezaki TemoyoAinda não há avaliações