Escolar Documentos

Profissional Documentos

Cultura Documentos

PQP

Enviado por

Muhammad ShazwanuddinTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PQP

Enviado por

Muhammad ShazwanuddinDireitos autorais:

Formatos disponíveis

PROJECT QUALITY PLAN

JBS ENGINEERING SDN. BHD.

Doc No : Rev. No : P Date Page : T.B.A : i

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

i.

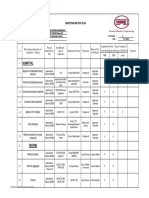

REVISION SUMMARY SHEET

This is a summary of the change that has been made to the policy documents contained within this procedure. Revision No P Revision Description Issue for Tender Submission Date Issued T.B.A

ii. DISTRIBUTION LIST

The following personnel are holders of controlled copies of this documents:

COPY NO. 1 (Master) 2 3 4 5 6 7

HOLDER QMR /Managing Director Project Director Project Manager Construction Manager QAQC PMC Consultant

USAGE Document Control Implementation Implementation Implementation Implementation Implementation Implementation

PROJECT QUALITY PLAN

JBS ENGINEERING SDN. BHD.

Doc No : Rev. No : P Date Page : T.B.A : i

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

CONTENTS i REVISION SUMMARY SHEET ii DISTRIBUTION LIST 1.0 PROJECT DESCRIPTION 1.1 Project Brief 1.2 Scope of Works 1.3 Project Particular 1.4 Work Programme 1.5 List of Drawing PROJECT ORGANIZATION 2.1 Client/Projects Owner 2.2 Project Manager/Project Management Consultant (PMC) 2.3 Consultant 2.4 Sub-contractor 2.5 Suppliers SITE ORGANIZATION 3.1 Organization Chart 3.2 Key Personnel Responsibilities 3.2.1 Project Manager (PM) 3.2.2 Construction Manager (CM) 3.2.3 Surveyor 3.2.4 Safety and Health Officer 3.2.5 Site Supervisor 3.2.6 Clerk PROJECT ADMINISTRATION / QUALITY REQUIREMENT 4.1 Quality System Structure 4.2 Quality Assurance Outline 4.2.1 General 4.2.2 Quality Control Activities 4.2.3 Verification Activities 4.2.4 Audit Activities 4.3 Record Management 4.4 Project Quality Review 4.5 Resource Management 4.5.1 Provision of Resources 3.6.2 Human Resources 3.6.3 Infrastructure 3.6.4 Work Environment and Safety 3.7 Process Control 3.8 Amendment To Contract 3.9 Design and Change Control 3.10 Procurement Control ASSURANCE

PAGE i ii

1 2

2.0

3 3

3.0

4 5 6 7 8 8 8 10 10 11 11 12 12 12 13 13 14 14 14 15 15 15 16 16 17

4.0

PROJECT QUALITY PLAN

JBS ENGINEERING SDN. BHD.

Doc No : Rev. No : P Date Page : T.B.A : i

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

3.11 3.12 4.0

4.10.1 Purchasing 4.10.2 Claim and Payment Inspection and Testing Servicing And Maintenance

17 17 18 18 19 19 19 20 20 20 20 20 20 20 21 21 22

MEASUREMENT, ANALYSYS AND IMPROVEMENT 4.1 General 4.2 Customer satisfaction 4.3 Control of Nonconforming Product 4.3.1 Reporting Nonconformance 4.3.2 Owner and Design Engineer / Consultant Complaint 4.3.3 Review and Disposal of Nonconformance 4.4 Analysis Of Data 4.5 Improvement 4.5.1 Continual Improvement 4.5.2 Corrective Action 4.5.3 Preventive Action APPENDICIES Appendix 1 - Work Programme Appendix 2 - List of Drawing Appendix 3 Site Organization Chart Appendix 4 List of Approved Subcontractor Appendix 5 Inspection and Test Plan (ITP) Appendix 6 Forms Master List & Related Form For Implementation

5.0

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

1.0 PROJECT DESCRIPTION 1.1 Project Brief The Sunggala Army Camp is located within Si-Rusa Sunggala sewerage catchment boundry, about 9 km from town center of Port Dickson. It can be easily accessible by Jalan Pantai/PD Teluk Kemang. Total area of the Army Camp is about 2,100 acres. The Camp having various types of localizes STPs such as ITPS, CST and IST. Most of the STPs are in very bad condition and some of the STPs totally not functioning which contribute to the environmental pollution. 1.2 Scope of Works This Project Quality plan shall be applied for the proposed design, construction and completion of this project. The scope of works comprises the following:

Conduct design, supply, construction, supervision and completion of the proposed main sewer, sub main sewer, collectors and reticulation sewers to cater sewerage flows from Sunggala Army Camp. Rationalization and decommission of the 15 numbers of existing STPs. Property sewer connection for the rationalization/decommission of the existing STP. Sewer connection from army camp to Si-Rusa Sunggala Trunk sewer CCTV inspection Inspection Prior to Handling Over sewerage system Testing and Commissioning

This document provides quality assurance requirements to be applied throughout the duration of the contract. 1.3 Project Particular 1.3.1 Project Title. The title of the Projects shall be as follows:Pakej D28 Kerja-kerja paip pembentungan di kem Tentera Sunggala Negeri Sembilan Darul Khusus (Reka dan Bina) 1.3.2 Project Details

Contract Sum Awarded Date Site Possession Contract Duration Completion Date Defect Liability Period

: To be advised : To be advised : To be advised : 24 months : To be advised : 24 Months

1.4 Work Programme

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

Work scheduling intended for the Contract in Microsoft Project format. The programme shall be adjusted and updated to reflect the changing site conditions and requirements Refer Appendix 1 Work Programme 1.5 List of Drawings. Refer Appendix 2 List of Drawing (To be advised later) 2.0 PROJECT ORGANIZATION 2.1 Project Owner Kementerian Tenaga, Teknologi Hijau dan Air (KeTTHA) Jabatan Perkhidmatan Pembentungan Tingkat 7,Blok B (Utara) Tel: 603 20809400 Pusat Bandar Damansara Fax: 603 20962609 50490 Kuala Lumpur Email: To be advised Project Management Consultant Indah Water Konsortium Sdn Bhd.

Level 3, Block J, Pusat Bandar Damansara,. 50490 Kuala Lumpur. Tel: 603 27801100 603 27801101 Email: To be advised

2.2

Fax:

2.3

Design Engineer & Consultant Perunding Inovasi. 13B, Jalan BRP 1/4, Bukit Rahman Putra, 47000, Sg Buluh, SELANGOR D.E .

Tel: 603 61405958 Fax: 603 61402090 Email: To be advised.

2.4

Sub-contractors and Suppliers Refer Appendix 4 List of Approved Subcontractors and Suppliers.

3.0 SITE ORGANIZATION 3.1 General The Project Team that has been assigned to carry out the project consists of On Site Personnel.

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

The On Site Personnel are the Project Manager (PM), Construction Manager (CM), QAQC, Safety And Health Officer, Site Supervisor, Clerk and Support Staff. Refer to Appendix 3 Site Organization Chart. 3.2 Key Personnel Responsibilities The following responsibilities have been assigned to the organisational positions for the project. 3.2.1 Project Manager (PM) Responsible for the execution and successful completion of the project to the satisfaction of the Owner. His responsibilities include: Execution & administration of the contract. Detailed study of drawings and work site to determine scope of works; Monitor & analyze project progress and recommend any improvements or remedial actions to the Company Director. Jointly with the QAQC representative on preparation and reviewing the respective Project Quality Plan; Initiate rectification works against any corrective action requests or complains; Liaison with owners representatives and authorities; Setting up of various departments at site office; Chairing site management meetings to review work progress and related site problems; Checking and submitting progress claims; Providing feedback to the Company Director/his staff regarding production rates; Certifying Sub-contractors progress claims; Resolve any contractual claims by subcontractor; Preparation of Construction Program and Progress Reports. Solving technical and design problems together with design engineer. Proposing design changes to design engineer to solve construction problems Cost control monitoring Calling and negotiating quotations for sub-contract works at site level Handle client and third party complaint addressed directly to site. Carrying out relevant maintenance works during defect and liability period

3.2.2

Construction Manager (CM)

To assist the Project Manager in execution of his daily responsibilities/duties To lead the team and re-check all relevant quantities needed for construction To co-ordinate with all sections of operation works and monitoring the work progress Determining method of construction Planning and delegation of task to site supervisory staff, equipment and plant operators.

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

Coordinating with subcontractors Controlling efficiency of works to minimize the cost of construction. Controlling quality of works to follow drawings and specifications. Executing rectification against any correction request or complain. Final joint inspection of the completed works for handling over. Control of safety on site. Minimization of environmental impact. Identifying the borrow and disposal area; Provide data to the Quantity Surveyor for progress claim submission to the client To arrange and prepare the as-built drawings 3.2.3 Quantity Surveyor Responsible for all quantity surveying activities relating to the project including: 3.2.4 Perform project cost control. Contract Administration and sub-contract procurement Purchasing Prepare the proposal for variations/claims. Preparation and submission of progress claim to Project Manager Preparation of sub-contractors progress payment

Quality Assurance /Quality Control (QAQC) Appointed person, assigned as Quality Assurance Representative at site (QA Representative) for day to day activities and audit. Specific responsibilities include:

3.2.5

To ensure site service and activities conform to quality requirements. Co-ordinate quality assurance activities on site. Monitor construction activities for possible quality and environmental problems. Review quality standards, inspection techniques and methods for appropriateness. Initiate or evaluate proposals and recommendations for new quality criteria or modified procedures, facilities, test equipment or new activities. Audit all measuring and test equipment. Follow-up and review non-conformance reports for corrective action requirements. Provide input into methods of disposition of non-conforming work. Maintain Nonconformance register; Compile information and prepare towards the development of the Project Quality Plan; Assist the Project Manager in preparation of Inspection and Test Plans; Ensure that all quality records are complete and maintained. Surveyor

To establish control points, Right of Way setting out and levels. To carry out alignment and setting out surveys. To carry out monthly joint measurement for work done with design engineers and owners representatives.

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

3.2.6 *

To keep proper filing and booking of all survey records To check all surveys equipment in good condition. To ensure test and calibration are carried out on survey equipments.

Safety Site Supervisor To assist the PM in a day-to-day operation in organizing and implementing occupational safety and health at the site inclusive of any inspection of the place of work for the purpose of checking effectiveness and efficiency of any measures taken in compliance with the Act or any regulation made under Act Site Supervisor The Site Supervisor shall be responsible for the following:

3.2.7

Supervising and controlling the direct labours and subcontractors work. Undertaking inspection of work to ensure conformance to specification. Identifying and reporting any incidence of non-conformance to either specification or system. 3.2.7 Clerk

Compile, manage and maintain proper site office documentations related to the project. Liaise with Head Office regarding personnel matters.

4.0

PROJECT ADMINISTRATION / QUALITY ASSURANCE REQUIREMENTS 4.1 Quality Assurance Outline 4.1.1 General

i)

The quality system to be implemented for the project is documented within this Project Quality Plan. Procedures are established to plan and control activities, which contribute to the quality of the work. The procedures are based on the requirements as stated in the contract documents. Project team is to implement the quality system and shall use all relevant procedures as compiled together with this Project Quality Plan.. The QA Representative or appointed person who reports to the Project Manager at site is responsible for the day to day operations concerning the assurance of quality for works at the project site. All Personnel involved with the Project will have a role to perform in implementation of this Project Quality Plan.

ii)

iii)

iv)

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

v)

Functions such as control systems for documentation, procurement, inspection, measuring and testing equipment, records management and training are incorporated into and form an integral part of the Project Quality Plan. Roles within this Project Quality Plan are distinguished as follows:

vi)

Site Supervisory staff shall be responsible for quality control by monitoring and checking the work under their immediate control according to the technical requirements of the contract. Project Manager shall be responsible for adherence to the Project Quality Plan procedures (including quality control) on site. Appointed internal auditors will assess the operation and effectiveness of the Project Quality Plan. This may include critical analysis of constituent work items being manufactured and constructed.

vi)

These integrated roles will contribute to the assurance of quality for all works under the project. Regular management review of the Project Quality Plan will be carried out to ensure its continuing suitability and effectiveness.

4.2.2

Quality Control Activities

i)

The function of quality control is to check, measure, test, inspect and where necessary record actions in a formalized manner to confirm compliance with the contract requirements. This Project Quality Plan details quality control requirements including receiving, in-process and final inspection and test. The personnel responsible for quality control will complete, as necessary, checklists, test reports and the like, which record successful completion of the inspection and test requirements. The site supervisory staff, surveyors, subcontractors, suppliers and specialist inspection/ testing agencies may carry out quality control activities. All inspections and tests specified for the project is developed into an inspection and test plan and shall be incorporated into the Project Quality Plan.

ii)

iii)

iv)

4.2.3

Verification Activities

i)

Verification is achieved by the Design Engineer and/or owners Project Engineer and his representatives undertaking formal checks of the quality of the work being submitted for acceptance. All verification activities will be documented to provide a record, which together with quality control records form the basis of assurance. These records will be managed through a system, which is planned and maintained as detailed in this Project Quality Plan and related procedures. To provide independent acceptance inspections at Hold Points and Witness Points nominated in Inspection and Test Plans, the QA Representative and/or the Design Engineer & Consultant will co-ordinate with the representatives of the Owner.

ii)

iii)

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

4.2.4

Audit Activities

i)

Audit is a verification activity internally or externally used to assess the operation and effectiveness of this Project Quality Plan as well as all respective Quality Procedures and/or Standard Operating Procedure Quality system internal audits shall be undertaken by internal auditors of ADAT 88 who are trained in the techniques of auditing. The auditors will objectively audit and report on the system to evaluate its operation and effectiveness.

ii)

4.3

Records Management Quality records are the documents that provide objective evidence of compliance (or noncompliance) with specified requirements. They include but not limited to: Inspection and test records Equipment list and calibration record Internal audit related reports Non-conformance documentation Drawings and specifications Materials and goods flows record Technical records (e.g. surveying data, material certificate) All kind project related correspondence Owner and third party complaints

Arrangements for the archiving of specific records to comply with both Owners and regulatory requirements shall be identified and controlled. Backup file shall be maintained for records kept in softcopy. 4.4 Project Quality Review The Project Manager shall convene and chair a review of the effectiveness of the Project Quality Plan in achieving the quality objectives of the project. The first review shall be held not later than one year after physical works commencement. Further reviews shall then be conducted when major changes are made or found as necessary. 4.6 Resource Management 4.6.1 Provision Of Resources ADAT 88 shall determine the resources needed during management reviews and before undertaking the project during the planning stage. The necessary resources shall be provided so as to ensure implementation and maintenance of the QMS and its continuing effectiveness and to ensure that customer requirements are met. 4.6.2 Human Resources

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

i)

General Personnel performing work affecting product quality shall be competent on the basis of appropriate education, training, skills and experience.

ii) Competency, Awareness and Training Performance appraisal and training needs shall be provided or any other action taken and evaluated to review its effectiveness. All personnel shall receive basic instruction in the companys policies, procedures and practices to ensure they are familiar with the companys operation. All personnel shall participate in training programmes relating to the companys SOP and shall be aware of the relevance and importance of their activities and how they contribute to the achievement of the quality objectives established. 4.6.3 Infrastructure ADAT 88 shall determine, provide and maintain the infrastructure needed. Site preparation for e.g. setting up of temporary works, utilities, site security and safety, etc. shall be undertaken during the mobilization stage. Plant and machinery required should be planned during the planning stage and necessary preventive maintenance shall be done. 4.6.4 Work Environment and Safety The Project Manager shall ensure the working environment in the site office, site and storage areas are suitable at all time to achieve conformity to product requirements. Particular attention shall also be placed on maintaining the site in state of order and safe. It is the Project Manager responsibility for ensuring that all reasonable and practical action is taken at site level to achieve the requirements of the Occupational Health and Safety Act 1994 as a minimum. All matters pertaining to safety requirements outlined in separate Health and Safety Plan maintained by Safety Officer at site office. 4.7 Process Control ADAT 88 shall ensure that controls are defined and maintained throughout the contract and will review project status in site and progress meetings. The Project Manager in conjunction with the Owners Representative and Resident Engineer will define requirements for inspection, witness and hold point. ADAT 88 shall assure that adequate control and co-ordination of projects as follows: a) b) Processes are performed by suitably qualified, experienced and trained personnel working to relevant SOP element Equipment used shall be controlled, calibrated, maintained and approved

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

c) d) e) f)

Material, equipment and services used shall be procured in a controlled manner and approved by the Owner or Design Engineer/Consultant Processes shall be performed in accordance with Quality Procedures, Site Instruction and drawing or specification, and organisational interfaces shall be identified and controlled Controlled and documented systems shall be available for the identification, segregation and disposal of non-conforming items The planning and monitoring requirements of projects are carried out by the assigned project staff

All the above shall be in lined and documented in Method Statement for each critical work to be carried out. Method Statement shall be prepared as required by Owners Representative or deemed necessary by the Project Manager and/or the Consultant. 4.8 Amendment To Contract When a variation to the original scope of work is identified, irrespective of origin, the Project Manager will initiate the following: Review of the change Advise the owner of any change to contract value or duration Obtain and record the Owners approval Advise the Project Director Design and Change Control In the event that site conditions dictate the need for design change, these shall be proposed and recorded through the use of design change form. The proposals shall be submitted by Project Manager after joint inspection with the Design Engineer/Consultant who then shall inform the Owner or his representative. Amended drawing shall be stamped Superseded and shall make cross-reference to the relevant design change form. The design change form and the new drawing should be kept together. The new drawings shall indicate the cross-reference for all relevant design change form. 4.10 Procurement Control 4.10.1 Purchasing All purchasing activities are controlled against the specified requirements and by means of the following : a) b) Approval from Design Engineer/ Resident Engineer and/or Owner, Approved Suppliers and Selected Subcontractors ADAT 88 has established and maintains a List of Approved Suppliers and Subcontractors. This is to ensure that the supply of materials, services and equipment are controlled. Refer Appendix 4 List of Approved Subcontractors & Suppliers Any purchasing and procurement to be made for this project shall comply with the respective procedures, contract requirements, design engineer/ resident engineer approval and/or owners representative instruction.

4.9

c)

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

d)

Where suppliers certificates are required for their supplied material, ADAT 88 shall make arrangements to obtain, review and distribute copies of the certificates to the design engineer/ resident engineer and/or owner for the selection of approved sources and for the control of supply. Where required, ADAT 88 shall arrange an independent test program to substantiate the manufacturers certificates. 4.10.2 Claim And Payment Claim for progress payment to the Owner shall be done by Project Manager on monthly basis. Verification of claimed quantity shall be done jointly with the Resident Engineer and Owners Representative. ADAT 88 to adhere to the quality procedure for payment to be made to the material supplied, Subcontractors, Design Engineer, capital expenditure and petty cash. All necessary documents to support payment to the various parties shall be prepared by using agreed format or any other way to be agreed by both parties.

e)

10.11

Inspection And Testing All materials or product to be incorporated into permanent works shall be inspected, tested, or otherwise verified by the Resident Engineer and/or Owners Representative, to demonstrate conformance to specification. Product or materials that are subsequently suspected as non-conforming will be identified and marked accordingly. If practical, non-conforming materials will be segregated to prevent accidental use. In the event that releases of incoming materials or product are urgently required for project progress, they may be released under "positive recall" conditions. In these circumstances the construction activities will be recorded on the master plan to allow immediate identification and replacement in the event of non-conformance. All works shall be subjected to inspection and/or testing to ensure compliance with specification as detail in Inspection and Testing Plan. Where special inspection and test needed beyond ADAT 88 competency, an independent inspection company shall be engaged. The specialist work shall subject to be tested for the duration of the works. The report issued shall be forwarded to the Owner and Design Engineer/Consultant. Both ADAT 88 and Owners representatives will carry out final inspection to ensure that the finished product conforms to specified requirements. The works will not be released until final inspection and test activities have been satisfactorily completed. This will include the availability of relevant documentation signed off with the appropriate authorisation. Refer Appendix 5 Inspection and Test Plan

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

4.12

Servicing And Maintenance. ADAT 88 will ensure adequate servicing and maintenance of permanent works during the defect and liability period as stated in the contract. ADAT 88 will provide adequate technical advice, materials supply and trained personnel to carry out satisfactory maintenance and servicing of product Maintenance works that are required resulting from owners complaint or works failure shall be treated as non-conformance. These works are to be recorded and carried out expeditiously.

.0

5 MEASUREMENT, ANALYSIS AND IMPROVEMENT 5.1 General The Project Manager shall plan and implement the monitoring, measurement, analysis and improvement processes need to ensure conformity of the works carried out in according to the contract requirements. 5.2 Customer Satisfaction The Project Manager shall monitor information relating to owners perception to determine whether owners requirements are met by monitoring and analyzing owners complaints received. Based on the feedback received, the Project Manager shall take appropriate actions to ensure owners satisfaction. 5.3 Control of Nonconforming Product 5.3.1 Reporting Non-conformance Site Personnel who identifies non-conformance will report the findings to the Project Manager. Non-conforming incoming materials will not be off loaded or received into storage area. They be identified and if practical the products or materials will be segregated and moved to an appropriate holding area to await evaluation and disposition. Work in progress and finished product that are non-conforming shall be marked or tagged with appropriate indicators, RED in color, to prevent accidental use. All non-conformances, whether in product, service, process or testing shall be duly recorded.

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

5.3.2

Owner and Design Engineer/Consultant Complaints All owners and design engineer/consultants verbal complaints shall be given appropriate attention and the person receiving the complaint shall ensure its satisfactory resolution. All owners and design engineer/consultants written complaints issued through Non-conforming forms shall be referred to the Project Manager.

5.3.3

Review and Disposal of Non-conformance The Project Manager will inspect non-conforming products, as soon as practical after being informed and decide whether the item can be : Reworked Accepted with concession Replaced or otherwise scrapped. All items that are reworked will be re- inspected before acceptance and the results will be reviewed and recorded. In the event that a non-conformance or its subsequent action will affect the Finished Product or delay delivery to the owner, the Project Manager will seek advice from the Technical/Construction Director regarding informing the owner.

5.5 Improvement 5.5.1 Continual Improvement The performance of the project shall be reviewed regularly by the Project Manager, Construction Director and Technical Director to ensure that necessary corrective and preventive actions are taken for continuous improvements. The Project Manager shall ensure corrective and preventive actions are taken to eliminate the causes of actual or potential non-conformity. The need for action to ensure that nonconformity does not recur shall be evaluated. 5.5.2 Corrective Action The Project Manager will approve corrective action prior to it being implemented. Any corrective action must be practical and cost justified. All corrective action will be subject to follow up before closing the relevant NCR. 5.5.3 Preventive Action Preventive actions are normally initiated during management reviews or through employee feedback. Data shall be analyzed, from performance, complaints, audits, feedback, etc. The management review committee shall delegate the personnel to carry out the necessary

JBS ENGINEERING SDN. BHD.

PROJECT QUALITY PLAN

CADANGAN MENAIKTARAF PAIP PEMBENTUNGAN DI JALAN SULTAN AHMAD SHAH, GEORGETOWN, PULAU PINANG (REKA DAN BINA)

Doc No : Rev. No : Date Page : T.B.A :

study and to recommend appropriate preventive actions. The effectiveness of the preventive actions taken shall be monitored. As a minimum, the review shall cover: Current operations System Improvement Request/Non-conformance Test result Internal reports Customer complaints

After assessing the practicality, effect and worth of proposed preventive action, the review shall make recommendations to the Technical Director for approval. Preventive action shall be implemented under the same rules as corrective action, and shall be reviewed by the next Management Review.

5.0

Appendicies Appendix 1 Appendix 2 Appendix 3 Appendix 4 Appendix 5 Appendix 7 Work Programme List of Drawing Site Organization Chart List of approved Subcontractors and Suppliers Inspection & Test Plan Form Master List and Related Forms For Implementation.

Você também pode gostar

- FAA - System Safety HandbookDocumento341 páginasFAA - System Safety HandbookPham Chung100% (1)

- Method Statement Steel Structure 1 4 Meg PDFDocumento26 páginasMethod Statement Steel Structure 1 4 Meg PDFemeka2012Ainda não há avaliações

- Excavation and TrenchingDocumento2 páginasExcavation and TrenchingvikasAinda não há avaliações

- Health Care Delivery SystemDocumento42 páginasHealth Care Delivery SystemAbigail VirataAinda não há avaliações

- Project Quality Plan (PQP)Documento18 páginasProject Quality Plan (PQP)Ko Lin Lin KoAinda não há avaliações

- Method Statement - Crack Control Joint For CCB RC WallDocumento7 páginasMethod Statement - Crack Control Joint For CCB RC WallReza RosenoAinda não há avaliações

- Method Statement FOR Concreting Work: ProjectDocumento6 páginasMethod Statement FOR Concreting Work: ProjectKelvin LauAinda não há avaliações

- Method Statement & Itp For Waterproofing WorkDocumento7 páginasMethod Statement & Itp For Waterproofing WorkRumi ZamAinda não há avaliações

- ITP Clearing and GrubbingDocumento12 páginasITP Clearing and GrubbingAntonio Tomas Gonzalez LosaAinda não há avaliações

- ITP For RC RC Slab, Beams WorkDocumento3 páginasITP For RC RC Slab, Beams WorkMohammed Ghareib NasrAinda não há avaliações

- Quality Plan 2 PDF FreeDocumento21 páginasQuality Plan 2 PDF FreeEng.arifAinda não há avaliações

- ItpDocumento7 páginasItpJose Sherin100% (1)

- 01 ITP TemplateDocumento6 páginas01 ITP TemplateHelsy FuentesAinda não há avaliações

- Contract Welding and Inspection Plan for Pulang Pisau Power Plant ProjectDocumento44 páginasContract Welding and Inspection Plan for Pulang Pisau Power Plant ProjectSamid MidmidAinda não há avaliações

- 027 ITP For Pre Cast Concrete PDFDocumento27 páginas027 ITP For Pre Cast Concrete PDFlinga2014Ainda não há avaliações

- Sop-Hr-02 - Time and AttendanceDocumento6 páginasSop-Hr-02 - Time and Attendanceapi-27819317167% (3)

- 03 Rebar InspectionDocumento1 página03 Rebar InspectionDawit SolomonAinda não há avaliações

- Design/Builder Completion InspectionDocumento73 páginasDesign/Builder Completion InspectionpradeepkgjAinda não há avaliações

- Method Statement For Stone WorksDocumento10 páginasMethod Statement For Stone WorksvisanuAinda não há avaliações

- Concrete Checklist: Structural and Design CheckDocumento8 páginasConcrete Checklist: Structural and Design CheckStephen AgyinAinda não há avaliações

- Lesson 10 Project Quality PlanningDocumento51 páginasLesson 10 Project Quality PlanningDevjit MandalAinda não há avaliações

- 5 Formwork ChecklistDocumento81 páginas5 Formwork ChecklistAlphaAinda não há avaliações

- PQP EpldtDocumento8 páginasPQP Epldtmartin leeAinda não há avaliações

- NAV-TP-0283 Scaffold ChecklistDocumento2 páginasNAV-TP-0283 Scaffold ChecklistRicky Hawk100% (1)

- 01-ABC Subcontract Plan.-Rev.01Documento6 páginas01-ABC Subcontract Plan.-Rev.01Shahid BhattiAinda não há avaliações

- Block Work Masonry MethodologyDocumento4 páginasBlock Work Masonry MethodologyEyutt HghghAinda não há avaliações

- Itp Civil WorkDocumento9 páginasItp Civil WorkChristian Albert Sinaga RumajarAinda não há avaliações

- Qa QCDocumento10 páginasQa QCBrain Dee Tech LtdAinda não há avaliações

- Qualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesDocumento7 páginasQualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesRHOWELLE TIBAYAinda não há avaliações

- Quality PlanDocumento21 páginasQuality PlanQianlei ZhuAinda não há avaliações

- SITE-SPECIFIC QC PLANDocumento3 páginasSITE-SPECIFIC QC PLANloveanbu24100% (1)

- MS-001-Form Work, Reinforcement Steel & Concrete WorksDocumento12 páginasMS-001-Form Work, Reinforcement Steel & Concrete WorksFrancis Phillip CapistranoAinda não há avaliações

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Documento9 páginasMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepAinda não há avaliações

- Excavation and Backfill: Method StatementDocumento6 páginasExcavation and Backfill: Method Statementtrealdi suryoAinda não há avaliações

- Contractor Quality Control Plan For Electrical Equipment InstallationDocumento7 páginasContractor Quality Control Plan For Electrical Equipment Installationhasan_676489616Ainda não há avaliações

- Quality Assurance Plan For Building ConstructionDocumento18 páginasQuality Assurance Plan For Building ConstructionAmit Kumar Pandey100% (1)

- CEMENT PLASTERING CHECKLISTDocumento1 páginaCEMENT PLASTERING CHECKLISTsankuj5354Ainda não há avaliações

- Quality Assurance RequirementsDocumento179 páginasQuality Assurance RequirementsBryan VertuodasoAinda não há avaliações

- Pressure Part Method StatementDocumento49 páginasPressure Part Method StatementSerkan Yaşa67% (3)

- QA/QC Plan Ensures Project ComplianceDocumento18 páginasQA/QC Plan Ensures Project ComplianceSen IMO67% (3)

- Project Quality Plan ChecklistDocumento3 páginasProject Quality Plan ChecklistMylean Monterola100% (3)

- SKANDHANSHI INFRA PROJECTS EXCAVATION METHOD STATEMENTDocumento6 páginasSKANDHANSHI INFRA PROJECTS EXCAVATION METHOD STATEMENTVinod MasaniAinda não há avaliações

- 10.method Statement Piling WorkDocumento6 páginas10.method Statement Piling Workشاز إياسAinda não há avaliações

- Quality Assurance Plan - SRMS Slope Protection & FencingDocumento10 páginasQuality Assurance Plan - SRMS Slope Protection & FencingTimothy AdzatiAinda não há avaliações

- Method Statement Trial TrenchDocumento6 páginasMethod Statement Trial TrenchSasi KumarAinda não há avaliações

- QAP Plan For Biratnagar AirportDocumento20 páginasQAP Plan For Biratnagar AirportNirmal bhandariAinda não há avaliações

- Method Statement of Mass Concrete Block Precast WorksDocumento41 páginasMethod Statement of Mass Concrete Block Precast WorksShams JogAinda não há avaliações

- Road Construction Essentials QA/QC PlanDocumento10 páginasRoad Construction Essentials QA/QC Planrafiullah amireeAinda não há avaliações

- Site Quality Observation Report #3 Tabuk-J&PDocumento15 páginasSite Quality Observation Report #3 Tabuk-J&PmasahinAinda não há avaliações

- Implementing Rules and Regulations for the Expanded Breastfeeding Promotion ActDocumento17 páginasImplementing Rules and Regulations for the Expanded Breastfeeding Promotion ActNoel Cagigas FelongcoAinda não há avaliações

- Method Statement For Construction - Method Statement - Non Suspended SlabDocumento3 páginasMethod Statement For Construction - Method Statement - Non Suspended SlabKellyAinda não há avaliações

- PQPDocumento109 páginasPQPFaizalFendi100% (4)

- Fire Exit Building Calculation 2Documento7 páginasFire Exit Building Calculation 2Mohd Rehan100% (1)

- Project Quality Plan for Egrong Waiting Area ModificationDocumento9 páginasProject Quality Plan for Egrong Waiting Area ModificationAlmario Sagun100% (2)

- Standard Operating Procedure For On Site Meter TestingDocumento4 páginasStandard Operating Procedure For On Site Meter TestingsanjayAinda não há avaliações

- Project Quality PlanDocumento80 páginasProject Quality Planpoqw123456100% (3)

- Civil Works Inspection - QA - QC-Construction LTDDocumento1 páginaCivil Works Inspection - QA - QC-Construction LTDNashrul KarimAinda não há avaliações

- Design & Management Plan, Organization and StaffingDocumento12 páginasDesign & Management Plan, Organization and StaffingJames PittsAinda não há avaliações

- National Water Supply Building Works Method StatementDocumento16 páginasNational Water Supply Building Works Method StatementPROJECT MANAGERAinda não há avaliações

- PQPDocumento24 páginasPQPkaandiAinda não há avaliações

- Quality Assurance Plan for ASARCO DemolitionDocumento20 páginasQuality Assurance Plan for ASARCO DemolitionRen SalazarAinda não há avaliações

- Renovation Works at Al Forsan Sports ResortDocumento7 páginasRenovation Works at Al Forsan Sports ResortAshimolowo BabatundeAinda não há avaliações

- Rev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectDocumento11 páginasRev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectM Waqas HabibAinda não há avaliações

- Cube TestDocumento1 páginaCube TestRicha YadavAinda não há avaliações

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocumento2 páginasQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- NEOM CV ApprovalDocumento12 páginasNEOM CV ApprovalAymanEssamAinda não há avaliações

- User'S Manual: Workloadindicators OfstaffingneedDocumento56 páginasUser'S Manual: Workloadindicators OfstaffingneedKang DjamalAinda não há avaliações

- CREW V. U.S. Department of Education: Regarding Outside Email Addresses: 8/24/2007 - Memorandum in OppositionDocumento13 páginasCREW V. U.S. Department of Education: Regarding Outside Email Addresses: 8/24/2007 - Memorandum in OppositionCREWAinda não há avaliações

- WTRTFDocumento384 páginasWTRTFNewsAinda não há avaliações

- IntroDocumento3 páginasIntroDarylAinda não há avaliações

- Government of India Approves Intrinsically Safe Electrical EquipmentDocumento2 páginasGovernment of India Approves Intrinsically Safe Electrical EquipmentNinad GawadeAinda não há avaliações

- Philippine Health Care Providers, Inc.: Commissioner of Internal RevenueDocumento17 páginasPhilippine Health Care Providers, Inc.: Commissioner of Internal RevenuePatricia Ann Nicole ReyesAinda não há avaliações

- The Independent Issue 546Documento44 páginasThe Independent Issue 546The Independent MagazineAinda não há avaliações

- Korean Legal System and The Human Rights of Persons With Mental Disorders: Current State and ChallengesDocumento24 páginasKorean Legal System and The Human Rights of Persons With Mental Disorders: Current State and ChallengesSoohyun NamAinda não há avaliações

- What Is A Woman ActDocumento30 páginasWhat Is A Woman ActActionNewsJaxAinda não há avaliações

- Who Technical Report Series, No. 953, 2009Documento178 páginasWho Technical Report Series, No. 953, 2009aquilesamparo100% (2)

- Manual For The Development of System Safety Program Plans For Commuter RailroadsDocumento0 páginaManual For The Development of System Safety Program Plans For Commuter Railroadsmkashkooli_scribdAinda não há avaliações

- DMir 1912 04 10 001-UlsterDocumento16 páginasDMir 1912 04 10 001-UlsterTitanicwareAinda não há avaliações

- The Major Sources of Loss Exposure Arising From Automobile Accidents AreDocumento22 páginasThe Major Sources of Loss Exposure Arising From Automobile Accidents AreAsielSantiagoLoboAinda não há avaliações

- Planning Officer I job descriptionDocumento1 páginaPlanning Officer I job descriptionDarlene GanubAinda não há avaliações

- Guideline To Machinery Directive 2006 - 42 - ECDocumento457 páginasGuideline To Machinery Directive 2006 - 42 - ECSam JoseAinda não há avaliações

- Trial Memorandum of The PetitionerDocumento11 páginasTrial Memorandum of The PetitionerAbegail Protacio GuardianAinda não há avaliações

- Pueblo Regional Center Residents v. John Hickenlooper, Et. Al.Documento45 páginasPueblo Regional Center Residents v. John Hickenlooper, Et. Al.Michael_Lee_RobertsAinda não há avaliações

- State of New Jersey Medicaid Fraud Division Provider Exclusion ReportDocumento109 páginasState of New Jersey Medicaid Fraud Division Provider Exclusion ReportppstreloAinda não há avaliações

- Schilling GT DisciplinaryDocumento9 páginasSchilling GT DisciplinaryDan LehrAinda não há avaliações

- Vibrant Gujarat Medical Scenario: Current Developments and Future OutlookDocumento18 páginasVibrant Gujarat Medical Scenario: Current Developments and Future OutlookNisarg PatelAinda não há avaliações

- Tricare Participation FormDocumento8 páginasTricare Participation FormMalsom SingsonAinda não há avaliações

- 2012-05-04 - MDEC Motion For JOP With ExhibitsDocumento102 páginas2012-05-04 - MDEC Motion For JOP With ExhibitsJack RyanAinda não há avaliações

- WA Risk Analysis TablesDocumento3 páginasWA Risk Analysis TableskanpsnAinda não há avaliações

- Sigma Marine Coatings Manual - Part4Documento2 páginasSigma Marine Coatings Manual - Part4EngTamerAinda não há avaliações