Escolar Documentos

Profissional Documentos

Cultura Documentos

BDA Free Standing Walls

Enviado por

EnginerdouglasDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

BDA Free Standing Walls

Enviado por

EnginerdouglasDireitos autorais:

Formatos disponíveis

TECHNICAL SUPPORT

BRICKLAYING TECHNIQUES

FREESTANDING BRICK WALLS

Freestanding external walls form an integral part of our hard landscaping features throughout public spaces, commercial, and residential developments. The difference in scale and form varies immensely from simple, low level boundary walls built to basic rule of thumb tradition, to more elaborate walls of different plan forms requiring detailed structural calculation; in all cases, the selection of bricks should consider the durability of the product in relation to the exposure of the site, and protection provided by coping or capping features. This Guidance Note outlines general aspects to consider in the specification and detailing of clay brick external walls. Overall Design The bearing capacity and ground conditions may need to be considered in certain locations, but for most typical garden and boundary walls, the width of the (concrete) foundation and height of the wall above ground level should follow simple guidelines as below. Although brick walls are inherently strong and robust, there is a limit of slenderness for thinner wall sections which needs to be considered in relation to lateral forces and stability. This can be overcome by increasing the wall thickness at the base or lower levels, or by increasing the effective thickness with projecting piers or with a zigzag or staggered plan form. scale 1:10

Coping 'F2' with continuous DPC

215mm Sheltered Areas

ZONE 1 ZONE 2 1750 550 ZONE 3 1600 575 ZONE 4 1450 575

H

H (mm) 1925 W (mm) 525

Exposed Areas

ZONE 1 H (mm) 1450 W (mm) 600 ZONE 2 1300 625 ZONE 3 1175 650 ZONE 4 1075 650

DP br 'F du

Foundation depth min 500mm

F2 bricks preferred throughout but 'F1' acceptable in more sheltered locations with suitable protection

Historically, a freestanding wall would be built with a proportion of bricks laid crossways for bonding, resulting in familiar patterns of stretcher and header faces; this is still very much an acceptable method of construction, providing an attractive appearance, and avoiding the necessity of wall ties between two separate leaves of stretcher bond. With some bricks, the stretchers and headers may vary in colour naturally, as a result of the setting pattern of bricks in firing, but contrasting brick types also feature in both traditional and new construction to accentuate decorative forms to good effect; where stability is provided through piers or in combination with plinths, the inset panels offer an opportunity for a variety of individual design patterns, and repetitive or linear forms in longer walls. References relating to this Freestanding Brick Walls literature: (1) (2) (3) (4) (5) (6) Sulphate attack A chemical reaction of soluble sulphates from the ground, or certain brick types, with constituents of cement causing expansion and damage to mortar BS EN 771-1 : 2011 BDA Guidance Note BDA Guidance Note BSI PD 6697 : 2010 BS 4729 : 2005 Specification for masonry units Part 1 : Clay masonry units Copings and Cappings Brick Retaining Walls Recommendations for the design of masonry structures to BS EN 1996-1-1 and BS EN 1996-2

BDA - Freestandin

Clay bricks of special shapes and sizes

TECHNICAL SUPPORT

BRICKLAYING TECHNIQUES

FREESTANDING BRICK WALLS

Durability It is important that the bricks chosen for external walls are of suitable durability to provide long term resistance to the effects of weathering and exposure, including frost and sulphate attack(1). The product Standard BS EN 771-1 : 2011(2) requires manufacturers to classify products in relation to exposure categories, and designation F2 is considered most suitable for detailing, particularly in locations of severe exposure. An appropriately detailed protective coping should be provided. (Another Guidance Note (3) is available which illustrates cappings and copings). It should also be recognised that the water absorption characteristic of a brick is related to the method of manufacturing, and is not a direct influence on the durability performance. A brick of F2 designation can be used throughout the wall, but where a more rustic brick (of high water absorption) is selected, specifiers often consider a contrasting brick of smooth appearance and low water absorption for capping elements and for the base courses; set in a strong mortar, this can assist in avoiding longer term staining of brick surfaces and mortar joints, and avoids the requirement for a horizontal damp proof course at low level, which would weaken the stability of the wall if installed incorrectly.

mm eas

ZONE 1

327mm Sheltered Areas

ZONE 2 2500 575 ZONE 3 2500 650 ZONE 4 2450 725

ONE 4

H

H (mm) 2500 W (mm) 525

50

75

eas

ZONE 1 H (mm) 2400 DPC bricks 'F2' durability W (mm) 725

Exposed Areas

ZONE 2 2175 775 ZONE 3 2000 800 ZONE 4 1825 850

ONE 4

75

50

mm

UK Wind Exposure Zones 1 to 4 (based on wind distribution)

t but ered ction

scale 1:10

Sheltered and Exposed Areas relate to local conditions, e.g. urban and open rural

In many residential developments, the ground level to either side of garden walls may vary, and this may require inclusion of a membrane to prevent water (and ground salt) migration from the higher level, although specific reference to detailing of retaining walls is made in another Guidance Note (4). Where paving is the finished surface to either side, this should be laid to falls away from the wall where possible, or provision made for a drainage strip to prevent unnecessary saturation of the lower courses.

tanding Brick Wall Details

TECHNICAL SUPPORT

BRICKLAYING TECHNIQUES

FREESTANDING BRICK WALLS

Mortar The durability of the mortar is most important especially for more exposed elements and reference should be made to BSI document PD6697(5) Recommendations for the design of masonry structures which recently replace the former code of practice BS 5628 part 3. For copings and cappings, and for base courses, a category M12 mortar should be used, with a similar strength throughout the wall in areas of severe exposure. For more moderate exposure a class M6 or M4 can be considered although the latter should not be used where a brick of higher soluble salts content (category S1) is specified, to avoid potential salt migration and expansive reaction with the mortar (1).

Movement joints Freestanding walls (and external parapet conditions) tend to be less restrained than walls of buildings, and are subjected to more horizontal movement potential, requiring adequate provision for vertical movement joints; as a general guide, joints should be considered at 5 6 metre centres, with a 3 metre centres for capping features, and main joints must extend from the base course below ground level, through to the coping or capping element.

scale 1:10

English Garden Wall

(3 course stretchers between header courses)

It is important to select a compressible joint filling material, and proprietary products are readily available; fibreboard and cork based materials are not suitable however, particularly when wet, as this significantly reduces the already limited compaction. Gun applied sealants can provide an attractive finish to the joint, with a range of colours to match or contrast with the brick finish. The practice of leaving a small (10mm) gap between linear walls may achieve a suitable separation in some cases, but can easily result in mortar blocking the space becoming ineffective, with issues of continuity through the coping or capping. scale 1:10

Flemish Garden Wall

(3 stretchers then cross bonding headers)

TECHNICAL SUPPORT

BRICKLAYING TECHNIQUES

FREESTANDING BRICK WALLS

Wall Features The simplest form of freestanding wall is of linear design with a consistent number of courses throughout, finished with a capping or coping in a horizontal plane. With sloping sites, this may result in a series of stepped sections, requiring a special end detail for the coping element; even with a basic brick on edge capping, solid units (preferably faced on bed) should be specified, or larger blocks with faced sides. Where access is required, a common feature at each end of the break in the wall is a column or pier, providing a suitable fixing for a gated entrance. The height of the brick wall may provide enclosure, but in many residential areas the boundary wall may comprise a series of intermediate piers projecting upwardly from a lower wall, providing support for metal railings or timber screen panels in-between. The fixings should take into account the potential characteristic (differential) movement through weather cycles, but also with timber fencing, resistance to wind pressure, causing a local stressing of the brick pier; brickwork should therefore be of good quality with a strong mortar and completely filled mortar joints. Both metal railings and particularly timber panels require periodic maintenance, and observations of the latter highlight the run-off of water and detritus causing a local saturation and staining of capping features and brickwork below.

If ground level to one side raised, consider membrane to prevent migration of water/salts

F2 bricks required to min 150mm above ground level

preferably fall away with hard landscaping

paving/land surfaces ideally sloping away from wall or drainage detail fall.

scale 1:10

BDA - Freestanding Brick Wall

TECHNICAL SUPPORT

BRICKLAYING TECHNIQUES

FREESTANDING BRICK WALLS

Angled Walls At changes of direction in plan, external and internal shaped angles should be incorporated to avoid the unsightly appearance of standard bricks overlapping; the British Standard for units of special shapes(6) includes a range of angled bricks developed to take into account the dimensions of bonding bricks historically with cross bonding, resulting in quarter bond, or the simple squint brick which allows stretcher bond to continue around the angle. The layout of the site boundary or landscaping feature may dictate changes of angle other than the standard 30, 45, or 60 degrees in the British Standard. This is not generally an issue for manufacturers who can provide purpose made units for external or internal angle applications. Appropriate specials would also be needed of course for any features such as plinths and cappings around the angle.

similarly with 'External Angle'

AN.1.1 'Squint' brick resulting in 'half' lap - stretcher bond

Angled Wall using Squint Brick

similarly with 'External Angle' AN.2.1 'Internal Angle' brick resulting in 'quater' lap e.g. english and flemish bond variations

Angled Wall using External Angle Brick

scale 1:10

An alternative to manufactured specials is the fabrication, or cutting and bonding, of standard bricks to form specific angles. The technique can be successful avoiding mould or die costs in production, but should be carried out in controlled conditions within a suitable environment, and good quality control is essential.

TECHNICAL SUPPORT

BRICKLAYING TECHNIQUES

FREESTANDING BRICK WALLS

Brick Wall Profiles

Wall Features In more open developments, continuous metal railings may be provided for decorative or safety reasons over lower freestanding walls. Clearly a sound fixing is required, but this should not be rigid enough to create stressing of the bricks locally, particularly if fixed directly to a brick on edge capping, and for longer sections (allowing for differential movement between metal railings and brickwork support) a series of balusters and detailed joints is recommended rather than continuously welded sections. A brick of low water absorption set in a strong mortar is preferable to a horizontal membrane dpc in the base courses. It is advisable however to include a dpc sandwiched in mortar immediately below the coping or capping, to prevent the downward movement of water (through mortar joints). Where a more robust detail is preferred, particularly in areas of public contact or vandalism, it is accepted practice to include the dpc at a lower level but within the upper courses. Traditionally built walls may incorporate a tile creasing which can assist in projecting water away from courses below, but a membrane dpc is still recommended for a more resistant detail.

215mm 'conventional' walls

327mm 'conventional' walls

staggered profile, beware unfaced sides with some brick types (particularly wirecut/extruded)

effective thickness increased by piers

stability achieved with columns/piers at either end

option for additional stability with piers to both sides and plinth detail to one or both sides

curve on plan to increase effective thickness

scale 1:10

TECHNICAL SUPPORT

BRICKLAYING TECHNIQUES

FREESTANDING BRICK WALLS

Curved Walls

Freestanding walls may also be curved on plan to follow site boundaries or to provide effective thickness in a serpentine form of gentle radius. Although the British Standard for special shapes includes a range of radial stretchers these are of convex faces and only suitable therefore for external curves applicable mainly for the outer leaf of buildings. It is possible to use standard bricks however to form a general curve, and with stretcher bond a threshold radius of 4 metres provides a curve without unsightly overlap in alternate courses. (With bricks of characteristic irregular arrises such as handmade units, the threshold can be reduced to 3.5 metres). Adopting header bond will also achieve a reduced curve, by creating more facets; in a full brick width wall and cross bonded, this will be limited by the acceptable tapering of mortar joints visually, on both sides of the wall. It should also be remembered that the header faces may not be of the same colouring as adjacent sections of stretcher brickwork, and with an increase in the mortar proportion, the curved element may stand out. Where tighter radii are required, this may involve purpose made specials, of both convex and concave profile.

Curve can also be limited to taper of mortar joint with standard facings With obtuse angles an unsightly overlap will occur and will therefore be unsuitable. Only with an acute angle and smaller radii can a standard brick be used.

Radial Bricks are preferable as they can perform smooth cylindrical facades.

Convex Facing Bricks are used for 'external' conditions. Concave Facing Bricks are required for 'internal' conditions. These come with either a straight or radiated back face

R ad iu s

RD. 2 Radial Stretcher 'convex'

(R )

Brick face = line of chord (L) Guidance for half lap/stretcher bond min. radius 3.5 to 4.0 metres Tighter radius with header bond but determined by acceptable taper of mortar joints. For Caluclation:

overlap 'h' line of arc

scale 1:10

overlap h = R-

R2- (0.5L)2

Você também pode gostar

- Guidance Note On Garden & Retaining WallsDocumento10 páginasGuidance Note On Garden & Retaining WallsthowchinAinda não há avaliações

- Foundations For WallsDocumento9 páginasFoundations For WallsAnamaria SuzanaAinda não há avaliações

- Crack Control for Concrete Masonry VeneersDocumento10 páginasCrack Control for Concrete Masonry VeneersAdam JonesAinda não há avaliações

- Articulated WallingDocumento24 páginasArticulated WallingYT LokeAinda não há avaliações

- Secant Pile CONSTRUCTION Project ReportDocumento7 páginasSecant Pile CONSTRUCTION Project ReportAftab ali100% (1)

- Brickwork DurabilityDocumento14 páginasBrickwork DurabilityxufafruitjuiceAinda não há avaliações

- Wall Detailing in Radaition FalloutDocumento9 páginasWall Detailing in Radaition FallouthammedAinda não há avaliações

- Gabion Wall and Sheet PilesDocumento18 páginasGabion Wall and Sheet PilesVasanthapragash NadarajhaAinda não há avaliações

- TCH Seminar Cavity WallDocumento30 páginasTCH Seminar Cavity WallSachin AbhiramAinda não há avaliações

- Earthquake Design and Brick WallsDocumento7 páginasEarthquake Design and Brick WallsIftekhar ShadAinda não há avaliações

- Structures: 04 - I096959 - Ch03.indd 99 04 - I096959 - Ch03.indd 99 1/4/2011 5:25:49 PM 1/4/2011 5:25:49 PMDocumento40 páginasStructures: 04 - I096959 - Ch03.indd 99 04 - I096959 - Ch03.indd 99 1/4/2011 5:25:49 PM 1/4/2011 5:25:49 PMTeo TegAinda não há avaliações

- CourtCare Squash Court Specification 2011 Web VersionDocumento26 páginasCourtCare Squash Court Specification 2011 Web Versionhassan_smss69Ainda não há avaliações

- Concrete Retaining Walls: Important ConsiderationsDocumento7 páginasConcrete Retaining Walls: Important ConsiderationsTomAinda não há avaliações

- Brick Bearing Wall Technical NotesDocumento11 páginasBrick Bearing Wall Technical NotesniroAinda não há avaliações

- 14 Masonry ConstructionMethodsDocumento78 páginas14 Masonry ConstructionMethodsMaverick LastimosaAinda não há avaliações

- 5 Rammed EarthDocumento138 páginas5 Rammed EarthSilviu PaduraruAinda não há avaliações

- 4-ATP-Building EnvelopeDocumento39 páginas4-ATP-Building EnvelopeShabbir AhmadAinda não há avaliações

- AE 544 Building PhotosDocumento43 páginasAE 544 Building PhotosTotok SulistiyantoAinda não há avaliações

- Unit Iv Cost Effective Construction Techniques Roofing TypesDocumento9 páginasUnit Iv Cost Effective Construction Techniques Roofing TypesDevakumarAinda não há avaliações

- 26 Single Wythe Bearing WallsDocumento15 páginas26 Single Wythe Bearing WallsMuslimsAinda não há avaliações

- CourtCare Squash Court Specification 2011 Web Version PDFDocumento26 páginasCourtCare Squash Court Specification 2011 Web Version PDFAditi AgarwalAinda não há avaliações

- Coping and CappingDocumento15 páginasCoping and CappingWawaChumelAinda não há avaliações

- Build 152 26 Build Right Low Retaining WallsDocumento4 páginasBuild 152 26 Build Right Low Retaining Wallssuejack2020Ainda não há avaliações

- Precast Concrete WallsDocumento3 páginasPrecast Concrete WallsInzaghi BirdAinda não há avaliações

- Types of Embedded Earth Retaining WallsDocumento17 páginasTypes of Embedded Earth Retaining WallsTun Sheikh HambaleeAinda não há avaliações

- Brick masonry detailing guideDocumento8 páginasBrick masonry detailing guideHekato AssumiAinda não há avaliações

- Chapter SixDocumento20 páginasChapter SixTemesgen YohannesAinda não há avaliações

- Retaining WallsDocumento5 páginasRetaining WallsAndy AmatoAinda não há avaliações

- Reinforced Ultra-Lightweight Cement Composite Flat Slabs: Experiments and AnalysisDocumento23 páginasReinforced Ultra-Lightweight Cement Composite Flat Slabs: Experiments and AnalysisNI KH ILAinda não há avaliações

- Cracking in Bricks and BrickworkDocumento2 páginasCracking in Bricks and BrickworkDaniyal AhmadAinda não há avaliações

- Tek 03-06CDocumento14 páginasTek 03-06CZebAinda não há avaliações

- Echelon Masonry Veneer DetailsDocumento7 páginasEchelon Masonry Veneer DetailsRanj N HassanAinda não há avaliações

- Causes and Solutions for Masonry CrackingDocumento8 páginasCauses and Solutions for Masonry CrackingVenkatesh ArunaAinda não há avaliações

- (GN24) Garden WallDocumento3 páginas(GN24) Garden WallEdwin HarrisAinda não há avaliações

- Crack Control in Concrete Masonry WallsDocumento4 páginasCrack Control in Concrete Masonry WallsAnonymous Re62LKaACAinda não há avaliações

- Larisch 2016 - Modern Concrete Technology Placement Methods and Their Influence On Waterproofing Performance of DiaphragDocumento10 páginasLarisch 2016 - Modern Concrete Technology Placement Methods and Their Influence On Waterproofing Performance of DiaphragAbdul-alim BhnsawyAinda não há avaliações

- Fyfestone Tech Movement ControlDocumento8 páginasFyfestone Tech Movement ControlJustin MusopoleAinda não há avaliações

- Besser BlocksDocumento6 páginasBesser BlocksZaheer AhmedAinda não há avaliações

- 978 1 349 130Documento2 páginas978 1 349 130Śurya KìranAinda não há avaliações

- CEMEX ReadyBlock Lightweight File016014Documento8 páginasCEMEX ReadyBlock Lightweight File016014Idrus IsmailAinda não há avaliações

- Prefabricated Construction SystemDocumento13 páginasPrefabricated Construction SystemHimani GaurAinda não há avaliações

- Water Penetration Resistance - Design and Detailing: Technical Notes 7Documento15 páginasWater Penetration Resistance - Design and Detailing: Technical Notes 7Samad SamadiAinda não há avaliações

- Industrial Building Architectural and Structural Design 1Documento6 páginasIndustrial Building Architectural and Structural Design 1api-655156856Ainda não há avaliações

- Development of Creep Model For Structural Insulated Timber-Foam Sandwich Walls Under Sustained Soil Pressure in Basements of Residential BuildingsDocumento12 páginasDevelopment of Creep Model For Structural Insulated Timber-Foam Sandwich Walls Under Sustained Soil Pressure in Basements of Residential Buildingseli700Ainda não há avaliações

- BDG NotesDocumento18 páginasBDG NotesTaiwo AyomideAinda não há avaliações

- Block Retaining WallDocumento11 páginasBlock Retaining WallSiti sAinda não há avaliações

- TEK 05-07A Floor and Roof Connections To CMU WallsDocumento5 páginasTEK 05-07A Floor and Roof Connections To CMU WallsAdam JonesAinda não há avaliações

- Publications Design and Detailing SolutionsDocumento13 páginasPublications Design and Detailing SolutionsLuis MarcosAinda não há avaliações

- Design of brick fin walls for tall wide-span buildingsDocumento5 páginasDesign of brick fin walls for tall wide-span buildingschoriya007Ainda não há avaliações

- Crack Control in Concrete Masonry WallsDocumento4 páginasCrack Control in Concrete Masonry WallsMohamed Mostafa IbrahimAinda não há avaliações

- How To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Documento10 páginasHow To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Cimpureanu FlorinAinda não há avaliações

- Concrete Wall in Tropical ClimateDocumento11 páginasConcrete Wall in Tropical ClimateSuryasis DasguptaAinda não há avaliações

- Introduction To MasonryDocumento4 páginasIntroduction To MasonryChiranjaya Hulangamuwa100% (5)

- LANDSCAPE DESIGN STRUCTURES From Time-Saver Standards For Landscape Architecture BookDocumento142 páginasLANDSCAPE DESIGN STRUCTURES From Time-Saver Standards For Landscape Architecture Book10ahmedmazumderAinda não há avaliações

- Design of Foundations: 6-1. Basic ConsiderationsDocumento18 páginasDesign of Foundations: 6-1. Basic ConsiderationsAlhilali ZiyadAinda não há avaliações

- Construction of A 3 Bedroom BungalowDocumento13 páginasConstruction of A 3 Bedroom BungalowElujekwute Benjamin100% (1)

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoAinda não há avaliações

- The Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcNo EverandThe Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcNota: 5 de 5 estrelas5/5 (1)

- Turf Wall Architecture and Turf Furniture Assembly GuideNo EverandTurf Wall Architecture and Turf Furniture Assembly GuideAinda não há avaliações

- 171-lb. CRANE RAIL: Head 4.3" 1/4" R To Approx. 3/8" R 4"Documento1 página171-lb. CRANE RAIL: Head 4.3" 1/4" R To Approx. 3/8" R 4"EnginerdouglasAinda não há avaliações

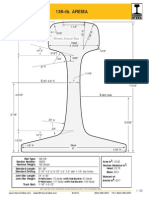

- 136-lb. AREMA: Shown Actual SizeDocumento1 página136-lb. AREMA: Shown Actual SizeEnginerdouglasAinda não há avaliações

- Lightweight Rail Fastening ClipDocumento2 páginasLightweight Rail Fastening ClipEnginerdouglasAinda não há avaliações

- ShopNotes Issue 76Documento36 páginasShopNotes Issue 76qpidoneuro100% (8)

- ShopNotes Issue 78Documento36 páginasShopNotes Issue 78Enginerdouglas100% (2)

- ShopNotes Issue 90Documento61 páginasShopNotes Issue 90Enginerdouglas88% (8)

- ShopNotes Issue 90Documento61 páginasShopNotes Issue 90Enginerdouglas88% (8)

- ShopNotes Issue 78Documento36 páginasShopNotes Issue 78Enginerdouglas100% (2)

- Lafarge Fondu Spec SheetDocumento5 páginasLafarge Fondu Spec SheetpankajmandloiAinda não há avaliações

- Shopnotes Index (01 90)Documento16 páginasShopnotes Index (01 90)Enginerdouglas50% (4)

- ShopNotes Issue 64Documento39 páginasShopNotes Issue 64qpidoneuro100% (5)

- Garra FG 27Documento2 páginasGarra FG 27EnginerdouglasAinda não há avaliações

- ShopNotes Issue 74Documento38 páginasShopNotes Issue 74Enginerdouglas100% (8)

- ShopNotes Issue 93Documento53 páginasShopNotes Issue 93Enginerdouglas100% (11)

- Wb312 WorkbenchDocumento11 páginasWb312 WorkbenchReneCarrilloAinda não há avaliações

- Wb312 WorkbenchDocumento11 páginasWb312 WorkbenchReneCarrilloAinda não há avaliações

- Barford SKR10 SpecificationsDocumento1 páginaBarford SKR10 SpecificationsEnginerdouglasAinda não há avaliações

- Barford SKR10 SpecificationsDocumento1 páginaBarford SKR10 SpecificationsEnginerdouglasAinda não há avaliações

- Architectural Patterns/Bungalow Style GuideDocumento10 páginasArchitectural Patterns/Bungalow Style GuideEnginerdouglasAinda não há avaliações

- Early BricksDocumento43 páginasEarly BricksEnginerdouglasAinda não há avaliações

- Brastan - Tabela TrilhosDocumento2 páginasBrastan - Tabela TrilhosEnginerdouglasAinda não há avaliações

- Us 912ds+Rail+Brochure SCRDocumento2 páginasUs 912ds+Rail+Brochure SCREnginerdouglasAinda não há avaliações

- Site Dumpers.: Product RangeDocumento20 páginasSite Dumpers.: Product RangeEnginerdouglasAinda não há avaliações

- Gothic, Tudor, Venetian & Islamic arch stylesDocumento5 páginasGothic, Tudor, Venetian & Islamic arch stylesEnginerdouglasAinda não há avaliações

- Garis Panduan Penyenggaraan Berjadual Sivil and Struktur - 1Documento9 páginasGaris Panduan Penyenggaraan Berjadual Sivil and Struktur - 1Kavi MaranAinda não há avaliações

- 2 Concrete Works CompuDocumento14 páginas2 Concrete Works CompuALFONSO RAPHAEL SIAAinda não há avaliações

- Peter EisenmanDocumento28 páginasPeter EisenmanRadhika VijayAinda não há avaliações

- Stairs 1Documento8 páginasStairs 1Jeremy SmathersAinda não há avaliações

- Classification Based On SizeDocumento2 páginasClassification Based On SizeDenice Mae IsipAinda não há avaliações

- Assessment of Prestressed Concrete Aplications in NigeriaDocumento5 páginasAssessment of Prestressed Concrete Aplications in NigeriaonyejekweAinda não há avaliações

- Metal Ceiling Inspection FormDocumento1 páginaMetal Ceiling Inspection FormAlizamin SalmanovAinda não há avaliações

- Concrete Masonry ArchesDocumento10 páginasConcrete Masonry ArchesArda YıldırımAinda não há avaliações

- Wells Cathedral, EnglandDocumento16 páginasWells Cathedral, EnglandHarsh SoniAinda não há avaliações

- Concorde Wood Raised FlooringDocumento8 páginasConcorde Wood Raised FlooringAlvin BaraAinda não há avaliações

- Cold Rooms Amp Insulated Panels TSSCDocumento32 páginasCold Rooms Amp Insulated Panels TSSCZar KhariAinda não há avaliações

- Public Works Department (PWD)Documento14 páginasPublic Works Department (PWD)Tanya SirohiAinda não há avaliações

- Overtime AccomplishmentDocumento9 páginasOvertime AccomplishmentKate PerezAinda não há avaliações

- Sole Plate TolerancesDocumento10 páginasSole Plate TolerancesLiam DevineAinda não há avaliações

- VIEW AV PRESENTATION Camella, Toscana at Bago Galera, Davao City (2-Br Affordable House) Is For SALEDocumento13 páginasVIEW AV PRESENTATION Camella, Toscana at Bago Galera, Davao City (2-Br Affordable House) Is For SALEEvelyn L. AguinaldoAinda não há avaliações

- Dosage TableDocumento5 páginasDosage TableAarish KhanAinda não há avaliações

- Modernism and Postmodernism: OppositionsDocumento13 páginasModernism and Postmodernism: OppositionsEdwinAinda não há avaliações

- 8 Stairs PDFDocumento6 páginas8 Stairs PDFMasoudRmdnAinda não há avaliações

- ISSB Water Tank Consruction Manual 120908 FINALDocumento25 páginasISSB Water Tank Consruction Manual 120908 FINALPaul Kimera100% (2)

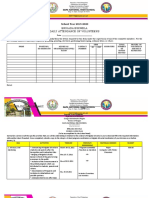

- Brigada Attendance SheetDocumento14 páginasBrigada Attendance Sheetjoris sulimaAinda não há avaliações

- Activity RecordDocumento2 páginasActivity RecorddentuningAinda não há avaliações

- B.arch Regulation 2017 SyllabusDocumento18 páginasB.arch Regulation 2017 SyllabuskumarAinda não há avaliações

- LRFD Accelerated Bridge ConstructionDocumento21 páginasLRFD Accelerated Bridge ConstructionJhon Escobar0% (1)

- Gap Product Guide 2015 Web PDFDocumento59 páginasGap Product Guide 2015 Web PDFSteve AskewAinda não há avaliações

- The Royal MausoleumDocumento8 páginasThe Royal MausoleumBokreta100% (1)

- Minor Works - Category - 15Documento1 páginaMinor Works - Category - 15Abraham ShumAinda não há avaliações

- Expandable House: For Disaster Relief and Flexible DwellingDocumento77 páginasExpandable House: For Disaster Relief and Flexible DwellingkimAinda não há avaliações

- Bungalow House Design Estimates Page-1Documento1 páginaBungalow House Design Estimates Page-1jarellano08Ainda não há avaliações

- AnalysisDocumento39 páginasAnalysislkovijayAinda não há avaliações

- MERKx Ke2Documento3 páginasMERKx Ke2TaniaGhinaAinda não há avaliações