Escolar Documentos

Profissional Documentos

Cultura Documentos

Anodizing Basics

Enviado por

roohollah13Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Anodizing Basics

Enviado por

roohollah13Direitos autorais:

Formatos disponíveis

ANODIZING BASICS

Anodizing of aluminum can achieve a very durable surface that is unaffected by weather for many years and many chemicals if done properly. The anodized surface can be dyed into many different colors using organic dyes. These colors can also be mixed to provide a full spectrum of other colors. The dyed surfaces can be subsequently sealed in a hot seal solution to protect away from corrosion in the surrounding environment. . MECHANICAL & CHEMICAL SURFACE TREATMENTS Aluminum can not be anodized and dyed without preparation. The mechanical and chemical preparatory treatments determine the final appearance of the metal surface since its optical properties are not modified by the transparent anodic coating or by dyeing. The mechanical treatment may include buffing, grinding, sandblasting and etc. The chemical treatment is to clean the metal surface free from oils, occluded impurities, soap residues and the natural oxide film. ANODIZING A porous anodic coating is formed during the anodizing process. The porous film can adsorb dyes to produce a full spectrum of colors. The natural oxide film is very thin and has to be replaced by a thicker artificial formed film. The most popular method of anodizing is to use a direct current (D.C.) sulfuric acid process. The following table is the one most used in the industry. Sulfuric acid (free) : Aluminum content : Current density Voltage Current Temperature Time : : : : : 165 g/l 225 g/ 5 15g/l 1.2 1.8 A/ dm2 12 V 20 V D.C. 18 22C 25 40 minutes 8 12 um

Coating thickness :

The following table gives a guide line to the effect of the D.C. sulfuric acid process parameters on the dyeing properties of anodic coating :-

Parameters H2SO4 Conc.

Deviation Higher

Dyeing Intensity Deeper

Mechanical Strength Lower

diyanodizing.com

Lower Aluminum ions Higher Lower Current Density Higher Lower Temperature Higher Lower Time Longer Shorter Coating Thickness Thicker Thinner

Paler

Higher

Modified Coating Modified Coating Structure Structure Paler Paler Deeper Deeper Paler Deeper Paler Deeper Paler Higher Higher Lower Lower Higher Higher Lower Higher Lower

Remarks Sulfuric acid concentration An increase in the sulfuric acid concentration intensifies its dissolving action on the metal, producing pores of more markedly comical shape and of greater average diameter. As the increased porosity provides a greater inner surface area, the adsorptive capacity is enhanced allowing dyeing of greater intensity to be produced. During the service life of the anodizing solution more and more free sulfuric acid is expended in dissolving, and as the concentration declines so does the absorptiveness of the coating. In order to ensure that successive dyeings are of equal intensity, it is most important to maintain the free sulfuric acid concentration within a narrow limit of 160 225 g/l. Aluminum content The dye adsorptive capacity decreases sharply below 5g/l AL, but then remains nearly constant at higher concentration. At over 15 g/l the solution does not work efficiently and there are likely to be irregularities in the anodic coating. So in order to achieve color uniformity, it is advisable to keep the content between 5 g/l to 15 g/l. Current density At high current density and constant coating thickness the dye adsorptive capacity is lower since the metal is exposed for a shorter time to the

diyanodizing.com

dissolving action of the sulfuric acid. In joint anodizing of alloys which differ in composition, fluctuations in current density may occur between one part and another which are reflected in color differences when the parts are dyed. For this reason, only one alloy should be anodized in a given batch : this is particularly important if the parts are to be dyed. Temperature A rise in temperature intensifies the dissolving action of the sulfuric acid resulting in softer, more porous coatings with higher capacity of dye adsorption. As the temperature has a very marked effect, close control is imperative. The tolerance limits are +/- 2C. In this connection it should be noted that if the heat convection is inadequate, local temperature variations occur which later will result in uneven dyeings. To safe guard against the occurrence of local overheating there should be provision for thorough agitation and cooling of the anodizing solution. Anodizing time and coating thickness The thickness of the anodic coating is almost exactly proportional to the product of the current density and the time. At constant current density (which is only approximately reached in plant production), the coating thickness and consequently the adsorptive capacity for dyes are linearly proportional to the anodizing time. It follows that fairly thick coatings are necessary if deep dyeings are to be produced. A thickness of 12 um anodic coating is usually enough for general application. However, when high color durability is demanded the coating should be allowed to grow more than 12 um in thickness. For building parts, a coating thickness of 25 um is necessary. COLORING The following dyeing parameters have a pronounced effect on the dyeings Dyeing temperature The rate of dyeing increases with increasing temperature. If the temperature is too high, buildup of the dye is halted before the full intensity is reached. Dyeings produced at high temperature do not bleed so freely in sealing solutions or rinsing waters and also are more difficult to strip. In some dyes, dyeing at room temperature is possible and easier to control the desired shade. In most other dyes, the adsorption is very slow causing the dyeing times over-long. In general, the temperature region of 50- 60C represents the optimum compromise between attainable depth and acceptable dyeing time. Dyeing time

diyanodizing.com

The normal dyeing time ranges between 3 to 15 minutes. Very short dye times of a few seconds may cause many of the dyes to bleed heavily in the sealing solution. Dyeing for longer than 30 minutes brings no advantages. If the required color intensity is not achieved after this time, the problems may be the anodic coating being too thin, the dye concentration being too low or the bath are contaminated by foreign impurities. pH value The optimum dyeing pH normally comes within the region of 5 to 6. Too high in pH retards the dye adsorption resulting in pale shade. Too low in pH may cause the aluminum to dissolve into the dye solution causing the dye solution to break down or forms precipitation. Dye concentration Generally, a dye concentration of 3 5 g/l is enough to achieve a deep shade of al colors other than black. 1 3 g/l maybe used for achieve a pale shade. For the black colors, 8 10 g/l must be used to achieve a jet-black tone. SEALING The hot sealing process The hot sealing closes the pores of the anodic coating and fixes the dyes deposited in the pores. This process is also referred to hydro-thermal sealing. The hot sealing process is affected by the time and temperature factors and by the composition and the pH of the sealing solution. The minimum sealing time is 2.5 minutes per um. The temperature should be as close to the boil as possible. The seal solution should be set at pH 5.5 to 6.0. The pH adjustment is obtained with dilute acetic acid or sodium hydroxide. The cold sealing process The cold sealing process is only suitable for closing the pores of natural color anodic coating. This type of process is referred to as impregnation sealing. The process depends upon the reaction of an anodic coating with nickel and fluoride ions at room temperature. The minimum sealing time is about 1.0 minutes per um. The temperature should be as close to 25C as possible. The seal solution should be set at about pH 6.0.The control of nickel to fluoride ratio is an important factor in respect of seal quality of the final product.

diyanodizing.com

Você também pode gostar

- Diy Hard Anodizing Chemicals KitDocumento7 páginasDiy Hard Anodizing Chemicals KitOtter1z100% (1)

- Anodized Aluminum ColorsDocumento10 páginasAnodized Aluminum ColorsIvy Li100% (1)

- Benefits of Anodizing AluminumDocumento31 páginasBenefits of Anodizing AluminumSenthil Kumar100% (2)

- Principles of Metal Surface Treatment and Protection: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series on Materials Science and TechnologyNo EverandPrinciples of Metal Surface Treatment and Protection: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series on Materials Science and TechnologyAinda não há avaliações

- Color On JewelleryDocumento13 páginasColor On JewellerynithansaAinda não há avaliações

- LCD Anodizing 2020Documento30 páginasLCD Anodizing 2020donny reborn100% (1)

- Low Current Density Anodizing Rev 0ADocumento18 páginasLow Current Density Anodizing Rev 0AtootalldeanAinda não há avaliações

- Nickel Electroplating: Power SupplyDocumento6 páginasNickel Electroplating: Power Supplyyonathan fausaAinda não há avaliações

- Material Finish GuideDocumento7 páginasMaterial Finish GuideRomie CubalAinda não há avaliações

- ANKURDocumento20 páginasANKURDevashish JoshiAinda não há avaliações

- Chrome PlatingDocumento11 páginasChrome PlatingMahesh Babu100% (1)

- Anodizing AluminumDocumento7 páginasAnodizing AluminumyunitaparerAinda não há avaliações

- Chrome Plating and Anodizing Operations GuideDocumento6 páginasChrome Plating and Anodizing Operations GuidePuguh Cahpordjo BaeAinda não há avaliações

- Blackening Processes For ZincDocumento13 páginasBlackening Processes For Zincvasudev_nAinda não há avaliações

- Electrophoretic DepositionDocumento7 páginasElectrophoretic Depositionpuneetchawla9Ainda não há avaliações

- Coating and Deposition Processes - Chapter 29Documento41 páginasCoating and Deposition Processes - Chapter 29xharpreetxAinda não há avaliações

- ElectroplatingDocumento18 páginasElectroplatingRahul Pandey100% (2)

- Hull Cell Review PDFDocumento4 páginasHull Cell Review PDFR.SubramanianAinda não há avaliações

- 07-Hull Cell R-10-14Documento22 páginas07-Hull Cell R-10-14Alejandro AvalosAinda não há avaliações

- Technical Data Sheet: Trichrome HB 1700 TDocumento3 páginasTechnical Data Sheet: Trichrome HB 1700 TLuuThiThuyDuong100% (1)

- Zinc DIE CASTINGDocumento10 páginasZinc DIE CASTINGFrancisco BocanegraAinda não há avaliações

- Testing Methods For Plating BathsDocumento3 páginasTesting Methods For Plating BathsR.Subramanian100% (1)

- Chrome PlatingDocumento14 páginasChrome Platingsonnu151Ainda não há avaliações

- ANODIZING: ELECTROLYTIC PROCESS INCREASES ALUMINUM OXIDE LAYERDocumento4 páginasANODIZING: ELECTROLYTIC PROCESS INCREASES ALUMINUM OXIDE LAYERShubham JainAinda não há avaliações

- Electroplating Cost Calculation - RefDocumento12 páginasElectroplating Cost Calculation - RefJitendra PatilAinda não há avaliações

- The Hull Cell Guide to Better ElectroplatingDocumento25 páginasThe Hull Cell Guide to Better ElectroplatingCarlos Alberto Soto Ramirez100% (2)

- Laton AtotechDocumento6 páginasLaton AtotechKaRenthLuNaAinda não há avaliações

- Electroplating ManualDocumento82 páginasElectroplating ManualWilliam Osburn100% (1)

- Anodizing Techniques at Home PDFDocumento10 páginasAnodizing Techniques at Home PDFpalosotAinda não há avaliações

- Zinc PlatingDocumento4 páginasZinc Platingrohitpatil330% (1)

- Anodizing InstructionsDocumento15 páginasAnodizing InstructionsCarl J. Wilkey67% (3)

- P&SF Guide to Plating ABS PlasticsDocumento4 páginasP&SF Guide to Plating ABS PlasticsLukeAinda não há avaliações

- Decorative Chromium PlatingDocumento8 páginasDecorative Chromium Platingcauthon82Ainda não há avaliações

- Anodising Aluminium for Protection and DecorationDocumento7 páginasAnodising Aluminium for Protection and DecorationChinmay Bhuta100% (1)

- Zinc Nickel Electroplating Guide ZyliteDocumento9 páginasZinc Nickel Electroplating Guide ZyliteBryan DixAinda não há avaliações

- Black OxideDocumento2 páginasBlack OxideGerman ToledoAinda não há avaliações

- Electroplating and Electroless Plating Corrosion EngineeringDocumento10 páginasElectroplating and Electroless Plating Corrosion Engineeringmm11_nedAinda não há avaliações

- Black PassivationDocumento12 páginasBlack PassivationZineb100% (1)

- Brass Plating GuideDocumento4 páginasBrass Plating GuideHomayoon GeramifarAinda não há avaliações

- Titanium Anodizing: An in House Evaluation by METALAST International, IncDocumento6 páginasTitanium Anodizing: An in House Evaluation by METALAST International, IncGian GianAinda não há avaliações

- Electro CoatingDocumento2 páginasElectro CoatingViswanathan SrkAinda não há avaliações

- Zinc Plating InfoDocumento4 páginasZinc Plating InfoUntung Ari Wibowo100% (1)

- Metal Finishing Processes Best PracticesDocumento44 páginasMetal Finishing Processes Best PracticesHoang TanAinda não há avaliações

- AnodizingDocumento11 páginasAnodizingwcw111Ainda não há avaliações

- Safecoat Hard AnodizingDocumento47 páginasSafecoat Hard AnodizingyahsooyAinda não há avaliações

- TALAT Lecture 5201: Aluminium Surface PretreatmentDocumento12 páginasTALAT Lecture 5201: Aluminium Surface PretreatmentCORE Materials100% (1)

- PVD Coatings PDFDocumento18 páginasPVD Coatings PDFetamil87Ainda não há avaliações

- Metal Finishing Guidebook-08Documento772 páginasMetal Finishing Guidebook-08monica100% (1)

- Chromium PlatingDocumento66 páginasChromium PlatingManikandan SudharsanAinda não há avaliações

- Zinc Electroplating Processes ComparedDocumento14 páginasZinc Electroplating Processes ComparedSHYAM KAYALAinda não há avaliações

- Hard Chrome 105 Plating ProcesDocumento3 páginasHard Chrome 105 Plating ProcesKishora BhatAinda não há avaliações

- Faculdade Estadual de Engenharia Química de Lorena - FAENQUILDocumento56 páginasFaculdade Estadual de Engenharia Química de Lorena - FAENQUILLuis Gustavo PachecoAinda não há avaliações

- Electroplating of PlasticsDocumento4 páginasElectroplating of PlasticsislammughalAinda não há avaliações

- TALAT Lecture 5204: Organic Coating of AluminiumDocumento17 páginasTALAT Lecture 5204: Organic Coating of AluminiumCORE MaterialsAinda não há avaliações

- AnodizingDocumento24 páginasAnodizingRahul Pandey100% (2)

- Bright Chrome HR 75Documento12 páginasBright Chrome HR 75Ringga sonifaAinda não há avaliações

- Specification Chart GuideDocumento2 páginasSpecification Chart GuideMichael DoyleAinda não há avaliações

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaAinda não há avaliações

- Highest Duty: My Search for What Really MattersNo EverandHighest Duty: My Search for What Really MattersAinda não há avaliações

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNo EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNota: 4 de 5 estrelas4/5 (28)

- The Fabric of Civilization: How Textiles Made the WorldNo EverandThe Fabric of Civilization: How Textiles Made the WorldNota: 4.5 de 5 estrelas4.5/5 (56)

- A Place of My Own: The Architecture of DaydreamsNo EverandA Place of My Own: The Architecture of DaydreamsNota: 4 de 5 estrelas4/5 (241)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureNo EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureNota: 5 de 5 estrelas5/5 (124)

- Pale Blue Dot: A Vision of the Human Future in SpaceNo EverandPale Blue Dot: A Vision of the Human Future in SpaceNota: 4.5 de 5 estrelas4.5/5 (586)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980No Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Nota: 4 de 5 estrelas4/5 (21)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationNo EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationNota: 4.5 de 5 estrelas4.5/5 (46)

- Sully: The Untold Story Behind the Miracle on the HudsonNo EverandSully: The Untold Story Behind the Miracle on the HudsonNota: 4 de 5 estrelas4/5 (101)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesNo EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesAinda não há avaliações

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseNo EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseNota: 3.5 de 5 estrelas3.5/5 (12)

- The Future of Geography: How the Competition in Space Will Change Our WorldNo EverandThe Future of Geography: How the Competition in Space Will Change Our WorldNota: 4.5 de 5 estrelas4.5/5 (4)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraNo EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraNota: 3 de 5 estrelas3/5 (10)

- Packing for Mars: The Curious Science of Life in the VoidNo EverandPacking for Mars: The Curious Science of Life in the VoidNota: 4 de 5 estrelas4/5 (1395)

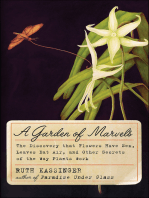

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsNo EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsAinda não há avaliações

- Reality+: Virtual Worlds and the Problems of PhilosophyNo EverandReality+: Virtual Worlds and the Problems of PhilosophyNota: 4 de 5 estrelas4/5 (24)

- The End of Craving: Recovering the Lost Wisdom of Eating WellNo EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellNota: 4.5 de 5 estrelas4.5/5 (80)

- The Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsNo EverandThe Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsNota: 4 de 5 estrelas4/5 (139)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansAinda não há avaliações

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNo EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsAinda não há avaliações