Escolar Documentos

Profissional Documentos

Cultura Documentos

Referinte Turnuri de Racire Si Cosuri de Fum

Enviado por

petronela.12Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Referinte Turnuri de Racire Si Cosuri de Fum

Enviado por

petronela.12Direitos autorais:

Formatos disponíveis

References

Power Generation Industry

Long-term protection of reinforced concrete structures in power plants poses the highest demands on rehabilitation and coating systems. Reliability of the structures long-term protection is a vital factor that ensures operational reliability of the entire power plant.

Ongoing dialogue with planners and power plant operators and MCs own research and development has made the company a reliable partner of the energy industry for more than 40 years when it comes to the protection of their concrete structures. Worldwide MC employees are developing project-specific solutions, be it for the new construction or repair of cooling towers, chimneys and reactor buildings.

In addition to the vastly differing demands from a structural point of view for each and every one of these structures, impact from weather conditions which have to be assessed differently depending on the respective climate zone, demand bespoke system solutions that are tailored to the respective overall conditions of the project.

Complementary to the technical demands of such rehabilitation and surface protection systems, the aesthetic finish of the power plants has become another important aspect. Here, highly UV-resistant coating systems from MC make it possible to achieve complex colour designs.

This brochure gives you an overview of international examples for the use of our system solutions for a diverse range of power plant structures.

Investments of such significance demand solutions that last!

Head of Division

Anja Spirres

Holger Schwarze

Protection Technologies

BELGIUM, DOEL

Nuclear Power Plant Doel

Product: Year: Project information: Zentricryl RBS 2007 Already in 1993 until 1994 one of the cooling towers at the nuclear power plant Doel was repaired on the inside and outside surfaces with the tried-and-tested surface protection system. Based on years of good experiences with the company, MC-Bauchemie was again called upon in 2006 when the reactor building 1 needed to be sealed. The particular challenge in this case was finding a system design with which the negative pressure required for operations could be achieved in the shortest possible time and which could maintain this pressure with the available aggregates. In this instance the system Zentricryl RBS was applied. Good cooperation resulted in further building elements being repaired, such as the cooling tower supports, for which Nafufill KM 250 was used.

BELGIUM, RUIEN

Coal-fired Power Plant Ruien

Product: Year: Project information: Nafufill KM 250, EmceColor-flex 2008 In 2008 the Nafufill KM 250 system was successfully used to repair damage to the chimneys. The surface protection used in this instance was EmceColor-flex. Systems from MC-Bauchemie were used in repairs of cooling towers here as early as the 1990s.

BELGIUM, VILVOORDE

Cogeneration Plant Vilvoorde

Product: Year: Project information: Nafufill KM 250, Zentricryl RBS 2008 C rack-bridging surface protection was required to repair the damaged exterior shells of this power plants cooling towers. Following the concrete repair works with Nafufill KM 250 the surface protection system Zentricryl RBS with its high crack-bridging properties was therefore used in this case.

BULGARIA, GALABOVO

Coal-fired Power Plant AES-3C Maritsa East 1

Product: Zentrifix F 82 XX, MC-DUR 1277 WV, MC-DUR VS NR3, MC-Schutzberzug 702 2008 / 2009 I n the construction of the new cooling tower great emphasis was placed on the surface protection of the concrete both inside and outside right from the start. Based on the analysis of the expected operational loads an important aspect here was the feeding of flue gasses into the cooling tower for the inside the MC-DUR VS NR3 surface protection system was chosen, while MC-Schutzberzug 702 protected the outside shell.

Year: Project information:

10

11

CZECH REPUBLIC, CHVALETICE

Power Plant Chvaletice

Product: MC-DUR 1800 TX, MC-DUR 1200 VK, Zentrifix EC 6, MC-DUR VS-PUR, MC-DUR 1277 WV, EmceColor-flex, MC-702 SX 1992 -1996 / 2007 A fter two cooling towers were successfully repaired on the inside and outside using systems from MC during 1992 to 1996, in 2007 it was the chimney that was refurbished with systems from MC.

Year: Project information:

12

13

CZECH REPUBLIC, DETMAROVICE

Hard-Coal-fired Power Plant Detmarovice

Product: MC-Schutzberzug 702 SX, EmceColor-flex, MC-DUR 1277 WV, MC-DUR VS NR3, MC-DUR VS-PUR 2002-2003 During 2002 and 2003 a new chimney was built. In its construction MC after-treatment and long-term protection systems were applied. For more than a decade the cooling towers of this plant have been maintained and repaired with products from MC, both inside and outside.

Year: Project information:

14

15

CZECH REPUBLIC, TEMELIN

Nuclear Power Plant Temelin

Product: MC-DUR 1277 WV, MC-DUR VS NR3, MC-Schutzberzug 702 SX, EmceColor-flex 1997-1999 / 2005 A fter all four cooling towers were successfully protected inside and two of them outside using MC products during 1997 to 1999, the same systems were again used in 2005 for the surface protection of the exterior shell of the two remaining cooling towers.

Year: Project information:

16

17

PR CHINA, TIANJIN

Coal-fired Power Plant Julian Cheng

Product: Zentrifix F 82 XX, MC-DUR 1277 WV, MC-DUR VS NR3 2009 F or the cooling tower with flue gas inlet for the new block of this power plant near Beijing the planner specified systems from MC-Bauchemie based on previous good cooperation with the company. The exterior surface protection was also carried out with MC products. Year: Project information:

18

19

PR CHINA, HANGU

Coal-fired Power Plant Beijiang

Product: Zentrifix F 82 XX, MC-DUR VS NR3, MC-RIM F 2009 F or the two cooling towers of the new power plant powered with seawater the client stressed his desire for lasting functionality of the surface protection as the long service life of the plant is paramount. Based on MC-Bauchemies experience with similar projects (Power Plant Rostock, SAFCO 4, Shuaiba 2 and SHARQ3) planners and principal opted for MC. This also applies to the concrete protection for the outer shell. Another reason for the successful cooperation between everyone involved was the regular support by MC staff onsite. Year: Project information:

20

21

PR CHINA, BEIJING

Coal-fired Power Plant Huaneng

Product: Zentrifix F 82 XX, MC-DUR 1277 WV, MC-DUR VS NR3, MC-Schutzberzug 702 2006 O ne of the largest cooling technology service providers in Germany recommended systems from MC for this project. After intensive consultations and the drafting of an individual concept MC was awarded the contract to supply the surface protection systems for the inside and the outside of the towers. The client was not only impressed by MCs application technology but also by excellent onsite support.

Year: Project information:

22

23

GERMANY, ALTBACH

Hard-Coal-fired Power Plant Altbach

Product: Zentricryl RBS, EmceColor-flex S MC-DUR 1277 WV 2003 D uring the hot summer of 2003 the repair of the hybrid cooling tower posed a particular challenge. The proven system MC-DUR 1277 WV was used on the inside. Since high loading by vibration caused by ventilators is to be expected in this cooling tower the highly crackbridging system Zentricryl RBS was selected for the outside surface protection. And due to the great heat during that summer the intended mineral levelling mortar was not used, instead the applicators were able to fall back on the acrylate system Zentrifix CR finish, which does not require any aftertreatment. Year: Project information:

24

25

GERMANY, BERGKAMEN

Coal-fired Power Plant Bergkamen

Product: MC-DUR VS-EW, MC-DUR 2103 M, MC-FLEX 2098 2005 T he cooling tower had been successfully restored inside and outside with MC products in the 1990s, but also needed to be toughened up at the chimneys opening in 2005. Of particular importance in this case was to apply a crack-bridging surface protection system at the mouth of the chimney to complement extensive concrete repair measures. Year: Project information:

26

27

GERMANY, BEXBACH

Coal-fired Power Plant Bexbach

Product: Year: Project information: Zentricryl RBS, EmceColor-flex S 2004 F or the outer shell repair works of this cooling tower particular emphasis was put on the high crack-bridging properties of the surface protection system. For this reason a combination of Zentricryl RBS/EmceColor-flex S was used.

28

29

GERMANY, BIBLIS

Nuclear Power Plant Biblis

Product: Nafufill KM 124, Zentrifix F 92, EmceColor-flex 1995 F or the outer repair of the cooling towers a crack-bridging system was required that was also used at the reactor domes. Further building components such as the cooling tower basin, the office buildings and the concrete fence were subsequently repaired with systems from MC as well. Year: Project information:

30

31

GERMANY, BOXBERG

Coal-fired Power Plant Boxberg

Product: Zentrifix F 82 XX, MC-DUR 1277 WV, MC-DUR VS NR3 1998 A fter several older cooling towers had already successfully been repaired with systems from MC, it naturally followed that in the construction of the new cooling tower Q at the Boxberg power plant, a surface protection was preventatively applied inside using the tried-and-tested systems from MC because of the flue gas inlet. Year: Project information:

32

33

GERMANY, BRAUNSCHWEIG

Cogeneration Plant Braunschweig

Product: Nafufill KM 250, MC-DUR 1200 VK, MC-DUR VS EW, MC-DUR 2103 M, MC-FLEX 2099 2006 A fter many years of operation the top end including the so called "down wash area" was partially damaged and had to be repaired and protected for coming decades of maintenance free operation. As this building is a landmark for its surrounding the colouration of the top coating was required in best possible quality. In addition the top coat MC-DUR 2103 M fulfils moderate crack bridging for near surface cracks.

Year: Project information:

34

35

GERMANY, CHEMNITZ

Hard-Coal Power Plant Chemnitz

Product: Nafufill GTS-HS, Zentricryl RBS, EmceColor-flex, MC-DUR 1277 WV, MC-DUR VS NR3 2008 P reliminary tests found high sulphate content in the concrete of the cooler to be repaired, which prompted the use of Nafufill GTS-HS as concrete replacement system. Because of the risk of crack formation Zentricryl RBS and EnceColor-flex were used on the outside. Inside the traditional structure with MC-DUR 1277 WV and MC-DUR VS NR3 was used.

Year: Project information:

36

37

GERMANY, ESSEN

Waste-to-Energy Plant Essen-Karnap

Product: Zentrifix F 82 XX, MC-DUR VS, MC-DUR VS-PUR, Betonflair 1990 T his chimney, a landmark for the Ruhr region, was protected with systems from MC-Bauchemie when it was newly built.

Year: Project information:

38

39

GERMANY, GELSENKIRCHEN

Coal-fired Power Plant Gelsenkirchen-Scholven

Product: Nafufill GTS, Zentricryl GS 2000, EmceColor-flex 2005 I n the case of this chimney it was especially important to ensure an economical and reliable application of the products. By way of consistently using a levelling mortar on acrylate basis that did not require any after-treatment the works could be completed within the scheduled timeframe. In the following year a further cooling tower was successfully repaired on the outside based on the same system. Year: Project information:

40

41

GERMANY, GRAFENRHEINFELD

Nuclear Power Plant Grafenrheinfeld

Product: Year: Project information: Zentricryl RBS, EmceColor-flex 1999 / 2000 F ollowing extensive tests and sample productions during the planning stage in 1998 the reactor dome was repaired successfully. At a later date the cooling tower basin was also sealed.

42

43

GERMANY, HEILBRONN

Cogeneration Plant Heilbronn

Product: Nafufill KM 250, Betonflair Uniprimer, EmceColor-flex 2009 T he tried-and-tested, crack-bridging and vapour-diffusion open system EmceColor-flex was used for the surface protection of the exterior of this cooling tower. Due to the condition of the substrate and based on its good workability Betonflair Uniprimer was applied first. Year: Project Information:

44

45

GERMANY, IBBENBREN

Hard-Coal-fired Power Plant Ibbenbren

Product: Zentrifix F 82 XX, MC-DUR 1277 WV, MC-DUR VS NR3, MC-Schutzberzug 702 1996 / 1997 T he chimney was repaired using proven systems after having been inspected thoroughly. Particularly challenging was here the existing epoxy resin paint at the opening, which could not be removed completely. The application was adapted jointly with owner, planer and applicator to suit the local conditions.

Year: Project information:

46

47

GERMANY, LIPPENDORF

Lignite-fired Power Plant Lippendorf

Product: Zentrifix F82 XX, MC-DUR 1277 WV, MC-DUR VS NR3 2001 P reventative surface protection for both cooling towers had been applied before they were put into operation. The interior of the shells had been protected against operational load impact, in this case a mixture of cooling tower plume and flue gas condensation. The shell exterior was protected against the impacts from the atmosphere. Each side of the tower shell has a surface of approximately 45,000 m. After 7 years of more or less uninterrupted operation the coating system on the inside of one of the two cooling towers was inspected by an expert. The inspection report certified that under continuous operation the service life of the surface protection is expected to be at least 20 years. Year: Project information:

48

49

GERMANY, NECKARWESTHEIM

Nuclear Power Plant Neckarwestheim

Product: Year: Project information: Zentricryl RBS, EmceColor-flex 2004 / 2008-2009 A fter the cooling tower had been successfully repaired with the use of MC systems, the restoration of the reactor building 2 was realised in 2008 and 2009.

50

51

GERMANY, NEURATH

Lignite-fired Power Plant Neurath

Product: Nafufill GTS, Zentrifix F 82 XX, MC-DUR VS NR3, MC-DUR 2203 2007- 2009 D uring 2007 to 2009 several cooling towers with flue gas inlets were again toughened up using new and more effective concepts. In this instance, besides the concrete repair particular emphasis was placed on a functioning interior shell surface protection system with sealed off pores, which would protect the interior effectively until the end of its lifespan. Of particular importance was UV protection above the waistline.

Year: Project information:

52

53

GERMANY, NIEDERAUSSEM

Lignite-fired Power Plant Niederauem

Product: Nafufill GTS, Zentrifix F 82 XX, MC-DUR VS NR3, MC-DUR 2203 2007-2009 B ased on the technical preparations and experiences in the power plants Weisweiler and Neurath newer, more efficient toughening concepts were developed for the repair of the interior shell. After the cooling towers of this power plant had during the 1990s already been protected against the aggressive impact of the flue gases fed in, MC systems were again applied in this repair measure.

Year: Project information:

54

55

GERMANY, ROSTOCK

Hard-Coal-fired Power Plant Rostock

Product: Zentrifix F 82 XX, MC-DUR VS NR3, MC-Schutzberzug 702 1992 T his power plant was the first new-built power plant in the new federal states after reunification. It is also the first power plant in Germany where the cooling tower is operated by sea-water (other power plants with this technology started operations in Saudi Arabia and in Kuwait between 2002 and 2008). Another important consideration is the fact that the operation uses flue gas inlets here as well. Due to the heavy load impact that this entails surface protection with systems from MC-Bauchemie became necessary. Year: Project information:

56

57

GERMANY, SPREMBERG

Lignite-fired Power Plant Schwarze Pumpe

Product: Zentrifix F 82 XX, MC-DUR VS NR3, MC-Schutzberzug 702 1994-1995 I n the new construction of blocks A and B of the brown-coal-fired power plant Schwarze Pumpe effective concrete protection for the interior shell was included in the planning right from the start because of flue gas inlets; this was performed using the MC systems MC-Schutzberzug 702 (outside) and MC-DUR VS NR3 (inside). An overhaul of the interior surfaces above the waistline was carried out in 2009 for one of the towers, the second cooling tower is planned to also receive a cover coat with UV-resistant polyurethane in 2010. Year: Project information:

58

59

GERMANY, WEISWEILER

Lignite-fired Power Plant Weisweiler

Product: Nafufill GTS, Zentrifix F 82 XX, MC-DUR VS NR3, MC-DUR 2203 2007- 2009 B ecause of intensive operational loading of the cooling towers with flue gas inlets damages occurred despite several surface protection measures having been carried out during the 80s and 90s. A completely new concept of repair and surface protection including partial static strengthening was therefore developed by a team of experts, with instrumental support from MC-Bauchemie. As a result all cooling towers of the power plant (amongst them block G) are being toughened with systems from MC.

Year: Project information:

60

61

POLAND, BELCHATOW

Lignite-fired Power Plant Belchatow

Product: MC-DUR 1277 WV, MC-FLEX 2099, MC-DUR VS NR3, MC Schutzberzug 702 2008-2009 A fter several cooling towers and chimneys of the existing power plant were already repaired successfully with MC products during the 1990s, MC products were again used in the new construction of another cooling tower. Additionally, special colours were required for the design of the exterior shell.

Year: Project information:

62

63

POLAND, KATOWICE

Power Plant Laziska

Product: Zentrifix KMH, Nafufill KM 250, MC-DUR 1277 WV, MC-DUR VS NR3, MC-DUR VS-PUR 2008 F or this cooling tower it was particularly important to repair the shoring in the water distribution level and the cooling tower basin. First of all the concrete was repaired using the tried-and-tested Nafufill KM 250 system, followed by the surface protection system MC-DUR VS NR3 combined with MC-DUR VS-PUR. Both chimneys were also repaired in this power plant, for which MCs surface protection systems matched to the respective load scenarios were used.

Year: Project information:

64

65

POLAND, OPOLE

Power Plant Opole

Product: Zentrifix KMH, Zentrifix GM2, MC-DUR 1277 WV, MC-DUR VS MC-Schutzberzug 702 SX, Betonflair W 1998 I n this plant the cooling tower was successfully repaired with MC products on the inside and outside. Whats worth mentioning here is that the colour design for the outer surface was done by the children from the primary school in Opole.

Year: Project information:

66

67

ROMANIA, IERNUT

Power Plant Iernut

Product: Nafufill KM 250, Betonflair Uniprimer, EmceColor-flex, MC-DUR 1277 WV, MC-DUR VS NR3, MC-CFK Sheets 2007-2009 F ollowing extensive inspections that identified a rather thin concrete cover it was decided to repair one cooling tower of this power plant with the PCC mortar Nafufill KM 250, which is statically creditable. Surface protection was then applied with the EmceColor-flex system. The inside surface was also repaired and was protected with the proven system MC-DUR VS NR3. Of great importance in this case was the static strengthening of the cooling towers with MC-CFK sheets. Another special feature was the colour design, luminous rings painted with RAL 3000.

Year: Project information:

68

69

RUSSIA, RYAZAN

Power Plant Ryazan

Product: MC-Schutzberzug 702, MC-DUR VS, MC-DUR VS-PUR 2007 I n this project during new construction the proven products from MC-Bauchemie were also being used. The deciding factor here was the possibility of concrete after-treatment in slip form construction with integrated long-term protection.

Year: Project information:

70

71

UNITED KINGDOM, FAWLEY

Petrochemical Manufacturing Plant ExxonMobil

Product: Year: Project information: MC-Schutzberzug 702 2008 R ecoating of the smoke band to provide protection from chemical attack and to create an aesthetically pleasing finish. MC-Schutzberzug 702 was selected as this product provides very short drying times between coats a requirement in order to minimise moving the access platforms.

72

73

MC-Bauchemie Mller GmbH & Co. KG Protection Technologies Am Kruppwald 1-8 46238 Bottrop Germany Phone: +49 (0) 2041 101-10 Fax: +49 (0) 2041 101-188 protection-technologies@mc-bauchemie.com www.mc-bauchemie.com

Você também pode gostar

- Tuned Mass DamperDocumento18 páginasTuned Mass DamperErick Hurtado100% (1)

- Calcul Fundatie Izolata Stalp MetDocumento3 páginasCalcul Fundatie Izolata Stalp MetVirginia Elena IordacheAinda não há avaliações

- Buloane de Ancoraj PDFDocumento29 páginasBuloane de Ancoraj PDFAndrei Cretu100% (1)

- Profile Zincate Calcul PaneDocumento2 páginasProfile Zincate Calcul PanecazilauAinda não há avaliações

- 2010 05 20 Reabilitare Pe DN2 M La Reghiu PDFDocumento573 páginas2010 05 20 Reabilitare Pe DN2 M La Reghiu PDFGabrielBarbuAinda não há avaliações

- Proiect FundatiiDocumento42 páginasProiect FundatiiFlorin FlorinellAinda não há avaliações

- Beton Si Beton ArmatDocumento50 páginasBeton Si Beton ArmatTilici AndreeaAinda não há avaliações

- Beton - Grinda Precomprimata PiDocumento24 páginasBeton - Grinda Precomprimata PiMihai Soplica PancuAinda não há avaliações

- Studies About Fire Behaviour of Polystirene and Mineral Wool Used For Thermoinsulating T Systems of BuildingsDocumento6 páginasStudies About Fire Behaviour of Polystirene and Mineral Wool Used For Thermoinsulating T Systems of BuildingsnamrytAinda não há avaliações

- Zid de SprijinDocumento4 páginasZid de SprijinAnonymous W6WPVDkeAinda não há avaliações

- Xtract StalpDocumento1 páginaXtract StalpAndrei TeoAinda não há avaliações

- Grinda Mixta Otel-BetonDocumento6 páginasGrinda Mixta Otel-BetonKalauz EdmondAinda não há avaliações

- 013 - Moga Ioan Moga Ligia TDocumento8 páginas013 - Moga Ioan Moga Ligia TMarshall BowmanAinda não há avaliações

- Armare Diafragme A4Documento11 páginasArmare Diafragme A4Kalauz EdmondAinda não há avaliações

- KG/M Masa (KG) Pozitie Denumire Grosime (MM) Latime (MM) Lungime (MM) Nr. BucDocumento3 páginasKG/M Masa (KG) Pozitie Denumire Grosime (MM) Latime (MM) Lungime (MM) Nr. BucVlad GavriliucAinda não há avaliações

- AllPlan Nemetchek 3d Tutorial 2005Documento190 páginasAllPlan Nemetchek 3d Tutorial 2005ČovjeknAinda não há avaliações

- Management ConstructiiDocumento12 páginasManagement ConstructiiAlexandru ChisAinda não há avaliações

- Calculul Unei Grinzi PrecomprimateDocumento12 páginasCalculul Unei Grinzi Precomprimateaniosha100% (1)

- Spectru ProiectareDocumento27 páginasSpectru ProiectareHoria Ionut MihneaAinda não há avaliações

- Trump To We ChicagoDocumento18 páginasTrump To We Chicagomusiomi2005Ainda não há avaliações

- R02 - A2 - Detalii FundatiiDocumento1 páginaR02 - A2 - Detalii FundatiiSergiu CostinAinda não há avaliações

- Combinatii de IncarcariDocumento4 páginasCombinatii de IncarcarilucianduAinda não há avaliações

- Jurnal Cabluri ExtDocumento2 páginasJurnal Cabluri ExtMihai StancescuAinda não há avaliações

- Anexa 1: Caracteristici Secţionale Ale Profilelor LaminateDocumento26 páginasAnexa 1: Caracteristici Secţionale Ale Profilelor LaminatealexAinda não há avaliações

- Proiect - Constructii - Metalice AndreiDocumento54 páginasProiect - Constructii - Metalice AndreiBujor NicusorAinda não há avaliações

- Work Portfolio - Eng. Neagu GeorgianDocumento21 páginasWork Portfolio - Eng. Neagu GeorgianGeorgian NeaguAinda não há avaliações

- Mathcad - Calcul Si Consolidare La Forta Taietoare (GRINDA)Documento4 páginasMathcad - Calcul Si Consolidare La Forta Taietoare (GRINDA)agent206Ainda não há avaliações

- Extras ArmareDocumento17 páginasExtras ArmareStaruiala GeorgeAinda não há avaliações

- Pod Rulant EurocodeDocumento9 páginasPod Rulant EurocodencristiAinda não há avaliações

- Trump BakerDocumento3 páginasTrump BakerNadya PriciliaAinda não há avaliações

- Săpătură 16.016 MC: TSA01B1 SAP - MAN.IN ConsumDocumento6 páginasSăpătură 16.016 MC: TSA01B1 SAP - MAN.IN ConsumJoey Cross fxAinda não há avaliações

- R14 Plan Cofraj, Arm Centuri Mansarda - 14 PDFDocumento1 páginaR14 Plan Cofraj, Arm Centuri Mansarda - 14 PDFCristi RanjaAinda não há avaliações

- Borderou Scoala 86Documento1 páginaBorderou Scoala 86emil_tase949Ainda não há avaliações

- About The Network ArchDocumento36 páginasAbout The Network ArchSergio Adolfo ParedesAinda não há avaliações

- Armare Stalp in ExcelDocumento4 páginasArmare Stalp in ExcelRepanov AlexAinda não há avaliações

- Tabla Cutata Cu Profil Inalt MBS 85 - Tabel IncarcariDocumento8 páginasTabla Cutata Cu Profil Inalt MBS 85 - Tabel IncarcariionutzglimbeaAinda não há avaliações

- Constructii Metalice III - Stilpi PDFDocumento12 páginasConstructii Metalice III - Stilpi PDFGhitulescu Catalin GabrielAinda não há avaliações

- Study On Seismic Upgrade of 5 Storey RC Building by Tuned Mass DamperDocumento31 páginasStudy On Seismic Upgrade of 5 Storey RC Building by Tuned Mass Damperbursuc2Ainda não há avaliações

- Faza / Phase: PTH: Armare Pilot Pile ReinforcementDocumento1 páginaFaza / Phase: PTH: Armare Pilot Pile ReinforcementBogdan Constantin-BabiiAinda não há avaliações

- NP 082 04 Actiunea VantuluiDocumento14 páginasNP 082 04 Actiunea Vantuluibebi66Ainda não há avaliações

- A1 Plan Sapaturi 1 - 50Documento1 páginaA1 Plan Sapaturi 1 - 50ic_lefterAinda não há avaliações

- Formular Comanda Armatura 1Documento6 páginasFormular Comanda Armatura 1Marinoiu MarianAinda não há avaliações

- Calcul Ferma Curenta de Acoperis: Evaluarea IncarcarilorDocumento32 páginasCalcul Ferma Curenta de Acoperis: Evaluarea IncarcarilorRoman Bentalo100% (1)

- F.C.C.I.A. Plan Fatada F.C.C.I.A.: Structura Metalica Tip ParterDocumento1 páginaF.C.C.I.A. Plan Fatada F.C.C.I.A.: Structura Metalica Tip ParterDenisa TurmacAinda não há avaliações

- Calculul La Forta Taiatoare Pereti Mulati + Dimensionare SpraituriDocumento4 páginasCalculul La Forta Taiatoare Pereti Mulati + Dimensionare SpraituriBza ZaBugAinda não há avaliações

- Calcul Imbinari MetaliceDocumento1 páginaCalcul Imbinari MetaliceBoureanu VictorAinda não há avaliações

- Ro=1/αi+R+1/αe: Ii.5. Note De Calcul Cladirea RealaDocumento4 páginasRo=1/αi+R+1/αe: Ii.5. Note De Calcul Cladirea RealaAndreiGorgosAinda não há avaliações

- Verificare Grinda MetalicaDocumento2 páginasVerificare Grinda MetalicaVirginia Elena IordacheAinda não há avaliações

- 64.cheson Armare CircularDocumento1 página64.cheson Armare CircularAnonymous kqcev0Ainda não há avaliações

- R03-Plan Fundatii HALA1Documento1 páginaR03-Plan Fundatii HALA1Augustin MacoveiAinda não há avaliações

- Incarcari PermanenteDocumento2 páginasIncarcari PermanenteIoana HlatcaAinda não há avaliações

- Model EtabsDocumento17 páginasModel EtabstfemilianAinda não há avaliações

- Cap.8 - Calculul Si Armarea ScarilorDocumento2 páginasCap.8 - Calculul Si Armarea ScarilorStefania OlareanuAinda não há avaliações

- A4 Mathcad - Tema 5 - PilotiDocumento7 páginasA4 Mathcad - Tema 5 - PilotiRobert AntalAinda não há avaliações

- Ritter Solar GMBH & Co. KGDocumento30 páginasRitter Solar GMBH & Co. KGMagdyAinda não há avaliações

- Single Shaft Design of Power PlantDocumento12 páginasSingle Shaft Design of Power PlantSrinivasa Rao PallelaAinda não há avaliações

- Tromble Wall ReviewDocumento28 páginasTromble Wall ReviewjothilakshmiAinda não há avaliações

- Ge Power Ststem Manuals PDFDocumento157 páginasGe Power Ststem Manuals PDFveejai_kumar100% (1)

- Harte 2009 Power PlantDocumento10 páginasHarte 2009 Power PlantSohan MeharwadeAinda não há avaliações

- chymney-Hadek-Karrena CR-24-2Documento8 páginaschymney-Hadek-Karrena CR-24-2dnageshm4n244Ainda não há avaliações

- Power Generation IndustryDocumento12 páginasPower Generation Industrypetronela.12Ainda não há avaliações

- IRP Chapter A-ConcreteDocumento11 páginasIRP Chapter A-Concretepetronela.12Ainda não há avaliações

- MC Aktiv 1 14 ENDocumento16 páginasMC Aktiv 1 14 ENpetronela.12Ainda não há avaliações

- Mycoflex Resyst en 02Documento2 páginasMycoflex Resyst en 02petronela.12Ainda não há avaliações

- Protectie FlexibilaDocumento2 páginasProtectie Flexibilapetronela.12Ainda não há avaliações

- Referinte Turnuri de Racire Si Cosuri de FumDocumento75 páginasReferinte Turnuri de Racire Si Cosuri de Fumpetronela.12Ainda não há avaliações

- Referinte Turnuri de Racire Si Cosuri de FumDocumento75 páginasReferinte Turnuri de Racire Si Cosuri de Fumpetronela.12Ainda não há avaliações

- MC PT-Injection Brochure UK 07-2013 ScreenDocumento40 páginasMC PT-Injection Brochure UK 07-2013 Screenpetronela.12Ainda não há avaliações

- Flooring SystemsDocumento94 páginasFlooring Systemspetronela.12Ainda não há avaliações

- Emcephob LE enDocumento2 páginasEmcephob LE enpetronela.12Ainda não há avaliações

- Emcephob NanoPermP enDocumento8 páginasEmcephob NanoPermP enpetronela.12Ainda não há avaliações

- Waste Water Treatment PlantsDocumento51 páginasWaste Water Treatment Plantspetronela.12100% (1)

- Bonding Systems For The Track SuperstructureDocumento6 páginasBonding Systems For The Track Superstructurepetronela.12Ainda não há avaliações

- Waste Water Treatment PlantsDocumento51 páginasWaste Water Treatment Plantspetronela.12100% (1)

- Flooring SystemsDocumento94 páginasFlooring Systemspetronela.12Ainda não há avaliações

- MC-DUR 2500: The Hybrid Screed System For Heavy-Duty Industrial FlooringDocumento4 páginasMC-DUR 2500: The Hybrid Screed System For Heavy-Duty Industrial Flooringpetronela.12Ainda não há avaliações

- MC DuroDesign EDocumento8 páginasMC DuroDesign Epetronela.12Ainda não há avaliações

- Flooring SystemsDocumento94 páginasFlooring Systemspetronela.12Ainda não há avaliações

- Emcephob LE enDocumento2 páginasEmcephob LE enpetronela.12Ainda não há avaliações

- Protectie FlexibilaDocumento2 páginasProtectie Flexibilapetronela.12Ainda não há avaliações

- Flooring SystemsDocumento94 páginasFlooring Systemspetronela.12Ainda não há avaliações

- Comparatives & Superlatives: FruitDocumento2 páginasComparatives & Superlatives: FruitKatherine MastersAinda não há avaliações

- Cash For WorkDocumento17 páginasCash For WorkChed PerezAinda não há avaliações

- Mod Is A 19032013Documento8 páginasMod Is A 19032013Garankuwa HiphopCommiteeAinda não há avaliações

- Legno Home Catalogue WardrobeDocumento64 páginasLegno Home Catalogue WardrobeSheik HassanAinda não há avaliações

- Pipiwharauroa, Te Rawhiti Newsletter, Volume 1 Issue 6Documento4 páginasPipiwharauroa, Te Rawhiti Newsletter, Volume 1 Issue 6lellobotAinda não há avaliações

- Organization Structure: Tata Steel Limited (Partial View)Documento2 páginasOrganization Structure: Tata Steel Limited (Partial View)Abhishek Handa100% (1)

- Urutan Katalog, KP & Item Di Tablet AB2345Documento30 páginasUrutan Katalog, KP & Item Di Tablet AB2345Ovel WoworAinda não há avaliações

- Describing My KitchenDocumento3 páginasDescribing My KitchenDaniel RamirezAinda não há avaliações

- Which of The Following Can Be Said About The KingDocumento34 páginasWhich of The Following Can Be Said About The Kingprasathkrp100% (2)

- Ultra-High Density Plantation of Mango - New Technology For Increasing The Income of The FarmersDocumento8 páginasUltra-High Density Plantation of Mango - New Technology For Increasing The Income of The FarmersAdyantKumarSingh100% (2)

- Fungi ClassificationDocumento8 páginasFungi ClassificationNAYAN JYOTI KALITA100% (1)

- Leaves:: Form and StructureDocumento37 páginasLeaves:: Form and StructureJane ManalusAinda não há avaliações

- Science 9 - Edible Cell ActivityDocumento9 páginasScience 9 - Edible Cell ActivitySheena Mar dela CruzAinda não há avaliações

- Seed and Seed Technology: Introduction, Definition and ImportanceDocumento42 páginasSeed and Seed Technology: Introduction, Definition and ImportanceMuhammad Nadeem AkramAinda não há avaliações

- RRL Kangkong Cupcake, Boniao, Ethel CainDocumento6 páginasRRL Kangkong Cupcake, Boniao, Ethel CainJasmin WillieAinda não há avaliações

- Ang Alamat NG Bigas FILIPINODocumento3 páginasAng Alamat NG Bigas FILIPINOMine CabuenasAinda não há avaliações

- Back Coal BallsDocumento20 páginasBack Coal BallsJuan Felipe Galan PalaciosAinda não há avaliações

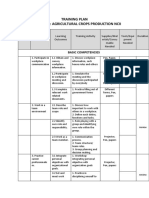

- Training Plan Qualification: Agricultural Crops Production NciiDocumento4 páginasTraining Plan Qualification: Agricultural Crops Production NciiLeonelyn Hermosa Gasco - CosidoAinda não há avaliações

- Cocktails 8: Mojito & Pina Colada Slushies!!Documento2 páginasCocktails 8: Mojito & Pina Colada Slushies!!EaterAinda não há avaliações

- The Wayland News June 2013Documento16 páginasThe Wayland News June 2013Julian HornAinda não há avaliações

- 14 Rapeseed Muster DDocumento20 páginas14 Rapeseed Muster DMamata khandappagolAinda não há avaliações

- Ordinea Adjectivelor in EnglezaDocumento6 páginasOrdinea Adjectivelor in Englezamadamail2408Ainda não há avaliações

- Print For ChrysoberylDocumento2 páginasPrint For ChrysoberylToh Yang75% (4)

- Concept Strengthening Sheet (CSS-04) Based On AIATS-04 (TYM) - PCBZDocumento16 páginasConcept Strengthening Sheet (CSS-04) Based On AIATS-04 (TYM) - PCBZTwinkle ShahAinda não há avaliações

- Soal Akademik Tes Masuk Sma Plus Yasop Balige 2 019 Bahasa InggrisDocumento12 páginasSoal Akademik Tes Masuk Sma Plus Yasop Balige 2 019 Bahasa Inggriswaqidi100% (1)

- Varieties of GrapesDocumento9 páginasVarieties of GrapesBilal ArshadAinda não há avaliações

- Gramma in Practice (2) Are These Those Is This ThatDocumento4 páginasGramma in Practice (2) Are These Those Is This ThatYan WongAinda não há avaliações

- The Witches 1996-1997 PDFDocumento50 páginasThe Witches 1996-1997 PDFNokatinAinda não há avaliações

- THE Peterman'S House Family Cookbook Cajun Lvl3Documento44 páginasTHE Peterman'S House Family Cookbook Cajun Lvl3annaAinda não há avaliações

- English Conversation For Arabs: EgyptDocumento38 páginasEnglish Conversation For Arabs: EgyptAnonymous ToHeyBoEbXAinda não há avaliações