Escolar Documentos

Profissional Documentos

Cultura Documentos

Ils Integrates Idec Microsmart Microsmart PLC For Batch Control of Bioreactor

Enviado por

Engr Nayyer Nayyab MalikTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ils Integrates Idec Microsmart Microsmart PLC For Batch Control of Bioreactor

Enviado por

Engr Nayyer Nayyab MalikDireitos autorais:

Formatos disponíveis

ILS Integrates IDEC Microsmart MicroSmart PLC for Batch Control of Bioreactor

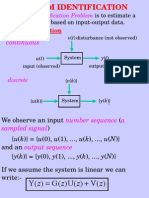

Choosing a PLC Vendor for Bioreactor Control ILS is a solution provider and system integrator for supervisory control, data acquisition, and information system storage, retrieval and reporting for the process industries. ILS specializes in solutions for the batch process industry, in particular, fermentation or biological applications for food, energy, pharmaceutical and biotechnology. Their primary focus had been software, with solutions based upon the ILS Batch Expert supervisory control and data acquisition (SCADA) platform. ILS saw the opportunity to introduce bioreactor control hardware utilizing the benefits of modern programmable logic controllers (PLCs). Their goal was to introduce a stand-alone bioreactor control box that included sensor inputs, control outputs, a touchscreen HMI and Ethernet port for OPC communication. A PLC was chosen as the platform for data acquisition and control as a PLC provided the greatest value for both development and support from both ILS and the customers perspective. The optimum solution should rely on off-the-shelf parts to minimize cost and provide an open platform for the customer to support and maintain. The control box offered by ILS is labeled the AFC 900 Series of bioreactor control systems. For ILS to be successful, a hardware vendor and PLC solution had to meet the following basic criteria: 1. Hardware meeting the technical requirements for batch control 2. Cost-effective hardware and programming software 3. Excellent customer service and support The IDEC MicroSmart Pentra Slim line FC5A-D32 PLC was the basis for the ILS AFC 900 Series. The IDEC Pentra Slim line series met technical requirements, and at a costeffective price for both the hardware and software. More importantly, IDEC provides direct support and introduced ILS to a third-party partner willing to assist in the development of AFC 900 Series. IDEC introduced ILS to Electrical Control Distributors (ECD), a company dedicated to the design and manufacture of specialized controls. ECD provided the hardware design and integration services based upon the requirements of ILS and based upon IDEC components. PLC Technical Requirements ILS wanted to meet specific hardware requirements that would differentiate the AFC 900 from competitors. The key was to provide processors a solution that included as many off-the-shelf components as possible. Many customers can maintain their own systems and proprietary systems are expensive, if not impossible, to maintain over time. The

ILS : P.O. Box 1309 : Warrenville, IL 60555 : USA Phone: (732) 715-2359 : Email: info@ils-automation.com Web: www.ils-automation.com

following table lists some of AFC 900 technical requirements with corresponding IDEC Pentra Slimline functionality: AFC 900 Requirement Ethernet Port for programming and OPC communication IDEC Pentra Functionality The IDEC Web Server Module facilitates PLC programming/monitoring and OPC communication. End-users can switch between programming and OPC communication through the HMI port. The IDEC WindSRV OPC server software in combination with the Ethernet module allows for communication through a LAN. The Pentra Slim line models support numerous simultaneous PID controllers. Flexible PID that includes all the hooks and auto-tuning capabilities. Up to two pulse outputs allows for control of two stepper motors. The stepper motors allow for variable speed RPM control of peristaltic pumps. The built-in IDEC high-speed counters allow the PLC to calculate RPMs based upon a motor encoder and the PWM allows the PLC to drive the DC motor. The IDEC FC4A-J8C1 high-density analog input module includes 8 16-bit analog inputs for current and voltage The IDEC FC4A-K2C1 includes 2 analog outputs for either current or voltage.

OPC communication through Ethernet for direct communication with SCADA over local area network (LAN) PID Control for temperature, pH and dissolved oxygen

Pulse Output for controlling peristaltic pump stepper motors

High-speed counting and Pulse Width Modulation (PWM) for controlling DC agitator motor 16-bit analog inputs for reading temperature, pH, DO

Analog outputs for controlling gas flow controllers

Serial input module for reading probes and scales

The IDEC FC5A-SIF2 serial module for reading values from scales and serial probes. The available serial command set within the PLC has been able to manage a variety of different vendor specific communication protocols.

Figure 1 is a picture of the ILS AFC 901 MF bioreactor control system. The AFC 901 MF includes an AC motor drive for agitation, cooling water feed/recycle valve for temperature control, variable RPM peristaltic pumps for substrate control, and fixed RPM on/off pumps for pH and foam control. Analog inputs include gas flow, temperature, pH and DO. Serial inputs include ports for Mettler-Toledo ISM serial probes.

ILS : P.O. Box 1309 : Warrenville, IL 60555 : USA Phone: (732) 715-2359 : Email: info@ils-automation.com Web: www.ils-automation.com

Figure 1 AFC 901 MF reactor Figure 2 shows a picture of the internal AFC 901 MF including the IDEC MicroSmart Pentra FC5A-D32 PLC, IDEC Web Server Module for programming and OPC communication, IDEC FC5A-SIF2 RS232C expansion modules, and FC4A-J8C1 highdensity analog input module.

Figure 2 IDEC PLC and communication modules

IDEC WindLDR - PLC Programming Software The IDEC WindLDR PLC programming software provides ILS engineers an easy-to-use and fully-functional platform for development, monitoring and maintenance of PLC operation. ILS realizes that the human resources to develop and maintain software, including PLC code, are a significant portion of project costs. The effort is made costeffective with the IDEC WindLDR software, IDEC training services, and IDEC documentation.

ILS : P.O. Box 1309 : Warrenville, IL 60555 : USA Phone: (732) 715-2359 : Email: info@ils-automation.com Web: www.ils-automation.com

Ease-of-use: WindLDR software maintains its ease-of-use even considering the many advanced instructions and features provided. Documentation: The manuals and other documentation, including web-based materials, are well written and detailed. This allows ILS engineers to make quick reference when the need arises. Support: If required, ILS emails IDEC technical questions. Training: IDEC provides convenient hands-on training throughout the year. PLC Programming Instructions: WindLDR software includes a rich set of PLC instructions and programming capability. Software Updates: IDEC provides automatic software updates as they are made available. IDEC routinely provides bug fixes and new features. On-Line PLC Monitoring: WindLDR software allows developers to monitor PLCs running within a PLC. Without this feature, the software testing and debugging effort is significantly larger. Off-line Simulation: WindLDR software allows the developer to simulate PLC code before downloading and testing with the PLC. This speeds the initial development effort. IDEC WindLDR - PLC Instructions The AFC control box takes advantage of many of the WindLDR PLC programming instructions, from simple to advanced. Below is a list of a portion of the instructions utilized: 32-bit floating-point math: Advanced control, instrumentation calibration, etc. are often easier to develop and maintain in float format as opposed to integer or Word format. The 32-bit floating point math capabilities make development and use by personnel, such as chemical engineers and scientists, much easier. User Communication: ILS customers often request that the PLC communicate with serial devices, such as a scale or instrument. The PLC serial commands allow ILS engineers to quickly develop new communication interfaces. For example, in less than a day an engineer was able to develop an interface to a Mettler-Toledo scale or even more advanced devices such as Mettler-Toledo ISM pH/DO probes. Coordinate Conversion: Conversion allows for multiple-point conversion for instrument calibration. This is used for pH, DO, temperature and flow calibration. Program Branching: Branching reduces code complexity and provides more flexibility to traditional ladder-logic.

ILS : P.O. Box 1309 : Warrenville, IL 60555 : USA Phone: (732) 715-2359 : Email: info@ils-automation.com Web: www.ils-automation.com

PID Instruction: ILS customer applications require PID control. The IDEC PLC PID implementation is fully features and well documented. Pulse: Motors for agitation and pumps are controlled through pulse outputs including a PWM command. Dual Timers: Dual timers that provide on/off type pulses are applied to control outputs such as pumps, valves and heaters. This feature is widely applied and reduces overall program complexity. Data Conversion/Data Comparison/Arithmetic/Shift and Rotate: Many of the advanced instructions have been applied. New Features: IDEC often adds new features that add significant benefit for ILS development and testing. For example, IDEC provided an update with a random number generator. This allowed ILS engineers to simulate how controllers would perform in the presence of a noisy instrument. The IDEC Advantage for ILS ILS customers often speak in terms of credits when performing a cost benefit analysis. IDEC easily provides the straight-forward credit. For a direct comparison of technical requirements IDEC PLC hardware and software provide, the value for the dollars spent. For ILS and its customers this initial credit is often only part of the final analysis. ILS labor costs to develop, maintain and deploy applications are not insignificant. IDEC offers easy-to-use products, documentation, training and support, which reduce this cost and add significantly to the credit. In addition, ILS often provides custom solutions and/or improvements to the application as the customer needs evolve. IDEC solutions make this possible. ILS customer credit is in the performance and long-term maintenance of the system. IDEC provides robust hardware and software that can perform over the long-term. In addition, the majority of ILS customers perform their own maintenance. IDEC software gives ILS customers the advantage of non-proprietary components. This provides the credit of long-term support through lower-cost access to parts and service. ILS Products and Services ILS offers automation products and system integration services. ILS products can include the following. 1. AFC 900 series control systems for batch and continuous processes based upon IDEC Pentra PLCs. 2. Batch Expert SCADA software that communicates through OPC to the AFC 900 and other OPC compatible control systems. Batch Expert provides supervisory control, batch recipe management (ISA S88), data historian and batch reporting.

ILS : P.O. Box 1309 : Warrenville, IL 60555 : USA Phone: (732) 715-2359 : Email: info@ils-automation.com Web: www.ils-automation.com

ILS system integration services include the following: 1. IDEC PLC and HMI integration and programming with emphasis on the process industries. 2. SCADA and OPC communication and integration with IDEC PLCs. This includes SCADA system from a variety of vendors. 3. Serial-based communication and system integration with IDEC PLC including Modbus and specific serial protocols. About ILS ILS has been providing automation and software solutions since 2001. Our expertise started with real-time, rule-based systems for laboratory, batch, manufacturing and business applications. ILS saw the need to integrate laboratory and hardware control systems with SCADA software and databases. With our background in process control and software, we have extended our products and services to control hardware, with emphasis on reliable and affordable integration with software and enterprises. We make sure integration can occur through accepted hardware protocols that can communicate easily with OPC and Modbus communication protocols. About ECD ECD was founded in 1992 by Mary and Fred Schwan as a distributor of products and services for the fabrication and maintenance of Electrical Control equipment. ECD is an IDEC partner and distributor providing integration services. Visit ECD on the Web at http://www.ecdcontrols.com . About IDEC IDEC designs and manufactures control automation products that are sold to original equipment manufacturers. Our goal is to meet our customers' ever-changing needs with quality products at a competitive price. Visit http://www.idec.com/usa for further information regarding IDEC products.

ILS : P.O. Box 1309 : Warrenville, IL 60555 : USA Phone: (732) 715-2359 : Email: info@ils-automation.com Web: www.ils-automation.com

Você também pode gostar

- PLC/SCADA Presentation Automation Process ControlDocumento39 páginasPLC/SCADA Presentation Automation Process ControlsaarjatAinda não há avaliações

- PLC and SCADA TrainingDocumento60 páginasPLC and SCADA Trainingdeepak_297Ainda não há avaliações

- SOFCON India Pvt. Ltd. Company ProfileDocumento16 páginasSOFCON India Pvt. Ltd. Company ProfilemalhiavtarsinghAinda não há avaliações

- Basics of PLC Workshop - Day 1 AgendaDocumento119 páginasBasics of PLC Workshop - Day 1 AgendaOwais Khan100% (2)

- PLC Comparison ChartDocumento6 páginasPLC Comparison ChartVictor CenicerosAinda não há avaliações

- Programmable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferDocumento41 páginasProgrammable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferAbhishek SinghAinda não há avaliações

- Programmable Logic ControllerDocumento31 páginasProgrammable Logic ControllerRaj RajAinda não há avaliações

- Training Viva PPT 4 YrDocumento23 páginasTraining Viva PPT 4 YrAkanksha PatelAinda não há avaliações

- AutomationDocumento34 páginasAutomationmahesh4975Ainda não há avaliações

- Introduction to Automation and PLC ProgrammingDocumento37 páginasIntroduction to Automation and PLC ProgrammingHappy ShubhamAinda não há avaliações

- World of Industrial Applications Brochure 2011-02 CPCEIDAPDocumento44 páginasWorld of Industrial Applications Brochure 2011-02 CPCEIDAPMarcelo Palacios SantanaAinda não há avaliações

- Report on Automation Using PLC - SCADADocumento47 páginasReport on Automation Using PLC - SCADAAman AJAinda não há avaliações

- PLC Scada IndustrialDocumento36 páginasPLC Scada IndustrialAnmolAinda não há avaliações

- PLC m1Documento11 páginasPLC m1Goutham KAinda não há avaliações

- Unit II Course MaterialDocumento11 páginasUnit II Course MaterialKumaresan ElectronicsAinda não há avaliações

- CLX 422 IPC DatasheetDocumento2 páginasCLX 422 IPC DatasheetPhoneGyi KyaungTharAinda não há avaliações

- PLCFamilyDocumento68 páginasPLCFamilyftirhiAinda não há avaliações

- Bu34p2a00 01eDocumento7 páginasBu34p2a00 01eAlex AlvesAinda não há avaliações

- ControlLogix Selection GuideDocumento88 páginasControlLogix Selection Guideronnell_naidooAinda não há avaliações

- Rohit ReportDocumento37 páginasRohit ReportRohitAinda não há avaliações

- Micrologix 1000 Programmable Controllers and Handheld ProgrammerDocumento23 páginasMicrologix 1000 Programmable Controllers and Handheld ProgrammerPatricia MendozaAinda não há avaliações

- JETIR2206863Documento7 páginasJETIR2206863Kishore MAinda não há avaliações

- Programmable Logic Control Trainer IT-1200SDocumento34 páginasProgrammable Logic Control Trainer IT-1200SImran ShaukatAinda não há avaliações

- Automation Training & PLC Programming CoursesDocumento11 páginasAutomation Training & PLC Programming CoursesGopala KrishnanAinda não há avaliações

- Temperature Sensor Interfacing With Embedded PLCDocumento5 páginasTemperature Sensor Interfacing With Embedded PLCInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- PLC Workshop 1-2 DayDocumento120 páginasPLC Workshop 1-2 DayHamza Khan Khattak100% (1)

- Control Engineering June 2016Documento107 páginasControl Engineering June 2016Ionut-Catalin DimacheAinda não há avaliações

- Lakshit Industrial TrainingDocumento32 páginasLakshit Industrial TrainingRenu ChoudheryAinda não há avaliações

- Compactlogix: Technical DataDocumento20 páginasCompactlogix: Technical DataRamaKrishnan RebelofmitAinda não há avaliações

- Ramgopal Embedded ResumeDocumento5 páginasRamgopal Embedded ResumeVinod KumarAinda não há avaliações

- Labview Fpga Implementation of A Pid Controller For D.C. Motor Speed ControlDocumento6 páginasLabview Fpga Implementation of A Pid Controller For D.C. Motor Speed ControlZaheer AbbasAinda não há avaliações

- PLC Interview Questions and Answers Part 1Documento54 páginasPLC Interview Questions and Answers Part 1Hagos AlemAinda não há avaliações

- Programmable Logic Controllers (PLCs): An OverviewDocumento53 páginasProgrammable Logic Controllers (PLCs): An Overviewokk chuAinda não há avaliações

- Vanguard Product BrochureDocumento6 páginasVanguard Product BrochurescribdkhatnAinda não há avaliações

- EIA MicroprojectDocumento21 páginasEIA MicroprojectSiddhi WakchaureAinda não há avaliações

- In The Name of Allah The Most Benificet and The Most MercifulDocumento24 páginasIn The Name of Allah The Most Benificet and The Most MercifulAsad RazaAinda não há avaliações

- Microsolution: Clutch/Brake ControlDocumento3 páginasMicrosolution: Clutch/Brake ControlGamaliel Garcia HernandezAinda não há avaliações

- Programmable Logic ControllerDocumento6 páginasProgrammable Logic ControllerSEP-PublisherAinda não há avaliações

- Lec - 5-Introduction To PLCDocumento60 páginasLec - 5-Introduction To PLCNurhussen NureAinda não há avaliações

- Control Engineering April 12Documento72 páginasControl Engineering April 12Mauro SánchezAinda não há avaliações

- Industrial AutomationDocumento28 páginasIndustrial Automation4happy12383% (6)

- Automation PresentationDocumento32 páginasAutomation PresentationAman Sharma100% (1)

- Industrial Training Report: Rishiraj Institute of Technology, IndoreDocumento36 páginasIndustrial Training Report: Rishiraj Institute of Technology, IndoreAbhishek PathakAinda não há avaliações

- Jatin Mer CVDocumento7 páginasJatin Mer CVsumitAinda não há avaliações

- Wiki PLC RtuDocumento219 páginasWiki PLC RtuboypardedeAinda não há avaliações

- Programmable Logic Controller: From Wikipedia, The Free EncyclopediaDocumento10 páginasProgrammable Logic Controller: From Wikipedia, The Free EncyclopediaAlda LopezAinda não há avaliações

- Delivery Release TIA Portal V15Documento6 páginasDelivery Release TIA Portal V15Giovanni JacintoAinda não há avaliações

- Automation & CNCDocumento31 páginasAutomation & CNCvirug1994Ainda não há avaliações

- Micro800 PLC SystemsDocumento16 páginasMicro800 PLC SystemsNicolás A. SelvaggioAinda não há avaliações

- PLC IkiPediaDocumento12 páginasPLC IkiPediaVivekKajlaAinda não há avaliações

- PLC Programmable Logic ControllerDocumento11 páginasPLC Programmable Logic ControllerRohit AgrawalAinda não há avaliações

- Programmable Logic ControllerDocumento6 páginasProgrammable Logic ControllerSEP-PublisherAinda não há avaliações

- Assignment 2 ControlDocumento19 páginasAssignment 2 Controlsaad6689Ainda não há avaliações

- Thanking organizations and individuals for support during trainingDocumento37 páginasThanking organizations and individuals for support during trainingAarif HussainAinda não há avaliações

- Automation Project ReportDocumento32 páginasAutomation Project ReportVicky Chaudhary100% (1)

- A Comparison of PACs To PLCsDocumento3 páginasA Comparison of PACs To PLCskouki982hotmailcomAinda não há avaliações

- Clase Tia Portal PLCDocumento34 páginasClase Tia Portal PLCHitklerLaynekerSebastian100% (1)

- 108 PDFDocumento28 páginas108 PDFcoulibalyoumarAinda não há avaliações

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosNo EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosNota: 5 de 5 estrelas5/5 (1)

- PhD Scholar Progress ReportDocumento1 páginaPhD Scholar Progress ReportEngr Nayyer Nayyab MalikAinda não há avaliações

- NandDocumento1 páginaNandEngr Nayyer Nayyab MalikAinda não há avaliações

- L5 PortDocumento41 páginasL5 PortSaifizi SaidonAinda não há avaliações

- QR BOARDING PASS ISLAMABAD TO LONDONDocumento2 páginasQR BOARDING PASS ISLAMABAD TO LONDONEngr Nayyer Nayyab MalikAinda não há avaliações

- Chap 11Documento60 páginasChap 11Engr Nayyer Nayyab MalikAinda não há avaliações

- LopDocumento1 páginaLopEngr Nayyer Nayyab MalikAinda não há avaliações

- Signal IsolatorDocumento1 páginaSignal IsolatorEngr Nayyer Nayyab MalikAinda não há avaliações

- Name CardDocumento1 páginaName CardEngr Nayyer Nayyab MalikAinda não há avaliações

- Assign 2 PCDDocumento9 páginasAssign 2 PCDEngr Nayyer Nayyab MalikAinda não há avaliações

- AbstractDocumento2 páginasAbstractEngr Nayyer Nayyab MalikAinda não há avaliações

- Stepper Motor InfoDocumento7 páginasStepper Motor InfoEngr Nayyer Nayyab MalikAinda não há avaliações

- LopinDocumento1 páginaLopinEngr Nayyer Nayyab MalikAinda não há avaliações

- Computer-Networks - Introduction Computer NetworkingDocumento23 páginasComputer-Networks - Introduction Computer Networkingapi-312772862Ainda não há avaliações

- Clad Exam Prep Guide EnglishDocumento16 páginasClad Exam Prep Guide EnglishmeetnatureAinda não há avaliações

- Courses To Be SelectedDocumento1 páginaCourses To Be SelectedEngr Nayyer Nayyab MalikAinda não há avaliações

- What Is A Computer Network?Documento20 páginasWhat Is A Computer Network?ssprudhviAinda não há avaliações

- ReadmeDocumento1 páginaReadmeMosa DalahmaAinda não há avaliações

- Mechanical Engineering: Sr. No. Core Areas PercentageDocumento1 páginaMechanical Engineering: Sr. No. Core Areas PercentageEngr Nayyer Nayyab MalikAinda não há avaliações

- MS Mechanical Engineering Course Plan and SyllabusDocumento12 páginasMS Mechanical Engineering Course Plan and SyllabusEngr Nayyer Nayyab Malik100% (1)

- 2Documento1 página2Engr Nayyer Nayyab MalikAinda não há avaliações

- Us Robotics Wireless Lan White PaperDocumento12 páginasUs Robotics Wireless Lan White PaperbiswasishereAinda não há avaliações

- What Is A Computer Network?Documento20 páginasWhat Is A Computer Network?ssprudhviAinda não há avaliações

- 1Documento13 páginas1Engr Nayyer Nayyab MalikAinda não há avaliações

- WEG CFW 11 Variable Frequency Drive 50019076 Brochure EnglishDocumento32 páginasWEG CFW 11 Variable Frequency Drive 50019076 Brochure EnglishevrimkAinda não há avaliações

- What Is A Computer Network?Documento20 páginasWhat Is A Computer Network?ssprudhviAinda não há avaliações

- Belden Variable Frequency Drive (VFD) White PaperDocumento6 páginasBelden Variable Frequency Drive (VFD) White Paperadventive1Ainda não há avaliações

- WegmvDocumento12 páginasWegmvEngr Nayyer Nayyab MalikAinda não há avaliações

- NI Tutorial 7109 enDocumento4 páginasNI Tutorial 7109 enEngr Nayyer Nayyab MalikAinda não há avaliações

- Hydraulic Proportional Closed Loop System Design PDFDocumento86 páginasHydraulic Proportional Closed Loop System Design PDFragdapattice100% (7)

- 078 Glodeanu MDocumento5 páginas078 Glodeanu MEngr Nayyer Nayyab MalikAinda não há avaliações

- NINA B112 - U BloxDocumento45 páginasNINA B112 - U BloxTomas LitvinasAinda não há avaliações

- KVL KCLDocumento6 páginasKVL KCLAllen WalkerAinda não há avaliações

- 701P49447 System GuideDocumento152 páginas701P49447 System GuideAmanda BattinieriAinda não há avaliações

- NB Perf TuningDocumento34 páginasNB Perf TuningDenAinda não há avaliações

- Toshiba Portege Z30 C Z12 WebDocumento2 páginasToshiba Portege Z30 C Z12 WebUsman KhanAinda não há avaliações

- Creation of Specification in CG02Documento7 páginasCreation of Specification in CG02Ricky Das0% (1)

- Simulation With Custom-Of-The-Shelf: And-Based Real-Time and Devices andDocumento5 páginasSimulation With Custom-Of-The-Shelf: And-Based Real-Time and Devices andNguefa FabriceAinda não há avaliações

- Android SSP APIDocumento17 páginasAndroid SSP APIkj9898Ainda não há avaliações

- Automatic Street Light Control Using LDRDocumento18 páginasAutomatic Street Light Control Using LDRkrimouneeshAinda não há avaliações

- Indian TEX Users Group: On-Line Tutorial On L TEXDocumento10 páginasIndian TEX Users Group: On-Line Tutorial On L TEXsatish_shrestha_2Ainda não há avaliações

- d1153r18 ATA ATAPI 4Documento339 páginasd1153r18 ATA ATAPI 4Raj Shekhar ReddyAinda não há avaliações

- Teacher Manual: Erts Lab IIT-BombayDocumento6 páginasTeacher Manual: Erts Lab IIT-BombaySridhar JayaramanAinda não há avaliações

- Introduction to Programming and Problem SolvingDocumento21 páginasIntroduction to Programming and Problem SolvingJada CameronAinda não há avaliações

- Oracle Solaris 10 Compared To Oracle Solaris 11Documento6 páginasOracle Solaris 10 Compared To Oracle Solaris 11dilaAinda não há avaliações

- G152e G156e G160e ACS800 Control Panel OperationDocumento14 páginasG152e G156e G160e ACS800 Control Panel OperationRig N80UY3Ainda não há avaliações

- MCU - PIC24FV32KA304 - MICROCHIP - Programming SpecificationsDocumento54 páginasMCU - PIC24FV32KA304 - MICROCHIP - Programming SpecificationsLudwig SchmidtAinda não há avaliações

- Features Description: 2K X 8 Asynchronous CMOS Static RAMDocumento8 páginasFeatures Description: 2K X 8 Asynchronous CMOS Static RAMKontak SynthetizadorAinda não há avaliações

- Chapter 3 SweDocumento69 páginasChapter 3 SweYiga TonnyAinda não há avaliações

- Question Bank Chapter 04 (AJP) - ObjectivesDocumento5 páginasQuestion Bank Chapter 04 (AJP) - Objectivesapi-3728136Ainda não há avaliações

- Toshiba Nemio XGDocumento27 páginasToshiba Nemio XGSergio D. Mercado Vera80% (10)

- Simon Bodner Resume 2022 66-DTXDocumento3 páginasSimon Bodner Resume 2022 66-DTXSAPNA tyagiAinda não há avaliações

- Question Bank PDFDocumento21 páginasQuestion Bank PDFAnshika Gautam100% (1)

- Open Catalog Interface (SAP ERP)Documento21 páginasOpen Catalog Interface (SAP ERP)Krishna SifyAinda não há avaliações

- The Design and Formula of DC To DC Converter SmpsDocumento9 páginasThe Design and Formula of DC To DC Converter Smpsdewidewi76Ainda não há avaliações

- E Library ManagmentDocumento69 páginasE Library ManagmentRitu rajAinda não há avaliações

- HYSECURE CLIENT BASED VPN Login and Mobile Token Registration ProcessDocumento11 páginasHYSECURE CLIENT BASED VPN Login and Mobile Token Registration Process8A SATYAM JHAAinda não há avaliações

- Technical Data: Pin AssignmentDocumento5 páginasTechnical Data: Pin AssignmentMaroAinda não há avaliações

- Arrangement Looper V2Documento3 páginasArrangement Looper V2Nahuel Federico KraussAinda não há avaliações

- Ura MolinaDocumento3 páginasUra Molinasps_angelAinda não há avaliações

- Neve VR Dynamic Offset AdjustementDocumento3 páginasNeve VR Dynamic Offset AdjustementSebAinda não há avaliações