Escolar Documentos

Profissional Documentos

Cultura Documentos

Filtrado A Granel de Combustibles - Sistema CAT

Enviado por

Leo Manaure RadaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Filtrado A Granel de Combustibles - Sistema CAT

Enviado por

Leo Manaure RadaDireitos autorais:

Formatos disponíveis

Information Release Memo

FIL06-05

July 2006

Cat Filters

BULK FUEL FILTRATION

Introduction Caterpillar Bulk Fuel Filtration systems, which will remove water and debris from bulk fuel storage units, are now available. Excessive amounts of dirt and/or water may be introduced into fuel during the transportation or storage process, which can prematurely plug and reduce fuel filter service intervals as well as accelerate fuel system component wear. In order to maximize the engine life, diesel fuel supplied to the fuel tank should have a maximum particulate level of ISO 18/16/13 with a maximum water content level of 0.1% (1,000 ppm). The Caterpillar Bulk Fuel Filtration system ensures that only clean fuel enters the fuel tank.

For Dealer Sales Personnel

The information contained herein is intended for circulation only to Caterpillar and dealer employees whose duties require knowledge of such reports and is intended exclusively for their information and training. Any reproduction of this release without the foregoing explanation is prohibited.

PELJ0671

Printed in USA

2006 Caterpillar

All Rights Reserved

Information Release Memo

IRM607120322

FIL06-05

Page 2

Applications The Caterpillar Bulk Fuel Filtration system is intended for use in any application where users store fuel for machines or engines. The filter coalescer units are placed in series between the fuel pump on the fuel storage tank and the fuel station. Smaller units are intended for remote day tank or fuel truck applications. The system does not require electrical power unless they are used in extremely cold climates. An optional electric fuel heater is available for cold climates where water removed from the fuel may freeze. The maximum fuel flow rate of the users fuel supply system determines the size of the filter coalescer filtration system. Four different units are available.

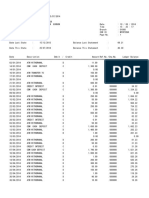

Part Number 284-0413 284-0415 284-0416 295-0048 Fuel Flow Rate 50 gpm 100 gpm 200 gpm 300 gpm

Features, Benefits, and Results

Information Release Memo

Features Gate valve 4-micron particulate filter

IRM607120322

FIL06-05

Page 3

Coalescer unit

Coalescing filter elements Separator cartridge Automatic water drain

Flow meter Slug control valve

Benefits & Results Shuts off flow during service or removal of unit Effectively traps and holds large volumes of particulate debris Filter elements may be quickly and easily replaced without the need for hand tools Strips water from fuel and automatically drains the water to an external water storage vessel Capable of removing 3% water by volume to less than .01% at the rated flow of the unit Float mechanism in the bottom of the unit monitors the water level Water removed by these elements falls to the bottom of the coalescer unit and is automatically drained to an external water storage vessel. A fine mesh fits over the coalescer to prevent tiny water droplets from escaping. When water level is at or below an acceptable level, the valve is shut off. When water level is above the acceptable level, the float will rise and trigger a rotary valve on the pivot of the float arm to open the automatic water drain valve. If the water and float continue to rise above normal, the slug control valve will completely shut off flow to prevent water from passing downstream. As the water level drops, the float drops, allowing the slug control valve to open and outlet flow to resume. Installed on the automatic water drain valve and allows the total amount of water removed to be monitored Used to temporarily reduce fuel flow to assure proper operation of the coalescer and particulate filters Reduces flow as filter restriction increases

Media References: Improving Component Durability Fuel Systems - Media Number SENR9620-02 Fluid Cleanliness Management - Media Number SEBF1020 Contact Information: Richard Douglas Caterpillar Global Mining (309) 675-5699

The information contained herein is intended for circulation only to Caterpillar and dealer employees whose duties require knowledge of such reports and is intended exclusively for their information and training. Any reproduction of this release without the foregoing explanation is prohibited. This IRM can be viewed and downloaded electronically from the Internet. Please refer to your marketing organization specific site for access to the Electronic Sales Library, which contains all of the active IRMs and product support communication materials. CAT, CATERPILLAR, their respective logos and Caterpillar Yellow, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. Electronic Sales Library Internal Caterpillar Employees http://cds.cat.com/PSMprev.nsf/$$MediaNumber

Você também pode gostar

- A Field Guide To Mining Machine ApplicationDocumento9 páginasA Field Guide To Mining Machine ApplicationLeo Manaure Rada100% (1)

- CBC Building Wiring Installation NC IIDocumento72 páginasCBC Building Wiring Installation NC IIFaysbuk KotoAinda não há avaliações

- VANAIR ADHD Operations ManualDocumento53 páginasVANAIR ADHD Operations ManualMiguel Angel Del Carpio Zuñiga100% (3)

- At22 MaintenanceDocumento37 páginasAt22 MaintenancefabuleukalengaAinda não há avaliações

- Caterpillar 143h II Spec SheetDocumento24 páginasCaterpillar 143h II Spec SheetRobinson Guaneme100% (2)

- ELC Work DescriptionDocumento36 páginasELC Work DescriptionHari100% (1)

- Benchmarks of Performance For Truck and Loader FleetsDocumento8 páginasBenchmarks of Performance For Truck and Loader FleetsLeo Manaure Rada100% (2)

- 12 Atlas Copco Xas96 Data SheetDocumento2 páginas12 Atlas Copco Xas96 Data SheetandersonbritoAinda não há avaliações

- Transmision FunkDocumento98 páginasTransmision FunkManuel Jesús Zhicay Quillay100% (1)

- Sullair 900 1150 ControllerDocumento52 páginasSullair 900 1150 ControllerRich_78Ainda não há avaliações

- Preventing OOS DeficienciesDocumento65 páginasPreventing OOS Deficienciesnsk79in@gmail.comAinda não há avaliações

- Geh250 2Documento4 páginasGeh250 2Ahmad IrshaidAinda não há avaliações

- Contamination Control ToolsDocumento18 páginasContamination Control ToolsLeo Manaure Rada75% (4)

- MultiHandy 2025 Manual (English)Documento24 páginasMultiHandy 2025 Manual (English)Muhammad Akbar WalennaAinda não há avaliações

- DS450 Shop Manual (Prelim)Documento94 páginasDS450 Shop Manual (Prelim)GuruRacerAinda não há avaliações

- Cat® Bulk Fuel Filtration SystemsDocumento4 páginasCat® Bulk Fuel Filtration Systemsdoncia100% (1)

- Angle Brooms 68iDocumento22 páginasAngle Brooms 68iBart JohnAinda não há avaliações

- Pts 1600 Cud S3at3 AppDocumento128 páginasPts 1600 Cud S3at3 ApptskumarAinda não há avaliações

- Turbina Power BDocumento84 páginasTurbina Power BDaniel zanelattoAinda não há avaliações

- Manual de Partes Reed B50V08 - B50HPv08 - PartsDocumento72 páginasManual de Partes Reed B50V08 - B50HPv08 - PartsNestor Oyaga Barrios0% (1)

- UNIC URW-506 DatasheetDocumento1 páginaUNIC URW-506 DatasheetMário BernardoAinda não há avaliações

- 993k Wheel Loader Before Operation ManualDocumento6 páginas993k Wheel Loader Before Operation ManualGustavo VargasAinda não há avaliações

- Vanair Compressor Maintenance ManualDocumento6 páginasVanair Compressor Maintenance ManualcarlosAinda não há avaliações

- Product Guide TrioDocumento32 páginasProduct Guide Triomarcosandia1974Ainda não há avaliações

- Section 16: Allison CT 700 Series Hydraulic Controls Parts CatalogDocumento4 páginasSection 16: Allison CT 700 Series Hydraulic Controls Parts Catalogamin chaabenAinda não há avaliações

- Pac H64 Fsc03 Skid: Diesel - Qmax 460 M /H (2,030 Usgpm) - Hmax 153 M (502 FT)Documento4 páginasPac H64 Fsc03 Skid: Diesel - Qmax 460 M /H (2,030 Usgpm) - Hmax 153 M (502 FT)xdanielleye_98868485Ainda não há avaliações

- International 4400Documento4 páginasInternational 4400marioAinda não há avaliações

- Catálogo de Peças Plataforma 1200SJP e 1350SJP (Ing)Documento400 páginasCatálogo de Peças Plataforma 1200SJP e 1350SJP (Ing)LuizAinda não há avaliações

- PEHJ015602 Cat Bulk Fuel Filtration Aug 2011Documento4 páginasPEHJ015602 Cat Bulk Fuel Filtration Aug 2011thailanAinda não há avaliações

- Catalogo Alemite PDFDocumento134 páginasCatalogo Alemite PDFRodrigo UlloaAinda não há avaliações

- Example PartsDocumento100 páginasExample Partsmuhammad aliAinda não há avaliações

- Troubleshooting para Mixer PDFDocumento16 páginasTroubleshooting para Mixer PDFMauricio Ariel H. OrellanaAinda não há avaliações

- Feeder: PDF Created With Pdffactory Pro Trial VersionDocumento3 páginasFeeder: PDF Created With Pdffactory Pro Trial VersionАлександрAinda não há avaliações

- Manual de Operación & Mantenimiento EEG 345Documento47 páginasManual de Operación & Mantenimiento EEG 345juan0377Ainda não há avaliações

- Valv. Alivio de Direcc. 416eDocumento4 páginasValv. Alivio de Direcc. 416eJosé GonzalezAinda não há avaliações

- QLT10Documento62 páginasQLT10leosignareAinda não há avaliações

- Catalogo Denison Serie PV PDFDocumento36 páginasCatalogo Denison Serie PV PDFEdison YesidAinda não há avaliações

- HP935, VHP750, MHP825, XHP750, XP1060, XP950, XHP650: Operation and Maintenance ManualDocumento61 páginasHP935, VHP750, MHP825, XHP750, XP1060, XP950, XHP650: Operation and Maintenance ManualAnthony Collucci100% (1)

- G2-7 G7L-15 G15L-22 Brendola Leaflet EN 2935086941Documento5 páginasG2-7 G7L-15 G15L-22 Brendola Leaflet EN 2935086941Владислав СередаAinda não há avaliações

- Master Parts Manual For All Kent Redline Air ToolsDocumento32 páginasMaster Parts Manual For All Kent Redline Air ToolsFernandoAinda não há avaliações

- PM Clinic GD655-5Documento9 páginasPM Clinic GD655-5Naughty VongAinda não há avaliações

- P&H 50t EscaleraDocumento19 páginasP&H 50t EscaleraOmanuel CapraAinda não há avaliações

- SPRAGUE J Pump BrochureDocumento8 páginasSPRAGUE J Pump BrochurechauduonguyenAinda não há avaliações

- MC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsDocumento228 páginasMC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsnAinda não há avaliações

- A-HOAC-MC001-E3 Eaton Aeroquip A-C Refrigeration CatalogDocumento69 páginasA-HOAC-MC001-E3 Eaton Aeroquip A-C Refrigeration Catalogbjave100% (1)

- Manual Instructivo CO 407Documento34 páginasManual Instructivo CO 407Juan RafaelAinda não há avaliações

- Denison-Parker Premier SeriesDocumento40 páginasDenison-Parker Premier SeriesDamAinda não há avaliações

- Demag CC 2800 1Documento64 páginasDemag CC 2800 1Fariz Safarulla100% (1)

- Fastner and Tooling Components. Fertrading Group Venezuela.Documento4 páginasFastner and Tooling Components. Fertrading Group Venezuela.Renso PiovesanAinda não há avaliações

- Hydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFDocumento5 páginasHydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFRomusAinda não há avaliações

- Calibration For 992 PDFDocumento6 páginasCalibration For 992 PDFMohammad MakhloufAinda não há avaliações

- s85 ServicioDocumento349 páginass85 ServicioRay Cepeda Mena100% (1)

- BW1114-B2 Bendix Brake CatalogDocumento116 páginasBW1114-B2 Bendix Brake Cataloggearhead1100% (2)

- ARG250-520automat2017 ENG2 PDFDocumento51 páginasARG250-520automat2017 ENG2 PDFGoran KaramikaAinda não há avaliações

- Original Instructions: 4-Way CassetteDocumento22 páginasOriginal Instructions: 4-Way CassetteJose Cuevas100% (1)

- D45-50KS Maint Manual 732584 & Up (Rev. 7-09)Documento92 páginasD45-50KS Maint Manual 732584 & Up (Rev. 7-09)Putra Dana100% (1)

- National Crane 500c Operators Maintenance Service Manual Parts Catalog SchematicDocumento22 páginasNational Crane 500c Operators Maintenance Service Manual Parts Catalog Schematicnicoleorr110382oka0% (1)

- 631D Trans Shift PointsDocumento20 páginas631D Trans Shift PointsDaveAinda não há avaliações

- Atlas Copco Rental: 100% Oll-Free Air Compressor Diesel DrivenDocumento1 páginaAtlas Copco Rental: 100% Oll-Free Air Compressor Diesel DrivenpowermanagerAinda não há avaliações

- Manual GDocumento84 páginasManual GTri Maizon100% (1)

- SLJ 100-38 - Manual Ame Super LiftDocumento35 páginasSLJ 100-38 - Manual Ame Super LiftAlexander Simanca Candela100% (1)

- PA25 v43 Maintenance ManualDocumento82 páginasPA25 v43 Maintenance ManualAnonymous ZLmk6mPPn50% (2)

- Dl7-Dl9-Dl11-Dl12-Service-Manual (4) - 121-155Documento35 páginasDl7-Dl9-Dl11-Dl12-Service-Manual (4) - 121-155Rafael Francisco Florez PerezAinda não há avaliações

- RCI 510 System SkyAzul Engl.. 3 PDFDocumento2 páginasRCI 510 System SkyAzul Engl.. 3 PDFTom WilberAinda não há avaliações

- 7480J Section A (Mobile)Documento244 páginas7480J Section A (Mobile)Hoang Minh Hung100% (1)

- Can Not Reach Top Engine RPM: Diagnostic CodesDocumento4 páginasCan Not Reach Top Engine RPM: Diagnostic CodesAmir Bambang YudhoyonoAinda não há avaliações

- Power Is Intermittently Low or Power Cutout Is Intermittent 320DDocumento4 páginasPower Is Intermittently Low or Power Cutout Is Intermittent 320DfalahAinda não há avaliações

- Gd825a 2Documento8 páginasGd825a 2Leo Manaure Rada100% (1)

- CPE Cisco LTE Datasheet - c78-732744Documento17 páginasCPE Cisco LTE Datasheet - c78-732744abds7Ainda não há avaliações

- Small Signal Analysis Section 5 6Documento104 páginasSmall Signal Analysis Section 5 6fayazAinda não há avaliações

- Power For All - Myth or RealityDocumento11 páginasPower For All - Myth or RealityAshutosh BhaktaAinda não há avaliações

- ABB Price Book 524Documento1 páginaABB Price Book 524EliasAinda não há avaliações

- 88 - 02 Exhaust Manifold Gasket Service BulletinDocumento3 páginas88 - 02 Exhaust Manifold Gasket Service BulletinGerrit DekkerAinda não há avaliações

- COGELSA Food Industry Catalogue LDDocumento9 páginasCOGELSA Food Industry Catalogue LDandriyanto.wisnuAinda não há avaliações

- Payment of GratuityDocumento5 páginasPayment of Gratuitypawan2225Ainda não há avaliações

- MBA - Updated ADNU GSDocumento2 páginasMBA - Updated ADNU GSPhilip Eusebio BitaoAinda não há avaliações

- PanasonicDocumento35 páginasPanasonicAsif Shaikh0% (1)

- Numerical Transformer Differential RelayDocumento2 páginasNumerical Transformer Differential RelayTariq Mohammed OmarAinda não há avaliações

- SMK Techno ProjectDocumento36 páginasSMK Techno Projectpraburaj619Ainda não há avaliações

- V Series: Three Wheel, Counterbalanced Lift TruckDocumento126 páginasV Series: Three Wheel, Counterbalanced Lift TruckВиктор МушкинAinda não há avaliações

- Copeland PresentationDocumento26 páginasCopeland Presentationjai soniAinda não há avaliações

- Assessment 21GES1475Documento4 páginasAssessment 21GES1475kavindupunsara02Ainda não há avaliações

- August 2015Documento96 páginasAugust 2015Cleaner MagazineAinda não há avaliações

- Product Manual: Panel Mounted ControllerDocumento271 páginasProduct Manual: Panel Mounted ControllerLEONARDO FREITAS COSTAAinda não há avaliações

- Circuitos Digitales III: #IncludeDocumento2 páginasCircuitos Digitales III: #IncludeCristiamAinda não há avaliações

- Marley Product Catalogue Brochure Grease TrapsDocumento1 páginaMarley Product Catalogue Brochure Grease TrapsKushalKallychurnAinda não há avaliações

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaDocumento3 páginasSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesAinda não há avaliações

- E Nose IoTDocumento8 páginasE Nose IoTarun rajaAinda não há avaliações

- Bank Statement SampleDocumento6 páginasBank Statement SampleRovern Keith Oro CuencaAinda não há avaliações

- Ssasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Documento167 páginasSsasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Sunil Singh100% (1)

- Admissibility of Whatsapp Messages in Court For Family MattersDocumento3 páginasAdmissibility of Whatsapp Messages in Court For Family Mattersnajihah adeliAinda não há avaliações

- Is.14785.2000 - Coast Down Test PDFDocumento12 páginasIs.14785.2000 - Coast Down Test PDFVenkata NarayanaAinda não há avaliações

- Gmo EssayDocumento4 páginasGmo Essayapi-270707439Ainda não há avaliações

- Bank of AmericaDocumento1 páginaBank of AmericaBethany MangahasAinda não há avaliações