Escolar Documentos

Profissional Documentos

Cultura Documentos

Analysis of Rates For Estimate of DPR

Enviado por

Anamika SinghTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Analysis of Rates For Estimate of DPR

Enviado por

Anamika SinghDireitos autorais:

Formatos disponíveis

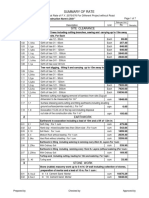

7 Stock Issue Rate of Emulsion Explosive ( unit per kg) Rate i) cost of Emulsion Explosive ( unit per kg)

@ Rs. 67 per No. at Ex store Dehradun 67.00 ii) VAT @ 12.5% 12.50 iii) Carriage from stockyard to project store @ Rs.1059.60/MT for177 km one way by truck of 9 MT capacity assuming @ 1kg each L.S. 1059.60 Sub Total iv) Supervision & storage charges @ 2% of sub total Cost per kg 2.00 Rs./No. 67.00 8.38

1.06 76.43 1.53 77.96 78.00

Say Rs. 8 Stock Issue Rate of Long Delay Detonetor LLD 5 metre ( unit per No.) Rate Rs./No. i) Long Delay Detonetor LLD 5 metre ( unit per No.) @ Rs. 15 per No. at Ex store Dehradun 15.00 15.00 ii) VAT @ 12.5% 12.5 1.88 iii) Carriage from stockyard to project store @ Rs.1059.60/MT for177 km one way by truck of 9 MT capacity assuming @ 1kg each L.S. 1059.6 1.06 Sub Total iv) Supervision & storage charges @ 2% of sub total Cost per No. 2.0 Say Rs. 17.93 0.36 18.29 18.00

/kg

/No.

9 Stock Issue rates of Drill steel for Jack Hammer ( unit Rs. per RM) Average rate of Drill steel rod i Cost of Drill steel rod (2'7") ii Cost of Drill steel rod (2'7") Size 34mm 40mm Total Average Rs. /No. 2565.00 2860.00 5425.00 2712.50 Rate Cost of steel per No. including taxes (Except Sales tax) at Dehradun 2712.50 ii) Add VAT @ 12.50% iii) Total cost iv) Add Transportation & Site handling, freight, insurance, etc. @ 5% Sub Total v) Life of drill steel rod as per CWC guidelines = 130 m a) Rate of drill rod per m b) Sharpening Charges L.S. Rs. 2.00 Total cost per RM 130.00 2.00 24.65 2.00 26.65 i) Rs./No. 2712.50 339.06 3051.56 152.58 3204.14

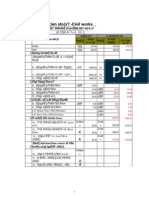

Cost of Materials Analysis of rates of Cartage of materials

Cartage of materials from Dehradun toTiuni (Distance from Dehradun Yard/Store to Tiuni = 177 km) Unit rate Rs./MT (As per item No. 141(b), 148(b) and 143(a)(ii)) S. Rate No. Distance Rs./km Rs./MT 1 2 3 4 5 6 7 8 upto 1 km. Extra for 2 to 3 km @ Rs. 9.50/km Extra for 4 to 5 km @ Rs. 7.0/km Extra for 6 to 10 km @ Rs. 6.3/km Extra for 11 to 20 km @ Rs. 4.80/km Extra for 21 to 30 km @ Rs. 4.0/km Extra for 31 to 50 km @ Rs. 3.40/km Extra for 51 to 177 km @ Rs. 2.7/km 50.00 9.50 7.00 6.30 4.80 4.00 3.40 2.70 Sub total Add contractor's profit @ 5% Sub total 50.00 19.00 14.00 31.50 48.00 40.00 68.00 342.90 613.40 30.67 644.07

13.00

Stacking of cement Head load from 90 m to 300 m @ Rs. 1.10 per qtl/30m chain for an av. distance of 240.00 m Total Rs. 1 Stock Issue rate of OPC 43 Grade Cement ( unit per bag) As per IS 8112 : 1989 Rate i) Cost of OPC 43 grade cement per MT ( 20bags) including tax at Dehradun @ Rs.250 per bag of 50 kg as per item No. 2 of chapter 1 PWD SOR by order dated 05.06.2009. 250.00 ii) Carriage from stockyard to Tiuni Plasu Project investigation worksite @ Rs. 665.87 /MT for177 km one way by truck 9 MT capacity Sub Total iii) Supervision & storage charges @ 2% of Sub Total Total cost per MT Cost of cement Rs. per bag of 50 kg = 5779.19/20 = Say Rs.

8.80

665.87 Per MT

Rs./MT

5000.00

665.87 5665.87 113.3174 5779.19 288.96 288.00 per bag

2 Stone Boulder at site for pillar ( unit per cum) Rate i) Cost of Graded/hand broken split boulder of 100-150 mm size at quarry as per item No. 2(g) of chapter 1 of PWD SOR ii) Add Contractor's profit @ 5% iii) Carraige of boulder an av. distance of 3 km by power transport = 65+10+10 iv) Carraige of boulder an av. distance of 1.00 km from quarry site to work site for foot tracks @ 44.00 per qt/ 0.50 km as per item No. 2(g) of PWD SOR 145 (b) = 0.71/.1 x 1/0.5 x 44 = v) Stacking of boulder Say Rs. 3 Sand at site for pillar ( unit per cum) Cost of coarse sand at quarry as per item No. 38 of chapter 1 of PWD SOR Cost of fine sand at quarry as per item No. 39 of chapter 1 of PWD SOR i) Cost of mixed sand at quarry (450+400)/2= ii) Add Contractor's profit @ iii) Carraige of boulder an av. distance of 3 km by power transport = 65+10+10 iv) Carraige of boulder an av. distance of km from quarry site to work site for foot tracks @ per qt/ km = 0.64/.1 x 1/0.5 x 44 = v) Stacking of sand Rate

Rs./cum

210.00 10.50 85.00

624.80 13.00 943.30 943.00 per cum Rs./cum 450.00 400.00 425.00 22.50 85.00

5%

1.00 44.00 0.50 563.20 13.00 1108.70 1023.50 per cum Rs./kg 5.00

Say Rs. 4 Lime white (unslacked) at site ( unit per kg) Rate i) Cost of Lime white (unslacked) for road as per item No. 18 of chapter 1 of PWD SOR ii) Carraige of boulder an av. distance of 1.00 km from quarry site to work site for foot tracks @ 44.00 per qt/ 0.50 km = 1/100 x 1/0.5 x 44 =

0.88

iii)

Sub Total Supervision & storage charges @ 2% of Sub Total Say Rs.

5.88 0.12 6.00 per kg 34.41 per lit

5 Cost of Diesel oil Rs. Per litre

Rs.

i ii iii iv v vi vii

Brick 333 No./MT Brick aggregate, Kankar, ballast Stone & Stone aggregate, shingle Lime & Shurki 0.85 cum/MT Diesel Oil density 960 kg/cum Sand Unskilled labour wages Semi skilled labour wages Highly skilled labour wages

0.94 cum/MT 0.71 cum/MT 1.0417 Cum/MT 0.64 cum/MT 130 3900 150 4500 220 6600

156 180 264

1.04167

3.2 a) Heavy Duty Jack Hammer 120 cfm Rs. / Hr a) Depreciation Charges i) Cost of Jack Hammer at site including Freight,insurance and all other taxes ii) Life of Jack Hammer in years Life time repair provision Life of Jack Hammer in hours Annual Scheduled Production Hours Depreciation charges in hours Depriciation charges in years Average Yearly Depriciation (in Rs.) Average Hourly Depriciation (in Rs.) b) Interest on capital investment Average annual cost 30000.00 X{(10+1)/(2X10)} Hourly interest-16500.00X12/100/2000 30,000.00 10.00 80.00 10,000.00 3,000.00 8,100.00 2,700.00 5,400.00 1.80

16,500.00 0.66

c) Repair and Maintenance Charges @ 80% of cost of machine/hour d) P.O.L charges compressed air required 120 cfm i) Cost of 120 cfm compressed air ii) Cost of lubricants and oil @ 25% of c(i) above. iii) Sundries and miscellaneous supplies @10% of (b) above iv) Pneumatic Rubber Hose Pipe 38mm dia with fitting 15m @ Rs. 120 per meter Total P.O.L Charges e) Labour Charges Rated yearly Life in hour with 80% efficiency = 0.8 x 3000 Regular 1) Operator -1 No. 2) Supervisor - 1/5 No. 3) Mechanic - 1/8 No. 2,400.00 6,600.00 1,320.00 825.00

2.40

456.00 114.00 0.24 9.00

579.24

Sub - total Casual 4) Helper-1/2 No. 5) Chowkidar 1/8 No. Sub - total Total Direct crew charges / month (in Total crew charges/ year (in Rs.) Hourly Crew charges/ hourly (in Rs.) Hourly Use Rate of Jack Hammer 120 cfm Say Rs.

8,745.00 1,950.00 487.50 2,437.50 11,182.50 134,190.00 55.91 640.01 640.00

Per hour

2.1 Compressed air for 100cfm A) Diesel Air Compressor 400 cfm (Stationary Type) a)Cost of Compressor at site including Freight, insurance and all other i) Depreciation Charges taxes Life in years ii) Life of air compressor in hours Life time repair provision (% of cost of equipment) Annual Scheduled Production Hours - three shifts iii) Depreciation charges w.r.t. life in hours Depreciation with reference to life in years Yearly Average Depriciation (in Rs.) Hourly Average Depriciation (in Rs.) b) Interest on capital investment Average annual cost 785160 X{(10+1)/(2X10)} Hourly interest-43183812/100/2000.00 Repair and Maintenance Charges @ 100% of cost of machine per hour = c) 785160x100/(12000x100) = d) P.O.L charges Rated HP of Machine Actual fuel consumption = 0.22 x 125 x C1 x C2 Type factor C1 = 1.0, Type factor C2 = 1.0 i) Cost of 27.50 ltr diesel @ Rs.34.41/Litre ii) Cost of lubricants and oil @ 25% of c(i) above. iii) Sundries and miscellaneous supplies @10% of (b) above Total P.O.L Charges e) Labour Charges Rated Life in hour/year with 80% efficiency Regular 1)Operator -1 No. 2) Electrician-1/2 No. 3) Foreman - 1/8 No. 4)Mechanic - 1/3 No. Sub - Total

785,160.00 10.00 12,000.00 100.00 3,000.00 176,661.00 70,664.40 123,662.70

431838

125 27.50

946.28 236.57 6.54

2,400.00 4,500.00 3,300.00 825.00 2,200.00 10,825.00

Casual 5)Helper-1 No. 6)Chowkidar 1/4 No. Sub - Total Total Direct crew charges / month (in Rs.) Total crew charges/ year (in Rs.) Hourly Crew charges/hour (in Rs.) Hourly Use Rate of 400 cfm Diesel Compressor Say Compressed air for 100 cfm 1392/4 =

3,900.00 975.00 4,875.00 15,700.00 188,400.00

1,391.81

41.22

17.27

65.43

1,189.39

78.5

1,392.00 348.00

4.3 Rock Excavation in tunnel ( per cum) 1) Labour Charge I) Quantity of excavated per m length of tunnel Finished size of drift Add for pay line ( 5cm ) Excavated size of drift = Cross section Area of tunnel = Add for overbreak @ 10% Quantity of Excavation per m length of tunnel = Progress per face per cycle Quantity of Excavation per cycles = 0.75 m. Quantity of Excavation per cycle per face = ii) Cycle Time Cycle Time Quantity of Excavation per day per face = 3.45 Say Average cycle per day = 3.00 cum III) Direct Labour Charge per day a) Foreman/Explosive inspector/Elecrtrician/explosive chargeman 1.0 No. per day @ Rs. b) Helper to electrician/hole cleaner/wireman for blasting 1 No. per day @ Rs. h) Beldars/Muckers 12.00 Nos. per day @ Rs. i) Muckers 12.00 Nos. @ Rs. 120 / day Total Amont Rs. Rate of Labour per Cum =6204/3 2) Machinery Charges

1.80 x 0.05 1.90 x 10%

2.10 2.20 4.18 4.60 4.60 0.75 3.45

0.75

24.0

hrs

24.0 3.45 3.00 3.00

264.00 180.00 180.00 120.00

264.00 180.00 4320.00 1440.00 6204.00 2068.00

Equipments i) Compressor ii) Jack Hammer Total Machinery Charges per day Rs. Total Machinery Charges per day Rs. 3) Material Charges Rate per cum A) Drilling & Blasting a) It is proposed that to achieve 0.75m progress per cycle1.00 m deep hole will be drilled

Nos. 1 1

Total Working working hour per hours per cycle day 3.0 3.00 3.0 3.00 2964.00 988.00

0.25

1.00

Cross section Area of drift = Assuming average spacing of blast holes = Area of rock cross section per hole = 0.75x0.75 No. of hole required per face 4.6/0.56 Additional hole for line drilling/ burn hole @5% Total hole Total depth of drilling =9 x 1 Rate of drill steel for jack hammer = Cost of drill steel =9x26.65 Quantity of Excavation per cycles = Cost of Drill steel per cum =239.83/3.45 b) Explosive i) Gelatine explosive Required per cum = 1 kg Cost of gelatine per kg Rate per cum ii) No. of detonator required Rate of detonator Cost of detonator & fuse coil = Quantity of Excavation per cycles = Rate per cum iii) Other consumable petty stores such as ablating bateries,galvanometers and blasting wires,etc. @ 50% of ( i ) Total Explosive charges per cum (i) + ( ii ) + (iii) = Total Drilling & Blasting cost (a)+(b) B) Provisions for pipe lines for air and water for wet drilling C) Timber for supports & packing L.S. D) Miscellaneous Supplies such as safety hats, gumboots, rain coats, wire ropes, manila ropes, vclamps, rubber gloves, shankles and artificial respirators, etc. Total material Charges (A)+(B)+(C )+(D) 4) Shop chrges ( i ) Machine Shop L.S. (ii ) Structural Shop L.S. (iii) Steel Metal Shop L.S ( iv ) Carpentary L.S Total Shop Charges per cum 6)Electrical material charges per cum L.S 7) Water charges per cum L.S

4.60 0.75 0.56 8.17 0.41 9.00 9.00 26.65 Rs. 239.83 3.45 69.54

m2 m c/c m2 Nos. Nos. Nos. m Rs./RM m3

Rs. Rs. Rs. Rs. Rs.

1.00 kg 78.00 78.00 9 Nos. 18.00 No. 162.00 3.45 46.98 m3

Rs. 39.00 Rs. 163.98 Rs. 233.52 Rs. Rs. 5.00 5.00

Rs. 10.00 Rs. 253.52 Rs. Rs. Rs. Rs. Rs. Rs. Rs. 10.00 10.00 5.00 5.00 30.00 10.00 5.00

8) Compressed air charges per cum L.S ABSTRACT OF CHARGES PER CUM 1) Direct labour Charges 2) Machinery charges 3) Material charges 5) Shop Charges 6) Electrical material charges 8) Water charges 9) Compressed air charges Total Add for electric energy @ 2% of total charges Add for construction of haulage road @ 5% of total charges Prime Cost Add for overhead charges and contractor's profit @ 10% of prime cost Total Hence, rate of construction of 1.80 m x 2.10 m size drift per RM including cost of all materials, labour, T&P required for completion of work = 3585.36 x 3.45 Say

Rs.

10.00

Rs. Rs. Rs. Rs. Rs. Rs. Rs. Rs. 2 5

2068.00 988.00 253.52 30.00 10.00 5.00 10.00 3364.52 67.29 168.23 3600.04 360.00 3960.04

10 Rs.

Rs. 13656.21 RM Rs. 13656.00 RM

m m sqm sqm sqm m cum hrs cum cum cum

Hourly Amount use rate in Rs. 348.00 1044.00 640.00 1920.00 2964.00

Name of work - Estimates for preparation of Detailed Project Report (DPR) of Tiuni-Plasu Hydroectric Project (3x24 = 72 MW) on River Tons , at Tiuni, Dehradun Analysis of Rates 3 Construction of investigation pits including costs of all materials, labour, T&P, etc. complete for the completion of work i) Earthwork in cutting or in embankment in ordinary soil excavation to be in the form of regular pits no exceeding 0.5m in depth and also including 1.5m lift and 30 m lead including costs of all materials, labour, T&P, etc. complete as per item no. 151 of chapter 4 of PWD SOR ii) excavation in soil mixed with earth mixed with boulders required the special T&P such as pick axes, sabbals, etc.as per item no. 152 & 157 of chapter 4 of PWD iii) Add forconstruction of 3m deep pits for every additional lift of 1.5 m of part thereof @ Rs. 600/lift as per item no. 160 of chapter 4 of PWD SOR Total Construction of investigation pits includingcosts of all materials, labour, T&P, etc. complete for the completion of work 4 Construction 0.75m in R.R. 1:6 CM of size 0.6m x 0.6 x of Demarkation Pillar including 12.5 mm cement plaster in 1:6 CM & 3 coats white washing including costs of all materials, labour, T&P, etc. complete required for the completion of work. i Cost of R.R. Pillar in 1:6 CM Material & Labour required as per item no. 209 & 211 of PWD prepared for Almora district. Material required Cement =

3600

per %cum

4000.00

per %cum

1200.00 8800.00

per %cum per %cum

88.00

per cum

per %cft 5.6 bag

per cum 1.98 bag

Stone boulder = Sand = Labour required per %cft Mason per day Beldar per day Coolie per day Bishti per day Cost of construction of R.R. Pillar Cost of Materials Cement @ Rs. 288 per bag = Stone boulder @ 943 per cum = Sand @ Rs.1023.5 per cum= Labour wages

100 cft 42 cft 4 3 2 0.25 Nos. Nos. Nos. Nos.

1.00 cum 0.42 cum

Sub Total A= per day = per day = per day = per day = Sub Total B= Add Contractor's Profit @ 10% Sub Total C= Add Sundries, T&P, water charges, etc. L.S. Total Total Cost of construction of R.R. Pillar per cum Say ii Cost of 12.5 mm thick cement plaster 1:6 CM Material & Labour required as per item no. 364 & 367 of PWD prepared for Almora district. Material required per %sft Cement = 0.72 bag Sand = 5.4 cft Labour required per %sft Mason per day 1.33 Nos. Beldar per day 0.5 Nos. Coolie per day 1.33 Nos. Bishti per day 0.5 Nos. Cost of construction of R.R. Pillar Cost of Materials Cement @ Rs. 288 per bag = Sand @ Rs.1023.5 per cum= Mason Beldar Coolie Bishti @ Rs. @ Rs. @ Rs. @ Rs. 220 130 130 130

569.89 943.00 429.87 1942.76 880.00 390.00 260.00 32.50 1562.50 156.25 1718.75 20.00 1738.75 614.40

per cum per cum per cum per cum per %cft per %cft per %cft per %cft per %cft per %cft per %cft per %cft per cum

2557.16 per cum 2557.00 per cum

per sq.m 0.25 bag 0.054 cum

73.27 per sq. m 55.27 per sq. m

Sub Total A= Labour wages per day = per day = per day = per day = Sub Total B= Add Contractor's Profit @ 10% Sub Total C= Add Sundries, T&P, water charges, etc. L.S. Total Total Cost of construction of R.R. Pillar per cum Say ii Cost of 3 coats white washing Material & Labour required as per item no. 431, 432 & 433 of PWD prepared for Almora district. Material required for first coat Lime = Labour required per %sft White washer per day Helper per day Cost of first coat white washing Cost of Lime = Labour wages per day = per day = Sub Total B= Add Contractor's Profit @ 10% Sub Total C= Add Sundries, T&P, water charges, etc. L.S. Total Total Cost of two coats Material required for two coats per %sft Lime = 4 lb Labour required per %sft White washer per day 0.10 Nos. Helper per day 0.10 Nos. Cost of first coat white washing White washer @ Rs. 150 Helper @ Rs. 130 Mason Beldar Coolie Bishti @ Rs. @ Rs. @ Rs. @ Rs. 220 130 130 130

128.54 per sq. m 292.60 65.00 172.90 65.00 595.50 59.55 655.05 20.00 675.05 72.66 per %sft per %sft per %sft per %sft per %sft per %sft per %sft per %sft per sqm

201.21 per sqm 201.00 per sqm

per %sft 2 lb 0.067 Nos. 0.067 Nos.

per sq.m 0.10 kg

Sub Total A=

0.58 per sq. m 0.58 per sq. m 10.00 per %sft 8.67 per %sft 18.67 per %sft 1.87 per %sft 20.53 5.00 per %sft 25.53 per %sft 2.75 per sqm 3.33 per sqm per sq.m 0.20 kg

Cost of Lime = Sub Total A= Labour wages per day = per day = Sub Total B= Add Contractor's Profit @ 10% Sub Total C= Add Sundries, T&P, water charges, etc. L.S. Total Total Cost of white washing of two coats Cost of three coats = Cost of white washing of two coats + difference in cost of one additional coat = 5.56 + (5.56 - 3.33) = Hence, Cost of construction of Demarkation Pillar of size 0.6m x 0.6 x 0.75m in R.R. 1:6 CM including 12.5 mm cement plaster in 1:6 CM & 3 coats white washing including costs of all materials, labour, T&P, etc. complete required for the completion of work = cost of 0.6m x 0.6m x 0.75m R.R. masonry work in 1:6 CM + 5 x(0.6m x 0.6m) sq.m 12.5 mm thick cement plaster in 1:6 CM + 5 x(0.6m x 0.6m) sq.m 3 coats white washing = Say Rs. White washer @ Rs. 150 Helper @ Rs. 130

1.17 per sq. m 1.17 per sq. m 15.00 13.00 28.00 2.80 30.80 10.00 40.80 4.39 5.56 per %sft per %sft per %sft per %sft per %sft per %sft per sqm per sqm

7.79 per sqm

1066.21 per pillar 1066.00 per pillar

5 Jungle clearnce before construction of approach path including costs of all materials, labour, T&P, etc. complete for the completion of work

Rate for jungle clearance work is neither incorporated in PWR SOR nor skeleton for the same work is mentioned in PWD Skeleton. Besides above labour constants/output of labourer for jungle clearance work is not given in the books "Estimating and Costing in Civil Engineering" written by B.N. Dutta, "Civil Engineering Estimating & Costing" written by V.N. Vazirani & S,C. Chandola and "Indian Practical Civil Engineers' Hanbook" written by P.N. Khanna. However, labour constant for 'clear site of all rubbish, cut down shrubs, undergroth and small trees not exceeding 600 mm girth, grub up roots and burn or remove from site' is recommended as 0.05 per sqm in a day on serial no. 30 of the table given under chapter 'Labour Output Constants for Building Work' of the book "Practical Information for Qauntity Surveyors" written by P.T. Jogelkar. Hence, Output of Mazdoor/beldar for the above work = 1/0.05 = 20 sq m per day. Alongwith above a specific rate for jungle clearance is given in ID SOR as Rs. 57 per %sqm. Output of labourer for the above work on the basis of ID SOR, assuming 10% contractor's profit & 1% for Sundries, T&P, etc.and prevailing labour rate as Rs.84 per manday =84/1.111 x100/57 = 132.6 sqm/day On the basis of above facts and past experience & practically feasible conditions, the output of a labourer for jungle clearance work is adopted as 125 sqm per day. Hence, rate for Jungle clearance including costs of all materials, labour, T&P, etc. complete for the completion of work = 125/130 Add sundries, T&P,etc. @ 1% Total Add contractor's profit @ 10%

0.962 0.010 0.971 0.097 1.068

per sqm per sqm per sqm per sqm per sqm

Say Rs. 6 Earth work in hill slope cutting for making approach path including costs of all materials. Labour, T&P, etc. required for completion of work i) Earthwork in hill side cutting in ordinary soil excavation to be in the form of regular pits no exceeding 0.5m in depth and also including 1.5m lift and 30 m lead including costs of all materials, labour, T&P, etc. complete as per item no. 151 of chapter 4 of PWD SOR ii) excavation in soil mixed with earth mixed with boulders required the special T&P such as pick axes, sabbals, etc.as per item no. 152 & 157 of chapter 4 of PWD SOR Total = = 7 Construction of 1.0 m wide approach path for survey & other investigations including cost of all materials, labour, T&P etc. complete for completion of work. hill slope up to a width i) Jungle clearance of of m before excavation of path @ 1.05 /sqm per km = 1000x3x1.05

1.05 per sqm

3600.00 per %cum

4000.00 per %cum 7600.00 per %cum 76.00 per cum

3.0 Rs. 3150.00 per km

Hill Profile 0.8391 m 400 Generally, hill slope of the Himalayan mountain in the project area ranges from 250 to 850. So, we adopt an average hill slope of 400 for hill side cutting to make path i.e. Quantity of earth work in hill slope cutting to make 1.0 m wide path per running metre= 1/2x1x tan 400 = 1.0 m

0.420 cum/RM

Total Quantity in 1.0 km Deduct the quantity of E/W in undulation of hill slope, nallah/filling portions @ 25% Net quantity of E/W to be excavated = Cost of E/W in hill side cutting = 216.38x76 Hence, Cost of construction of 1.0 m wide approach path for survey & other investigations including cost of all materials, labour, T&P etc. complete for completion of work = 3150+23914.35 =

419.55 cum/km 104.89 cum/km 314.66 cum/km Rs. 23914.35 per km

Rs. 27064.35 per km

7 Construction of 2.0 m wide approach path for survey & other investigations including cost of all materials, labour, T&P etc. complete for completion of work. hill slope up to a width i) Jungle clearance of of m before excavation of path @ 1.05 /sqm per km = 1000x5x1.05

4.0 Rs. 4200.00 per km

Hill Profile 1.2586 m 400 Generally, hill slope of the Himalayan mountain in the project area ranges from 250 to 850. So, we adopt an average hill slope of 400 for 1.5 m hill side cutting and 0.50 m in filling to make path i.e. Quantity of earth work in hill slope cutting to make 1.0 m wide path per running metre= 1/2 x 1.50 x 1.50 x tan 400 = Total Quantity in 1.0 km Deduct the quantity of E/W in undulation of hill slope, nallah/filling portions @ 25% Net quantity of E/W to be excavated = Cost of E/W in hill side cutting = 486.841x76 Hence, Cost of construction of 2.0 m wide approach path for survey & other investigations including cost of all materials, labour, T&P etc. complete for completion of work = 4200+37000.13 = 1.50 m

0.944 cum/RM 943.95 cum/km 235.99 cum/km 707.96 cum/km Rs. 53805.15 per km

Rs. 58005.15 per km Say Rs. 58005.00 per km

7 Construction of 2.5 m wide machine path for survey & other investigations including cost of all materials, labour, T&P etc. complete for completion of work. hill slope up to a width a) Jungle clearance of of m before excavation of path @ 1.05 /sqm per km = 1000x5x1.05

5.0 Rs. 5250.00 per km

Hill Profile 1.6782 m 400 b) Generally, hill slope of the Himalayan mountain in the project area ranges from 250 to 850. So, we adopt an average hill slope of 300 for 2.0 m hill side cutting and 0.50 m in filling to make path i.e. Quantity of earth work in hill slope cutting to make 1.0 m wide path per running metre= 1/2 x 2 x 2x tan 400 = Total Quantity in 1.0 km Deduct the quantity of E/W in undulation of hill slope, nallah/filling portions @ 20% Net quantity of E/W to be excavated = Cost of E/W in hill side cutting = 1582.56x76 Rs. c) Filling, compaction, ramming, etc of Earth and stone in rest 0.5 m filling portion of road in valley side assuming same hill slope of 400 per km = 1/2 x 0.5 x 0.5 x tan 400 = Labour required for %cft as per item no. 161 of PWD skeleton prepared for Almora district Beldar 2.50 Nos. @ 130 per day Coolie 2.5 Nos. @ 130 per day Bhisti 1 no. @ 130 per day Sub Total Add contractor's profit @ 10% 2.00 m

1.978 cum/RM 1978.20 cum/km 395.64 cum/km 1582.56 cum/km 120274.56 per km

104.88 cum

325.00 325.00 130.00 780.00 78.00

Total Hence, cost of earth & stone filling, compaction,ramming, etc. in valley side in 0.5 m portion including cost of all maerials, labour, T&P, etc. complete = 104.88 x 303.18 c) Dressing of kutcha road including filling of ruts khud and cutting where necessary to proper shape including disposal of surplus earth as directed by Engineer-in-charge as per item No. 533 (b)stone masonry in pusta wall in an d) Dry of PWD SOR for LV roads average length of path = 150 x [(0.75+.045)/2]x 1.25 i.e. Quantity of R. R. dry masonry per km = i) Cost of Graded/hand broken river boulder size more than 150 mm at quarry as per item No. 2(h) of chapter 1 of PWD SOR ii) Add Contractor's profit @ iii) Carraige of boulder an av. distance of 3.0 km by power transport = 65+10+10 Carraige of boulder from road head to worksite by mule @ Rs. per qt/ up to 0.5 km for an average distance of 1 km as per item No. 144of PWD SOR = [0.71/.1 x 0.5/0.5 x 10] + [0.71/.1 x 0.5/0.5 x 5] = iv) Stacking of boulder Rate of R.R. dry stone masonry in pusta/retaining wall /breast wall as per item no. 518(a) of PWD SOR = 435.50+220 = Cost of R.R. dry stone masonry in pusta/retaining wall /breast wall = 655.50 x 150.00 = e) Dry boulder hand packed pusta in 10% length Quantity of R. R. dry masonry per km = 100x1.25x0.75/2 Hence cost of Dry boulder hand packed pusta in 10% length = 46.88 x 303.18 = Hence, Cost of construction of 2.0 m wide

858.00 per %cft 303.18 per cum

31796.02 per km

Rs. 15%

3500.00 per km 112.50 cum

5%

220.00 11.00 85.00

10.00 0.50

106.50 13.00 435.50

655.50

73743.75 per km

46.88 cum 14211.57

approach path for survey & other investigations including cost of all materials, labour, T&P etc. complete for completion of work = 5250+37000.13 =

Rs. Say Rs.

248775.91 per km 248776.00 per km

71493.75

Você também pode gostar

- 3rd Running Bil 353 NH (Act)Documento4 páginas3rd Running Bil 353 NH (Act)mad21_Ainda não há avaliações

- Engineering AppreciationDocumento96 páginasEngineering AppreciationkrishbistAinda não há avaliações

- Tack Coat 23 March 18Documento2 páginasTack Coat 23 March 18Anamika SinghAinda não há avaliações

- Arunachal Pradesh Analysis of Rates For Road and Bridge Works 2010Documento232 páginasArunachal Pradesh Analysis of Rates For Road and Bridge Works 2010Harish Kumar MahavarAinda não há avaliações

- Data Rates-Canal Works Part 1Documento20 páginasData Rates-Canal Works Part 1vpmohammedAinda não há avaliações

- TUNNEL CONCRETING RATE ANALYSISDocumento21 páginasTUNNEL CONCRETING RATE ANALYSISvpmohammedAinda não há avaliações

- Rate AnalysisDocumento15 páginasRate AnalysisBhagirath Bishnoi100% (1)

- Sample rate analysis for resin grouted rock boltDocumento1 páginaSample rate analysis for resin grouted rock boltkuldip_1973Ainda não há avaliações

- MCC DSR Rate AnalysisDocumento280 páginasMCC DSR Rate AnalysisAbhijeet VardheAinda não há avaliações

- DAM ALLIED WORKS CONCRETE RATEDocumento21 páginasDAM ALLIED WORKS CONCRETE RATEvpmohammedAinda não há avaliações

- Rate AnalysisDocumento5 páginasRate AnalysismustafaAinda não há avaliações

- Question Calculate Rate Analysis For Size Stone Masonry (SSM) in CM 1:6 in Foundation SolDocumento1 páginaQuestion Calculate Rate Analysis For Size Stone Masonry (SSM) in CM 1:6 in Foundation SolAnusha ChikmathAinda não há avaliações

- Basics of Quantity Surveying: Business DiagnosticsDocumento25 páginasBasics of Quantity Surveying: Business DiagnosticsJay Badiyani100% (1)

- Data Rates-Dam Works-Part 8Documento21 páginasData Rates-Dam Works-Part 8vpmohammedAinda não há avaliações

- 20mm Bitumen Carpet Road ConstructionDocumento167 páginas20mm Bitumen Carpet Road ConstructionrkpragadeeshAinda não há avaliações

- Cold mix vs hot mix cost comparisonDocumento8 páginasCold mix vs hot mix cost comparisonChManikumarAinda não há avaliações

- Sanitary Rate 075 - 76 Siraha FinalDocumento122 páginasSanitary Rate 075 - 76 Siraha FinalSirhali BuildersAinda não há avaliações

- Ganga Nagar Lab BuildingDocumento19 páginasGanga Nagar Lab BuildingAyush TiwariAinda não há avaliações

- RCC SLAB 11-12 Rate AnalysisDocumento2 páginasRCC SLAB 11-12 Rate AnalysisRiazahemad B Jagadal0% (1)

- Cost Analysis For Brick WorkDocumento14 páginasCost Analysis For Brick WorkVittal Kumar50% (2)

- Schedule-of-rates-MI 2014-15Documento151 páginasSchedule-of-rates-MI 2014-15Vinisha RaoAinda não há avaliações

- 20KL SUMP TITLEDocumento3 páginas20KL SUMP TITLEvisali garikapatiAinda não há avaliações

- Analysis of Item Rates: Norms 2041Documento11 páginasAnalysis of Item Rates: Norms 2041Saurav LamichhaneAinda não há avaliações

- Triangle Construction 4th R.A. Bill For Township IIDocumento81 páginasTriangle Construction 4th R.A. Bill For Township IItriangle269Ainda não há avaliações

- EstimateDocumento14 páginasEstimateAnonymous fQLEF2tQpqAinda não há avaliações

- Toilet EstimateDocumento74 páginasToilet Estimatedee balkondaAinda não há avaliações

- Public Health Data 2010-11Documento40 páginasPublic Health Data 2010-11msr1471Ainda não há avaliações

- Civil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFDocumento6 páginasCivil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFArjun S SanakanAinda não há avaliações

- Civil Rate Analysis 069-70 Kathmandu - FinalDocumento234 páginasCivil Rate Analysis 069-70 Kathmandu - FinalBinaya Shahi50% (2)

- SOR RURAL 17-18 PWRD Assam 18-01-2018Documento1.351 páginasSOR RURAL 17-18 PWRD Assam 18-01-2018Monjit Gogoi100% (2)

- Rate Analysis 15-09 Final Road LATESTDocumento18 páginasRate Analysis 15-09 Final Road LATESTKotoju Rajitha SaisindhujaAinda não há avaliações

- Rate Analysis (2016) - Cpwd-Part1Documento4.174 páginasRate Analysis (2016) - Cpwd-Part1dreamspacearchitects100% (1)

- Pakistan Public Works Mortar RatesDocumento378 páginasPakistan Public Works Mortar RatesShehzad ShahAinda não há avaliações

- Estimate of RoadDocumento17 páginasEstimate of RoadshambhuAinda não há avaliações

- Rate Analysis For ShutteringDocumento2 páginasRate Analysis For ShutteringNitin SharmaAinda não há avaliações

- Rate AnalysisDocumento4 páginasRate AnalysisTabrez AhmedAinda não há avaliações

- Rate Analysis-NormsDocumento7 páginasRate Analysis-NormsGajendra Joshi0% (1)

- Rate Analysis For 1CUM ConcreteDocumento7 páginasRate Analysis For 1CUM ConcreteHitesh JaniAinda não há avaliações

- Ready reckoner guide for quantity surveyorsDocumento105 páginasReady reckoner guide for quantity surveyorsanaszkAinda não há avaliações

- Standard PCC DrainDocumento2 páginasStandard PCC Drainrajinder kutaalAinda não há avaliações

- Rate Analysis of Materials Used in PCC and Plum ConcreteDocumento7 páginasRate Analysis of Materials Used in PCC and Plum ConcreteSeema DubeyAinda não há avaliações

- Rate Analysis - Khulna - Barisal - GopalganjDocumento280 páginasRate Analysis - Khulna - Barisal - Gopalganjmd mohiuddinAinda não há avaliações

- BSR 2020 (With Vat)Documento81 páginasBSR 2020 (With Vat)Lalith Rohana100% (1)

- Swimming Pool Price BidDocumento48 páginasSwimming Pool Price Bidindian royalAinda não há avaliações

- RA BILL 9 For BD ROAD After Adding All BillDocumento20 páginasRA BILL 9 For BD ROAD After Adding All BillnandiniAinda não há avaliações

- Rate AnalysisDocumento18 páginasRate AnalysisSyed ZamanAinda não há avaliações

- Maharashtra Jeevan Pradhikaran Rate Analysis 2012 2013Documento177 páginasMaharashtra Jeevan Pradhikaran Rate Analysis 2012 2013ulhas_nakasheAinda não há avaliações

- A-Complete Building-Estimation-Sample by WWWDocumento66 páginasA-Complete Building-Estimation-Sample by WWWapi-234133280100% (1)

- Analysis of RateDocumento45 páginasAnalysis of RateDigvijay SinghAinda não há avaliações

- Bill of QuantityDocumento14 páginasBill of QuantityAshok KcAinda não há avaliações

- DSR Analizer Ver.12Documento368 páginasDSR Analizer Ver.12sunil777tvpm100% (3)

- Grade - 10 Civil Engineering - Estimating Costing and SupervisionDocumento49 páginasGrade - 10 Civil Engineering - Estimating Costing and SupervisionBhuwan BhusalAinda não há avaliações

- Cost Analysis For Bridge and CulvertsDocumento14 páginasCost Analysis For Bridge and CulvertsjnshreyAinda não há avaliações

- Rate Analsis Chapter No 25 Iron WorkDocumento76 páginasRate Analsis Chapter No 25 Iron WorkSarin100% (1)

- Anganwaadi Model Building EstimateDocumento860 páginasAnganwaadi Model Building EstimateRajendra Prasad GubbalaAinda não há avaliações

- Government road project cost estimateDocumento8 páginasGovernment road project cost estimatenitish JhaAinda não há avaliações

- MCGM BLDG Sor 13.11Documento210 páginasMCGM BLDG Sor 13.11Shashi VaishAinda não há avaliações

- Sump Estimate APRSCL 15-4-2011Documento102 páginasSump Estimate APRSCL 15-4-2011pandu123456Ainda não há avaliações

- Analysis of RateDocumento6 páginasAnalysis of Ratehs_civilAinda não há avaliações

- Basic Data Kar Part 2Documento21 páginasBasic Data Kar Part 2vpmohammedAinda não há avaliações

- Rate AnalysisDocumento14 páginasRate AnalysispsycinAinda não há avaliações

- Letter No 913 15-07-2016 Standing CommitteeDocumento4 páginasLetter No 913 15-07-2016 Standing CommitteeAnamika SinghAinda não há avaliações

- Price Variation Clause DT 15-6-2016Documento1 páginaPrice Variation Clause DT 15-6-2016Anamika SinghAinda não há avaliações

- Modern Baby NamesDocumento1 páginaModern Baby NamesAnamika SinghAinda não há avaliações

- PIU Dehradun - Forest Report FormA - 04!10!2017Documento1 páginaPIU Dehradun - Forest Report FormA - 04!10!2017Anamika SinghAinda não há avaliações

- Civil Service RegulationDocumento147 páginasCivil Service RegulationAnamika SinghAinda não há avaliações

- Hindi Names - BabynamesDocumento1 páginaHindi Names - BabynamesAnamika SinghAinda não há avaliações

- Principle 1: Win People To Your Way of ThinkingDocumento2 páginasPrinciple 1: Win People To Your Way of ThinkingAnamika SinghAinda não há avaliações

- New Ip Url of Pwims (Sor) Software - Sor - UrlDocumento2 páginasNew Ip Url of Pwims (Sor) Software - Sor - UrlAnamika SinghAinda não há avaliações

- IRC GuidelinesDocumento48 páginasIRC GuidelinesAnamika SinghAinda não há avaliações

- Hydrology Bowla Nand PrayagDocumento81 páginasHydrology Bowla Nand PrayagAnamika SinghAinda não há avaliações

- Pmgsy R. June2013Documento52 páginasPmgsy R. June2013Anamika SinghAinda não há avaliações

- Swadeshi Chikitsya Part 1Documento107 páginasSwadeshi Chikitsya Part 1rajivdixitmp3.com96% (28)

- Govlawircy1984sp11 0 PDFDocumento144 páginasGovlawircy1984sp11 0 PDFAmeen SyedAinda não há avaliações

- Hydraulic Design of Headrace and Tailrace Channel For ADocumento10 páginasHydraulic Design of Headrace and Tailrace Channel For AVineet Chaudhary0% (1)

- Analysis of Rates For Rural RoadsDocumento2 páginasAnalysis of Rates For Rural RoadsAnamika SinghAinda não há avaliações

- Ijetae 0413 1Documento6 páginasIjetae 0413 1Tameka BennettAinda não há avaliações

- Analysis of Rates For Rural RoadsDocumento2 páginasAnalysis of Rates For Rural RoadsAnamika SinghAinda não há avaliações

- Pmgsy R. June2013Documento52 páginasPmgsy R. June2013Anamika SinghAinda não há avaliações

- Analysis of Rates For Rural RoadsDocumento2 páginasAnalysis of Rates For Rural RoadsAnamika SinghAinda não há avaliações

- Ijetae 0413 1Documento6 páginasIjetae 0413 1Tameka BennettAinda não há avaliações

- PCI - Operations Manual For Roads - NRRDADocumento5 páginasPCI - Operations Manual For Roads - NRRDAAnamika SinghAinda não há avaliações

- Ijetae 0413 1Documento6 páginasIjetae 0413 1Tameka BennettAinda não há avaliações

- Irc SP 62 2014 PDFDocumento64 páginasIrc SP 62 2014 PDFviharikapavuluri1290Ainda não há avaliações

- Pmgsy R. June2013Documento52 páginasPmgsy R. June2013Anamika SinghAinda não há avaliações

- PCI - Operations Manual For Roads - NRRDADocumento5 páginasPCI - Operations Manual For Roads - NRRDAAnamika SinghAinda não há avaliações

- Section 3.4 The Conditional and Related StatementsDocumento11 páginasSection 3.4 The Conditional and Related Statementsmister sparklesAinda não há avaliações

- Journal of Travel & Tourism MarketingDocumento19 páginasJournal of Travel & Tourism MarketingSilky GaurAinda não há avaliações

- Methanol Technical Data Sheet FactsDocumento1 páginaMethanol Technical Data Sheet FactsmkgmotleyAinda não há avaliações

- 102DNDocumento2 páginas102DNManuel ZavalaAinda não há avaliações

- ManupptDocumento65 páginasManupptKrishanarju VenkatesanAinda não há avaliações

- 2022 Anambra State ITN Mass Campaign Report in Nnewi North LGA by Idongesit EtukudoDocumento15 páginas2022 Anambra State ITN Mass Campaign Report in Nnewi North LGA by Idongesit EtukudoIdongesit EtukudoAinda não há avaliações

- Mineral Processing Course: ThickeningDocumento50 páginasMineral Processing Course: ThickeningAdham Elbrawy100% (1)

- Grupo Stoncor Description - Stonhard Carboline Fibergrate PDFDocumento22 páginasGrupo Stoncor Description - Stonhard Carboline Fibergrate PDFAndres OsorioAinda não há avaliações

- Formulating and Solving LPs Using Excel SolverDocumento8 páginasFormulating and Solving LPs Using Excel SolverAaron MartinAinda não há avaliações

- CA Ashish Dewani - Resume-1Documento2 páginasCA Ashish Dewani - Resume-1Payal JainAinda não há avaliações

- Delhi University SEC Exam Date Sheet March 2023Documento2 páginasDelhi University SEC Exam Date Sheet March 2023aamir9ali-42Ainda não há avaliações

- Evolution of The Fire SprinklerDocumento11 páginasEvolution of The Fire SprinklerPedro DudesonAinda não há avaliações

- Risk and Risk ManagementDocumento8 páginasRisk and Risk ManagementMARY JUSTINE PAQUIBOTAinda não há avaliações

- Test 420001 PDFDocumento13 páginasTest 420001 PDFmaria100% (1)

- Check For Palindrome: Compute GCD and LCMDocumento3 páginasCheck For Palindrome: Compute GCD and LCMAadhi JAinda não há avaliações

- Proposal BP3IP FinalDocumento3 páginasProposal BP3IP FinalGiant SeptiantoAinda não há avaliações

- ETEC 520 - Assignment 2 Group ProjectDocumento19 páginasETEC 520 - Assignment 2 Group ProjectjennbosAinda não há avaliações

- Ayurveda Signs of LifeDocumento15 páginasAyurveda Signs of LifeSanjeethAinda não há avaliações

- Mental AspectDocumento29 páginasMental AspectBenjii CarlosAinda não há avaliações

- GbiDocumento14 páginasGbimaurice86Ainda não há avaliações

- 1 Clock Domain CrossingDocumento35 páginas1 Clock Domain CrossingRamakrishnaRao SoogooriAinda não há avaliações

- Mascot LD series hydraulic motor specsDocumento6 páginasMascot LD series hydraulic motor specsM S GokulAinda não há avaliações

- The historical evolution of organizational behavior and how it shaped modern managementDocumento3 páginasThe historical evolution of organizational behavior and how it shaped modern managementSaravanan Swagger100% (1)

- Gmail LogoDocumento12 páginasGmail Logovinodram993480Ainda não há avaliações

- Global Financial Reporting Convergence: A Study of The Adoption of International Financial Reporting Standards by The Swedish Accountancy ProfessionDocumento21 páginasGlobal Financial Reporting Convergence: A Study of The Adoption of International Financial Reporting Standards by The Swedish Accountancy Professionihda0farhatun0nisakAinda não há avaliações

- Advances in X-Ray Analysis - Volume 33 - 1989Documento685 páginasAdvances in X-Ray Analysis - Volume 33 - 1989CVAinda não há avaliações

- A Comparative Study of Different Image Denoising Methods: Afreen Mulla, A.G.Patil, Sneha Pethkar, Nishigandha DeshmukhDocumento6 páginasA Comparative Study of Different Image Denoising Methods: Afreen Mulla, A.G.Patil, Sneha Pethkar, Nishigandha DeshmukherpublicationAinda não há avaliações

- 2023 Grades 10-12 Mathematics ATP MediationDocumento14 páginas2023 Grades 10-12 Mathematics ATP Mediationkaybeach007Ainda não há avaliações

- Soft Computing Techniques Assignment1 PDFDocumento14 páginasSoft Computing Techniques Assignment1 PDFshadan alamAinda não há avaliações