Escolar Documentos

Profissional Documentos

Cultura Documentos

Information Models and Functions For CIM in Shipbuilding

Enviado por

Jhony BlackDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Information Models and Functions For CIM in Shipbuilding

Enviado por

Jhony BlackDireitos autorais:

Formatos disponíveis

J Mar Sci Technol (1997) 2:148-162

Journal of

Marine Science and Technology

9 SNAJ 1997

Information models and functions for CIM in shipbuilding

KAZUHIRO AOYAMA a n d TOSHIHARU NOMOTO Department of Naval Architecture and Ocean Engineering, Faculty of Engineering, University of Tokyo, 7-3-1 Hongo, Bunkyo-ku, Tokyo 113, Japan

Abstract: In order to make significant progress in design and

manufacturing systems, all industries must consider integration. This paper considers information models and functions for a computer integrated design and manufacturing system in shipbuilding. The authors propose the product model and several alterative functions for designing a ship's structure, and develop a "ship definition system for computer integrated design and manufacturing." This system is called SODAS (System of Design and Assembly for Shipbuilding). An object-oriented concept is used to develop this system. In order to define a ship's structure, the authors propose the product models of "parts member" and "parts connection," and the product models of "Room," "Unit," and "Module" are introduced to define the compartments, internal structures and intermediate products of a ship. Therefore, all information about a product from the design to the production stage is stored in the product model. As well as the product model, the "design function," "cutting function," and "virtual assembling function'are introduced. By using the design function, any type of ship's structure can be designed, and by using the cutting function, the design of a ship's structure can be cut into smaller elements. By using the virtual assembling function, a simulation of the manufacture of a ship's structure can be carried out.

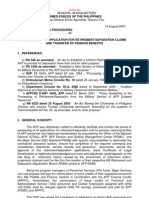

systems have been developed to support design and manufacture. The environment of design and manufacture is constantly changing, and manufacturing industries have to adapt to these changes. So new systems which support design and manufacturing activities must be developed. A relatively new concept in manufacturing systems is proposed here. This is a " C o m p u t e r Integrated Manufacturing system" (CIM), which represents a new generation in such systems (Fig. 1). Various manufacturing industries have made efforts to develop CIM. In the shipbuilding industry, which is a mature industry, various possibilities have already been tried out in several companies. In this paper, the authors pay particular attention to research into the development of CIM in shipbuilding ~-3 in two main areas.

- - M o d e l i n g design and manufacturing activities in

shipbuilding. Various activities and targets are analyzed and organized in an attempt to clarify which information should be generated, transmitted, and processed by a computer. - - Developing a prototype system for CIM in shipbuilding. A prototype system of CIM in shipbuilding is developed based on shipbuilding models. Smalltalk, which is an object oriented language, is used to develop this system.

Key words: product model, CIM, CAD/CAM/CAE

Introduction

Large-scale computer systems have been developed in order to support design and manufacturing activities. In the shipbuilding industry, computers have been in use since the 1960s, and many computer

Design and manufacturing systems in shipbuilding

Problems in developing CIM

In order to develop CIM, it is necessary that information on design and manufacturing activities is integrated. However, a preliminary consideration of integration shows that there are several problems in the current system three of which are outlined below.

Address correspondence to: K. A o y a m a Received for publication on Dec. 10, 1996; accepted on June 16, 1997

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

149 - - Modeling the product. Expression of product on a computer. - - Modeling manufacturing processes. Expression of manufacturing activities on a computer. Modeling the manufacturing environment. Expression of the manufacturing environment, such as the factory, the production equipment, and the workers, on a computer.

-

Characteristics of the design process

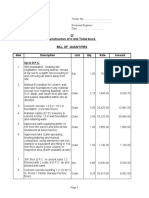

The design stages in manufacturing can be classified as follows: Fig. 1. Computer integrated manufacturing by product model Concept design ~ Elementary design ~ design --~ Production design Detailed

- - Isolated information. Since many individual systems support individual aspects of business, the information generated is isolated. - - The administration and transmission of essential information is inadequate. Since the transmission of information depends on human intervention, essential information is not always available. - - The generation of information is more important than its transmission. In current systems, designers think that the generation of effective information is more important than its subsequent transmission.

Information on a product is generated at each design stage, and the information generated at each stage is different. Therefore, it is thought that design activities can be examined in the following way. - - The designer configures a product from the requirements specified at each design stage. - - The designer then generates enough information on a product for manufacture to take place. These design characteristics also apply to shipbuilding design. Design information is generated at each stage of the activity. This information must then be separated into design requirements and design targets. Here, the design process is expressed on the computer. The designer's activities are then separated into the generation of product information and the processing of that information at each design stage (elementary design, structural design, detailed design, and production design). The design process itself is then modeled on the computer as a design process model. Figure 2 shows the modeling of design processes in shipbuilding. Elementary design. In the elementary design stage, the main purpose is the selection of the principal dimensions and the design of the general arrangement of the ship. At this stage, the target for the design is the whole product (i.e. the whole ship). The principal dimensions and line offsets, and the arrangement of the compartments are considered. A hull form and a structural style are also decided to satisfy the customer's requirements. Structural design. The main purpose of the structural design is a consideration of the structures which will satisfy the style requirements agreed at the elementary design stage. That is, the internal structures of the ship are designed to give maximum strength for that style. Many structural members are designed at this stage, and

Modeling for design and manufacturing systems

At the various design and manufacturing stages, information is generated, transmitted, and processed. Such information from manufacturing systems is of four types. Information on manufacturing targets (design requirements, design specifications, engineering drawings, product performance, production processes, etc.). Information on manufacturing control (production planning, production results, stock, orders, shipments, etc.). - - I n f o r m a t i o n on manufacturing processes (design procedures, production preparation procedures, etc.). Information on manufacturing resources and environment (technological data, production equipment, etc.).

-

It is thought that integration of the generation of necessary information for production activities and the transmission and administration of such information is vital in the development of CIM. Therefore, products and manufacturing activities have been modeled along the following lines.

150

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

Fig. 2. Model of the design process and product model

the designer checks the strength of the main structures which are composed of those members. Detailed design and production design. In the detailed design and production design stages, details of the strength and ease of productivity of the structural members are considered. To do this, a great deal of detailed information must be generated.

oriented language. In SODAS, several objects are defined for the product model in shipbuilding: These are a parts object, a connection object, a room object, a unit object, a module object, and so on.

Targets of design

Two of a ship's functions are carrying cargo and keeping of float. In order to secure the loading capacity and buoyancy, various closed spaces (compartments, holds, and tanks) are designed within a ship. From the view point of "Space", it is possible to divide the structural parts of a ship into these groups. Compartments, holds, and tanks. The external form of a ship is composed of a side shell, a deck plate, and a bottom shell. The closed spaces are generated in the ship by these members. The closed space of the ship's hull is divided~into several compartments, holds, and tanks by several partition plate members. Internal structures. The primary structural members (primary plate members and primary section members) are designed to keep the shapes of the closed spaces in a ship. Small plate members and section members (secondary members) are designed to reinforce primary structural members. Structural members and parts. There are two types of structural members. One is a plate parts member, and the other is a section member. One member is joined to another by welding. The structural members are de-

Product model in shipbuilding

Many models are needed to support the various design activities in which a computers is used. If these models are entirely independent from each other, handling them becomes difficult. So the concept of the integrated model is very important. However, the integrated model is not clearly defined, so this aspect is now considered. The final shape of a product is not an adequate description of that product for the computer. It is necessary to input a lot of information which does not explicitly appear in the overall shape of the product. That information must be considered in the design process, and the model which describes all this information is a "product model".4 If the product model in shipbuilding is defined and the product can be expressed on the computer, than all the product information can be used at the various design stages. This paper reports on the development of a CIM system for shipbuilding. This system is called SODAS (System Of Design and Assembling for Shipbuilding). It was developed using Smalltalk, which is an object-

K. Aovama and T. Nomoto: Models for CIM in shinbuildin~

151

Fig. 3. Room object

signed at the structural design stage. At the production stage, the target of cutting, bending, and assembling is not for structural members but for parts.

Room (compartments, holds, and tanks)

This paper considers those spaces which are compartments or tanks in the design. This type of space is defined as a room, and this concept is used to support the elementary design. " R o o m " is a generic term for a closed space such as a compartment, hold, or tank in a ship. By modeling the design of a ship's structure on the design of a room (see section on Design function for spaces), the generation of information about plate members and welded joints are related. So a designer can understand the many influences which affect the joining of plates into their correct shape. When the expression of a room is input on the computer, it is important to have a design model which uses the concept of a room. - - The volume of a room can be calculated. The shape of a partition plate can be designed with no inconsistences.

-

Fig. 4. Unit object

In this work the shape of a room is defined by a solid model which is the boundary representation (B-Reps). The data of a winged-edge structure can be generated from the shape data of a plate m e m b e r and the geometrical connective relation of plate members. In this work, the shape of a room is generated from the information on plate parts and parts connections Figure 3 shows a flow diagram of the generation of the room. Room object. A room object is defined as information about a compartment and various tanks. The shape of a room object is expressed as a solid model which encloses several parts members. This object is generated (designed) by the design function for spaces.

Unit (structural unit of ship structures)

Every ship has her own structural style. However, there are a lot of common partial structures in a ship. It is possible to define a c o m m o n partial structure as a "structural unit." It is thought that the design of ship's structures can be expressed as the design of a combination of structural units. Such a structural unit is called a "Unit" in this paper. A designer can design the ship's structure by considering a combination of units, and can handle easily many parts members by unit. Unit object. A unit object is defined as information on primary and secondary internal structures. This object

152

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

Fig. 5. Module object

has some parts objects, and is generated (designed) by the design function for internal structures. In this paper, three types of unit are defined. Figure 4 shows a plate unit and a section unit. Box unit. A box unit is defined by some plate parts members. A closed space can be extracted as a room by the plate parts members of which it is composed. The biggest box unit is the ship's hull. The box unit of the ship's hull is composed of a side shell, a deck plate, and a b o t t o m shell. Plate unit. A plate unit is an internal structure which supports the designed space. A plate unit can be designed by following the design parameters (the position of a strut, the depth of a strut or a ring, etc.). Some parts members are generated, and internal structures of various shapes are designed. These parts members are stored by this unit. Section unit. A section unit is a set of several section parts members. This unit is designed of plate parts

members to increase the bending strength of each plate parts member.

Module (intermediate product)

Production activities are composed of a combination of various production stages. A n intermediate product is assembled at each production stage, and this product is carried to th~ following production stage. Therefore, production activities can be expressed as a "flow of intermediate products." In this paper, "Module" is defined as an intermediate product which is the target of a production activity. A production planner can use a module as a unit in the administration of production information. A module is defined as a set of parts to express an intermediate product which is the construction unit at each production stage. A data structure of the module is expressed as a hierarchical structure, shown in Fig. 5. The module of the lowest layer is composed of one part. The module relates to the module construction m e t h o d of the shipbuilding industry.

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

153 computer. Shape data, connection data, attribute data, and so on are described in the information on a parts member. Parts object. A parts object is defined as information on a parts member, the shape of a parts m e m b e r is expressed by a surface model, and the thickness and material are described as attribute data. The parts object is stored in the unit object. A designer can arbitrarily extract the designed parts object from the unit object. Therefore, parts information can be taken out directly and changed if necessary. Since the shapes of a plate parts member and a section parts m e m b e r are characteristic, objects of them are defined individually. Figure 6 shows a representation of the shape of each parts object. Plate parts. The shape of a plate parts m e m b e r is expressed by a surface model in three-dimensional space, and plate thickness is disregarded. This shape is described by several vertices and several edges. Section parts. The web shape of a section parts member is expressed by a surface model. A section form is described by attribute data. The shape of this object is expressed by sweeping a section form along a web shape.

Connective relation between parts members

Fig. 6. The shape of a parts object, a A plate parts object, b A section parts object

Fig. 7. Connection object

A connective relation between parts members is defined as a "connection object." Information on the location of a connection is described by a wire frame model, and the two parts objects which are joined to each other are described in this object. Moreover, this connection object is described in these two parts objects as information on the connective relation. Figure 7 shows the data structure of a connection object. At the level of a geometrical element, we can recognize the information on the relation of these elements. A geometrical element is a vertex, an edge, or a loop, which defines the shape of parts. The relations of all geometrical elements of jointed parts shapes are described by the information on the connective relation. Connection object. Information on a connection between two parts members is defined as a "Connection Object." This information is later converted into weldline information.

Module object. A module object is defined as information about intermediate products at the production stage. This object has some parts objects, and is generated (designed) by the cutting function and the virtual assembling function.

Parts members

Function for elementary design and structural design

In order to generate and store information on a product as the product model at the elementary design and structural design stages, the design function is defined in

Information on plate parts members and section parts members is the basic element of ship structure on a

154

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding - - The designer inputs data of a plane which define the surface of a partition of plate parts. An example of these data are one point and a normal vector of a plane. -The intersection of this plane by the shape of the selected room is calculated. This intersection is described as the shape of the partition plate parts. - - The connective relation object with the plate parts object which composes the box unit and the partition plate parts object is generated at the same time. Generation of new rooms. A designer can design several partition plates using the above-mentioned function. The flow of the generation of new rooms from partition plates is shown below. - - Small rooms ("child" rooms) are formed by considering the shapes of the partition plate parts and the shape of the divided room ("parent" room). The shape of this small room is defined by a solid model. - - The shape of the new small room is checked by using information on the shape of the divided room, the shapes of plate parts generated, and the connective relation objects generated. - - New rooms are generated with a new shape, which is checked. - - New box units are generated. The new generated partition plate parts and several plate parts which make the divided room are stored in this new box unit. The concept of a wall. The shape of a room is expressed as a polyhedron, and the surface of a room corresponds to the plate parts. The plane of which this polyhedron is composed is called a "wall." A wall is a geometrical concept without thickness. The wall exists as the boundary between the plate and the room. Moreover, the wall is one section of the polyhedron of the room at the same time as being the area on the surface of the plate parts (Fig. 9).

Fig.

8. Design function for space

SODAS. There are two design functions, these are "design function for spaces" and "design function for internal structures."

Design function for spaces (rooms)

One closed space (room) is divided into several spaces (rooms) by the design function for spaces. Compartments and tanks in a ship can be designed using this function. It is thought that this function corresponds to the elementary design of a ship. Since a designer can easily confirm the shape of a room, he can understand the various influences of the design of partition plate parts. A design support system, including a few small functions, has been developed in SODAS. Figure 8 shows the flow of this function. Generation of new partition plates. The initial room, which is an internal space in the hull, can be extracted from the plate parts such as shell plates and deck plates. The shape o f this room is defined by a solid model. The outline of the generation of new partition plates is shown below. - - A designer can design several partition plate parts in a room. The shapes of those plate parts can be taken out according to the shape of the room.

Design functibn for internal structures

The design function for internal structure is used to design longitudinal structural members and transverse structural members to reinforce plate members (Fig. 10). The concept of a parametric design is introduced for this function and it can easily design this complicated structure. Using this function, the plane unit object and the section unit object are generated as the internal structures in a ship. The outline of this function is given below. Designing the plane unit. The plane unit is an internal structure to support designed inner spaces. Various

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

155 shapes of internal structures must be defined. The plane unit is designed as follows. - - T h e designer selects the r o o m for which he wants to design an internal structure. - - The designer inputs as m a n y design p a r a m e t e r s as are necessary to define the internal structural shape. - - The external shape of the internal structure is designed automatically using information about the room. - - Information on the connective relation is generated automaticlly. - - The shape of the internal structure is defined by the design p a r a m e t e r specified. Several other parts, e.g. face plate parts, bracket parts, and so on, are designed. - - The generated parts are stored in the plate unit. Designing the section unit. The section unit is a set of several section parts. Because a landing line is necessary to design section parts, the designer must design this line, and the mounting direction and the type of section parts are necessary to define the shape of the parts. The section unit is designed as follows. - - The designer selects the wall which he wants to use to design an internal structure. - - The designer inputs the design p a r a m e t e r s which are necessary to define an internal structure. For example, one design p a r a m e t e r is the n u m b e r of section parts. - - The landing lines of the section parts are designed on the selected wall. The designer can input the landing lines directly. - - The designer inputs information on each section part. This information consists of a mounting direction, the type of section parts, and so on. The shape of the section parts is generated. - - Information on the connective relation is generated automatically.

Fig. 9. Room and wall

Description of design information and design modification

It is believed that design activity is an act by which the intention of the design is described according to the design parameters. W h e n a design is finished, we can see only the final form of the product, we cannot see the designer's intention for that product. However, the designer's intention is very important, and so it is essential to store it as part of the design information on the product model. In this paper, the design processes and the design p a r a m e t e r s are considered to express the design proce-

Fig. 10. Design function for internal structure

156 dure in order to describe the design information on the product model.

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

Description of the design process

Restriction by structure. Before the design process is described, it is important to recognize the relations between rooms and units. There are characteristic restrictions in both the room and the unit. - - The shape of a small room (i.e. a child room) with in a large room (i.e. a parent room) is restricted by the shape of the large room. - - The external shape of an internal structure is never bigger than the shape of the r o o m to which the internal structure belongs. The restriction which is imposed by the design flow is used for the design functions based on the concepts of the room and the unit. In this paper the restriction is considered as follows. - - There are the parent rooms and child rooms. The child rooms are designed inside the parent room. The parent room restricts the child room. The unit (internal structure) inside the parent room is the child room. If the parent is the room, the parent restricts the children.

-

Fig. 11. Data structure of rooms

In this paper, the restriction of the relations between parent and child is defined as a "restriction by structure," and the relations between parent and child express the restrictions which exists in the design flow of the ship's structure. Hierarchical data structure. The design function for space does not actually divide the r o o m shape. The shape of the child room is only calculated, and the original shape of the parent room is stored. Therefore, by storing all the rooms which are divided, the hierarchical data structure of the rooms is generated (Fig. 11). By specifying the relation between the unit and the room, the hierarchical data structures of units and rooms are also generated. If the relations between the parents and children of all rooms and all units are expressed as hierarchical data structures, the design process can be stored in the product model. Finally, "the whole of the ship" is expressed as a "tree of the rooms and the units."

Fig. 12. Design parameters

come the geometrical restraints to the product shape? In this paper, the restriction of the product shape by the design parameters is defined as "restriction by design parameters." Design editor. In SODAS, the room shapes and the unit shapes are designed using drawing tools (Fig. 13). The set of these tools is the "design editor." This editor is two-dimensional, and the drawing area of the editor is in a section of the room. The flow of design by the design editor is shown below.

Description Of design parameters

Restriction by design parameters. The reference value is useful for the description of a product shape. The description by a reference value is called a design parameter on the drawing sheet and in the computer aided design (CAD) (Fig. 12). Design parameters be-

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

157

Hg. 13. Design tools for a plate unit

Description of the design procedure

In this approach, the description of the design parameters and the hierarchical data structure are used to describe the design procedure (Fig. 14). The design parameters for a child room (or unit) are described under parent room. Therefore the design parameters are stored with a hierarchical relationship between rooms. This means that the entire design procedure is described.

Design modifications

A designer can design a ship's structure using the above-mentioned design functions (Fig. 15). In order that the system can respond to the demands of the designer's modifications, S O D A S incorporates a description of these design functions as a design process (Fig. 16). In this approach, the parent room controls the Restrictions by design parameters as design information on the child room (or unit). Therefore, one demand of the design modification is to modify the restrictions by design parameters for a parent room. Modification of an internal structure. The design parameters are described in the parent room. The designer can modify these parameters, and the internal structure is then automatically re-designed. This process of re-design is similar to the process of design. Modification of a room. When a designer wants to modify the shape of a room with a child structure (a r o o m with an internal structure), the restriction by structure of the child structure will be changed. Since design information about the child structure is controlled in the parent room, the shape of the child structure is changed by using its own design information.

Fig. 14. Description of the design procedure

- - The designer selects the box unit which is the target for the design for partition plates and internal structures. - - The drawing area of the design editor is extracted from a room shape of the box unit selected. - - The designer draws lines on the drawing plane. The designer sets the position of each line using the design parameters. The designer inputs the attributes of each line (the lines of a partition plate, an internal structural shape, etc.). Drawn lines are changed to partition plate parts or internal structural shapes.

-

The design parameter object is defined to control the design. All information on the design of the room or unit (i.e. the section form of the room, information about lines and vertices which change the plate parts, reference lines, etc.) is saved by the design parameter object.

t58

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

Fig. 15. Example of a ship's structure

Fig. 16. Design modifications

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

159

Fig. 17. Cutting function

Fig. 19. Virtual assembling function

When the changed room has child structure, the redesign of the child structure is automatically processed by the design procedure described above.

Functions for detailed design and production design

It is important to generate more detailed information for the production stage from information that is generated at the elementary design stage and the structural design stage. For example, it is necessary to define in detail the shape of all parts edges and the treatment of the plate parts when they meet at a corner. In SODAS, the virtual assembling function is introduced to define detailed information for the production design. This section covers the cutting function and the virtual assembling function.

Cutting function

The parts members which are designed by the design function is not show any differences in thickness or section form. The designed structure must be decomposed into erection modules, middle modules (i.e. middle intermediate products) or small modules (i.e. small intermediate products). In an actual design, the designed parts members must be divided into small parts. There are three reasons for this division.

Fig. 18. Design module by cutting function

160

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding The flow of the cutting function is shown below (Fig. 17). The designer picks out a parts member. The designer inputs the cutting lines on the parts member. The shape of the parts member is divided at the cutting line. The shape of the new parts member is generated. The attribute information is copied from the divided parts member to the new parts members. The connective relation object is generated between the two newly generated parts members. The connective relation object of the divided parts member is divided in the same way as the division of the parts member.

------

This function can be used not only for the division of a parts member, but also for the division of a module. When a module is divided, it is treated as though the target of the division is a structure which consists of several parts members. This structure might be a structure of the intermediate product which must be divided once, or it might be the entire designed structure (Fig. 18).

Virtual assembling function

The structure divided by the cutting function is a partial structure which was designed by a designer, and information about its parts is not enough for the production stage. Therefore, SODAS contains a "virtual assembling function." The virtual assembling function is a function that enables the designer and the scheduler to define the assembly order by picking out each part from the structure which has been designed by the cutting function. In other words, this function is for process planning in shipbuilding. The designer can input information on production using this function. For example, the selection of a welding process, a welding condition, a detail of the shape of an edge, or the value of extending certain parts can be considered. Moreover, if the virtual assembling function has highlevel definition, it is possible to have a system which can check the interference between a fillet weld which has already been done and the corner of the floor plate member which is being inserted. This system supports the production design by which the cutout is applied to the floor plate member. The detailed shapes of the production parts are designed from information about the designed structure using this function (Fig. 19).

Fig. 20. Detailed shape of parts

1. To show differences in plate thickness and section form. 2. To generate subdivisions of structures in the module construction. 3. To buy steel plates and sections from the steelworks. The first point is important at the structural design stage, and the second and third points are used at the detailed design stage and the production design stage, respectively. However, the concept of the generation of information about parts is the same at all stages. In this paper, this division of parts members is defined as the cutting function. This function corresponds to the detailed design of parts.

Designing the detailed shapes of parts

It was shown that information about the detailed shapes of parts for production can easily be obtained by using

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding

161

Fig. 21. Product definition spiral and application systems

the virtual assembling function. However, it is necessary to generate information about these detailed shapes before they are first cut at the production stage. Figure 20 shows how information about the detailed shapes of parts is generated. In order to generate detailed information about parts, the designer has to select a lot of detailed information such as details of shape, details of beveling, the value of a groove, the value of extending parts, and so on. In the structural design of SODAS, the shapes of parts members are expressed as a surface model. However, it is more advantageous to express the shapes of these parts as a solid model in the production design. For instance, it is convenient to express the shapes of parts as solid model so that we can use this information to generate data for the NC cutting machine. Since plate thickness is described as attribute data in SODAS, this thickness has to be processed. It is therefore necessary to develop a function which will change a surface model to a solid model. In order to decide on the detailed geometric data of any part, it is necessary to consider the influence of all the parameters of adjacent parts (especially the thickness of an adjacent plate). When all these preparations have been made, the designer only has to arrange the cutting data for NC.

That is, the designer must specify which is the nesting bridge data, the cutting order, the piercing data, and so on, and then start the cutting process on the computer.

Product definition spiral and simulation of design

This paper has considered the nature of a product model for shipbuilding and what functions are needed to generate that product model. The growth process of the product model for shipbuilding through the elementary design stage to the detailed design stage is expressed in the product definition spiral. This spiral shows the design function, the cutting function, and the virtual assembling function, which are all necessary for the product model to be developed in sufficient detail (Fig. 21). We can understand the relation between the product definition spiral and the application systems, but usually it is difficult to judge whether the information we have is the best for design or planning in the product definition system without the application systems. With SODAS, we can design a general arrangement with the design function for space, and we can design a ship's structure with the design function for internal structures. The transverse ring members, the longitudi-

162 nal members, and the small structural members are generated by this function. The system can respond quickly to a designers demands. We can calculate the capacity of tanks, and the weight and center of gravity of any structure very easily, and information about the connective relation is generated automatically. Information on the position and length of the connected line is easily accessed by using the connection information. Conclusion This paper has considered the product model in shipbuilding which integrates all the available information about design and manufacturing activities. It also shows a prototype CIM system in shipbuilding. The product model is represented by objects. A room object, a unit object, a module object, a parts object, and a connection object are defined in this prototype system, and several functions for generating the product model are included. These are a design function for spaces, a design function for internal structures, a cutting function, and a virtual assembling function. Any type of ship can be designed by the design function. Information on compartments, holds, and tanks is generated as room objects by the design function for spaces and various internal structures are generated as unit objects in the room by the design function for internal structures. These design functions support the elementary design and the structural design in shipbuilding. The parts objects generated contain infor-

K. Aoyama and T. Nomoto: Models for CIM in shipbuilding mation on the connective relation as a connection object. The designer can divide the designed structure into small pieces (parts) using the cutting function, and the pieces can be assembled into a module by the virtual assembling function. This module is defined as the module object. These functions are useful in designing the detailed shapes of parts and in production planning in shipbuilding. This paper also introduced the product definition spiral. This spiral expresses the flow of the generation of the product model in shipbuilding.

References

1. Nomoto T, Aoyama K (1992) Ship definition system in computer integrated design and manufacturing. In: Vieria CB, Martins P (eds) Computer applications in the Automation of shipyard operations and ship design VII. Elsevier, Amsterdam, pp 177185 2. Nomoto T, Aoyama K, Hariyanto (1994) An implementation of a product definition system in computer integrated design and manufacturing. 8th International Conference on Computer Applications in Shipbuilding, vol 1. pp 19-33 3. Nomoto T, Aoyama K (1995) Product modeling in CIM for shipbuilding and its application for production planning. International Symposium on Practical Design of Ships and Mobile Units, pp 1389-1398 4. Kimura F (1992) New directions of CAD/CAM research and development for CIM. Proceedings International CIM Symposium 1992, pp 1-20 5. Sara T, Kimura F, Suzuki H e t al (1985) Designing machine assembly structure using geometric constraints in product modelling. Ann CIRP 34:169-172

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Relationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourDocumento16 páginasRelationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourToe ToeAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Frito Lay AssignmentDocumento14 páginasFrito Lay AssignmentSamarth Anand100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- To The Owner / President / CeoDocumento2 páginasTo The Owner / President / CeoChriestal SorianoAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Community-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDocumento28 páginasCommunity-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDiane Rose LacenaAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Midterm Exam StatconDocumento4 páginasMidterm Exam Statconlhemnaval100% (4)

- E OfficeDocumento3 páginasE Officeஊக்கமது கைவிடேல்Ainda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- ESK-Balcony Air-ADocumento2 páginasESK-Balcony Air-AJUANKI PAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Sewing Machins Operations ManualDocumento243 páginasSewing Machins Operations ManualjemalAinda não há avaliações

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Documento6 páginasType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Documento3 páginasEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandAinda não há avaliações

- LISTA Nascar 2014Documento42 páginasLISTA Nascar 2014osmarxsAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- MPPWD 2014 SOR CH 1 To 5 in ExcelDocumento66 páginasMPPWD 2014 SOR CH 1 To 5 in ExcelElvis GrayAinda não há avaliações

- Annisha Jain (Reporting Manager - Rudrakshi Kumar)Documento1 páginaAnnisha Jain (Reporting Manager - Rudrakshi Kumar)Ruchi AgarwallAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Verma Toys Leona Bebe PDFDocumento28 páginasVerma Toys Leona Bebe PDFSILVIA ROMERO100% (3)

- Common Base AmplifierDocumento6 páginasCommon Base AmplifierMuhammad SohailAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- CE5215-Theory and Applications of Cement CompositesDocumento10 páginasCE5215-Theory and Applications of Cement CompositesSivaramakrishnaNalluriAinda não há avaliações

- Change Language DynamicallyDocumento3 páginasChange Language DynamicallySinan YıldızAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Crivit IAN 89192 FlashlightDocumento2 páginasCrivit IAN 89192 FlashlightmAinda não há avaliações

- Dbms UPDATED MANUAL EWITDocumento75 páginasDbms UPDATED MANUAL EWITMadhukesh .kAinda não há avaliações

- SEBI Circular Dated 22.08.2011 (Cirmirsd162011)Documento3 páginasSEBI Circular Dated 22.08.2011 (Cirmirsd162011)anantAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- SOP No. 6Documento22 páginasSOP No. 6Eli CohenAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- 16 Easy Steps To Start PCB Circuit DesignDocumento10 páginas16 Easy Steps To Start PCB Circuit DesignjackAinda não há avaliações

- Standard Cost EstimatesDocumento12 páginasStandard Cost EstimatesMasroon ẨśầŕAinda não há avaliações

- WPGPipingIndex Form 167 PDFDocumento201 páginasWPGPipingIndex Form 167 PDFRaj AryanAinda não há avaliações

- TENDER DOSSIER - Odweyne Water PanDocumento15 páginasTENDER DOSSIER - Odweyne Water PanMukhtar Case2022Ainda não há avaliações

- VB 850Documento333 páginasVB 850Laura ValentinaAinda não há avaliações

- LR Format 1.2Documento1 páginaLR Format 1.2Ch.Suresh SuryaAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Troubleshooting For Rb750Glr4: Poe Does Not WorkDocumento7 páginasTroubleshooting For Rb750Glr4: Poe Does Not Workjocimar1000Ainda não há avaliações

- Ambient Lighting Vol 6 CompressedDocumento156 páginasAmbient Lighting Vol 6 Compressedadvait_etcAinda não há avaliações

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDocumento20 páginasAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenAinda não há avaliações