Escolar Documentos

Profissional Documentos

Cultura Documentos

Magnetic Particle Exam

Enviado por

m05_485246Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Magnetic Particle Exam

Enviado por

m05_485246Direitos autorais:

Formatos disponíveis

TWI Knowledge Summary

Magnetic Particle Inspection

How does it work?

Magnetic particle inspection (MPI) is used for the detection of surface and nearsurface flaws in ferromagnetic materials. A magnetic field is applied to the specimen, either locally or overall, using a permanent magnet, electromagnet, flexible cables or hand-held prods. If the material is sound, most of the magnetic flux is concentrated below the material's surface. However, if a flaw is present, such that it interacts with the magnetic field, the flux is distorted locally and 'leaks' from the surface of the specimen in the region of the flaw. Fine magnetic particles, applied to the surface of the specimen, are attracted to the area of flux leakage, creating a visible indication of the flaw. The materials commonly used for this purpose are black iron particles and red or yellow iron oxides. In some cases, the iron particles are coated with a fluorescent material enabling them to be viewed under a UV lamp in darkened conditions. Magnetic particles are usually applied as a suspension in water or paraffin. This enables the particles to flow over the surface and to migrate to any flaws. On hot surfaces, or where contamination is a concern, dry powders may be used as an alternative to wet inks. On dark surfaces, a thin layer of white paint is usually applied, to increase the contrast between the background and the black magnetic particles. The most sensitive technique, however, is to use fluorescent particles viewed under UV (black) light. MPI is particularly sensitive to surface-breaking or near-surface cracks, even if the crack opening is very narrow. However, if the crack runs parallel to the magnetic field, there is little disturbance to the magnetic field and it is unlikely that the crack will be detected. For this reason it is recommended that the inspection surface is magnetised in two directions at 90 to each other. Alternatively, techniques using swinging or rotating magnetic fields can be used to ensure that all orientations of crack are detectable. The method of magnetisation depends on the geometry of the component and whether or not all or only part of the specimen is to be magnetised. Permanent magnets are attractive for on-site inspection, as they do not need a power supply. However, they tend only to be used to examine relatively small areas and have to be pulled from the test surface. Despite needing their own power supply, electromagnets (yokes) find widespread application. Their main attraction is that they are easy to remove (once the current has been switched off) and that the strength of the magnetic field can be varied. For example, an AC electromagnet can be used to concentrate the field at the surface where it is needed. Hand-held electrical prods are useful in confined spaces. However, they suffer two major disadvantages that can rule out their use altogether. Firstly, arc strikes can occur at the prod contact points and these can damage the specimen surface. Secondly, because the particles must be applied when the current is

on, the inspection becomes a two-man operation. Bench units are fixed installations used to test large numbers of manufactured specimens of various sizes. The electrical components of a mobile unit (as described above) are incorporated in the bench unit making testing more rapid, convenient and efficient. In some cases, MPI can leave residual fields which subsequently interfere with welding repairs. These can be removed by slowly wiping the surface with an energised AC yoke.

What will it find?

MPI is used to detect surface-breaking and near-surface flaws in ferromagnetic materials. It cannot, however, be used to detect deeply embedded flaws, nor can it be used on non-ferromagnetic materials, such as aluminium, copper or austenitic stainless steel.

Where is it used?

MPI is often used to look for cracking at welded joints and in areas identified as being susceptible to environmental cracking (e.g. stress corrosion cracking or hydrogen induced cracking), fatigue cracking or creep cracking. Wet fluorescent MPI finds widespread use in looking for environmental damage on the inside of vessels. Further information on each of these cracking mechanisms and their significance in piping systems is given in API 570.

Further information

TWI offers training courses on magnetic particle inspection. TWI Industrial Members and JoinIT North East users have access to the NDT Selector Toolkit Additional information about magnetic particle inspection can be found in the items detailed below: FAQ: What are the principles of Magnetic Particle Inspection (MPI) in NonDestructive Examination (NDE)? FAQ: What are the advantages and disadvantages of Magnetic Particle Inspection (MPI) in Non-Destructive Examination (NDE)? FAQ: What are the subclasses of magnetic particle indications?

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- 1-ADM-Aluminum Design Manual & SpecificationDocumento83 páginas1-ADM-Aluminum Design Manual & SpecificationAyham Aljawhary100% (2)

- Water Cooled Chiller - SOPDocumento13 páginasWater Cooled Chiller - SOParunceedee100% (4)

- ZHF XPXN 0SB39 Omi 001-1Documento29 páginasZHF XPXN 0SB39 Omi 001-1Online 4-lifeAinda não há avaliações

- Physics 11 Forces and Newton's LawsDocumento9 páginasPhysics 11 Forces and Newton's LawsJERLIE ANNA LALYNE ACURAMAinda não há avaliações

- Charge-Coupled DevicesDocumento55 páginasCharge-Coupled Devicesmyth100% (1)

- Sizing Pressure RelievingDocumento20 páginasSizing Pressure RelievingNuch NapapornAinda não há avaliações

- Chemie Ingenieur Technik Volume 73 Issue 6 2001 (Doi 10.1002/1522-2640 (200106) 73:6-605::aid-Cite6054444-3.0.Co 2-g) Görge Baltin Heinz Köser Klaus-Peter Wendlandt - Reactive DesorDocumento1 páginaChemie Ingenieur Technik Volume 73 Issue 6 2001 (Doi 10.1002/1522-2640 (200106) 73:6-605::aid-Cite6054444-3.0.Co 2-g) Görge Baltin Heinz Köser Klaus-Peter Wendlandt - Reactive Desorlili purwasihAinda não há avaliações

- Heat and Thermodynamics 34-37 PDFDocumento4 páginasHeat and Thermodynamics 34-37 PDFChaudhary Shahzaib AliAinda não há avaliações

- CSTRDocumento25 páginasCSTRAinul Mardhiah Abdul Rahim100% (1)

- Select All The Correct AnswersDocumento11 páginasSelect All The Correct AnswershAinda não há avaliações

- Chapter 1 Fluid MechanicsDocumento49 páginasChapter 1 Fluid MechanicsHunain AK100% (1)

- UUSITALODocumento9 páginasUUSITALOMarcosAinda não há avaliações

- 1993 - Avshalom C. Elitzur, Lev Vaidman - Quantum Mechanical Interaction-Free Measurements BOMBADocumento14 páginas1993 - Avshalom C. Elitzur, Lev Vaidman - Quantum Mechanical Interaction-Free Measurements BOMBAGxilleAinda não há avaliações

- Energy - Work - Resources of EnergyDocumento23 páginasEnergy - Work - Resources of EnergykhalidAinda não há avaliações

- Oxo-Degradable Additive: GeneralDocumento4 páginasOxo-Degradable Additive: GeneralLaili AzkiyahAinda não há avaliações

- DPI General CatalogueWeb PDFDocumento149 páginasDPI General CatalogueWeb PDFsunny_boy73Ainda não há avaliações

- Indiabix ThermoDocumento44 páginasIndiabix ThermoZir AeAinda não há avaliações

- CH en 3453 - HW 02 - 2014Documento2 páginasCH en 3453 - HW 02 - 2014Dennis LingAinda não há avaliações

- Experiment 6 Conservation of EnergyDocumento5 páginasExperiment 6 Conservation of EnergyHarold ParenasAinda não há avaliações

- Instrumentation Lab4 ReportDocumento10 páginasInstrumentation Lab4 ReportDaniel PhilpottAinda não há avaliações

- D 5656 - 01 - Rdu2ntytmdeDocumento6 páginasD 5656 - 01 - Rdu2ntytmdeJOHNAinda não há avaliações

- Ch.1 Determination of The Formula of A HydrateDocumento3 páginasCh.1 Determination of The Formula of A HydrateKaterina_YildizAinda não há avaliações

- Ph2161 Engineering Physics Important 2 Marks and 16 MarksDocumento25 páginasPh2161 Engineering Physics Important 2 Marks and 16 MarksKarthik Raman100% (1)

- Chapter 8, 11 Heath Textbook Chemistry 11Documento6 páginasChapter 8, 11 Heath Textbook Chemistry 11Venus WangAinda não há avaliações

- Safety ValvesDocumento8 páginasSafety ValvesvenkeekuAinda não há avaliações

- Chapter1 The Crystal Structure in SolidsDocumento19 páginasChapter1 The Crystal Structure in SolidsTahsin MorshedAinda não há avaliações

- Properties of Water: Physical and Chemical PropertiesDocumento17 páginasProperties of Water: Physical and Chemical PropertiesHasaan WaheedAinda não há avaliações

- Plastics Material Selection Criteria: BY N.Mohan Kumar Cipet ChennaiDocumento16 páginasPlastics Material Selection Criteria: BY N.Mohan Kumar Cipet ChennaisouravAinda não há avaliações

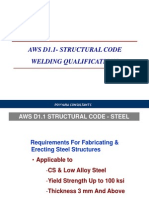

- Aws D1.1welding Qualification.Documento10 páginasAws D1.1welding Qualification.idealparrotAinda não há avaliações

- Earth Science Module 5 AnswersheetDocumento2 páginasEarth Science Module 5 AnswersheetCorazon MARCIANOAinda não há avaliações