Escolar Documentos

Profissional Documentos

Cultura Documentos

Unisab III Operating en Logo

Enviado por

Pedro BancayanDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Unisab III Operating en Logo

Enviado por

Pedro BancayanDireitos autorais:

Formatos disponíveis

Compressor type: Shop no.

: Password: Software version:

____________________ Refrigerant:

_____________

________________________________________ ________________________________________ ________________________________________

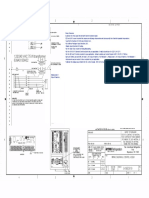

Operating manual - Unisab III Control Control system for refrigerating compressors

Version 1.00

Operating manual - Unisab III 002672-en 2007.09

1/37

Preface This Unisab III Operating manual covers reciprocating as well as screw compressors, unless otherwise stated. The manual offers a description of the Unisab III control system including function, application and service. This manual is produced by: Johnson Controls Denmark ApS Christian X's Vej 201 8270 Hoejbjerg, Denmark Phone +45 87 36 70 00 Fax +45 87 36 70 05 CVR No 19 05 61 71 Copyright 2007 Johnson Controls Denmark ApS This manual must not be copied without the written permission of Johnson Controls Denmark ApS and the contents must not be imparted to any third parties nor be used for any unauthorised purposes. Contravention will be prosecuted. Please read the manual carefully so that you fully understand the Unisab III control system and know how to operate it correctly. Damage occurring as a result of incorrect operation is not covered by Johnson Controls Denmark's guarantee. Note the version number of this manual. The version number is printed on the preceding page. It is important that this number is identical to the Unisab III version number, which is shown in the picture Service/Diagnosis/Software/Software version. Never use a manual with lower version number than Unisab III. Warning! If it is necessary to service the Unisab III control system, the power supply to the compressor motor must be switched off on the main switch to prevent the compressor from starting up accidentally. As the Unisab III cabinet contains live parts it is very important to comply with the safety regulations on site. Failure to do so may cause damage to equipment and affect personal safety. Even though the power supply to Unisab III is switched off, some of the terminals may still be live. Only authorized personnel is allowed to service Unisab III. If Unisab III is connected to a network, always remember that the compressor can be started from REMOTE. This cannot be avoided solely by changing settings on the Unisab III display. Emergency stop Activate the emergency stop by a light touch and deactivate it by turning it clockwise. The emergency stop breaks the power circuit of the compressor motor starter/motor guard. Activation of the emergency stop during operation will immediately disconnect the motor guard while there is still power on Unisab III. The compressor state can therefore always be read. Whenever the emergency stop is activated during operation, the alarm text Compr. motor error will appear in the display. Before the compressor can be restarted, deactivate the alarm by /RESET key and release the emergency stop. means of the Please note: If Unisab III is set at Remote or Auto, the compressor will restart automatically.

Power supply: Consumption: Ambient temperature: Humidity: Tightness:

Technical data Nominal VAC Tolerance Hz 85-250 47-63 32 VA 0-55C (during operation) 10-90% relative humidity (not condensing) IP 54

Operating manual - Unisab III 002672-en 2007.09

3/37

Contents

1. Operating Unisab III control

1.1. Introduction

1.1.1. Start-up 1.1.2. Display 1.1.3. Front panel 1.1.4. Menu structure 1.1.5. Session 1.1.6. Changing set values 1.1.7. Favourites 1.1.8. Manual and auto operation 1.1.9. Shutdown and alarm acknowledgement 1.1.10. Factory setting 1.1.11. Set values

5 5 5 7 7 9 16 18 20 21 23 23 24 25 25 26 27 27 28 29 31 32 32 35 36 36

1.2. Pressure levels and temperatures

1.2.1. Measured and calculated pressure levels - screws 1.2.2. Measured and calculated temperatures - screws 1.2.3. Measured and calculated pressure levels - recips. 1.2.4. Measured and calculated temperatures - recips. 1.2.5. Measured/calculated pressure levels/temp. - HPO/HPC 1.2.6. Notes 1.2.7. Oil pressure calculations

1.3. Timers

1.3.1. Timer values - screw compressors 1.3.2. Timer values - reciprocating compressors

1.4. Spare parts

1.4.1. Spare parts for Unisab III

Operating manual - Unisab III 002672-en 2007.09

4/37

Operating Unisab III control

1. Operating Unisab III control

1.1. Introduction

The purpose of the Unisab III control system is to monitor, protect, control and regulate reciprocating and screw compressors. The control cabinet as well as the electrical components have been connected from factory. Thus, only a few connections are needed to link to the electrical installations on site. Unisab III is programmed according to the type of compressor it is going to control. See section Setup (Engineering manual). Unisab III offers different ways of controlling/regulating compressor capacity according to pressure levels or temperatures. Compressor capacity can be regulated both manually and automatically. Furthermore, a number of limiting functions have been incorporated. In periods of overloading these limiting functions will intervene and limit compressor capacity until the situation has returned to normal. Consequently, the number of undesirable operational stops will be reduced as well as the need for supervision. Compressors fitted with Unisab III Control can be linked via the built-in communication system, Multisab. In this way compressors can work in a common refrigerating system, thus optimizing the operation of the entire compressor plant. The communication system further allows Unisab III to be connected to a PLC or PC central monitoring, control and data logging system. Unisab III can be linked to and communicate with former Sabroe control units such as Unisab II. Unisab III is operated by means of a front panel as shown in Fig. 3. The front panel is wellarranged with only a few keys and a distinct display. Unisab III does not lose its preset or changed values in the event of a temporary power failure. It contains a battery which is used by the built-in timer to ensure that time and date are always correct even if power has been disconnected. The hour counter and any stored alarm values will maintain the correct time.

1.1.1. Start-up

On delivery all electrical components in the compressor are connected to Unisab III. On site it is only necessary to add the correct supply voltage from the local installations. The electric wiring must be carried out according to the wiring diagrams for Unisab III at the end of this manual. Note in particular that no outside voltage must be applied to the digital inputs of Unisab III. the supply voltage must be between 85 VAC and 250 VAC.

Before any voltage is applied to Unisab III, the emergency stop switch must be activated. When voltage is applied to Unisab III, the default picture shown below will appear in the display and Unisab III will be ready for operation.

Operating manual - Unisab III 002672-en 2007.09

5/37

Operating Unisab III control

Fig. 1: Default picture

As Unisab III has been programmed with values for alarm limits, shutdown limits, set points, etc., the compressor can be started immediately. However, some of the values must be adapted to the actual operating situation. It is also recommended to read this manual carefully to acquire a thorough knowledge of how to operate Unisab III. Unisab III is operated exclusively by means of the front panel keys. Reading of operating conditions as well as changing limiting values and set points is carried out via the display. The display contains a number of different pictures. The control panel is usually closed and locked with two screws at the bottom of the front panel. When turning the screws, the front panel is loosened and can be lifted to an open position, yet still fastened to the cabinet. See Fig. 2.

Fig. 2: Unisab III with front open

This way the front panel remains easy to operate and easy access to the cabinet interior is obtained. When Unisab III is open, it is still fully operational.

Operating manual - Unisab III 002672-en 2007.09

6/37

Operating Unisab III control

1.1.2. Display

Top bar

Content area

Info bar F-key area

Fig. 3: Unisab III front

Display The display has a background illumination with screen saver function. It consists of a top bar with navigation information, a content area with 7-11 lines of information, an info bar with mode and status information and an F-key area with information about the active function keys. Pressure levels, temperatures, set points as well as alarm and shutdown limits can be read in the display. The contrast is factory set but may be adjusted, if required. See subsection Contrast (display) in the Engineering manual.

Actual capacity Compressor mode Compressor status Password security

Fig. 4: Info bar in Unisab III display

Compressor no. (if remote connected) 1

Smiley status:

OK Alarm

Information about active timer

Shutdown

1.1.3. Front panel

The Unisab III front panel is divided into three sections: The control section - to control the compressor. The menu section - to select menu pictures and change values. The F-key section - to operate function keys.

Operating manual - Unisab III 002672-en 2007.09

7/37

Operating Unisab III control

Control section Light above start key Off/green/yellow/red light indicating whether the compressor is stopped, running, in alarm mode or in shutdown. At start-up this light flashes green until Unisab III has received feedback from the motor starter. At the same time the text Starting (light flashes) and Running (light steady) can be seen at the bottom line of an operating picture. Yellow flashes = alarm. Red flashes = shutdown.

The compressor starts in manual operation when pressing this key once. Works only if the compressor is set at manual mode.

The compressor stops at manual operation when pressing this key once. Works only if the compressor is set at manual mode. Menu section

Move left in the menu system. Used to select pictures or a digit when changing a value.

Move right in the menu system. Used to select pictures, a value or a digit when changing a value.

Move up in a menu or in a picture in order to point to a certain line, or when changing a digit to a higher value.

Move down in a menu or in a picture in order to point to a certain line, or when changing a digit to a lower value.

The Enter (check) key has several functions. When changing the set values, pressing this key will enter the change into the Unisab III memory. To make changes, you must use the password provided by Johnson Controls Denmark. As to the encoding of a password, see section 1.1.6. Changing set values.

The Escape (full turn) key has several functions. When changing the set values, pressing this key will discard your changes. See section 1.1.6. Changing set values.

Operating manual - Unisab III 002672-en 2007.09

8/37

Operating Unisab III control

F-key section

Function key 1. Has several functions, eg bringing the menu to the display.

Function key 2. Has several functions, eg increasing capacity during manual operation.

Function key 3. Has several functions, eg decreasing capacity during manual operation.

Function key 4. Has several functions, eg shutdown reset. The function of each key will always be shown in the display above the key.

1.1.4. Menu structure

Unisab III includes a number of different pictures for compressor operation, set values, configuration, etc. These pictures are built up in a menu system where a certain picture can be selected by means of the arrow keys. The menu tree shows the structure and the number of pictures in the menu systems for: Screw compressors Single-stage reciprocating compressors Two-stage reciprocating compressors

In the menu tree, the selection of pictures is carried out by means of the arrow keys on the front panel. The and keys allow you to move left or right in the menu tree.

The and keys allow you to move up or down in the menu tree by moving the dark cursor from line to line. Press /MENU to get to the main menu consisting of the following menus: Favourites - a number of user definable operational pictures Alarm - list of active alarms Shutdown - list of active shutdowns Control values - all operational values with limits and set points History - historical shutdown information Service - maintenance and diagnosis information Setup - all compressor set up, configuration, timers, session etc.

Operating manual - Unisab III 002672-en 2007.09

9/37

Operating Unisab III control

Unisab III HMI menu tree Bold text = menu Normal text = a selectable picture

Menu level 1 Favourites Menu level 2 Default User 1 User 2 User 3 User 4 User 5 User 6 Menu level 3 Menu level 4

Manage favourites

Alarms

Shutdown

Control values

Suction

Values Pressure Bar Limits Control

Pressure Deg.

Limits Control

Temperature

Limits Control

Superheat

Limits Control

Table 1: Unisab III HMI menu tree

Operating manual - Unisab III 002672-en 2007.09

10/37

Operating Unisab III control

Menu level 1 Control values

Menu level 2 Discharge

Menu level 3 Values Pressure Bar Limits Control

Menu level 4

Pressure Deg.

Limits Control

Temperature

Limits Control

Superheat

Limits Control

Oil

Values Pressure Limits Control

Filter pressure

Limits (screws only) Control

Temperature

Limits Control

Separator temp.

Limits (UniScrew only) Control

Motor

Values Current Limits Control

Power

Limits Control

Revolutions

Limits (VFD only) Control

Capacity

Values Capacity Control (Not VFD)

Cap. slide pos.

(Not recip.)

Vi slide pos.

Control (Auto Vi only)

Yield

Table 2: Unisab III HMI menu tree

Operating manual - Unisab III 002672-en 2007.09

11/37

Operating Unisab III control

Menu level 1 Control values

Menu level 2 Process temp.

Menu level 3 Values Process out temp. Limits Control

Menu level 4

User

Values User input 1 Limits Control

Intermediate

Values Pressure Bar

(Two-stage recip. only) Limits

Pressure Deg.

Limits

Temperature History Shutdown Control state

Limits

Measured values Input state Output state

No of shutdowns

Table 3: Unisab III HMI menu tree

Operating manual - Unisab III 002672-en 2007.09

12/37

Operating Unisab III control

Menu level 1 Service

Menu level 2 Maintenance

Menu level 3 Service timers

Menu level 4

Diagnosis

Hardware

Analog inputs

Analog outputs Digital inputs Digital outputs

Software

Software version

Power on Zero cap. pos. (screws only) COP Proficom Rotatune piston (rota rec. only) Sep. velocity (Screws only) Misc. functions Superuser password Examine all parameters Setup Compr. Control

Sequencing

Table 4: Unisab III HMI menu tree

Operating manual - Unisab III 002672-en 2007.09

13/37

Operating Unisab III control

Menu level 1

Menu level 2 Configuration

Menu level 3 Drive

Menu level 4

Compressor Block Plant Oil system Communication Dig. in via Profibus Measuring External input Aux. output Aux. limits R000 Calibration Pressure (If Aux output) (If Profibus Yes)

Process temperature Position Frequency Analog input Analog output Digital input Digital output Factory reset Timers Timer list (Recip./Screw)

Timer setup Date - Time Oil charging Motor fan P band factor Transfer Take-over

(Recip./Screw)

(Screws only) (VFD only)

(Recip. only) (Recip. only)

Table 5: Unisab III HMI menu tree

Operating manual - Unisab III 002672-en 2007.09

14/37

Operating Unisab III control

Menu level 1

Menu level 2 Session

Menu level 3 Password

Menu level 4

Serial number Remote connect

User interface Language

Table 6: Unisab III HMI menu tree

Operating manual - Unisab III 002672-en 2007.09

15/37

Operating Unisab III control

1.1.5. Session

When selecting the menu Session, the following picture appears:

Fig. 5: Session menu

Password When you want to change a parameter you must enter a four digit password.

In Unisab III there are 4 password levels: Monitoring (no password) - monitoring access only User - access to change set points linked to normal operation Superuser - access to change configuration and critical set points Supervisor - Johnson Controls Denmark supervisor level

and . Choose the appropriate level with and Switch between the password levels with enter the four digit password using the arrow keys. When you have entered the four digits, press and then /OK. If the password is accepted you will return to the picture where you wanted to change a parameter and may change the parameter value with the and keys.

In section 1.1.6. Changing set values, you will find a detailed example of how to change a parameter, eg a limit value. You can always log into Unisab III even if you are not prompted for a password. Simply choose Current user in the Password picture in the Session menu.

Operating manual - Unisab III 002672-en 2007.09

16/37

Operating Unisab III control

You may change the predefined password for a password level. Choose Change passwords in the Password picture in the Session menu. Log in at the level where you want to change your password and enter your new password. Make sure you remember your new password as you will need to contact Johnson Controls Denmark in order to have the password re-established if you forget it. User interface The user interface appearance can be changed (see section 1.1.6. Changing set values). This may be carried out even when the compressor is running. Menu Auto Expand. If this feature is set to No the automatic expansion and collapse of the menu tree will be disabled. The menu system will no longer automatically open to a lower menu level or close a lower level when you continue to the next higher level. Menu Auto Continue. If this feature is set to No you will not automatically continue from a lower level menu into the next higher level menu, without using the level up (left) arrow key. Languages Like any other function setting (see section 1.1.6. Changing set values) the language can be changed to any of the following, even when the compressor is running: en=English fi=Finnish fr=French es=Spanish da=Danish de=German cs=Czech sv=Swedish ru=Russian pl=Polish pt=Portuguese nl=Dutch it=Italian no=Norwegian hu=Hungarian el=Greek tr=Turkish When Unisab III is switched on for the first time the set language will be English (en).

Operating manual - Unisab III 002672-en 2007.09

17/37

Operating Unisab III control

1.1.6. Changing set values

This example illustrates how to change set values, ie alarm limits, shutdown limits, set points, timer starting value etc. First you must position the (dark) cursor on the value you want to change. In this example it is the low shutdown limit for suction pressure. Proceed as follows: In the menu illustrated below, move the cursor to Control values with the and keys. Press to go to Suction and once again to go to (suction) Values and again to get to the Suction/ Values picture.

In the next picture, move the cursor down to Suction pressure with the /LIMITS to get to the (suction) limits picture.

key and then press

Press four times to get to the Low shutdown value. To change the low shutdown limit, press .

You must enter a password to continue. To change this low shutdown limit you must choose a Superuser (or higher level) password.

Operating manual - Unisab III 002672-en 2007.09

18/37

Operating Unisab III control

Switch between the password levels with the and keys. When you have selected the appropriate level with the key, you must enter in this case the four digit Superuser password using the arrow keys.

When you have entered the four digits, press change the Low shutdown limit with the and

and keys.

/OK.

If the password is accepted, you are now back in the Suction pressure limits picture and may

When you have set the limit value, press

to store the value in the memory. Before pressing . By doing

you have the possibility to undo the parameter change by pressing instead of so, the changes you have just made will not be stored in the memory.

Operating manual - Unisab III 002672-en 2007.09

19/37

Operating Unisab III control

1.1.7. Favourites

Favourites contain a number of overview pictures for daily compressor operation. There is one predefined favourite picture designated as Default. The other six favourites pictures are user definable, named User 1 to User 6. Each favourite picture may contain up to seven parameters.

The User 1 to User 6 favourites pictures are as the name indicates user definable.

In the Manage Favourites picture, press /MANAGE. You are now ready to select values, set points, limits, timers or any other parameter you want to insert or you may bookmark into a User favourite.

Operating manual - Unisab III 002672-en 2007.09

20/37

Operating Unisab III control

Place the cursor on the value you want to insert from (almost) any picture, eg a suction pressure set point, and press /BOOKMARK.

Unisab III automatically skips back to the Manage Favourites picture. In this picture, place the cursor on the user picture you want to insert the value into, eg. the User 1 favourite. Press /CONFIRM to insert the actual setpoint into User 1.

Press /OK to continue bookmarking. Repeat this operation up to seven times, ie until the User 1 picture is full as shown below.

You can change the order of the parameters by using the arrow keys to move parameters up and down in the User 1 picture. When satisfied with the order, press Favourites picture to terminate. /DONE in the Manage

1.1.8. Manual and auto operation

Select compressor control mode Compressor control mode, ie Stopped, Manual, Auto or Remote operation, is selected in the Setup menu in the Compr Control picture.

Operating manual - Unisab III 002672-en 2007.09

21/37

Operating Unisab III control

Alternate between manual and auto/remote control mode In the Default or any User favourites picture (if set up by the user) you may set Manual Mode to Yes, ie switch from remote or auto to manual operation. You can always switch between Manual and Auto/Remote even during operation.

In Manual operation, the compressor operation (ie starting/stopping and regulating capacity) is entirely controlled by the operator overruled only by the built-in capacity limiters and the alarm/shutdown supervision. In Auto operation, the compressor operation is controlled by the built-in regulator - depending on its configuration during commissioning. In Remote operation, the compressor operation is controlled by a remote regulator/sequence controller - depending on configuration during commissioning. The built-in capacity limiters and the alarm/shutdown supervision are also active in Auto and Remote. Manual loading or unloading of capacity In manual mode and can be used for manual loading or unloading of capacity. Pressing increases capacity and pressing decreases capacity. All manual compressor operation must be carried out from one of the seven favourite pictures. Manual start In manual mode and if the compressor is ready you can start the compressor by pressing . Compressor status in the info bar will be prelubrication, starting or running depending on compressor type. During the starting period the light diode above the start key will flash green. After feedback from the motor starter, the light diode changes to a steady green light. Manual stop You can stop the compressor immediately by pressing . Compressor status in the info bar will be cap. slide down or pause depending on compressor type. The light diode above the start key will be off.

Operating manual - Unisab III 002672-en 2007.09

22/37

Operating Unisab III control

1.1.9. Shutdown and alarm acknowledgement

A compressor shutdown is acknowledged by pressing /RESET. If the cause of shutdown is no longer present the shutdown message will disappear from the shutdown queue. A shutdown stops the compressor immediately and is indicated by quick red flashes in the light diode above the start key. An acknowledged shutdown where the alarm cause is still present is indicated by slow red flashes in the light diode.

A compressor alarm is automatically acknowledged when the alarm cause is no longer present and the alarm message will disappear from the alarm queue. An alarm does not stop the compressor. It is indicated by quick yellow flashes in the light diode above the start key.

1.1.10. Factory setting

On delivery Unisab III is preset with factory settings for all appropriate points. Although other values may have been entered from factory or after delivery, Unisab III can always be reset to its factory settings. A factory reset affects the following points: Alarm and shutdown limits Regulator settings Timer setup Control mode

The factory settings are stated in the tables in the sections Alarm and shutdown, Timers and Compressor regulation (Engineering manual). Before performing a factory reset, always stop the compressor for safety reasons. Select Setup/Configuration/Factory Reset and change Factory Reset from No to Yes. and within a few seconds Unisab III will display the Favourites/Default picture Now press shown in Fig. 1. The reset operation is complete and Unisab III is now restored to its factory settings. Unisab III must then be adjusted to the actual operating conditions. Remember to fill in the forms for actual settings before making a factory reset. These forms (Settings for Unisab III 1.00) are included in the back of this manual.

Operating manual - Unisab III 002672-en 2007.09

23/37

Operating Unisab III control

1.1.11. Set values

The following tables show the different set values for pressures, temperatures and timers respectively. The stated values are minimum, maximum and factory settings.

Operating manual - Unisab III 002672-en 2007.09

24/37

Operating Unisab III control

1.2. Pressure levels and temperatures 1.2.1. Measured and calculated pressure levels - screws

Measuring Suction pressure (bar) High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown Low alarm Low shutdown Low alarm Low shutdown Low alarm Low shutdown Set point 1 Set point 2 Low alarm Low shutdown Min. 1.5 -1.0 -1.0 4.0 3.0 -1.0 1.5 1.0 0.0 0.0 1.0 0.5 0.0 0.0 1.5 1.0 1.5 1.0 0.0 0.0 1.5 1.0 0.0 0.0 0.0 0.0 Max. 9.0 6.0 6.0 24.0 22.0 -1.0 6.0 5.0 6.0 5.0 6.0 5.0 10.0 10.0 6.0 5.0 6.0 5.0 10.0 10.0 6.0 5.0 10.0 20.0 1.5 1.3 Factory 5.0 1.5 1.0 16.0 15.0 -1.0 4.0 2.5 0.0 0.0 1.5 1.2 2.5 4.0 2.0 1.5 4.0 3.0 5.5 7.0 2.0 1.5 2.5 3.0 1.0 0.7 Note 3+4+5 3+4+5 3+4+5 1+6 1+6 1+5 2+7 2+7 2+9 2+9 2+9 2+9 21 21 2+9+17 2+9+17 2+9 2+9 22 22 2+9 2+9 21 21 2+11a 2+11a

Discharge pressure (bar) Oil pressure (bar) Calculated value SAB Mk 1 compressors Oil pressure (bar) Calculated value SAB Mk 2 compressors Oil pressure (bar) Calculated value SAB Mk 3, Mk 4 compressors SAB 202, 283 Mk1, 330, 355 Mk1, FV 19, SV 24/26, FV 24/26 Oil pressure (bar) Calculated value VMY Mk 2-2.5 compressor Oil pressure (bar) Calculated value VMY Mk 3 compressors

Low alarm Low shutdown Set point 1 Set point 2 Low alarm Oil pressure (bar) Low shutdown Calculated value Set point 1 SAB 120-151 and SAB 193-355 Set point 2 Diff. pressure across oil filter (bar) High shutdown Calculated value High alarm All types except SAB 80, SAB 120-151 and SAB 193-355 Diff. pressure across oil filter (bar) High shutdown Calculated value High alarm SAB 120-151 and SAB 193-355 Low alarm Oil pressure (bar) Low shutdown Calculated value Set point 1 SAB 80 Set point 2 Diff. pressure across oil filter (bar) High shutdown Calculated value High alarm SAB 80

0.0 0.0 1.5 1.0 0.0 0.0 0.0 0.0

4.0 4.0 6.0 5.0 10.0 20.0 2.5 2.5

1.7 2.0 2.0 1.5 0.5 16.0 1.6 1.4

2+11b 2+11b 2+9 2+9 20 20 2+11a +19 2+11a +19

Table 7: Measured and calculated pressure levels - screw compressors

Operating manual - Unisab III 002672-en 2007.09

25/37

Operating Unisab III control

1.2.2. Measured and calculated temperatures - screws

Measuring High shutdown High alarm Discharge temperature (C) Low alarm Low shutdown High shutdown Oil temperature (C) High alarm All types except SAB 120-151 Low alarm and SAB 193-355 Low shutdown High shutdown Oil temperature (C) High alarm SAB 120-151 and SAB 193-355 Low alarm Low shutdown High shutdown High alarm Oil separator temperature SAB 120-151 and SAB 193-355 Low alarm Low shutdown High shutdown High alarm Process out temperature (C) Low alarm Low shutdown High shutdown Suction gas superheat (C) High alarm Low alarm Calculated value Low shutdown Low alarm Discharge gas superheat (C) Low shutdown Set point 1 Calculated value Set point 2 Min. 60.0 50.0 -65.0 40.0 30.0 10.0 0.0 40.0 30.0 10.0 0.0 40.0 30.0 0.0 0.0 -60.0 -60.0 -100.0 -100.0 6.0 5.5 0.0 0.0 5.0 0.0 0.0 0.0 Max. 130.0 120.0 -65.0 80.0 70.0 50.0 40.0 110.0 110.0 50.0 40.0 80.0 70.0 50.0 40.0 100.0 100.0 100.0 100.0 120.0 120.0 40.0 40.0 40.0 40.0 999.9 999.9 Factory 100.0 90.0 -65.0 65.0 60.0 25.0 20.0 75.0 70.0 25.0 20.0 65.0 60.0 15.0 10.0 60.0 50.0 4.0 2.0 110.0 100.0 2.0 0.0 10.0 0.0 5.0 10.0 Note 1+6 1+6 2+7 2+7 2+7 2+7 2+7 2+7 2+7 2+7

1+6 1+6 1+6 1+6 2+7+12 2+7+12 2+7+10 2+7+10 2+7+10 2+7+10 23 23

Table 8: Measured and calculated temperatures - screw compressors

Measuring User input 1 (4-20 mA)

Table 9: 4-20 m User input 1 signal

High shutdown High alarm Low alarm Low shutdown

Min. -999.9 -999.9 -999.9 -999.9

Max. 999.9 999.9 999.9 999.9

Factory 0.0 0.0 0.0 0.0

Note 3+18 3+18 3+18 3+18

Operating manual - Unisab III 002672-en 2007.09

26/37

Operating Unisab III control

1.2.3. Measured and calculated pressure levels - recips.

Measuring Suction pressure (bar) High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown Min. 1.5 -1.0 -1.0 4.0 3.0 -1.0 4.0 3.0 -1.0 -1.0 5.0 5.0 0.5 0.5 Max. 9.0 6.0 6.0 24.0 22.0 -1.0 24.0 22.0 10.0 10.0 7.0 7.0 5.0 5.0 Factory 5.0 2.5 1.5 16.0 15.0 -1.0 7.0 6.0 -1.0 -1.0 6.0 5.5 4.0 3.5 Note 3+4+5 3+4+5 3+4+5 1+6 1+6 1+5 1+6 1+6 1+6+16 1+6+16 2+5+16 2+5 2+5+14 2+5+14

Discharge pressure (bar)

Intermediate pressure (bar) Two stage compressors only

Oil pressure (bar) Calculated value

Table 10: Measured and calculated pressure levels - reciprocating compressors

1.2.4. Measured and calculated temperatures - recips.

Measuring Discharge temperature (C) High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown Low alarm Low shutdown Min. 60.0 50.0 -65.0 40.0 30.0 0.0 0.0 -60.0 -60.0 -100.0 -100.0 50.0 50.0 -20.0 -20.0 6.0 5.0 0.0 0.0 5.0 0.0 Max. 155.0 155.0 -65.0 105.0 105.0 50.0 40.0 100.0 100.0 100.0 100.0 155.0 120.0 50.0 50.0 120.0 120.0 40.0 40.0 40.0 40.0 Factory 125.0 120.0 -65.0 80.0 75.0 30.0 25.0 60.0 50.0 4.0 2.0 100.0 95.0 4.0 2.0 110.0 100.0 4.0 2.0 10.0 0.0 Note 1+6 1+6 2 2 2+7 2+7 1+6 1+6 1+6 1+6 2+7 2+7 2+7 2+7 2+7 2+7 2+7+13 2+7+13 2+7+10 2+7+10

Oil temperature (C)

Process out temperature (C)

Intermediate gas temperature (C) Two-stage compressors only Suction gas superheat (C) Calculated value Discharge gas superheat (C) Calculated value

Table 11: Measured and calculated temperatures - reciprocating compressors

Measuring User input 1 (4-20 mA)

Table 12: 4-20 m User input 1 signal

High shutdown High alarm Low alarm Low shutdown

Min. -999.9 -999.9 -999.9 -999.9

Max. 999.9 999.9 999.9 999.9

Factory 0.0 0.0 0.0 0.0

Note 3+18 3+18 3+18 3+18

Operating manual - Unisab III 002672-en 2007.09

27/37

Operating Unisab III control

1.2.5. Measured/calculated pressure levels/temp. - HPO/HPC

Measuring Suction pressure (bar) High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown High shutdown High alarm High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown High shutdown High alarm Low alarm Low shutdown Low alarm Low shutdown Min. 1.5 -1.0 -1.0 4.0 3.0 -1.0 5.0 5.0 0.5 0.5 60.0 50.0 -65.0 40.0 30.0 0.0 0.0 -20 -20 -20 -20 6.0 5.0 0.0 0.0 5.0 0.0 Max. 25.0 25.0 25.0 40.0 40.0 -1.0 7.0 7.0 5.0 5.0 170.0 170.0 -65.0 105.0 105.0 70.0 70.0 100.0 100.0 100.0 100.0 120.0 120.0 40.0 40.0 40.0 40.0 Factory 10.0 3.5 2.5 35.0 33.0 -1.0 6.0 5.5 4.0 3.5 26.0 25.2 160.0 155.0 -65.0 80.0 75.0 20.0 15.0 75.0 70.0 4.0 2.0 110.0 100.0 4.0 2.0 10.0 0.0 Note 3+4+5 3+4+5 3+4+5 1+6 1+6 1+5 2+7 2+7 1+15 1+6 1+6 2+24 2+24 2+7+24 2+7+24 1+6 1+6 1+6 1+6 2+7 2+7 2+10+13 2+10+13 2+7+10 2+7+10

Discharge pressure (bar)

Oil pressure (bar) Calculated value High diff. pressure Pc - Pe (bar) Calculated value Discharge temperature (C)

Oil temperature (C)

Process out temperature (C) Suction gas superheat (C) Calculated value Discharge gas superheat (C) Calculated value

Table 13: Measured and calculated pressure levels and temperatures - HPO/HPC

Measuring User input 1 (4-20 mA)

Table 14: 4-20 mA User input 1 signal

High shutdown High alarm Low alarm Low shutdown

Min. -999.9 -999.9 -999.9 -999.9

Max. 999.9 999.9 999.9 999.9

Factory 0.0 0.0 0.0 0.0

Note 3+18 3+18 3+18 3+18

Operating manual - Unisab III 002672-en 2007.09

28/37

Operating Unisab III control

1.2.6. Notes

Note 1 Note 2 Note 3 Note 4 Note 5 Shutdown cannot be switched off until the problem has been solved. Shutdown can be switched off immediately ( Shutdown is switched off automatically. Safety limits can be entered in bar or C/R. Shutdown monitoring active when digital output "compressor starting signal" has been selected. Shutdown monitoring always active - except when Blocked has been selected in the picture Compressor ctrl mode. Shutdown monitoring delayed 300 sec. after compressor start. Shutdown monitoring delayed 180 sec. after compressor start. Shutdown monitoring delayed 45 sec. after compressor start. A 0.0 setting prevents monitoring. 300 sec. delay, regardless of when limits are exceeded. 600 sec. delay, regardless of when limits are exceeded. The compressor must have been above 5% capacity. When below 5% capacity monitoring is prevented. Shutdown monitoring delayed 15 sec. after compressor start. 60 sec. delay, regardless of when limits are exceeded. HPO and HPC compressors only. Shutdown monitoring delayed 20 sec. after compressor start. For VMY Mk 2-2.5, calculate the following: (see Fig. 6) Oil pressure = Oil pressure 3 (after oil filter) - Discharge pressure 2. For all other compressor types (except SAB 80, see Note 20), calculate the following: Oil pressure = Oil pressure 3 (after oil filter) - Suction pressure 1. The limits are not active until Ext. inp. s. has been selected in the menu Setup / Configuration/External input. For SAB 80 the differential pressure across the oil filter is calculated as follows: (see Fig. 6) Oil filter diff. pressure = Discharge pressure 2 - Oil pressure 4 (after oil filter). The stated oil filter pressure will thus be 0.1 to 0.7 bar higher than the actual pressure loss across the filter due to the pressure loss across the oil separator and the oil cooler. 29/37 /RESET key).

Note 6

Note 7 Note 8 Note 9 Note 10 Note 11a Note 11b Note 12

Note 13 Note 14 Note 15 Note 16 Note 17

Note 18

Note 19

Operating manual - Unisab III 002672-en 2007.09

Operating Unisab III control

The maximum allowed pressure drop across the oil filter is 1.2 bar. Consequently, the alarm limit should be set between 0.8 and 1.4 bar or lower. The shutdown limit should be set between 1.1 and 1.7 bar or lower. Note 20 Set points 1 and 2 are used for shutdown monitoring of the mechanical oil pump, see Engineering manual. For SAB 80, the oil pressure is calculated as follows: (see Fig. 6) Oil pressure = Oil pressure 3 (after pump) - Suction pressure 1. The set points are only used if the compressor is equipped with an electrical oil pump. The set points are used to control the oil pump. When the differential pressure falls below set point 1, the oil pump will start. When the differential pressure exceeds set point 2 for 60 seconds, the oil pump will stop. The set points are used to control the full flow pump. When the pressure falls below set point 1, the full flow pump will start. When the pressure exceeds set point 2 for 60 seconds, the full flow pump will stop. The set points are used for liquid slugging, alarm and shutdown. This alarm/shutdown is released by a sudden decrease in discharge temperature which is greater than the liquid slugging alarm/shutdown set point for a fixed 5-second period. Set point 1 = alarm set point. Set point 2 = shutdown set point. Oil temperature settings on heat pumps should be increased to: High shutdown: 95 High alarm: 90 Low alarm: 55 Low shutdown: 50 For SABCube, the differential pressure across the oil filter is calculated as follows: (see Fig. 6): Oil filter diff.pressure = Discharge pressure 2 - Oil pressure 3 (after oil filter). The shown oil filter pressure will thus be 0.1 to max. 0.5 bar higher than the actual pressure loss across the filter due to the pressure loss across the oil separator and the oil cooler.

Note 21

Note 22

Note 23

Note 24

Note 25

Operating manual - Unisab III 002672-en 2007.09

30/37

Operating Unisab III control

1.2.7. Oil pressure calculations

SAB 80

Oil filter Oil pump Oil cooler Compressor

Oil separator

Others

Oil filter Oil pump Oil cooler Compressor

Oil separator

SABCube

Oil filter Compressor Oil cooler

Oil separator

Suction pressure Oil pressure (before compressor)

Discharge pressure Oil pressure 2 (between pump and filter)

Fig. 6: Oil pressure calculations

Operating manual - Unisab III 002672-en 2007.09

31/37

Operating Unisab III control

1.3. Timers 1.3.1. Timer values - screw compressors

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 Value Start-start delay Stop-start delay Start delay Stop delay Suction ramp Slide max. Factory Low High Unit Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Adjustable Yes Yes Yes Yes Yes Yes Yes No No No No No No Yes No No No No No No Yes Yes Yes Yes Yes Yes Yes Yes No Yes Yes Yes No No Yes No No No Yes

1200 600/60 3600 300 60 3600 300 0 3600 300 60 3600 0 0 1200 300 60 3600 10/60/0/6/50/ Prelub. 1)/2)/3)/4)/5)/6) 0 120 0 600/90/60/120 Oil flow 1)/2)/3)/4)/5)/6) --/600/0 Oil flow delay 1)/2)/3)/4) 50/0/20/10 --No oil/flow 1)/2)/3)/4)/5) 10/2/6/120/30 Lubrication time/flow 1)/2) 60/300 Differential pressure OK 60 Oil pressure low 1)/2)/3) 45/300/25 Filter differential pressure high 1)/2) 300/600 60 120 Oil temperature low 300 Oil temperature high 300 Superheating low 300 Superheating high 300 Discharge pressure overload 300 Current overload 300 Motor start 45 5 120 PMS feedback 60 10 300 F.F. Pump start 10 5 30 Oil pump start 10 5 30 Oil rectifier start 900 0 3600 Oil rectifier delay 300 0 3600 Oil rectifier disable 3600 0 7200 Start high pressure 30 0 120 No chiller 10 Capacity negative 5000 60 20000 Start unload 1)/2) 15 0 60 Low suction pressure 0 0 60 Lubricating pressure 120 Vi-pause 60 Oil log shutdown 30 0 300 Low oil flow 180 Oil circuit alarm 600 Oil circuit shutdown 900 SSSTV delay 0 0 60

Table 15: Timer values - screw compressors

Operating manual - Unisab III 002672-en 2007.09

32/37

Operating Unisab III control

Notes Timer 7 1. 2. 3. 4. 5. 6. For SAB 202, SAB Mk3 and VMY Mk3. For SAB 163 Mk1. For SV 10/20, FV 10/20, SAB 110 SR/LR, SAB 128 HR and SAB 163 HR. For SAB 283 Mk1, SAB 355 Mk1, GSV, RWF and SAB 330 B. (B is short for Booster, which can be selected in the Config. menu). For SAB 330 HP. (HP means Booster = No). For SAB 120151 and SAB 193355 prelubrication is not used.

Timer 8 1. 2. 3. 4. 5. 6. For SAB 202, SAB Mk3 and VMY Mk3. For SAB 163 Mk1. For SV 10/20 and FV 10/20 For SAB 283, SAB 355, GSV, RWF and SAB 330 B. (B is short for Booster, which can be selected in the Config. menu). For SAB 330 HP. (HP means Booster = No). For SAB 120151 and SAB 193355 prelubrication is not used.

Timer 9 1. 2. 3. 4. For SAB Mk2 110/128/163, SAB 80 and SABCube. For compressors with prelubrication delay = 0 sec. For SV 10/20 and FV 10/20. SAB 120151 and SAB 193355.

Timer 10 1. 2. 3. 4. 5. For SAB 110, 128, 163, 202 and VMY compressors. For SV 10/20 and FV 10/20. For GSV/RWF. For SAB 80. SAB 120151 and SAB 193355.

Timer 11 1. 2. For SAB 202, SAB Mk3 and VMY Mk3, SV 10/20 and FV 10/20. For SAB 163 Mk1.

Timer 13 1. 2. 3. For SAB 202, SAB Mk2, SAB Mk3, VMY, SAB 80, SAB 283 Mk1, SAB 355 Mk1, SV 10/20 and FV 10/20. For SAB 163 Mk1 SAB 120151 and SAB 193355.

Operating manual - Unisab III 002672-en 2007.09

33/37

Operating Unisab III control

Timer 14 1. 2. For all compressors except SAB 120151 and SAB 193355. For SAB 120151 and SAB 193355.

Timer 31 1. 2. For FV17/19 and FV25/26. For SAB xxx HR/SABCube.

Operating manual - Unisab III 002672-en 2007.09

34/37

Operating Unisab III control

1.3.2. Timer values - reciprocating compressors

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 Value Start-start delay Stop-start delay Start delay Stop delay Suction ramp Delay up Delay down Take-over max. Take-over delay Intermediate pressure low Filter differential pressure high Total unload Oil pressure low Oil pressure high Oil temperature low Oil temperature high Superheating low Superheating high Discharge pressure overload Current overload Motor start PMS feedback Oil cooling on Oil return Oil rectifier start Oil rectifier delay Oil rectifier disable Start high pressure No chiller Not used Not used Low suction pressure Not used Not used Not used Not used Not used Not used Not used Factory 1200 300 300 300 0 600 60 0 300 20 300 300 60 20 300 0 15 300 300 300 15 60 60 600 900 300 3600 30 10 0 Low 600/60 60 0 5 0 5 5 0 300 15 5 10 60 0 0 0 0 0 0 High 3600 3600 3600 3600 1200 1200 1200 3600 300 600 120 300 1500 1200 3600 3600 7200 120 60 Unit Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Sec. Adjustable Yes Yes Yes Yes Yes Yes Yes Yes No No No No No No No No 1)No 2)Yes No No No Yes Yes Yes Yes Yes Yes Yes Yes No Yes -

Table 16: Timer values - reciprocating compressors

Notes 1. 2. For discharge superheat For suction superheat

Operating manual - Unisab III 002672-en 2007.09

35/37

Operating Unisab III control

1.4. Spare parts 1.4.1. Spare parts for Unisab III

Item Spare parts set Display front, Sabroe logo Print cassette 85-250 VAC Cable for display front (600 mm) Cable for display front (2000 mm) Pressure transducer MSI P499AGJS 551C 1-9 bar 1) Pressure transducer MSI P499AGJS 552C 1-25 bar Pressure transducer MSI P499AGJS 553C 1-59 bar 2) Pt100 sensor 4-conductor (1/4 thread) Notes: 1) Not used for HPO/HPC compressors 2) Only used for HPO/HPC compressors Part number 1573-013 1573-012 1554-545 1554-546 1373-337 1373-338 1373-333 1373-264

Position transmitter SAB 110 S SAB 110L SAB 128 SAB 163 Cap. SAB 163 Vi SAB SAB SAB SAB SAB SAB SAB SAB SAB 202 202 202 202 81 83 85 87 89 S Cap. L Cap. S Vi L Vi

Part number 1553-298 1553-299 1553-288 1553-284 1553-285 1373-296 1373-295 1373-301 1373-297 1373-273 1373-274 1373-275 1373-276 1373-277 1373-057 1373-061

SAB 283 Mk1 Cap. SAB 283 Mk1 Vi

Operating manual - Unisab III 002672-en 2007.09

36/37

Operating Unisab III control

Position transmitter for new SAB (RWF) compressors Description Aluminium tube for LS Linear transmitter (2) LS Volume trans- Indicator rod mitters for SS Linear transmitter (1) SS Capacity transmitters SAB 193 SAB 233 SAB 283 SAB 355 534D1251H02 534D1251H02 534D1251H02 534D1251H02 534D1251H03 534D1251H02 534D1251H02 534D1251H02

534C1314H01 534C1314H01 534C1314H02 534C1314H03 534C1478H02 534C1478H02 534C1478H02 534C1478H02

(1) Short stroke, without well. Short stroke linear transmitter assembly, with well: 534C1478H01. (2) Long stroke, without well. Long stroke linear transmitter assembly, with well: 534D1251H01.

Position transmitter for new SAB (XJS, SJF) compressors Description Indicator rod for SS Linear transmitter (3) SS SAB 120 534B0987H01 534C1552H02 SAB 151 534B0872H01 534C1552H02

(3) Short stroke, without well. Short stroke linear transmitter assembly, with well: 534C1552H01.

Operating manual - Unisab III 002672-en 2007.09

37/37

Date: __________ Init.: __________

Settings for Unisab III 1.00

Customer: End user:

Compressor shop no.: Local compr. no. : ROC no.: Order no.: Plant type: Compressor type: Software version/date: Set up >Compr. Control Function Setting Mode Control On Capacity controller Auto Start Auto Stop Cold Store Climate Compensation Multisab master Set up >Sequencing Function Start no System no System controller

No 1 2 3 4 5 6 7 8

No 1 2 3

Setting

Setup> Configuration>Calibrate >Press transducer Suction Adjust Discharge Adjust Oil Adjust Diff./Imed Adjust Oil. Adjust Eco Adjust >Process out Temp. Process out Adj >Position Cap. Pos Cap. Zero Ad Cap. 100 Adj Vi Position Vi. Zero Adj Vi. 100 Adj >Motor Freq Motor Freq Frq. Zero Adj Freq. 100 Adj

Page 1/4

Settings for Unisab III 1.00

Setup>Configuration No. 1 2 3 4 5 6 7 8 >Drive Function Motor range Amp Motor range KW Motor nom kW Display Motor input signal Rotatune Motor rpm min. Motor rpm max. Setting No. 1 2 3 4 5 6 7 8 >Oil system Function Oil pump Full Flow Pump Oil Cooling Oil controller Water Cooling Oil Rectifier Sep.Vel.Ref Sep.Vel.CR Setting No. 1 2 3 4 5 6 >Communication Function Setting Compressor Baud rate Profibus Profi. node no. Profi. baud rate GSD file no.

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

>Compressor block Function Setting Compressor Type Swept Volume Volume Ratio Vi Low Range Vi Mode % Mech. Zero Manual Zero Booster Economizer Eco Low Cap. Neutral zone Eco High Suction Unloading Unload assist Cap.decr.assist rate Volume dead band >Plant Function Refrigerant Compressor Start System Common Evap/Cond HP on Two Stage High Limit Take Over COP Active Chiller Flow factor Liquid subcool

No. 1 2 3 4

>Measuring Function Press./Temp. Pressure range Low Suct. Press Capacity signal >Aux output Function Activate when Signal Low Signal High

Setting

No. 1 2 3

Setting

1 2 3

>External (user 1) input Function 4 mA 20 mA

No. 1 2 3 4 5 6 7 8 9 10 11 12

Setting Setup>Session Language

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14

>Dig. In Via Profibus Function Dig. Input 1 Dig. Input 2 Dig. Input 3 Dig. Input 4 Dig. Input 5 Dig. Input 6 Dig. Input 7 Dig. Input 8 Dig. Input 9 Dig. Input 10 Dig. Input 11 Dig. Input 12 Dig. input 13 Dig. Input 14

No. 1

>Factory reset Function Factory reset

Setting

Setup>Configuration>R000 Temp C/R -90 -85 -80 -75 -70 -65 -60 -55 -50 -45 -40 -35 Press Bar Temp C/R -30 -25 -20 -15 -10 -05 00 05 10 15 20 25 Press Bar Temp C/R 30 35 40 45 50 55 60 65 70 75 80 Press Bar

Page 2/4

Settings for Unisab III 1.00

Setup>Timers>Timers Setup No.

01

(1)

Function

Start-Start Delay

Setting

No.

13

Function

Oil Pressure Low (*S) Oil Pressure Low (*R) Filter diff high (*S) Oil press high (*R) Oil Temp Low Oil Temp High Superheat Low Superheat High Disch Press O/load Current Overload

Setting

45/300/25

No.

25

Function

Oil Rect. Start

Setting

60 300 20 300 300 0 300 15 300 300 26 27 28 29 30 31 Oil Rect. Pause Oil Rect. Disable Start HP No Chiller Cap. Negative (*S) Start Unload (*S) 10

02 03 04 05 06 07

Stop-Start Delay Start Delay Stop Delay Suction Ramp Slide Max (*S) Delay Up (*R) Pre lubrication (*S) Delay Down (*R) Oil Flow (*S) Transfer max (*R) Oil Flow Delay (*S) Take Over Delay (*R) No Oil Flow (*S) Interm Press Low (*R) Lub time/flow (*S) Filter Diff High (*R) Diff press OK (*S) Total unload (*R)

14 15 16 17 18 10/60/0/6/ 50/0 600/90/60/ 120/600/0 50/0/20/10 21 300 10/2/6/120 /30 20 60/300 300 60 24 23 22 19

08

20

300

32

Low suct. press

09

Motor Start

33

Lub Pressure (*S)

145

10

PMS Feedback

34

Vi pause

(*S)

60

11

F.F. Pump Start(*S) Oil Cool On (*R) Oil Pump Start(*S) Oil Return (*R)

35 36 37 38 39

Oil Log Shutdown (*S) Low Oil Flow (*S) Oil Cir. Alm (*S) Oil Cir. Shutdown (*S) SSSTV delay

60 180 600 900

12

Setup>Timers>P Band Factor (1) Delay Up (*R)

Setup>Timers>Transfer (1) Factor Down (*R) Zone (*R)

Setup>Timers>Take Over (1) Factor Up (*R)

Delay Down (*R) Start Delay Stop Delay

Factor Start (*R) Zone (*R)

Setup>Service>Maintenance Estimated compressor main service Hour counter Time to next main service C Time to next part service B Time to next part service A

Page 3/4

Settings for Unisab III 1.00

Control values> Alarm-/Shutdown Limits & Regulator Settings (1) Suction>Suction pressure [C/R] Suction>Suction superheat Discharge>Disch. pressure [C/R] Discharge>Disch. Temperature Discharge>Disch. Superheat High Shut down High Low Alarm Alarm Low Shut down SP No. 1 SP No. 2 NZ PB T. Integ. T. Diff. MIN PULS RUN TIME

Oil>Oil pressure Oil>Oil filter pressure (*S) Oil>Oil temperature Oil>Oil separator temperature (*S) Motor>Motor current Motor>Motor Power Capacity>Capacity (*S) Capacity>Vi Position (*S) Process temp>Process out temp User> User input 1 Intermediate>Interm. pres. [C/R] (*R) Intermediate>Interm. temperature (*R)

Notes: (*S) = Screw, (*R) = Reciprocating (1) The value(s) will be changed to factory settings by a Factory reset.

Page 4/4

Date: _____________

Init.: _____________

2007.07

Diagnosis for Unisab III

Customer: Compressor shop no. __________________ __________________ Order no.: Compressor type: _____________ _____________ Unit Text Text Text Text 0-14 Text Diagnosis Digital Digital input output

History Shutdowns Control state Alarm text (type of alarm) Date and time of alarm Compressor mode Compressor status Start Multisab state History shutdowns Measured values Suction temp. Suction press. Suction superheat Discharge temp. Discharge press. Discharge superheat Oil temp. Oil press. Capacity Vi slide pos. (S) Motor rev. Motor current Motor power Oil filter press. (S) Process out temp. User input 1 Oil sep. temp. Intermediate press. (R) Intermediate temp. (R) Notes: (S) = Screw compressors (R) = Reciprocating compressors Current operating conditions

Current operating conditions

Unit C C/R C C C/R C C Bar % % rpm Amp. kW Bar C % C C/R C

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Input

Output

1/1

Você também pode gostar

- Unisab III 1.08 Operating en 2010 10Documento48 páginasUnisab III 1.08 Operating en 2010 10Fabio Splendor0% (5)

- Unisab III 1.08 Operating en 2010 10Documento48 páginasUnisab III 1.08 Operating en 2010 10Matheus MonteiroAinda não há avaliações

- Unisab-III-1.10 Operating 2013-10 en PDFDocumento56 páginasUnisab-III-1.10 Operating 2013-10 en PDFRadwan AL TrougAinda não há avaliações

- Sullair Supervisor Controller Manual - 02250146-049Documento32 páginasSullair Supervisor Controller Manual - 02250146-049martin_jaitman82% (11)

- HIMOINSA Manual CEM 6 PRO Monitoring and ControlDocumento83 páginasHIMOINSA Manual CEM 6 PRO Monitoring and ControlLuis Jesus88% (8)

- M1 Series - PCDocumento18 páginasM1 Series - PCAbdalhakeem AlturkyAinda não há avaliações

- As-002 C enDocumento78 páginasAs-002 C enkfathi5550% (2)

- Arburg 221 ManualDocumento92 páginasArburg 221 ManualZeljko Djukic73% (15)

- Air Pilot Electronic Unit Operating InstructionsDocumento10 páginasAir Pilot Electronic Unit Operating Instructionsmohamed100% (2)

- M1 Series - DM M1 Series - Digital Manometer User ManualDocumento17 páginasM1 Series - DM M1 Series - Digital Manometer User ManualVro JackAinda não há avaliações

- AirMaster P1ÄÜÆ® Ñ (¿ ®) PDFDocumento10 páginasAirMaster P1ÄÜÆ® Ñ (¿ ®) PDFkaduz800% (1)

- Cams 1v-2p ManualDocumento48 páginasCams 1v-2p Manualjoecentrone100% (2)

- Frigo 76 Ireland ManualDocumento78 páginasFrigo 76 Ireland ManualPrasanna GopalrathinamAinda não há avaliações

- 6230 5537 70 Ed00 (EN)Documento32 páginas6230 5537 70 Ed00 (EN)sebastianAinda não há avaliações

- Manuel D'installation Et D'utilisationDocumento96 páginasManuel D'installation Et D'utilisationSébastien AndrienAinda não há avaliações

- Operation and Maintenance Manual: Lincon Electric At050514#Documento31 páginasOperation and Maintenance Manual: Lincon Electric At050514#jorgeAinda não há avaliações

- Operation and Maintenance Manual For ModelsDocumento33 páginasOperation and Maintenance Manual For ModelstgffcgfgAinda não há avaliações

- Load Moment Indicator Operators Manual: Serial No.: 55M1258EOADocumento15 páginasLoad Moment Indicator Operators Manual: Serial No.: 55M1258EOAlinagarcia28Ainda não há avaliações

- Automatic Mains Failure: Mcpherson ControlsDocumento21 páginasAutomatic Mains Failure: Mcpherson ControlsAmir DillawarAinda não há avaliações

- Universal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysDocumento21 páginasUniversal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysBrianHazeAinda não há avaliações

- APM Basic manual-C2TX Extruder With BPV & RTCDocumento20 páginasAPM Basic manual-C2TX Extruder With BPV & RTCwagtail8520Ainda não há avaliações

- MR Service ManualDocumento42 páginasMR Service ManualqdzungAinda não há avaliações

- Mh6n Mh12n ManualDocumento4 páginasMh6n Mh12n ManualMelissa Porter100% (3)

- CNC Turning Redone v2Documento52 páginasCNC Turning Redone v2timoshAinda não há avaliações

- In-NT - Operator GuideDocumento13 páginasIn-NT - Operator GuidesdiamanAinda não há avaliações

- Ic-2200 UmDocumento11 páginasIc-2200 UmAlexeyAinda não há avaliações

- Manual Solarni Regulator Cm3024z 12 24v30a S LCDDocumento7 páginasManual Solarni Regulator Cm3024z 12 24v30a S LCDJaime Andres Villegas Mansilla100% (1)

- Air Control 4: User ManualDocumento32 páginasAir Control 4: User ManualMesafint kassieAinda não há avaliações

- Screw Air Compressor User ManualDocumento32 páginasScrew Air Compressor User ManualToussaint67% (3)

- Harsen GU611A-EN0724 PDFDocumento34 páginasHarsen GU611A-EN0724 PDFSteven J Baynes100% (2)

- Rotary Screw Air Compressor ManualDocumento44 páginasRotary Screw Air Compressor ManualHugh O'Brien Gwaze100% (1)

- PDF MH MSC 12 PFCPDF DDDocumento21 páginasPDF MH MSC 12 PFCPDF DDHardi NusantaraAinda não há avaliações

- InteliCompact NT Operator Guide 8 2016Documento13 páginasInteliCompact NT Operator Guide 8 2016GiangDoAinda não há avaliações

- InteliCompact NT Operator Guide 8 2016Documento13 páginasInteliCompact NT Operator Guide 8 2016Everton SilvaAinda não há avaliações

- RG-T en A2936 R2Documento4 páginasRG-T en A2936 R2Noureddine LingburgAinda não há avaliações

- Manual Micro Compressor Controller (MCC)Documento19 páginasManual Micro Compressor Controller (MCC)sebastianAinda não há avaliações

- Bilgmon488 Instruction ManualDocumento25 páginasBilgmon488 Instruction ManualÖzgürMetinAinda não há avaliações

- Unisab II (0178-449-ENG-logo)Documento224 páginasUnisab II (0178-449-ENG-logo)Jorgr NúñezAinda não há avaliações

- LMI НС3926 PDFDocumento45 páginasLMI НС3926 PDFГригорий Григорян100% (3)

- Mpu 4 ManDocumento44 páginasMpu 4 ManmagicchrisAinda não há avaliações

- ABB Controller IM - C501 - 10.manual (SLPC) PDFDocumento108 páginasABB Controller IM - C501 - 10.manual (SLPC) PDFsimansonAinda não há avaliações

- CMD 2 ManualDocumento30 páginasCMD 2 ManualAbdul Manan60% (5)

- Short Operating Manual ALLROUNDER 221 KDocumento92 páginasShort Operating Manual ALLROUNDER 221 Km asifAinda não há avaliações

- ES4000 Basic-2Documento16 páginasES4000 Basic-2Travis RaboinAinda não há avaliações

- Gu601a En0507 PDFDocumento30 páginasGu601a En0507 PDFChhoan Nhun100% (2)

- GCM01 Mu GB 12.2Documento33 páginasGCM01 Mu GB 12.2carrettiAinda não há avaliações

- Mounting Instructions / Manual MV1171Documento21 páginasMounting Instructions / Manual MV1171leonardseniorAinda não há avaliações

- Aimil LTD.,: The Troubleshooting Manual Compression Testing MachineDocumento6 páginasAimil LTD.,: The Troubleshooting Manual Compression Testing Machinevasudeva yasasAinda não há avaliações

- Topcon X20 Monitor Instructions 2013Documento35 páginasTopcon X20 Monitor Instructions 2013Chan TkfcAinda não há avaliações

- AGC-4 Operator's Manual 4189340690 UK - 2012.07.13Documento21 páginasAGC-4 Operator's Manual 4189340690 UK - 2012.07.13Felipe LimaAinda não há avaliações

- CM2A/3A Series: User'S ManualDocumento26 páginasCM2A/3A Series: User'S ManualPIKO MOBAinda não há avaliações

- Curtis Se Controller ManualDocumento30 páginasCurtis Se Controller ManualSousaFV89% (9)

- 1021Documento14 páginas1021VenkiBolla50% (2)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneAinda não há avaliações

- Introduction to the simulation of power plants for EBSILON®Professional Version 15No EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Ainda não há avaliações

- Nikon D500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo EverandNikon D500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsAinda não há avaliações

- The Complete Guide to Olympus' E-m1 - Firmware 2.0 ChangesNo EverandThe Complete Guide to Olympus' E-m1 - Firmware 2.0 ChangesAinda não há avaliações

- Fujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo EverandFujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- BE Spec Quantum HD 201202 PressQuality PDFDocumento4 páginasBE Spec Quantum HD 201202 PressQuality PDFPedro BancayanAinda não há avaliações

- RS-F4 Series Pressure Switches: Product DatasheetDocumento2 páginasRS-F4 Series Pressure Switches: Product DatasheetPedro BancayanAinda não há avaliações

- BE Spec Quantum HD 201202 PressQuality PDFDocumento4 páginasBE Spec Quantum HD 201202 PressQuality PDFPedro BancayanAinda não há avaliações

- ETX Proto - 50 1J028 1000 - 200Documento38 páginasETX Proto - 50 1J028 1000 - 200Pedro BancayanAinda não há avaliações

- Chapt - 4 CHLORINE DIOXIDE PDFDocumento41 páginasChapt - 4 CHLORINE DIOXIDE PDFRaul Tixe100% (4)

- PLUS+1 Mobile Machine Displays: DP250 SeriesDocumento4 páginasPLUS+1 Mobile Machine Displays: DP250 SeriesPedro BancayanAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- PLUS+1 Mobile Machine Displays: DP250 SeriesDocumento4 páginasPLUS+1 Mobile Machine Displays: DP250 SeriesPedro BancayanAinda não há avaliações

- ABB ACH 550 Technical User ManualDocumento456 páginasABB ACH 550 Technical User ManualPedro BancayanAinda não há avaliações

- Frick Quantum™ LX/HD System Interface Panel: Installation-Operation-MaintenanceDocumento24 páginasFrick Quantum™ LX/HD System Interface Panel: Installation-Operation-MaintenancePedro BancayanAinda não há avaliações

- 120/240 VAC 75 W Transformer 639A0130H02Documento1 página120/240 VAC 75 W Transformer 639A0130H02Pedro BancayanAinda não há avaliações

- Manual BT-50 enDocumento146 páginasManual BT-50 enluig7291% (32)

- Como Probar Sensor de Ambient e SplitDocumento7 páginasComo Probar Sensor de Ambient e SplitLuis CansinoAinda não há avaliações

- ETX Proto - 50 1J028 1000 - 200Documento38 páginasETX Proto - 50 1J028 1000 - 200Pedro BancayanAinda não há avaliações

- Maual de Servico Chiller OldDocumento88 páginasMaual de Servico Chiller OldPedro BancayanAinda não há avaliações

- Frick Quantum LXDocumento104 páginasFrick Quantum LXPedro BancayanAinda não há avaliações

- Klippon POK - Polyester EnclosuresDocumento19 páginasKlippon POK - Polyester EnclosuresPedro BancayanAinda não há avaliações

- Schematic Diagram - Main Section (1/3) - : (Mode:Play)Documento4 páginasSchematic Diagram - Main Section (1/3) - : (Mode:Play)Pedro BancayanAinda não há avaliações

- Designing Switching Voltage Regulators With The TL494Documento29 páginasDesigning Switching Voltage Regulators With The TL494Fabrício Angiene100% (1)

- Trasformadores para Sistema de Salida de AudioDocumento17 páginasTrasformadores para Sistema de Salida de AudioPedro BancayanAinda não há avaliações

- Board Set Conversion DBS - 3Documento5 páginasBoard Set Conversion DBS - 3Pedro BancayanAinda não há avaliações

- LG 47LW6500 LT12C Led LCDDocumento104 páginasLG 47LW6500 LT12C Led LCDFilipe AmaroAinda não há avaliações

- LogMan II. Reefer Container Monitoring. Users Manual. Transportation SolutionsDocumento25 páginasLogMan II. Reefer Container Monitoring. Users Manual. Transportation SolutionsPedro BancayanAinda não há avaliações

- LogmanDocumento7 páginasLogmanPedro BancayanAinda não há avaliações

- Operating Manual Version 2 7 PDFDocumento338 páginasOperating Manual Version 2 7 PDFPedro BancayanAinda não há avaliações

- Mcr8Sd, Mcr8Sm, Mcr8Sn Sensitive Gate Silicon Controlled RectifiersDocumento9 páginasMcr8Sd, Mcr8Sm, Mcr8Sn Sensitive Gate Silicon Controlled RectifiersPedro BancayanAinda não há avaliações

- Oscilloscope Tutorial PDFDocumento5 páginasOscilloscope Tutorial PDFPedro BancayanAinda não há avaliações

- York Air Cooled Screw Liquid Chillers (Style G)Documento120 páginasYork Air Cooled Screw Liquid Chillers (Style G)Braun-installations100% (1)

- Haier HL42BG-B LCD TV SM PDFDocumento43 páginasHaier HL42BG-B LCD TV SM PDFPedro BancayanAinda não há avaliações

- Sauer Shipping enDocumento12 páginasSauer Shipping enJH Prima MudaAinda não há avaliações

- CEO Corner New Products Powerful Pocket SimulatorDocumento23 páginasCEO Corner New Products Powerful Pocket SimulatorMOHAMMA MUSAAinda não há avaliações

- Flash Tank Heat Recovery Boiler BookDocumento6 páginasFlash Tank Heat Recovery Boiler Bookfauzi endraAinda não há avaliações

- Catalogue Water Cooled Screw ENG FDocumento44 páginasCatalogue Water Cooled Screw ENG FAdolfo PerezAinda não há avaliações

- Hydrate Plug in Oil Dominated Systems by OLGADocumento10 páginasHydrate Plug in Oil Dominated Systems by OLGAmahmoodnazeriAinda não há avaliações

- Flowserve Seal PDFDocumento28 páginasFlowserve Seal PDFSamir Benabdallah100% (1)

- 1 Colmac DX Ammonia Piping Handbook 4th EdDocumento64 páginas1 Colmac DX Ammonia Piping Handbook 4th EdAlbertoAinda não há avaliações

- IR CompressorDocumento30 páginasIR CompressorkingofngayeAinda não há avaliações

- AnnisaS2 MDY OptimizingCommissioningSchedulingEPCCIndustryProjectsbyDocumento9 páginasAnnisaS2 MDY OptimizingCommissioningSchedulingEPCCIndustryProjectsbyAniketsingh MundlothAinda não há avaliações

- Safety Features For Oil and Gas SeparatorsDocumento2 páginasSafety Features For Oil and Gas SeparatorsHubert Davis100% (1)

- Investigation of Multiphase Metering Systems and MeasuringDocumento91 páginasInvestigation of Multiphase Metering Systems and MeasuringMD Redwan IslamAinda não há avaliações

- Working Instructions 32 - 40Documento466 páginasWorking Instructions 32 - 40Carlos GuerraAinda não há avaliações

- TM - Mini VRF ODU BDocumento123 páginasTM - Mini VRF ODU BDelpoAinda não há avaliações

- B2 WorkingInstructionsDocumento635 páginasB2 WorkingInstructionsWagner GuimarãesAinda não há avaliações

- CNPCIC Field Production Test Separator GuideDocumento18 páginasCNPCIC Field Production Test Separator Guidesalahadine maideAinda não há avaliações

- Ba00294pen 1513 PDFDocumento96 páginasBa00294pen 1513 PDFJigyesh SharmaAinda não há avaliações

- Air Lift PumpDocumento23 páginasAir Lift PumpFrancisco OppsAinda não há avaliações

- Aeon 9000spDocumento2 páginasAeon 9000spSergiSerranoAinda não há avaliações

- Separation of Ammonia and WaterDocumento5 páginasSeparation of Ammonia and WaterJamie MaloneAinda não há avaliações

- GDF FiltersDocumento8 páginasGDF FiltersFati ZoraAinda não há avaliações

- Oil Manual Rev 01Documento149 páginasOil Manual Rev 01Djamel Ait MohamedAinda não há avaliações

- Biogas in DistilleryDocumento6 páginasBiogas in Distillerysatnam1979Ainda não há avaliações

- Reservoir Fluid Sampling Techniques ExplainedDocumento7 páginasReservoir Fluid Sampling Techniques Explainedl3gsdAinda não há avaliações

- Futur TBT 4380966 01Documento76 páginasFutur TBT 4380966 01Carlos David Obando0% (1)

- Post Applied For: FIELD OPERATOR: E-Mail IDDocumento6 páginasPost Applied For: FIELD OPERATOR: E-Mail IDDIJUAinda não há avaliações

- BITZER Output data summaryDocumento10 páginasBITZER Output data summarySaša ColićAinda não há avaliações

- TB1-004 Boiler Water CarryoverDocumento2 páginasTB1-004 Boiler Water Carryoverjesus_manrique2753100% (2)

- Types of EvaporatorsDocumento12 páginasTypes of Evaporatorsapi-377437388% (8)

- DNVPS Fuel Testing Procedures Part 1Documento23 páginasDNVPS Fuel Testing Procedures Part 1KaiAinda não há avaliações

- Interface Level Measurement Displacer and DP TransmitterDocumento4 páginasInterface Level Measurement Displacer and DP TransmitterBobismy Alterego Bob100% (2)