Escolar Documentos

Profissional Documentos

Cultura Documentos

CS-2001-01 PT Titus Air Sedang LPG

Enviado por

io1_roDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CS-2001-01 PT Titus Air Sedang LPG

Enviado por

io1_roDireitos autorais:

Formatos disponíveis

CS-2001-01, rev 1.

doc

PT Titis Sampurna Air Sedang Project, Sumatra, Indonesia. LPG Production Plant.

Project Value: Year Completed:

$6,500,000 2001

Introduction

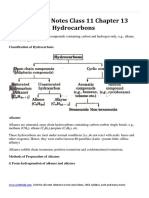

Meeting the increasing Indonesian demand for LPG, PT Titis Sampurna developed a remote gas field in Sumatra for LPG production. Due to the remote nature of the site the entire plant has been skid mounted. Top Level (background) and Bottom Level of Gas Dewpoint Package

Plant Summary

Gas Dewpoint Package

LPG Production Plant

The condensate stream from the LTS is sent to the Deethaniser Column, along with the liquid stream from the plants Inlet Separator.

This plant consists of the The gas enters the plant through following major equipment a Gas/Gas Heat Exchanger and a Propane Chiller, which reduces items: the gas temperature to 25 C. Gas Dewpoint Skid. Both of these exchangers are LPG Recovery and Purification. designed with MEG (Mono Propane Refrigeration. Ethylene Glycol) injection to prevent hydrate formation. MEG Regenerator.

The vapour from the Deethaniser is compressed and joins with the product gas from the Gas/Gas Exchanger The gas then enters the Low before entering the pipeline. Thermal Oil Package. Temperature Separator (LTS) The bottoms from the Vessel. Deethaniser enter the The gas from the LTS passes Depropaniser Column. Process Details back through the Gas/ Gas Heat The LPG product is taken Exchanger, the Condensate from the top of the column Plant Throughput: passes onto the LPG Production while the stabilised Gas: 28MMSCFD Package and the MEG/Water condensate from the bottom phase is sent to the MEG is then cooled and sent to Condensate: 282 t/day storage. Regeneration Package. Product Gas: 27MMSCFD LPG Production: 190 t/day Stabilised Cond: Gas Water Cont: 1555 bbl/day 9 lb/MMSCF

Process Group, 2007

CS-2001-01, rev 1.doc

MEG Regeneration Package

The MEG Regeneration Package regenerates 4,060 kg/hr of rich MEG from 76-wt% to 80 wt%.

Propane Refrigeration Package

This Package is designed to provide 1660 kW of refrigeration duty for the Gas Chiller, supplying the propane at 34 C.

Hot Oil Package

MEG Regeneration Package

The Hot Oil Package is designed to provide 3600 kW of heating duty High LPG Recovery for both the Deethaniser and Using large counter-current Depropaniser Reboilers. gas/gas exchangers and maximising the recovery of cold Plant Features from the recovered LPG has Features of this plant include: resulted in high LPG recovery efficiencies while minimising the size of the external propane refrigeration package.

MEG Injection.

Utilising MEG injection to prevent hydrate formation through the gas-chilling phase prevents the need for large and expensive dehydration equipment. In this manner the water is removed simultaneously in the plants LTS.

Partially assembled Gas Dewpoint Package

Process Group, 2007

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- ISO Hazard Checklist (WW) IDM UpdateDocumento6 páginasISO Hazard Checklist (WW) IDM UpdateKelly Lawson100% (1)

- KAMAX - Bolt and Screw CompendiumDocumento60 páginasKAMAX - Bolt and Screw Compendiumjzaw65Ainda não há avaliações

- KAMAX - Bolt and Screw CompendiumDocumento60 páginasKAMAX - Bolt and Screw Compendiumjzaw65Ainda não há avaliações

- GSP 01 PDFDocumento2 páginasGSP 01 PDFarielAinda não há avaliações

- UpRight LX-31-41-50 Service Manual PDFDocumento148 páginasUpRight LX-31-41-50 Service Manual PDFJankoAinda não há avaliações

- Roof Equipment, Elevator, and Boiler Safety RequirementsDocumento212 páginasRoof Equipment, Elevator, and Boiler Safety RequirementsAngel Franz DeLima ReañoAinda não há avaliações

- Guidelines and Case-Studies On The Use of 3D Printing in VET EducationDocumento37 páginasGuidelines and Case-Studies On The Use of 3D Printing in VET Educationio1_roAinda não há avaliações

- 2015 Organic Farming ReprapDocumento17 páginas2015 Organic Farming Reprapio1_roAinda não há avaliações

- Introduction To 3D PrintingDocumento56 páginasIntroduction To 3D Printingio1_roAinda não há avaliações

- Curricula of A 3D Printing CourseDocumento15 páginasCurricula of A 3D Printing Courseio1_roAinda não há avaliações

- Mae5230 CFD Intro Notes PDFDocumento17 páginasMae5230 CFD Intro Notes PDFDebabrata PaulAinda não há avaliações

- Ab Plastic Injector Comparison ChartDocumento1 páginaAb Plastic Injector Comparison Chartio1_roAinda não há avaliações

- Romania Country ProfileDocumento6 páginasRomania Country Profileio1_roAinda não há avaliações

- ARTROMOT-K3 Operation ManualDocumento10 páginasARTROMOT-K3 Operation Manualio1_roAinda não há avaliações

- EvaluaEvaluation of A Short-Run Injection Molding Processtion of A Short-Run Injection Molding Process With SomosDocumento18 páginasEvaluaEvaluation of A Short-Run Injection Molding Processtion of A Short-Run Injection Molding Process With Somosio1_roAinda não há avaliações

- It Will Be Awesome If They Don'T Screw It UpDocumento16 páginasIt Will Be Awesome If They Don'T Screw It UpJeferson ChristhAinda não há avaliações

- CNC Machine Feedback Devices and Positioning SystemsDocumento6 páginasCNC Machine Feedback Devices and Positioning Systemsio1_ro100% (1)

- Megatron Injection Machine: Industrial Arts Supply CompanyDocumento1 páginaMegatron Injection Machine: Industrial Arts Supply Companyio1_roAinda não há avaliações

- Development of Small Injection Moulding Machine For Forming Small Plastic Articles For Small-Scale IndustriesDocumento13 páginasDevelopment of Small Injection Moulding Machine For Forming Small Plastic Articles For Small-Scale Industriesio1_roAinda não há avaliações

- Creative DirectionsDocumento40 páginasCreative Directionsio1_roAinda não há avaliações

- CiS Brochure Oil GasDocumento2 páginasCiS Brochure Oil Gasio1_roAinda não há avaliações

- Teamviewer BrochureDocumento10 páginasTeamviewer BrochurecristianAinda não há avaliações

- Steam Fired EuropeDocumento8 páginasSteam Fired Europeio1_roAinda não há avaliações

- ATI Oil & Gas Brochure Rev FINDocumento12 páginasATI Oil & Gas Brochure Rev FINio1_roAinda não há avaliações

- CAM GuideDocumento10 páginasCAM Guideio1_roAinda não há avaliações

- Acid Gas RemovalDocumento2 páginasAcid Gas Removalio1_roAinda não há avaliações

- Illustrated Product Catalogue Major ProjectsDocumento26 páginasIllustrated Product Catalogue Major Projectsio1_roAinda não há avaliações

- Acid Gas RemovalDocumento2 páginasAcid Gas Removalio1_roAinda não há avaliações

- Acid Gas RemovalDocumento2 páginasAcid Gas Removalio1_roAinda não há avaliações

- Norsok ST 2001Documento131 páginasNorsok ST 2001mamounsdAinda não há avaliações

- GE Air Cooled Heat EschangersDocumento11 páginasGE Air Cooled Heat Eschangerssammar_10Ainda não há avaliações

- Data For SeparatorsDocumento1 páginaData For Separatorsio1_roAinda não há avaliações

- Internals For Glycol Dehydration SystemsDocumento6 páginasInternals For Glycol Dehydration Systemsio1_roAinda não há avaliações

- LPG BULK INSTALLATIONS AND PIPEWORK TOPIC PACKDocumento67 páginasLPG BULK INSTALLATIONS AND PIPEWORK TOPIC PACKASKOKO100% (1)

- Turky PPT PDFDocumento30 páginasTurky PPT PDFSanjai bhadouriaAinda não há avaliações

- Chemistry Notes Class 11 Chapter 13 HydrocarbonsDocumento26 páginasChemistry Notes Class 11 Chapter 13 HydrocarbonsShashank PratapAinda não há avaliações

- Acts Igures: Excise Tax On Petroleum Products in The PhilippinesDocumento2 páginasActs Igures: Excise Tax On Petroleum Products in The PhilippinesAlanAinda não há avaliações

- Visit To LPG PlantDocumento6 páginasVisit To LPG PlantOsama HasanAinda não há avaliações

- Authority Submission For Industrial Equipment Design and CommissioningDocumento23 páginasAuthority Submission For Industrial Equipment Design and CommissioningJess Goh100% (1)

- B21 5530 EnglishDocumento20 páginasB21 5530 EnglishWillianAinda não há avaliações

- Safety-Super Gas - LPG MSDS PDFDocumento2 páginasSafety-Super Gas - LPG MSDS PDFatripathi2009Ainda não há avaliações

- IP Research Report - Ignition Probability Review Model Devel PDFDocumento146 páginasIP Research Report - Ignition Probability Review Model Devel PDFjiaolei9848100% (1)

- Oisd 1444Documento120 páginasOisd 1444Vivek HarshanshulAinda não há avaliações

- ACEA Pocket Guide 2016 2017Documento78 páginasACEA Pocket Guide 2016 2017Catalin LecaAinda não há avaliações

- Man L2832a EngineDocumento5 páginasMan L2832a EngineNam Anh TrầnAinda não há avaliações

- Environment Protection Act Multiple Choice QuestionsDocumento10 páginasEnvironment Protection Act Multiple Choice Questionsபெரியகருப்பையா0% (1)

- SEEMPDocumento19 páginasSEEMPswapneel_kulkarniAinda não há avaliações

- Victrix Tera 24 PlusDocumento56 páginasVictrix Tera 24 Plusadi angAinda não há avaliações

- SOP-017-Testing of Specific Gravity of CondensateDocumento9 páginasSOP-017-Testing of Specific Gravity of CondensateAmnaKamranAinda não há avaliações

- Minutes of Meeting SMPV GCR Review With Annex PDFDocumento22 páginasMinutes of Meeting SMPV GCR Review With Annex PDFsri kanthAinda não há avaliações

- Heating ValuesDocumento2 páginasHeating ValuesBikal PokharelAinda não há avaliações

- ST Vincent Vs LPG RefillerDocumento9 páginasST Vincent Vs LPG RefillerKlariz Dee CeeAinda não há avaliações

- Unit 5 - Mineral Resources What Are Minerals?: Pakistan StudiesDocumento13 páginasUnit 5 - Mineral Resources What Are Minerals?: Pakistan StudiesTaha YousafAinda não há avaliações

- Glossary of energy and financial termsDocumento2 páginasGlossary of energy and financial termsJoseAndresCarreñoAinda não há avaliações

- How NITCO delivers answers through innovation and local focusDocumento45 páginasHow NITCO delivers answers through innovation and local focusSudhir YadavAinda não há avaliações

- Mumbai Municipal Corporation Water Charges and Sewerage Rules 2015-16Documento70 páginasMumbai Municipal Corporation Water Charges and Sewerage Rules 2015-16shivam jagtapAinda não há avaliações

- Chapter 1Documento5 páginasChapter 1Sehrish ZaidiAinda não há avaliações

- Alfa Catalog Pro US CompressedDocumento21 páginasAlfa Catalog Pro US CompressedChris-Mench TanAinda não há avaliações

- FUEL GAS PIPING STANDARDSDocumento38 páginasFUEL GAS PIPING STANDARDSLi ReAinda não há avaliações