Escolar Documentos

Profissional Documentos

Cultura Documentos

Kydex TB 140-A Fundamentalsofthermoforming 061412

Enviado por

Lyle HornbakerTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Kydex TB 140-A Fundamentalsofthermoforming 061412

Enviado por

Lyle HornbakerDireitos autorais:

Formatos disponíveis

Technical Brief Fundamentals of Thermoforming KYDEX Sheet

For information applicable to KYDEX FST please refer to 300 series technical briefs.

TB - 140-A

Thermoforming Processes

The process of forming a thermoplastic sheet into a three dimensional shape by clamping the sheet in a frame, heating it to render it soft, then applying differential pressure to make the sheet conform to the shape of a mold or die positioned below the frame. Three basic methods of thermoforming: 1) Vacuum Forming 2) Pressure (compressed air) Forming 3) Mechanical (plug assist) Forming

Vacuum Forming and Methods

The most popular method of thermoforming The forming process is accomplished solely with vacuum A male or female mold is pressed into the hot sheet to create a seal Vacuum is applied, drawing the hot material into or around the mold The vacuum is held until the material is cooled to prevent shrinkage

Snap-Back Vacuum Forming - Male

- A vacuum box seals the heated plastic sheet to the clamping frame. - Vacuum applied through this box pre-stretches the material into a bubble. - The mold enters the pre-stretched plastic sheet and seal to the clamping frame. - Vacuum is applied through the mold, and the vacuum box is allowed to vent to the atmosphere. - Very deep draws can be obtained with this system, and undesirable material thinning can be greatly minimized.

KYDEX, LLC

ISO 9001 and 14001 Certified

Customer Service 6685 Low St, Bloomsburg, PA 17815 USA Phone: 800.325.3133, +1.570.389.5810 Outside the US: +1.570.389.5814 Fax: 800.452.0155, +1.570.387.7786 Email: info@kydex.com Technical Service Phone: 800.682.8758 Fax: +1.570.387.8722 Outside the US: +1.570.387.6997 Email: techservice@kydex.com

www.kydex.com

2012 KYDEX, LLC. All rights reserved. KYDEX is a registered trademark of KYDEX, LLC. | 061412

Technical Brief Fundamentals of Thermoforming KYDEX Sheet

For information applicable to KYDEX FST please refer to 300 series technical briefs.

TB - 140-A

Pressure Forming

This technique is normally accomplished by forcing a hot plastic sheet against a mold, usually female, by introducing compressed air to the backside of the heated sheet. Pressure forming is a sophisticated version of the vacuum forming process. This process closes the appearance gap with traditional molding techniques. It uses air pressure as a forming aid to increase the detail on the mold side.

- The pressure applied is approximately five times higher than with vacuum forming. - Makes it possible to obtain highly detailed parts and textured finishes. - Air pressure above the heated sheet gives a higher quality finish with sharp edges, undercuts, and other closer tolerance details. - Features that could not be achieved by vacuum alone can be obtained with pressure forming.

The result to the customer is a product that achieves the look and feel of an injection or structural foam molded part. For smaller volume runs, pressure forming offers injection-molded quality and details.

Tools and Molds Used for Forming KYDEX Sheet

In determining what type of mold to use, consider the following:

Type of Production:

KYDEX, LLC

ISO 9001 and 14001 Certified

Customer Service 6685 Low St, Bloomsburg, PA 17815 USA Phone: 800.325.3133, +1.570.389.5810 Outside the US: +1.570.389.5814 Fax: 800.452.0155, +1.570.387.7786 Email: info@kydex.com Technical Service Phone: 800.682.8758 Fax: +1.570.387.8722 Outside the US: +1.570.387.6997 Email: techservice@kydex.com

1. 2. 3. 4. 5.

Prototype Parts with close tolerances Quantity of parts Pressure-formed parts Parts requiring break-away tool

www.kydex.com

2012 KYDEX, LLC. All rights reserved. KYDEX is a registered trademark of KYDEX, LLC. | 061412

Technical Brief Fundamentals of Thermoforming KYDEX Sheet

For information applicable to KYDEX FST please refer to 300 series technical briefs.

TB - 140-A

Heating Elements Used in Thermoforming

All heating elements are suitable for thermoforming KYDEX sheet.

Calrods Elements IR Ceramic Elements Halogen Element Heaters Quartz Element Heaters Gas Catalytic Heaters

Calrods

Metal tubular heaters were popular in the 90s. They are still in use in some of the older thermoformers.

Pros:

They last a long time and are somewhat inexpensive to build into an oven.

Cons:

They tend to age and degrade quickly, causing inefficient heating. Longer heat up time. Heat non-uniformly and limits the possibilities of multiple heating zones.

KYDEX, LLC

ISO 9001 and 14001 Certified

Customer Service 6685 Low St, Bloomsburg, PA 17815 USA Phone: 800.325.3133, +1.570.389.5810 Outside the US: +1.570.389.5814 Fax: 800.452.0155, +1.570.387.7786 Email: info@kydex.com Technical Service Phone: 800.682.8758 Fax: +1.570.387.8722 Outside the US: +1.570.387.6997 Email: techservice@kydex.com

www.kydex.com

2012 KYDEX, LLC. All rights reserved. KYDEX is a registered trademark of KYDEX, LLC. | 061412

Technical Brief Fundamentals of Thermoforming KYDEX Sheet

For information applicable to KYDEX FST please refer to 300 series technical briefs.

TB - 140-A

Ceramic

Ceramic elements may still be the most widely used in todays thermoforming machines.

Pros:

Very versatile Long lasting Easily zoned for balanced heating Favored for long production runs since they are durable and maintain excellent uniform heating Moderately priced

Cons:

Only drawback are the moderate heat up times and slow response times when being compared to Quartz and Halogen heaters

Features:

1. 2. 3. 4. Ceramic heaters are 96% infrared energy efficient, leading all other types of infrared emitters. They are the best heaters on the market for zone control. Watt density can be easily controlled to produce the most gentle heat on the market. Ceramic infrared heats objects not the air.

Quartz and Halogen Elements

These elements are continually gaining a large share of new machinery sold today. They tend to be best used in shuttle type machines.

Pros:

Fast response times. Very versatile, have excellent temperature control. Rapid cool-down and heat-up times. Easy to zone like ceramics. Both elements give the ability to incorporate heat levels or heat steps in within a cycle. Ideal for fast cycling times. High radiant efficiency.

KYDEX, LLC

ISO 9001 and 14001 Certified

Customer Service 6685 Low St, Bloomsburg, PA 17815 USA Phone: 800.325.3133, +1.570.389.5810 Outside the US: +1.570.389.5814 Fax: 800.452.0155, +1.570.387.7786 Email: info@kydex.com Technical Service Phone: 800.682.8758 Fax: +1.570.387.8722 Outside the US: +1.570.387.6997 Email: techservice@kydex.com

Cons:

The only drawback is longevity. Elements are made of glass tubes, which makes them more fragile and easily damaged. They are typically more expensive.

www.kydex.com

2012 KYDEX, LLC. All rights reserved. KYDEX is a registered trademark of KYDEX, LLC. | 061412

Technical Brief Fundamentals of Thermoforming KYDEX Sheet

For information applicable to KYDEX FST please refer to 300 series technical briefs.

TB - 140-A

Gas Catalytic

A diffusion type heater, that operates on chemical oxidation reduction process that reduces the methane or propane gas in the presence of platinum and oxygen, into moisture, carbon dioxide, and produces infrared energy from this reaction.

Pros:

Economical alternative to the high energy cost associated with electric resistance elements. Catalytic heaters will cost 50% - 80% less to operate then electric heaters.

Cons:

Balancing of the temperature zones is more sensitive than other heating elements.

Features:

1. Glass, metal or kormic emitter surface material 2. Ceramic standoffs used to keep electrically conductive material separated from resistance wire 3. High temperature cement bond 4. Refractory board to hold resistance wire 5. Precision-resistance wire 6. Heavy gauge aluminum steel frame 7. Blanket insulation layer 8. Ceramic bushings to insulate terminals 9. Stainless steel terminals 10. Quartz thermowell tube (optional)

Thermoforming KYDEX Sheet Product

Before thermoforming, the following issues should be addressed: 1. Are there doors opened around the machine? a) Close doors or use a welding curtain to block air flow. 2. Are there fans and/or vents operating around machine? a) Turn fans and vents off or redirect them. 3. Are the back and sides of the machine open to air flow? a) Close in the thermoformer heating area to block air flow. This makes it an enclosed heating chamber. Addressing the above issues will aid in repeatability in thermoformed parts.

KYDEX, LLC

ISO 9001 and 14001 Certified

Customer Service 6685 Low St, Bloomsburg, PA 17815 USA Phone: 800.325.3133, +1.570.389.5810 Outside the US: +1.570.389.5814 Fax: 800.452.0155, +1.570.387.7786 Email: info@kydex.com Technical Service Phone: 800.682.8758 Fax: +1.570.387.8722 Outside the US: +1.570.387.6997 Email: techservice@kydex.com

www.kydex.com

2012 KYDEX, LLC. All rights reserved. KYDEX is a registered trademark of KYDEX, LLC. | 061412

Technical Brief Fundamentals of Thermoforming KYDEX Sheet

For information applicable to KYDEX FST please refer to 300 series technical briefs.

TB - 140-A

Tools and Molds Used for Forming KYDEX Sheet

Type of mold (Male vs. Female):

1. 2. 3. 4. 5. 6. Where on the part are the tolerances needed? Which side of the parts needs the detail? Male molds are cheaper to build than female molds. Are parts to be fitted or bond together? Closer tolerances can be held with a male mold. Parts using a female mold will have greater thickness at the flange area of the part and thinning at the bottom. Pre-stretching can minimize the thinning. 7. Parts using a male mold will be thicker where the material first comes in contact with mold.

Multiple mold cavities:

1. Molds can be produced with multiple cavities incorporated into one tool. 2. Molds can be produced for various designed parts in one tool to maximize usage of sheets. 3. Rule of thumb used for spacing cavities in such molds is space at twice the height of the part. This allows for enough material to be distributed to the side walls of the molds.

Adjustable Clamp Frames

These frames eliminate the need for storing and replacing different short frames for every sheet width. The system will handle your maximum sheet sizes down to 6" X 6" in 114" increments. The clamp frames can be arranged for either bottom or top loading. Clamp frames utilize standard clamp frame components with other off-the-shelf items enabling users to vary the length of the clamp frames. This system reduces clampframe set up time to under 5 minutes.

Advantages of Clamp Frames:

1. Standard MAAC clamp frame components: cylinders and extrusion can be interchanged with standard clamp frames. 2. The sheet is gripped on a single plane, there is no offset in the comers. 3. Position of the clamp frames can be noted and stored along with the part menu in the notes section and easily returned to the exact position the next time the product is run. 4. 5. 6. 7. 8. 9.

KYDEX, LLC

ISO 9001 and 14001 Certified

NO TOOLS are required for any part of the adjustment. Large airflow passages insure quick even operation of the cylinders. Requires approximately 112" of material to be clamped meaning less waste and trim. No "old-style" steel pin bars. All aluminum, meaning better heat transfer. Light-weight and cost effective when compared to competing systems. No need to store all those different size clamp frames.

Customer Service 6685 Low St, Bloomsburg, PA 17815 USA Phone: 800.325.3133, +1.570.389.5810 Outside the US: +1.570.389.5814 Fax: 800.452.0155, +1.570.387.7786 Email: info@kydex.com Technical Service Phone: 800.682.8758 Fax: +1.570.387.8722 Outside the US: +1.570.387.6997 Email: techservice@kydex.com

www.kydex.com

2012 KYDEX, LLC. All rights reserved. KYDEX is a registered trademark of KYDEX, LLC. | 061412

Technical Brief Fundamentals of Thermoforming KYDEX Sheet

For information applicable to KYDEX FST please refer to 300 series technical briefs.

TB - 140-A

New Technologies in Cut Sheet Thermoforming

Quicker clamp frame:

Routine clamp frame change can take up to 4 hours depending on number of stations Typically consists of replacing the short clamp frame segments for every different sheet width Adjustable clamp frames offer the ability to vary the length of the clamp frames without having to add or remove clamp frame sections Changeovers takes only fewer than 5 minutes (per station) Ability to document the position of these clamp frames and easily return them to the exact position the next time the product is run Helps in reducing sheet sizes to minimize wastage

Mold Changeover:

Mold changeovers are another one of the leading factors causing machine downtime. Most molds are unique, built by different suppliers and most thermoformers end up with a large quantity of different mold bases and mold configurations. The key to quick mold change is to make all design factors on each mold common to each other. For uncommon mold bases, the use of steel plates with precisely spaced bolt patterns or aluminum plates with T-slots have been most popular. Stand alone or common mold bases allows one mold (attached to the 1st mold base) to be run in production while another mold is being secured to the 2nd mold base outside the machine. This can even be taken a step further by having all of the utilities connected outside the machine. Scales, locating pins, locating cones or back stops can be consistently used to locate the mold base to the platen. Hand clamps/ automatic clamps controlled through the machine can be used to secure the base to the platen.

KYDEX, LLC

ISO 9001 and 14001 Certified

Customer Service 6685 Low St, Bloomsburg, PA 17815 USA Phone: 800.325.3133, +1.570.389.5810 Outside the US: +1.570.389.5814 Fax: 800.452.0155, +1.570.387.7786 Email: info@kydex.com Technical Service Phone: 800.682.8758 Fax: +1.570.387.8722 Outside the US: +1.570.387.6997 Email: techservice@kydex.com

Mold Base Change System

www.kydex.com

2012 KYDEX, LLC. All rights reserved. KYDEX is a registered trademark of KYDEX, LLC. | 061412

Technical Brief Fundamentals of Thermoforming KYDEX Sheet

For information applicable to KYDEX FST please refer to 300 series technical briefs.

TB - 140-A

Thermoforming and Mold Shrinkage

Most thermoformed parts shrink on forming Shrinkage must be considered during mold construction Shrinkage varies with: The amount and type of material orientation during forming Mold temperature (hotter the mold temperature, the more mold shrinkage), length of time the part remains on the mold, and whether it is a male or female mold The recommended mold shrinkage for KYDEX thermoplastic sheet for a male mold is 0.4% - 0.6% and for a female mold is 0.5% - 0.7% 0.080 and thicker gauge sheets require two-sided (sandwich) heaters. Heating (dwell) time varies with the heat source, oven conditions, dimensions, and age of the oven. An indication of overheating is a shiny part surface. Reduce the percentage of heat delivered and increase the heating time to maintain crisp part definition. Recommended heater settings: 30-50% of top heat , 50-70% of bottom heat capacities. Bottom heat is maintained higher as the distance between the heating elements and the sheet is greater than the top distance. Heat rises and is trapped under the sheet allowing it to absorb faster to the core of the sheet. Optimum forming temperature range for KYDEX sheets is 365-400F (depending on the thickness of material).

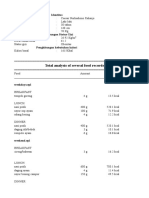

Heating KYDEX Thermoplastic Sheet

Sheet Thickness Range 0.028-0.080 0.080-0.125 0.125-0.500

Approximate Dwell Time 15-80 seconds 80-140 seconds 140-up seconds

Forming Temperature Range 330-350F 350-385F 385-400F

The following are guidelines for thermoforming KYDEX sheet products. A good rule of thumb is: - Up to 0.125 thickness, every millimeter in thickness = 1 second in dwell time - > 0.156 thickness, every millimeter in thickness = add 1.25 seconds in dwell - This provides an approximation of the required forming temperature range

KYDEX, LLC

ISO 9001 and 14001 Certified

Customer Service 6685 Low St, Bloomsburg, PA 17815 USA Phone: 800.325.3133, +1.570.389.5810 Outside the US: +1.570.389.5814 Fax: 800.452.0155, +1.570.387.7786 Email: info@kydex.com Technical Service Phone: 800.682.8758 Fax: +1.570.387.8722 Outside the US: +1.570.387.6997 Email: techservice@kydex.com

Because we cannot anticipate or control the many dierent conditions under which this information and our products may be used, we do not guarantee the applicability of the accuracy of this information or the suitability of our products in any given situation. Users should conduct their own tests to determine the suitability of each product for their particular purposes. Data in the physical property table represents typical values and are to serve only as a guide for engineering design. Results are obtained from specimens under ideal laboratory conditions. Right to change physical properties as a result of technical progress is reserved. THE PRODUCTS DISCUSSED ARE SOLD WITHOUT WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE, EITHER EXPRESSED OR IMPLIED, EXCEPT AS PROVIDED IN OUR STANDARD TERMS AND CONDITIONS OF SALE. Buyer assumes all responsibility for loss or damage arising from the handling and use of our products, whether done in accordance with directions or not. In no event shall the supplier or the manufacturer be liable for incidental or consequential damages. Also, statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent. Consult local code and regulatory agencies for specic requirements regarding code compliance, transporting, processing, recycling and disposal of our product. Product not intended for use as a heat resistant surface. Texture, product grade and other conditions may cause variations in appearance. This information supersedes all previously published data.

www.kydex.com

2012 KYDEX, LLC. All rights reserved. KYDEX is a registered trademark of KYDEX, LLC. | 061412

Você também pode gostar

- Horiz - Vert Router TableDocumento17 páginasHoriz - Vert Router TableLyle Hornbaker100% (1)

- Kydex TB 140-E Troubleshootingthermoformingproblems 061412Documento4 páginasKydex TB 140-E Troubleshootingthermoformingproblems 061412Lyle HornbakerAinda não há avaliações

- Gosse Luna Lux BrochureDocumento1 páginaGosse Luna Lux BrochureLyle HornbakerAinda não há avaliações

- Gosse Luna Lux BrochureDocumento1 páginaGosse Luna Lux BrochureLyle HornbakerAinda não há avaliações

- Making Accurate Straight-Edges From ScratchDocumento2 páginasMaking Accurate Straight-Edges From ScratchLyle HornbakerAinda não há avaliações

- Clone of A Biesemeyer Table Saw FenceDocumento4 páginasClone of A Biesemeyer Table Saw FenceLyle Hornbaker100% (2)

- Refining A High-Quality BandsawDocumento6 páginasRefining A High-Quality BandsawLyle HornbakerAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Quarter 2 Week 5Documento54 páginasQuarter 2 Week 5rixzylicoqui.salcedoAinda não há avaliações

- Neurovascular Assessment PDFDocumento5 páginasNeurovascular Assessment PDFNasrullah UllahAinda não há avaliações

- Aphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMCDocumento2 páginasAphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMC2aliciast7Ainda não há avaliações

- Dosage Calculations, CH 10 ProblemsDocumento1 páginaDosage Calculations, CH 10 ProblemsJacqueline GreerAinda não há avaliações

- CR-7iA CR-4iA Installation and Setup Guide (B-83774JA-1 01)Documento1 páginaCR-7iA CR-4iA Installation and Setup Guide (B-83774JA-1 01)lidiia.pavlkukAinda não há avaliações

- Digestzen SoftgelsDocumento1 páginaDigestzen SoftgelsMarianAinda não há avaliações

- Tugas Gizi Caesar Nurhadiono RDocumento2 páginasTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoAinda não há avaliações

- 621F 721F Op's ManualDocumento362 páginas621F 721F Op's ManualMilAuto87100% (1)

- Insurance CodeDocumento18 páginasInsurance CodeKenneth Holasca100% (1)

- 01 Mono Channel BurnerDocumento1 página01 Mono Channel BurnerSelwyn MunatsiAinda não há avaliações

- Supply Chain Logistics Manager in Dallas FT Worth TX Resume Calvin HarperDocumento2 páginasSupply Chain Logistics Manager in Dallas FT Worth TX Resume Calvin HarperCalvinHarperAinda não há avaliações

- 45relay Rm4ua PDFDocumento1 página45relay Rm4ua PDFtamky SubstationAinda não há avaliações

- Blessing of The Advent WreathDocumento3 páginasBlessing of The Advent WreathLloyd Paul ElauriaAinda não há avaliações

- PDAJChallenge KitDocumento15 páginasPDAJChallenge KitElango Minnoor100% (1)

- All India Quota Medical Seats (MBBS) With AIPMT 2015 Score PDFDocumento5 páginasAll India Quota Medical Seats (MBBS) With AIPMT 2015 Score PDFjuhiAinda não há avaliações

- Catalogo StafsjoDocumento12 páginasCatalogo StafsjoBruno Bassotti SilveiraAinda não há avaliações

- Ronnel Del RioDocumento5 páginasRonnel Del Rioamity balweg100% (2)

- Revised Man As A Biological BeingDocumento8 páginasRevised Man As A Biological Beingapi-3832208Ainda não há avaliações

- Interactive and Comprehensive Database For Environmental Effect Data For PharmaceuticalsDocumento5 páginasInteractive and Comprehensive Database For Environmental Effect Data For PharmaceuticalsRaluca RatiuAinda não há avaliações

- PED16 Foundation of Inclusive Special EducationDocumento56 páginasPED16 Foundation of Inclusive Special EducationCHARESS MARSAMOLO TIZONAinda não há avaliações

- Radiesthesia and The Major ArcanaDocumento72 páginasRadiesthesia and The Major ArcanaStere Stere67% (3)

- Barangay Clearance SampleDocumento1 páginaBarangay Clearance SampleBarangay Onse Malaybalay100% (3)

- Raffles Hotel Jakarta Pricelist 2020Documento2 páginasRaffles Hotel Jakarta Pricelist 2020kielachela aaAinda não há avaliações

- Pengaruh Pembangunan Center Point of IndDocumento11 páginasPengaruh Pembangunan Center Point of IndSumitro SafiuddinAinda não há avaliações

- Huayi: Refrigeration CompressorDocumento2 páginasHuayi: Refrigeration CompressorVARDANAinda não há avaliações

- Industrial SpecialtiesDocumento103 páginasIndustrial SpecialtiesRahul ThekkiniakathAinda não há avaliações

- MODEL 1332 MODEL 1432: Slide LengthDocumento8 páginasMODEL 1332 MODEL 1432: Slide LengthFabian FragosoAinda não há avaliações

- Stats Review CH 1-6Documento15 páginasStats Review CH 1-6Megha BanerjeeAinda não há avaliações

- Achievement Test Science 4 Regular ClassDocumento9 páginasAchievement Test Science 4 Regular ClassJassim MagallanesAinda não há avaliações

- CA500Documento3 páginasCA500Muhammad HussainAinda não há avaliações