Escolar Documentos

Profissional Documentos

Cultura Documentos

Advanced Treatment of Landfill Leachate Effluent Using Membrane Filtration

Enviado por

Amin MojiriDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Advanced Treatment of Landfill Leachate Effluent Using Membrane Filtration

Enviado por

Amin MojiriDireitos autorais:

Formatos disponíveis

International Journal of Scientific Research in Environmental Sciences (IJSRES), 1(3), pp. 36-43, 2013 Available online at http://www.ijsrpub.

com/ijsres 2013 IJSRPUB

Full Length Research Paper Advanced Treatment of Landfill Leachate Effluent Using Membrane Filtration

Hamidi Abdul Aziz1,*, Chae Tyng Feng1, Mohammed J. K. Bashir2

2 1

School of Civil Engineering, Engineering Campus, Universiti Sains Malaysia, 14300, Nibong Tebal, Penang, Malaysia, Department of Environmental Engineering, Faculty of Engineering and Green Technology, Universiti Tunku Abdul Rahman, 31900, Kampar, Perak, Malaysia Phone, modbashir@gmail.com *Corresponding Author: cehamidi@eng.usm.my

Received 14 February 2013; Accepted 02 March 2013

Abstract. Treatment of water by membrane filtration process has been well established. However, its application on landfill leachate effluent treatment is quite limited. This study was undertaken to investigate suitability of this process on leachate effluent treatment generated from Pulau Burung semi aerobic sanitary landfill. Three types of membrane namely Nylon, Resin and Poly-propylene (PP) were used in this study. The pore sizes were 1 m and 5 m. The effects of different filtration rates on leachate treatment were studied. The parameters studied were COD, colour, suspended solids (SS) and turbidity. A set of batch studies were carried out in order to evaluate the effectiveness of the membrane filtration process in leachate effluent treatment. The results indicated that Poly-propylene membrane with pore size 1 m had the best performance in reducing all the parameters whereas the Resin membrane gave the poorest results. It can be deduced that the filtration rate of 10 mL/min exhibited the highest removal efficiency. Poly-propylene membrane with pore size 1 m and at filtration rate of 10 mL/min was found to be the most effective membrane to remove COD, colour, SS and turbidity . Key words: Membrane filtration, landfill leachate, advanced treatment, Poly-propylene membrane.

1. INTRODUCTION Landfilling has remains as the most common method for the disposal of municipal solid wastes generated by different communities in Malaysia. One of the typical problems that associate with the landfilling method is generation of the leachate. Al-Hamadani et al. (2004) reported that landfill leachate is a heavily contaminated and a likely hazardous liquid that is produced as a result of water infiltration through solid wastes generated industrially and domestically. Leachate can migrate away from landfill; it may cause serious pollution to the groundwater aquifer as well as adjacent surface water. Consequently, one of the major issues to deal with is the collection, storage and suitable treatment of highly contaminated leachate (Baig et al., 1999).The impact of landfills is also long term. This is due to the fact that landfills will continue to produce leachate and release biogas for a long period after closure (Bashir et al., 2012). Therefore, biological treatment and physicochemical treatment techniques such as activated sludge treatment, rotary disc, sedimentation with coagulation, activated carbon adsorption, membrane processes have been widely used in leachate treatment. These methods can contribute to the removal of chemical oxygen demand (COD), biological oxygen demand (BOD5), metals, suspended solids, colour, and ammonia (Agamuthu, 2001).

Membrane technologies other than simple osmosis like electrodialysis and ultrafiltration are not common in leachate treatment due to the fact that most membrane technologies will suffer from problems that associated with blockage of the membranes. This is because the membrane surface and inside the membrane process are deposited by inorganic, organic and microbiological substances (Wiszniowski et al., 2005). Membrane processes deal in separating two solutions with different concentrations by a semi permeable membrane. In this process, pressure is added to the more concentrated solution, forcing the water to flow from the higher concentration to the lower concentration. Microfiltration (MF) and ultrafiltration (UF), operated singly or in combination with reverse osmosis (RO) and nanofiltration (NF) are membrane processes applied in landfill treatment (Bodzek, 1999; Trebouet et al., 2001). Robinson (2005) reported that in the late 1980s, UF and RO systems were used to clean leachate by separating and concentrating the solids. Due to the high ability of modern high-rejection osmosis membranes to retain both organic and inorganic contaminates, an efficiency level of 9899% can be achieved (Peters, 1998). The results of tests carried out with membranes in a previous research project suggested that membrane filtration could be effective for solid or liquid separation. One of the major disadvantages of these membrane processes is fouling or biofouling of the membrane, induced by deposits of inorganic,

36

Aziz et al. Advanced Treatment of Landfill Leachate Effluent Using Membrane Filtration

organic and microbiological substances on both the membrane surface and inside the membrane pores. Successful application of membrane technology for the treatment of the landfill leachate requires an efficient control of membrane fouling (Trebouet et al., 2001 and Bodzek, 1999). The removal of potential foulants including dissolved organic and inorganic substances, colloidal and suspended particles can be achieved by pH adjustment, pre-filtration and coagulation. This study was carried out to study the effect of filtration rate, filter pore size and different membrane type in removing suspended solids, colour, turbidity and COD from pre-treated landfill leachate. Also, to investigate the efficiency of the different membrane,

i.e. Nylon, Resin and Poly-propylene (PP) with pore size 1 m and 5m. Its focused on Pulau Burung Sanitary Landfill is a semi-aerobic landfill which is situated within Byram Forest Reserve in Penang, Malaysia. 2. MATERIALS AND METHODS 2.1. Sampling and Characterization Effluent leachate samples were collected from final sedimentation tank of the Pulau Burung landfill (PBL) leachate treatment plant before it is discharged to the drain. Figure 1 shows the schematic diagram of the treatment procedures in PBL treatment plant.

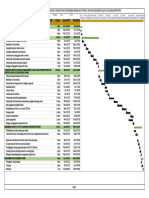

Fig. 1: The schematic diagram of the treatment procedures in PBL treatment plant The samples were transported to the laboratory and stored in a refrigerator at 4C to minimize biological and chemical reactions according to the Standard Method of Water and Wastewater (APHA, 2005). The samples were analyzed for COD, colour, suspended solids (SS) and turbidity to determine its initial values. COD was measured based on the closed reflux, colorimetric method by DR/2010 spectrophotometer. SS determination was conducted using the Photometric Method by DR/2010 spectrophotometer. SS was measured at 810 nm wavelength (program number 630).The unit of suspended solids is in mg/L and the range is from 0 to 750 mg/L. Turbidity was determined by Attenuate Radiation Method (direct reading), by DR/2010 spectrophotometer. Turbidity was determined at 860 nm wavelength (program number 750). The unit for turbidity is FAU (Formazin Attenuation Unit) and the range is from 0 to 4400 FAU. Colour was measured by APHA Platinum-Cobalt (PtCo) standard method, by DR/2010 spectrophotometer. Colour was measured at 455nm wavelength (program number 120) and the range is from 0 to 500PtCo. Before each determination, samples were filtered with filter paper with pore size 0.45m and the distilled water was used as blank. The characteristics of the samples are demonstrated in Table 1.

37

International Journal of Scientific Research in Environmental Sciences (IJSRES), 1(3), pp. 36-43, 2013

Table 1: Characteristics of pre-treated leachate at PBL

Parameter COD Colour SS Turbidity Units mg/L Pt Co mg/L FAU Maximum 630 128 63 106 Minimum 220 96 21 34 Average 425 106 40 67

2.2. Experimental Procedure Firstly, a tank size 350 mm 550 mm 400 mm was chosen as the membrane reactor. Since gravity flow was used in this system, the bottom of the tank was drilled and the hole was connected with a pipe. In Feeding Tank

order to increase the pressure head of the leachate effluent, the reactor was placed on the table. The pipe was connected with a valve which is used to control the filtration rate of the leachate effluent. The flow system was then connected as shown in Figure 2.

Valve used to control filtration rate

Return Effluent

Membrane Filter

Effluent Pump Container

Fig. 2: Diagram of experimental set up of the reactor

The effect of filtration rate from (10 to 50 ml/min) in removing suspended solids, colour, turbidity and COD were studied. Poly-propylene membrane with pore size 5 m was used in this study. Furthermore, a series of experiment carried out to study the efficiency of different types of membrane filters (Nylon, Resin and Poly-propylene (PP) with pore size 1 m and 5m). Besides that, the effect of pore size of membrane also studied by comparing the results obtained by PP (1 m) and PP (5m) membrane. Each filtration was continuously run for 4 days in a week. Daily changes of each parameter were determined. At the end of each week, the removal percentage of each parameter was determined for each of flow rate and each type of membrane filter using standard methods (APHA, 2005).

3. RESULTS AND DISCUSSION 3.1. The effect of filtration rate on the removal efficiency Colour Removal: Lower filtration rate exhibited better removal of colour as demonstrated in Fig.3. This is may be due to the higher retention time. Colour removal efficiency at all filtration rates were fairly low and in the range between 4 to 18%. This is may be due to the suspended solids and turbidity removal in this study was not very good, therefore, the overall results for colour removal was also very low (< 20%). The presence of ion metallic or organic dissolved matters like humic substance (Zouboulis et al., 2004) in leachate effluent which can pass through the membrane filter. COD removal: Fig. 3 shows the effected of filtration rate on COD removal, COD removal efficiency increased when the filtration rate was decreased. The COD removal efficiencies were 38.6

38

Aziz et al. Advanced Treatment of Landfill Leachate Effluent Using Membrane Filtration

%, 34.8% and 22.2% obtained at filtration rates of 10, 20 and 30 ml/min, respectively. According to Vogel et al. (2000), it is difficult to achieve lower COD value in leachate effluent. It may be caused by higher ammonia level in leachate as ammonia is a difficult inorganic matter to oxidize or reduce. Vogel et al. 1 (2000) also pointed out that one third ( 3 ) of the COD in leachate is influenced by the inorganic matters such as Fe (II), manganese (II), sulphide, ammonia and chloride. Therefore, the achievement was very low for this case in simple membrane filtration process. SS Removal: The SS removal at filtration rate of 50 mL/min was very low (about 54%) compared to the others. At filtration rate of 40 mL/min, removal fluctuates from first day to third day of experiment. At filtration rates of 30 and 40 mL/min, the removal were almost same at the end of the experiment. Good removal of SS was observed at filtration rate of 10 and 20 mL/min, with 78% and 71% reduction, respectively. It can be concluded that low filtration

rate can give good results in removing the SS due to higher retention time. The overall removal of SS achieved by membrane filter, Poly-propylene (5 m) was below 80%. This may be caused by the dissolved matter and colloidal materials which is available in the leachate. These type of materials can pass through the micro-membrane and normally it is called permeate (Ziyang and Youcai, 2007). Graph of particle size distribution on the filtrates sample at filtration rate of 10 mL/min (Fig. 4), indicated that about 28% of the particulate in leachate are less than 5m. This means that at least 28% of the particulate can pass through the micro-membrane and remained in the samples. Turbidity Removal: Fig. 3 shows turbidity removal efficiency at different filtration rates. The results were similar as the case of SS removal. As seen from Fig. 3, the turbidity removal efficiency at all filtration rates were low and in the range of 45 to 77%. This is due to the SS in leachate can contribute greatly to the turbidity (Ziyang and Youcai, 2007).

Fig. 3: The effect of different filtration rates on A) colour, B) COD, C) SS, and D) Turbidity, removal efficiency

39

International Journal of Scientific Research in Environmental Sciences (IJSRES), 1(3), pp. 36-43, 2013

6 5

Volume (%)

Particle Size Distribution

4 3 2 1 0 0.01 0.1 1 10 Particle Size (m) 100 1000 3000

Fig 4: Particle Size Distribution of the Filtrates Samples [d (0.1) = 2.721 m; d (0.5) = 18.509 m; d(0.9) = 339.503 m] 3.2 Effect of different membrane type on the removal efficiency The effect of different types of membranes, i.e. Nylon, Resin and Poly-propylene (PP) on the removal of colour, COD, SS and turbidity were carried out by using constant filtration rate of 10 mL/min. The effect of pore size of membrane was also studied by using PP (1 m) and PP (5 m). Colour Removal: Nylon membrane exhibited the highest colour removal as illustrated in Fig.5, which ranging from 18-24%. Besides that, there was no significant different on the removal of colour by PP (1 m) and PP (5 m) membranes. The removals obtained by both were in the range of 10 to 20%. The colour removal by Resin membrane was fairly low, which was less than 12%. However, all the membranes did not give very good results (< 24%). As previously stated, this may be due to the presence of ion metallic or organic dissolved matters like humic substance (Zouboulis et al., 2004) in leachate effluent which can pass through the micro-membrane and remained in the leachate (Ziyang and Youcai, 2007). Thus, poor result for colour removal was obtained in this study. COD Removal: Fig. 5 (B) shows that the COD removal by PP (1 m) and PP (5 m) membrane were greater than 35%, which was 41.7% and 38.6%, respectively. There was no significant dropped on the removal for these two membrane. However, for Nylon membrane with pore size 5 m, the percentage of COD removal dropped to 21.0%. The removal for Resin membrane with pore size 5 m was less than 13%. Besides that, it can be deduced from Figure 4 that smaller pore size exhibited higher removal of COD. The range of percentage of COD removal by 1 m membrane was 28 to 42% as compared with 18 to 38% at 5 m. SS Removal: Fig. 5 (C) shows SS removal efficiency by using different types of membrane filters at constant filtration rate (10 mL/min). Percentage of SS removal using the Resin membrane was very low with only 51% reduction. In addition, it can be deduced from Figure 4that there was no significant different on the removal of SS by Nylon, PP (1 m) and PP (5 m) membranes. The removals for these membranes were in the range of 74 to 84% of SS removal. PP (1 m) has the best performance in removing SS from the leachate effluent. This is because it has the smallest pore size compared with the others. Turbidity Removal: Fig. 5 (D) shows turbidity removal efficiency by using different types of membrane filters at constant filtration rate, 10 mL/min. There was no significant different on the removal of turbidity by PP (1 m), PP (5 m) and Nylon membranes. The removals for these membranes were in the range of 54 to 86%. However, the range of turbidity removal was between 10 to 53% for Resin membrane. Most of the results had almost similar trend with the SS removal. As can be seen from Fig. 5, all the lines have almost similar trends with the SS removal. This is due to the suspended solids can contribute to the turbidity of the leachate (Ziyang and Youcai, 2007). Therefore, once the SS were removed, the turbidity of the leachate also decreased.

40

Aziz et al. Advanced Treatment of Landfill Leachate Effluent Using Membrane Filtration

Fig. 5: Effect of different membrane type on A) colour, B) COD, C) SS, and D) Turbidity removal efficiency.

4. CONCLUSION From the previous results, the best performance of COD, colour, suspended solids and turbidity removal efficiency achieved at filtration rate of 10 ml/min were 38.6%, 18.0%, 78.3% and 76.7% respectively, whereas 50 mL/min gave the poorest results for all parameters removal except for colour. Removal efficiency of COD, colour, suspended solids, and turbidity removal was increased by using low filtration rate. Poly-propylene (PP) was the most efficient on parameters removal as compared with the others. However, PP (1 m) performance was better than PP (5 m), the result shows 41.7% removal of COD, 84.4% removals of SS and 86.2% removal of turbidity. Nylon membrane (5 m) was most efficient on colour removal as compared to the others (22.6% of colour removal). Removal of colour was not really efficient with membrane filtration method. Thus, other treatment method such as coagulation and flocculation method may be studied further. Ferric chloride can also be used to remove colour. REFERENCES Agamuthu P (2001). Solid Waste: Principles and Management. Kuala Lumpur: University of Malaya Press. Al-Hamadania YAJ, Yusoff M.S, Umar M, Bashir MJ.K, Adlan MN (2011). Application of psyllium husk as coagulant and coagulant aid in

semi-aerobic landfill leachate treatment. Journal of Hazardous Materials, 190: 582-587 APHA (2005). Standard Methods for the Examination of Water and Wastewater, 21st edition. Washington, DC: American Public Health Association. Baig S, Coulomb I, Courant P, Liechti P (1999). Treatment of landfill leachates: Lapeyrouse and Satrod case studies. Ozone Science Engineering, 21: 1 22. Bashir MJK, Aziz HA, Aziz SQ, Abu Amr SS (2012). An Overview of Electro-oxidation Processes Performance in Stabilized Landfill Leachate Treatment. Desalination and Water Treatment, iFirst 115. doi: 10.1080/19443994.2012.734698 Bodzek M (1999). Membrane techniques in wastewater treatment. In: Goosen MFA, Shayya WH (Ed) Water management purification and conservation in arid climates. Technomic Publishing Company, Lancaster-Basel, pp. 121184. Peters A (1998). Purification of landfill leachate with reverse osmosis and nanofiltration. Desalination, 119: 289 293. Robinson AH (2005). Landfill leachate treatment. Membrane Technology, 6: 6- 12. Trebouet D, Schlumpf JP, Jaouen P, Quemeneur F (2001). Stabilized landfill leachate treatment by combined physicochemical nanofiltration processes. Water Research, 35: 2935- 2942.

41

International Journal of Scientific Research in Environmental Sciences (IJSRES), 1(3), pp. 36-43, 2013

Vogel F, Julien H, Hug A, Rudolf P (2000). The mean oxidation number of carbon (MOC) a useful concept for describing oxidation processes. Water Research, 34: 2689 2702. Wiszniowski J, Robert D, Surmacz-Gorska J, Miksch K, Weber JV ( 2005). Landfill leachate treatment methods: A review. Environ. Chem., 4: 51-61. Ziyang L, Youcai Z (2007). Size-fractionation and characterization of refuse landfill leachate by

sequential filtration using membranes with varied porosity. Journal of Hazardous Materials, 147: 257-264. Zouboulis A, Chai XL, Katsoyiannis A, (2004). The application of bio flocculant for the removal of humic acids from stabilized landfill leachate. Journal of Environmental Management, 70:35 41.

42

Aziz et al. Advanced Treatment of Landfill Leachate Effluent Using Membrane Filtration

Dr Aziz is a Professor in environmental engineering at the School of Civil Engineering, Universiti Sains Malaysia. Dr. Aziz received his Ph.D in civil engineering (environmental engineering) from University of Strathclyde, Scotland in 1992. He has published over 200 refereed articles in professional journals/proceedings and currently sits as the Editorial Board Member for 8 International journals. Dr Aziz's research has focused on alleviating problems associated with water pollution issues from industrial wastewater discharge and solid waste management via landfilling, especially on leachate pollution. He also interests in biodegradation and bioremediation of oil spills.

Mr. Chae Tyng Feng received his B.Sc. degree in Civil Engineering from School of Civil Engineering, Universiti Sains Malaysia (USM), Malaysia.

Dr Mohammed J.K. Bashir is an Assistant Professor in environmental engineering at the faculty of engineering and green technology, Universiti Tunku Abdul Rahman (UTAR), Malaysia. Dr. Bashir received his B.Sc. degree in Civil Engineering from Islamic University of Gaza, Palestine. He received M.Sc and Ph.D in Environ. Eng. from School of Civil Engineering, Universiti Sains Malaysia. He received several award and has published many refereed articles in professional journals/proceedings. Dr. Bashir's research has focused on wastewater treatment, solid and hazardous waste management, environmental sustainability.

43

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Phytoassessment of An Enhanced Naturally Attenuated Oil-Polluted Soil After Exposure To Various Concentrations of Sodium Bicarbonate SolutionDocumento13 páginasPhytoassessment of An Enhanced Naturally Attenuated Oil-Polluted Soil After Exposure To Various Concentrations of Sodium Bicarbonate SolutionAmin MojiriAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Physicochemical and Microbial Composition of Wastewater Samples Collected From A Petrochemical Company in Southern NigeriaDocumento10 páginasPhysicochemical and Microbial Composition of Wastewater Samples Collected From A Petrochemical Company in Southern NigeriaAmin MojiriAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Validation of Fiber Quality Linked SSR Markers Derived From Allotetraploid (Gossypium Hirsutum) in Diploid (Gossypium Arboreum)Documento9 páginasValidation of Fiber Quality Linked SSR Markers Derived From Allotetraploid (Gossypium Hirsutum) in Diploid (Gossypium Arboreum)Amin MojiriAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Effect of Superabsorbent Polymers On The Water Holding Capacity and Water Potential of Karkhe Noor Sandy SoilsDocumento8 páginasThe Effect of Superabsorbent Polymers On The Water Holding Capacity and Water Potential of Karkhe Noor Sandy SoilsAmin MojiriAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Effect of Millimeter Waves With Low Intensity On Peroxidase Total Activity and Isoenzyme Composition in Cells of Wheat Seedling ShootsDocumento7 páginasEffect of Millimeter Waves With Low Intensity On Peroxidase Total Activity and Isoenzyme Composition in Cells of Wheat Seedling ShootsAmin MojiriAinda não há avaliações

- A Review of Genetic and Epigenetic Mechanisms in Heavy Metal Carcinogenesis: Nickel and CadmiumDocumento15 páginasA Review of Genetic and Epigenetic Mechanisms in Heavy Metal Carcinogenesis: Nickel and CadmiumAmin MojiriAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Comparison of The Physical Characteristics and GC/MS of The Essential Oils of Ocimum Basilicum and Ocimum SanctumDocumento10 páginasComparison of The Physical Characteristics and GC/MS of The Essential Oils of Ocimum Basilicum and Ocimum SanctumAmin MojiriAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Review of Destructive Effect of Nano Silver On Human Health, Environment and AnimalsDocumento9 páginasA Review of Destructive Effect of Nano Silver On Human Health, Environment and AnimalsAmin MojiriAinda não há avaliações

- Histopathological Effect of Paraquat (Gramoxone) On The Digestive Gland of Freshwater Snail Lymnaea Luteola (Lamarck: 1799) (Mollusca: Gastropoda)Documento7 páginasHistopathological Effect of Paraquat (Gramoxone) On The Digestive Gland of Freshwater Snail Lymnaea Luteola (Lamarck: 1799) (Mollusca: Gastropoda)Amin MojiriAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- Studies of Physicochemical Properties of Rhizosphere of Elaeis Guinensis in AyingbaDocumento5 páginasStudies of Physicochemical Properties of Rhizosphere of Elaeis Guinensis in AyingbaAmin MojiriAinda não há avaliações

- Effects of Tide On Zooplankton Community of A Tributary of Upper Bonny Estuary, Niger Delta, NigeriaDocumento18 páginasEffects of Tide On Zooplankton Community of A Tributary of Upper Bonny Estuary, Niger Delta, NigeriaAmin MojiriAinda não há avaliações

- Effect of Starch Granule Morphology On Production of Bioethanol From Cassava and Sweet PotatoDocumento6 páginasEffect of Starch Granule Morphology On Production of Bioethanol From Cassava and Sweet PotatoAmin MojiriAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Inhibitory Properties of Organic Pest Control Agents Against Aphid (Aphididae: Homoptera) On Canola Brassica Napus L. (Brassicaceae) Under Field EnvironmentDocumento7 páginasThe Inhibitory Properties of Organic Pest Control Agents Against Aphid (Aphididae: Homoptera) On Canola Brassica Napus L. (Brassicaceae) Under Field EnvironmentAmin MojiriAinda não há avaliações

- Effect of Processing Variables On Compaction and Relaxation Ratio of Water Hyacinth BriquettesDocumento9 páginasEffect of Processing Variables On Compaction and Relaxation Ratio of Water Hyacinth BriquettesAmin MojiriAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Inhibitive Effect of Some Natural Naphthenates As Corrosion Inhibitors On The Corrosive Performance of Carbon Steel in CO2-Saturated BrineDocumento13 páginasInhibitive Effect of Some Natural Naphthenates As Corrosion Inhibitors On The Corrosive Performance of Carbon Steel in CO2-Saturated BrineAmin MojiriAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Livestock Products and EnvironmentDocumento9 páginasLivestock Products and EnvironmentAmin MojiriAinda não há avaliações

- Solvent-Free Synthesis and Spectral Studies of Some 9-Anthryl-1H-PyrazolinesDocumento9 páginasSolvent-Free Synthesis and Spectral Studies of Some 9-Anthryl-1H-PyrazolinesAmin MojiriAinda não há avaliações

- Host Preference and Performance of Fruit Flies Bactrocera Zonata (Saunders) and Bactrocera Cucurbitae (Coquillett) (Diptera: Tephritidae) For Various Fruits and VegetablesDocumento7 páginasHost Preference and Performance of Fruit Flies Bactrocera Zonata (Saunders) and Bactrocera Cucurbitae (Coquillett) (Diptera: Tephritidae) For Various Fruits and VegetablesAmin MojiriAinda não há avaliações

- Inward FDI, Growth and Environmental PolicyDocumento11 páginasInward FDI, Growth and Environmental PolicyAmin MojiriAinda não há avaliações

- Assessing Relationships in Kenyan Sorghum Landraces by Use of Simple Sequence Repeat Molecular MarkersDocumento12 páginasAssessing Relationships in Kenyan Sorghum Landraces by Use of Simple Sequence Repeat Molecular MarkersAmin MojiriAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Full Length Research Paper: ISSN: 2322-4541 ©2013 IJSRPUBDocumento7 páginasFull Length Research Paper: ISSN: 2322-4541 ©2013 IJSRPUBAmin MojiriAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- An Investigation Into Factors Affecting Productivity of Produces by Karoun Agriculture and Industry CompanyDocumento13 páginasAn Investigation Into Factors Affecting Productivity of Produces by Karoun Agriculture and Industry CompanyAmin Mojiri100% (1)

- Monitoring and Configuration of Energy Harvesting System Using WSNDocumento10 páginasMonitoring and Configuration of Energy Harvesting System Using WSNAmin MojiriAinda não há avaliações

- Democratic Regression in Nigeria: A Critical Discourse On The Character and Tendencies of The Political Parties As Explanatory FactorsDocumento9 páginasDemocratic Regression in Nigeria: A Critical Discourse On The Character and Tendencies of The Political Parties As Explanatory FactorsAmin MojiriAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Time-Dependent Creep Analysis of Rotating Thick-Walled Cylindrical Pressure Vessels Under Heat FluxDocumento10 páginasTime-Dependent Creep Analysis of Rotating Thick-Walled Cylindrical Pressure Vessels Under Heat FluxAmin MojiriAinda não há avaliações

- Synthesis and Characterization of Two New Oxo-Centered Trinuclear Complexes of Manganese and IronDocumento7 páginasSynthesis and Characterization of Two New Oxo-Centered Trinuclear Complexes of Manganese and IronAmin MojiriAinda não há avaliações

- Calculation of Lattice Parameters and Energy Band Structure and Density of States the β-ZrNCl with Ab InitioDocumento9 páginasCalculation of Lattice Parameters and Energy Band Structure and Density of States the β-ZrNCl with Ab InitioAmin MojiriAinda não há avaliações

- Assessing Cracks in Reinforced Concrete Structure Using Acoustic EmissionDocumento6 páginasAssessing Cracks in Reinforced Concrete Structure Using Acoustic EmissionAmin MojiriAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Remediation of Tetrachloroethylene - Contaminated Soil With Zero Valent Iron Utilizing Electrokinetic ReactorsDocumento10 páginasRemediation of Tetrachloroethylene - Contaminated Soil With Zero Valent Iron Utilizing Electrokinetic ReactorsAmin MojiriAinda não há avaliações

- Factors Influencing Anemia and Night Blindness Among Children Less Than Five Years Old (0 - 4.11 Years) in Khartoum State, SudanDocumento13 páginasFactors Influencing Anemia and Night Blindness Among Children Less Than Five Years Old (0 - 4.11 Years) in Khartoum State, SudanAmin MojiriAinda não há avaliações

- American Water WorksDocumento7 páginasAmerican Water WorksLisa SorgAinda não há avaliações

- DAO 34 and 35 Water Quality Criteria and Effluent RegulationsDocumento33 páginasDAO 34 and 35 Water Quality Criteria and Effluent Regulationscris guzonAinda não há avaliações

- Kech207 PDFDocumento17 páginasKech207 PDFhoney teckaniAinda não há avaliações

- New Concepts On Carbon Redirection in Wastewater Treatment PlantsDocumento12 páginasNew Concepts On Carbon Redirection in Wastewater Treatment Plantsbk9784Ainda não há avaliações

- TerminologyDocumento77 páginasTerminologyBianca Emanuela LazarAinda não há avaliações

- Ecological Riverfront DesignDocumento146 páginasEcological Riverfront Designsakthivisalakshi100% (2)

- Environmental Concepts and ThreatsDocumento69 páginasEnvironmental Concepts and ThreatsBeltcarl Anthony Lamigo BacalsoAinda não há avaliações

- Winery Wastewater Treatment For Water Reuse Purpose - Conventional Activated Sludge Versus Membrane Bioreactor MBRDocumento7 páginasWinery Wastewater Treatment For Water Reuse Purpose - Conventional Activated Sludge Versus Membrane Bioreactor MBRsulihah12Ainda não há avaliações

- Science of The Total Environment: M.S. Fountoulakis, S. Terzakis, A. Chatzinotas, H. Brix, N. Kalogerakis, T. ManiosDocumento8 páginasScience of The Total Environment: M.S. Fountoulakis, S. Terzakis, A. Chatzinotas, H. Brix, N. Kalogerakis, T. Maniosbaquir_aligAinda não há avaliações

- SANSEM WebinarDocumento6 páginasSANSEM WebinarNiwled UyAinda não há avaliações

- First Floor Drainage System: D E F G H I J K L A B CDocumento1 páginaFirst Floor Drainage System: D E F G H I J K L A B CMary Joyce AngalaAinda não há avaliações

- Oel1 Ahmed SaleemDocumento12 páginasOel1 Ahmed SaleemEESHATUR RAZIAAinda não há avaliações

- MDA EmergencyActionPlan 109428 7Documento62 páginasMDA EmergencyActionPlan 109428 7WXYZ-TV Channel 7 DetroitAinda não há avaliações

- Dot-Hwy NPDES Annual RPT 2019-20Documento166 páginasDot-Hwy NPDES Annual RPT 2019-20harsh pathaniaAinda não há avaliações

- 01 Water Supply Engineering-Lecture 1-Introduction 2019-2020 PDFDocumento10 páginas01 Water Supply Engineering-Lecture 1-Introduction 2019-2020 PDFSeashells Do ImpossibleAinda não há avaliações

- BBIA Landside Infrastructure Final Design ReportDocumento167 páginasBBIA Landside Infrastructure Final Design ReportTayyabah ZafarAinda não há avaliações

- Week 5 LADocumento6 páginasWeek 5 LARenzo FormanesAinda não há avaliações

- Research Paper On Septic TankDocumento4 páginasResearch Paper On Septic Tankzqbyvtukg100% (1)

- Tomher Septic - Tank 2022Documento2 páginasTomher Septic - Tank 2022Robin LaiAinda não há avaliações

- Lecture 4-Water Treatment 2Documento27 páginasLecture 4-Water Treatment 2Muhammad AhmadAinda não há avaliações

- Ijciet 08 09 044 PDFDocumento7 páginasIjciet 08 09 044 PDFnivedhithaAinda não há avaliações

- Memorandum of Agreement: (Name of Company, A Corporation Created Under The Laws of The Philippines With An OfficeDocumento2 páginasMemorandum of Agreement: (Name of Company, A Corporation Created Under The Laws of The Philippines With An OfficeErlyn Bacoy QuizoAinda não há avaliações

- Membrane Tech Lowers WW Treatment CostsDocumento9 páginasMembrane Tech Lowers WW Treatment CostsAkhmad RidhaniAinda não há avaliações

- Construction schedule for sewerage system & STPDocumento1 páginaConstruction schedule for sewerage system & STPNana BarimaAinda não há avaliações

- 1 - Ra 9275 - The Clean Water ActDocumento66 páginas1 - Ra 9275 - The Clean Water ActVitaliano Francia, Jr. IIAinda não há avaliações

- Swimming Pool Drain Stack Plumbing PlanDocumento1 páginaSwimming Pool Drain Stack Plumbing PlanEmmanuel TamayoAinda não há avaliações

- Wollega University: M.Sc. Proposal OnDocumento45 páginasWollega University: M.Sc. Proposal OnYaikob Kebede100% (1)

- Appendix 41 - Roy Hill Mine Water Management PlanDocumento28 páginasAppendix 41 - Roy Hill Mine Water Management PlanFrancisco HernandezAinda não há avaliações

- KazmifceDocumento7 páginasKazmifceسومر محمدAinda não há avaliações

- 2006 - Alberta Septage Hauler and Receiving Industry Project - Survey, Research, Jurisdictional and Technical Scan PDFDocumento125 páginas2006 - Alberta Septage Hauler and Receiving Industry Project - Survey, Research, Jurisdictional and Technical Scan PDFempiibAinda não há avaliações

- Nine Black Robes: Inside the Supreme Court's Drive to the Right and Its Historic ConsequencesNo EverandNine Black Robes: Inside the Supreme Court's Drive to the Right and Its Historic ConsequencesAinda não há avaliações

- Conviction: The Untold Story of Putting Jodi Arias Behind BarsNo EverandConviction: The Untold Story of Putting Jodi Arias Behind BarsNota: 4.5 de 5 estrelas4.5/5 (16)

- The Law Says What?: Stuff You Didn't Know About the Law (but Really Should!)No EverandThe Law Says What?: Stuff You Didn't Know About the Law (but Really Should!)Nota: 4.5 de 5 estrelas4.5/5 (10)

- Reasonable Doubts: The O.J. Simpson Case and the Criminal Justice SystemNo EverandReasonable Doubts: The O.J. Simpson Case and the Criminal Justice SystemNota: 4 de 5 estrelas4/5 (25)

- A Contractor's Guide to the FIDIC Conditions of ContractNo EverandA Contractor's Guide to the FIDIC Conditions of ContractAinda não há avaliações

- Reading the Constitution: Why I Chose Pragmatism, not TextualismNo EverandReading the Constitution: Why I Chose Pragmatism, not TextualismAinda não há avaliações