Escolar Documentos

Profissional Documentos

Cultura Documentos

Details

Enviado por

Ravi KrishnanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Details

Enviado por

Ravi KrishnanDireitos autorais:

Formatos disponíveis

NLCs EXPERIENCE IN MINING LIGNITE - A CASE STUDY *R.Deivam, **M.

Sivakumar INTRODUCTION: Neyveli Lignite Mines play a major role in generating the energy needs of the states of South India. Lignite mining at Neyveli commenced about half a century ago by Neyveli Lignite Corporation Ltd (NLC), a Government of India Enterprise. Continuous mining technology using Bucket Wheel Excavators (BWE), Belt conveyors and Spreaders was adopted. The transfer and adoption of Bucket Wheel Excavator technology at Neyveli was a landmark event, and it has helped the company to reap profits during its life. The successful deployment of BWEs was made possible by adopting suitable modifications in the design of the buckets, teeth and structural parts to tackle the hard and abrasive nature of overburden strata. The lignite mining is also faced with adverse hydrological conditions caused by confined aquifer occurring below lignite seam, with an upward thrust of 5 to 8 Kg/cm2. The challenges posed by nature on lignite mining were aptly handled in the Neyveli mines by continuous improvement in coherence with the technological development and up-scaling capacity of BWEs and by continuously optimizing the Ground water pumping pattern. Initially smaller capacity 350 litre BWEs with 1000 mm fabric belt conveyors deployed were upgraded to 1400 litre Bridge type BWEs and 2400 mm steel cord belt conveyors, to augment the lignite production from 3.5 MT/Annum to 24 MT/Annum. The paper traces the history of the developments introduced in lignite mining at Neyveli mines during the past five decades. 2. LIGNITE RESOURCES OF INDIA: Unlike coal, lignite is a low calorific fossil fuel for producing electricity. About 38.93 billion tones (BT) of lignite reserves of various categories have been identified in India, (Table. 1) mostly in the states of Tamil Nadu, Puducherry, Rajasthan, Gujarat, Jammu & Kashmir and Kerala. Tamil Nadu and Puducherry possesses 31.74 BT of lignite (Fig. 1).

State Tamil Nadu Rajasthan Gujarat Puducherry Kerala Jammu & Kashmir West Bengal Total

Table: 1 Lignite resources of India Lignite Reserves in Million Tonnes 31327.02 4485.43 2662.75 416.61 9.65 27.55 1.15 38930.16

NEYVELI LIGNITE MINES: Neyveli Lignite Corporation Limited (NLC) presently operates four opencast lignite mines namely Mine-I of 10.5 MT/Annum., Mine-II of 10.5 MT/Annum. Mine-IA of 3.00 MT/Annum. and Barsingsar Lignite Project

(BLP) at Rajasthan of 2.1 MT/a. Mine-II is under expansion from 10.5 MT/Annum. to 15 MT/Annum. (Table-2) The lignite produced is mainly used for power generation.

* - Dy. General Manager/ Mine Planning/ Mine-I&IA, NLC Ltd. ** - Chief Manager/ Mine Project Planning, NLC Ltd 1

38930 MT

4485

38930 Fig - 1 TABLE-2: SALIENT FEATURES OF NLC MINES Particulars Mining Area Details Capacity / Annum Lignite Reserve OB Thickness Lignite Thickness Average Stripping Ratio Mining Started on Lignite First Exposed Overburden Excavated * Lignite Mined * Linked Power Station Unit Sq.Km. Units Million Tons Million Tons. Mts. Mts. Tons: m3 Date Date Mill. Cu. Mtr Million Tons. Name Mine I 27.00 Mine I 10.5 365 45 to 110 8 to 26 1: 5.5 20.05.1957 24.08.1961 1405.67 260.87 Mine - IA 12.00 Mine -IA 3.0 120 55 to 110 6 to 24 1: 7.0 30.07.2001 24.03.2003 118.98 14.02 Mine - II 42.00 Mine - II 10.5 + 4.5 613 45 to 103 8 to 22 1: 5.5 14.04.1981 30.09.1984 1000.11 164.10 BARSINGSAR (RAJASTHAN) 9.70 BLP 2.1 53 44 to 118 15 to 25 1: 4.81 07.08.06 21.05.2007 16.50 0.04 TPS 2X125MW (250) **

Generation Capacity MW * As on 1st April 2008

TPS - I (600MW (7 TPS - II & TPSI ST-CMS (Pvt.) X 210 MW + 2 x Expn. (2 X 210 (250 MW) 250 MW) MW) 1020 250 1470 + (500)** ** Under execution

3. METHODOLOGY OF MINING: The lignite deposit in Neyveli lignite field forms a part of Cauvery basin. A thick formation of upper cretaceous, tertiary and subrecent sedimentary rocks, both marine and fresh water are overlaying the Archean basement. Lignite is mainly of single seam with 1 in 100 gradient. The overburden in Neyveli field mainly consists of argillaceous and ferruginous sandstone. Continuous mining by Bucket Wheel Excavator (BWE) belt conveyor spreader combination is deployed for both excavation of overburden and extraction of lignite in NLC mines. NLC started with a 350 L. BWE and at present it uses 1400 L BWEs. A huge reservoir of artesian aquifer water occurs below the entire lignite bed, exerting an upward pressure of 5 to 8 Kg/cm2. Unless this water pressure is reduced before mining, it will burst the lignite seam and flood the mines. This problem is solved by selective formation of bore wells and pumping to depressurize the water pressure to safe mining condition. The water is being used in thermal power station. 4. HISTORY OF TECHNOLOGICAL DEVELOPMENT: The Neyveli Lignite Corporation Limited was formed in November 1956, with a primary objective of exploiting the lignite reserves in Neyveli lignite field for generation

of power, as there was burgeoning demand of power. The most favourable mining area containing about 200 MT mineable Lignite was selected. The Mine was planned with a life span of 57 years, at a production level of 3.5 million tones per annum. The overburden capping varied between 50 m. to 80 m. and that of lignite from 10 m. to 25 m., with an average stripping ratio of 1: 4. The continuous type of excavators (BWE) as used in German and Australian Brown Coal Mining Industries were recommended for adoption, after various techno-economic studies. Mining started in 1957 by deploying a set of conventional mining equipments and gradually SME (Specialized Mining Equipment) were added one by one from 1958 to 1961. Initially BWE of 350 L. and 700 L. capacity were introduced with 1000 mm. / 1200 mm. fabric belts and matching capacity of spreaders. The development phase of the mine was completed in September 1961. However, the full production stage of 3.5 MT of lignite per annum could not be achieved even after six years (Table-3), due to capacity constraints of the excavators (BWEs) working in the hard strata conditions and other related problems at Neyveli. Table: 3

GROWTH OF OB & LIGNITE PRODUCTION OF NLC FROM 1957

Year OB IN MM

3

Units in MM3/MT

1957-58 1958-59 1959-60 1960-61 1961-62 1962-63 1963-64 1964-65 1965-66 1966-67 1967-68 2.40 0 3.24 0 3.45 0 4.07 0 4.05 0.00227 3.16 0.35 4.68 1.20 6.97 1.60 9.03 2.56 10.52 2.46 13.91 3.44

LIGNITE IN MT Year OB IN MM

3

1968-69 1969-70 1970-71 1971-72 1972-73 1973-74 1974-75 1975-76 1976-77 1977-78 1978-79 16.24 3.98 14.84 4.28 12.33 3.39 15.18 3.72 12.78 2.89 13.23 3.33 12.24 2.94 12.25 3.03 18.12 4.02 16.42 3.58 18.04 3.30

LIGNITE IN MT Year OB IN MM3 LIGNITE IN MT Year OB IN MM

3

1979-80 1980-81 1981-82 1982-83 1983-84 1984-85 1985-86 1986-87 1987-88 1988-89 1989-90 23.87 3.25 34.25 4.45 33.06 5.88 33.96 6.40 41.49 6.63 55.03 7.11 60.35 7.29 60.90 8.55 59.53 10.15 62.08 11.41 64.36 11.24

1990-91 1991-92 1992-93 1993-94 1994-95 1995-96 1996-97 1997-98 1998-99 1999-00 2000-01 64.58 11.76 73.07 12.54 86.02 13.31 83.76 14.15 85.37 15.41 93.40 17.21 94.21 17.35 96.50 18.11 95.74 18.17 100.47 17.55 109.05 18.17

LIGNITE IN MT Year OB IN MM

3

2001-02 2002-03 2003-04 2004-05 2005-06 2006-07 2007-08 122.25 18.37 109.03 18.62 116.07 20.56 120.44 21.57 119.66 20.44 128.07 21.01 135.83 21.59

LIGNITE IN MT

Several improvements and design changes / modifications had to be carried out in the bucket wheel excavators which were not able to tackle efficiently the hard, abrasive nature of Neyveli overburden. The problem of confined aquifer exerting an upward pressure of 5 to 8 Kg/cm2 at the bottom of lignite had also to be controlled by adopting a predetermined pumping pattern which took some years to develop. The mine was not able to achieve the production targets to fulfill the demand of downstream units and no significant improvement of production till 1967-68. During the period of third and fourth five year plans (1961-65 and 1966-70), it was also proposed to expand the power station capacity from 250 MW to 400 MW and then to 600 MW to cope up with increasing demand of power in the state and to expand the capacity of mine correspondingly from 3.5 MT/a. to 4.8 MT/a. and then to 6.5 MT/a. Though expansion of power station went without any major setback, the corresponding increase in the capacity of the mine could not be achieved, even after the introduction of equipments proposed in the Project Report. Lignite production continued to be in the range of 2.4 MT/a. to 3.4 MT/a. as against the demand of 4.8 MT/a. which would further increase to 6.5 MT/a. by late 70s when the power station reached 600 MW. The major reasons for the shortfall in SME production were: There was no provision for forward preparation of ground with explosives. On actual experience it was found that without forward preparation, it was impossible to keep BWEs in a healthy stage even when operated at the rate of production much below the manufacturers specification. On account of the abrasive nature of hard Cuddalore sandstone strata, the buckets and teeth were damaged rapidly causing frequent stoppages and high downtime.

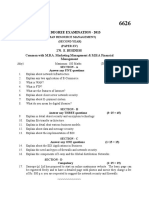

5. EVOLUTION OF BUCKET WHEEL TEETH: The physical and geological investigations showed that the nature of sandstone in the overburden strata varies from very coarse-grained hard sandstone to very fine-grained friable sandstone. The hematite nodules embedded in the formation offer a very high resistance to the teeth of bucket wheel excavator. The cutting resistance of such strata varies between 150200 Kg/cm as against 70 to 100 Kg/cm in West German overburden strata. The first set of original teeth supplied by supplier of the equipment (M/s. LMG) fitted to 350 L. bucket wheel excavator lasted only 3 hours. This meant that the excavator had to be stopped for a major portion of the time for changing the teeth alone. Many field tests were carried out by changing the design of the teeth initially spade shape teeth used in front of bucket had been changed to ripper type, the angle of fixing them to the bucket and cutting lips etc. In addition, tungsten inserts were brazed to the teeth. Ultimately the life of the teeth could be improved to more than 250 hours (Fig. 2). However, the shock loads on account of hard and abrasive soil conditions, reflected on the other machinery parts, particularly the bucket wheel drives, bearings, shafts and ultimately the loading boom structures. These were strengthened and modified suitably with the cooperation of the manufacturers and the material composition was improved to withstand greater stresses and strains in the structural parts. Improvements also made / carried out progressively in other main parts of the machines such as turn table, under carriage, crawlers and pivot points. Details of some major modification carried out are shown in Table-4. Improvements attained out of such modifications have been substantial and the experience gained has helped in arriving at the present set of equipment in which most of the problems have been eliminated.

Fig.2

E 1- Right Corne r Tooth

E 2- Le ft S ide Tooth LH - Left Side Tooth

E1 E2

RH- Right Side Tooth

C2 - Ce ntra l Tooth Le ft C1 - Ce ntra l Tooth Right

RH C1 1. Fitt ed in all positions 2. 3. H ard faced with electrodes F itted fitted in L H , RH,C1,C2 in C 1,C2 4. F it ted in LH , RH C2 5.

LH

6. Fitted in LH , RH F it ted in Position C1,C2

7. Wid ia Inserts fitted in Position C1,C2

LIF E 3 1/2 Hours ( A p pro ximatly)

L IF E 6 1/2 Hours ( A pp roximatly)

LIFE 2 1/2 Hours ( A p pro ximatly)

LIFE 15 1/2 Hours ( A p pro ximatly)

L IF E 100 Hours ( A pp roximatly)

L IF E 50 Hours ( A p proximatly)

LIF E 100 Hours ( A pp roximatly)

8. Fitted in Position LH ( Sh orter In Length )

9. F itted in Po sition RH ( Lo ng er In Length )

10. Fitted in Po sitio n RH . 4 Inserts ( Lo nger In Length )

11. F itted in Position LH . 4Inserts ( Sho rter In Length )

12. With Wid ia insertsHard F aced With Electrods F itted in Position C1,C2

13. With Widia in serts Fitted in R H ( L on ger in Length) H arde F aced With Electrods

14. With Wid ia inserts Fitted in Position LH ( Shorter in Len gth ) H ard e F aced With Electrods

LIF E 200 Hours ( A p pro ximatly)

LIF E 200 Hours ( A p pro ximatly)

LIF E 250 Hours ( A pp roximatly)

LIFE 250 Hours ( A p pro ximatly)

LIFE 250 Hours ( A p pro ximatly)

L IF E 250 Hou rs ( Ap p ro ximatly )

L IF E 250 Hou rs ( Ap p ro ximatly )

Forward preparation is also very important for the performance of BWEs in the hard strata. Presently more than 45% of the

overburden soil is blasted for loosening of the Matrix in inside Benches for ease in Excavation.

TABLE-4 EQUIPMENT MODIFICATIONS INTRODUCED IN BWE AT NEYVELI Problems Modification Component Encountered Profile modified to suit the cutting condition. Tungsten Carbide hard cutting inserts provided. In addition to Heavy wear due to hard facing of wear out areas. Fixing of teeth body to Bucket teeth abrasion and breaking buckets with high tensile bolts instead of wedges and ordinary bolts. Profile modified. Lips are provided with hard facing. Bucket and Heavy wear and tear cutting bows Provided chain backs to avoid build up and spillage. Thick and wear resistant plates and strips provided. Bucket wheel Heavy wear and build Ring chute modified with thick wear plates. Hoppers ring chute up in chute provided with synthetic material lining to avoid soil build up and also wear. Frequent failure of the Cyclo gears modified into planetary gears and also the Rotary plate Cyclo gears fluid coupling was introduced. Bucket wheel Bucket wheel boom head modified with solid plate boom, discharge Structural failures construction and all booms made either with plate boom, construction or with built up sections instead of lattice

Component Superstructure

Problems Encountered

Modification

Slewing counter weight Number of conveyor flights Slewing center pivot (700 L. machines) Bucket wheel gearbox Slewing mechanism

construction. Super-structure and other booms, built up construction and plate construction against lattice construction. Bearing with axle modified in the old machines and Frequent failure of slewing counterweight totally eliminated in the new pivot bearing machines. Three conveyors in the old system. Short belts Changed to 2 conveyor systems eliminating short required frequent flights. replacement Frequent contamination Position of the bearing changed and center pivot bearing with soil strengthened. Frequent failure in the Single step down gearbox without speed variation. differential system Frequent failure of Cyclo gears in slewing Cyclo gears eliminated and planetary system introduced. system particularly in 350 L. machines

Modification of Bucket to handle Sticky Clay: In addition to hard abrasive overburden soil, an entirely different strata was also encountered in Mine II of NLC, which is located 5 Km. south of Mine I. A blackish alluvial clay formation occurs on the top 7 to 17 m. thickness in the southern portion of second mine. This alluvial clay formation carried large quantities of KANKAR nodules with very low alumina Al2O3 content and iron content Fe2O3. When wet, the clay absorbs water, swell (about 1.6 to 1.7 times) and become plastic (plasticity index of about 35%), soft and slushy.

This soil (Alluvial Clayey Overburden) was choking the bucket and the excavated soil was not freely discharging from the buckets. The capacity of the buckets got reduced due to the clay build up on sides and the back of the bucket resulting in low excavation rates. At times the total bucket was fully choked / packed with clay. About 25 to 30% of the soil excavated spilled onto the ground necessitating repeated dozing for clearing and re-handling the soil.

Teflon sheet Fig: 3

Several modifications were carried out for the satisfactory handling of the sticky clay and proper discharge from the buckets. Various experiment measures tried were: Perforating buckets with holes and slots on the sides (which reduce contact area) instead of plates. Providing buckets with linolex rubber solution. Coating buckets with special rubber solution. Providing buckets with special ceramic lining plates Lining of buckets with high density polyethylene (HDPE) Teflon sheets. The result of lining of Teflon sheets (Anti friction) was encouraging. Hence, now all the buckets, chutes leading to the rotary plates, diverters etc. are all lined with Teflon sheets(Fig: 3). Similarly, the solid back of the buckets were cut open and chains were filled to the back of the buckets. The sticking of the soil was reduced considerably in the chain backed bucket due to the whipping action of the chains and the soil is getting emptied from the bucket easily, resulting in improved production performance. 6. QUALITY OF LIGNITE: Lignite contains 65-70% of carbon, 2025% of oxygen, about 5% of hydrogen and small amounts of Nitrogen and Sulphur. The average Calorific value of lignite is 2600 K.cal/Kg. It cannot be compared favorably with the high Calorific value of pure Coal. Yet lignite has an advantage of being free burning (non coking), having low ash and giving rapid and complete combustion. Since the volatile matter is usually high, lignite burns readily. Air dried lignite is quite suitable for direct burning. For high capacity boilers, lignite can be burnt in the pulverized form. Lignite is being mined only through opencast mining method due to associated geo mining problems. Continuous mining method with Bucket Wheel Excavator-ConveyorSpreader technology is adopted in all the Neyveli Lignite Mines. Problems due to Marcasite: Occurrence of Marcasite within the lignite seam is a common phenomenon. Marcasite which is a Ferrous Sulphide mineral (FeS2)

occurs as thin veins within the lignite seam and is more predominant in Mine-II. The Marcasite veins are not uniform and do not follow any pattern. It is sporadic in nature and hence could not be segregated while mining. They create clinker formation when fed into Thermal boilers and affect the performance of the Power Plant. Hence before dispatch to Thermal bunkers this Marcasite is separated by hand picking at Lignite storage bunkers. Due to hard and abrasive nature, they at times create problem like damaging the Bucket wheel teeth, frequent changing of teeth etc during mining operation. 7. DEPLOYMENT OF CONVEYORS IN NLC MINES: Initially from 1959 to 1965 about 8 km of belt conveyor of 1000mm for lignite handling (1000 TPH) and 1200mm (2500 TPH) wide belt conveyors for OB handling were in operation. HURDLES FACED SINCE INCEPTION: In the initial stages the conveyor carrying capacity was just matching with the carrying capacity of the loading equipment. While using smaller width conveyor the conveyor were designed to capacity that matched with equipments. The Bucket wheel excavator at times due to loose strata condition used to deliver spurt loads which will be more than the excavator capacity. When these load were transmitted to the belt conveyor, there were stoppages due to overload, overflowing, choking of transfer points etc., the above nature of stoppages lead to snapping of belts, burning of motors, and also needs manual cleaning of the loaded belt to the entire stretch. Trouble shooting and resetting of the electric contactor relay were time consuming. Due to overload the high resistance fuse used flown off very frequently. Later the conveyor carrying capacity/ handling capacity has been designed at 25 to 30% more than the capacity of the loading equipments. There by the choking of transfer points and tripping due to overload has been avoided. More over the running of the conveyor has become smooth. As the strength of the conveyor belt is more and designed to carry 30 % more than the loading equipment capacity, the belt snaps / joint failures are eliminated.

The belt joints were snapped/ failed frequently since this system of power transmission from motor to belt was normal gear transmission. As the drive power of the conveyor increased and fluid coupling, slip-ring transmission etc., were introduced to transmit the motor power to belt, there is smooth transmission of power and no belt joint snaps etc. The carrying and return idlers were of fixed type and if any small misalignment of the conveyor / frames cause the line out of the conveyor belt and there by damaging of the costly belt and causing more stoppage for changing of the belt in premature damage. The installation of suspended garland type idlers during 1980s (self aligned idlers) instead of fixed idlers was one of the major modification / break through development with belt conveyor system design. These idlers have an in built tendency to make the belt run centrally. Thereby belt edge damaging is totally eliminated. Moreover the garland idlers station (or) transfer points. The troughing angles also got standardised and for conveyor of 1500 mm the troughing angle is 30o and for 1800 mm and 2000 mm conveyors the troughing angle is got

fixed as 40o. Further all the fabric belts have been removed and only steel cord belts have been introduced as given in Table-5. Initially NLC used 1000mm, 1200mm width fabric belts. Since their tensile strength is low each of the conveyors has been laid for a length of 300 to 400 m. Due to short length of the conveyors the life of the belt was only 10000 hours which warranted frequent replacement of the belt. In 1970s 1500 mm overburden conveyor belts were changed to nylon x nylon with a drive power of 4 x 75 kw with fluid couplings. However in this case also conveyor length is restricted to 75 kw motors by which the conveyor lengths gone up to 500 to 550 m only. In late 1970s, 1800 mm wide steel cord conveyor belts were introduced with a drive power of 3 x 400 kw were extended upto 1.2 km with a carrying capacity of 8000 tph. In 1980s fabric and nylon belts were removed and steel cord belts were introduced in a phased manner. Presently steel cord belts of tensile strength of 4000 kg/cm width of the belt are in operation. The length of the steel cord belt conveyors are increased to 2.5 to 3.0 km. The life of the belt also increased to 30000 to 35000 hours. Details of conveyors - Table No.3

Conveyor width mm 1000 1200 1500 1500 1600 1800 2000

Strength Troughing angle Carrying of the Carrying Return side capacity belt tph side Fabric <1000 30 o 0o 1200 NY-NY 1000 30 o 0o 1400 o o NY-NY 1200 30 0 1800 NY-NY 1200 30 o 10 o 2000 Steel cord 1600 30 o 15 o 4700 Steel cord 2000 40 o 15 o 8000 Steel cord 2250 40 o 15 o 11000 3150 2400 Steel cord 4000 45 o 15 o 20000 This 2400mm conveyor troughing angle has been modified as below 2400 Steel cord 4000 40 o 15 o 20000 o 2400 Steel cord 4000 40 15 o 20000 The conveyor procured after 1976 are all having thyrister control system with induction motor. The conveyor procured after 1994 are all having PLC system. The Variable Voltage Variable frequency drives have been used for new conveyor in order to have optimum energy consumption.

Type of belt

Capacity of motor used (kw) 45 45 75 350 350 400 630 1250 1250 1250

SHIFTING OF THE CONVEYORS: There are shiftable conveyors at the mine cutting face and dumping yard. At the mine cutting face / mine advancing side after completion of each block of 40/80 m face

conveyor has to be shifted to tackle the next fresh block of 40/80 m, since Bucket Wheel Excavator can cut 40 m block only at a time and if Mobile Transfer Conveyors is provided then exploitation of 80 m block is possible. Similarly in the dumping yard, dumping of each 100 m to 120 m width, the dumping conveyor has to be shifted 100 m laterally to do a fresh dumping block. Since in the initial stages the conveyors were small in size, the shifting of conveyors was carried out just by pushing with dozers to new location. However in due course the conveyor sizes were increased. The 2000 mm workshop type drive heads are weighing about 80 to 100 tonnes and were pushed / shifted using bigger size bulldozers and special equipment called pipe layers of 90 tonnes capacity. The 2000 mm conveyors are also heavy in structure and the steel cord belt running in this conveyor is also of more in weight. Hence instead of pushing by dozers, a unit called pipe layer fitted with shifter head are used in shifting the conveyors. The 2000mm drive heads of latest type are weighed about 250 tonnes, since all the drive powers / units with motor, gear box, electrical panel are mounted on the conveyor itself. They are weighing 250 tonnes and shifting these drive station are not possible by just bulldozer and 90 t pipe layers. These heavy drive heads of higher drive powers are moved / shifted using hydraulic walking pads. These walking pads are of set (2 nos ) fitted one walking pad at each side of the drive station. They lift the drive station using hydraulic power and moved about half a meter at a time. These walking pads are having a limitation. They can shift the drive station with a lifting limit of about 250 tonnes. Due to these slow process of shifting the idle time / non production time increases at every shifting. More over in due courses the length and carrying capacity of the conveyor also increased to tackle the need of high demand in material handling. Now a days conveyor of 3.0 km with a carrying capacity of 20000 tph, 2400 mm steel cord belt of ST 4000 are in use. These conveyors having a drive power of 4 X 1250 kw ( 4 motors of 1250KW ) at drive heads with other drive units and electrical kiosks. These drive units weight is more than 500 tonnes. These units cannot be moved with walking

pads. Even if it is moved with walking pads, the slow processing of shifting these conveyors will increase the down time of costlier production system. Hence an improved type of transporting these drive heads called Transport Crawlers were introduced. These transport crawlers can be inserted under these heavy drive units which can lift the drive units and move at a faster rate ( 8 m/min ). IMPLEMENTATION OF VVVF DRIVES IN CONVEYOR: NLC has recently procured conveyor (2000mm & 2400mm) with variable voltage variable frequency (VVVF) drives motor. This improvisation is helpful in optimizing power consumption. The advantages of using VVVF drives are as follows: VVVF drives are fully digital using proven technology based on pulse encoder feedback technology for individual motors. VVVF drives are able to feed standard squirrel cage induction motors. The power factor of the system is not less than 0.90, so that there is substantial saving of energy. The drives facilitate smooth starting and thereby resulting in lesser downtime of the conveyor / machine. The drives have digital control with highly accurate speed setting and repeatability ensuring maximum precision for process control. Along with the fault messages, the display includes energy consumption, motor speed and elapsed running time etc. for easy monitoring, which replaces the analog metering and reduces cumbersome wiring. Provision to connect to PLC through suitable bus. Built-in monitoring unit to view the online status, faults, parameter values. Provision to up-load / download of drive parameters to a laptop PC and vice-versa. Special testing instruments, laptop computer with suitable software, are available for recording and load analyzing of VVVF drives. The application of mechanical brake is possible at any desirable speed as specified by the machine builder, through PLC software programme.

GROUND WATER CONTROL (GWC): (Fig :4)

1. WELLS ON THE GROUND LEVEL (1960s)

Ground water wells 1960s: Surface & periphery 60 Wells :Discharge 60000GPM

(1970s) 2. SURFACE WELLS BENCH WELLS AND FLANK WELLS ON THE (NORTH &

SOUTH)

(Fig :4)

1970S :Surface and top Bench of the mines (Non-Mining Activity Region) 40,000 to 50,000 GPM 1980S(Late) : Spoil bank & on the flanks (North & South). 30,000 to 35,000 GPM

(Late 1980s) 3. INSIDE SPOIL BANK WELLS AND ON THE FLANKS

(NORTH & SOUTH)

As already mentioned the aquifer water with upward pressure below lignite has to be controlled / tackled for safe mining operation. The ground water operations started in 1961, for depressurization of aquifer. As the mine advanced, the pattern of pumping was also revised from time to time for the maximum draw down with optimum pumpage. In 1961-64 these pumpings were from ground level (surface pumping grid pattern). The pump wells were operated around the mine at surface level. There were more than 60 wells with a pumping capacity of 55,000 to 60,000 GPM. This pattern was changed to bench pumping grid pattern and spoil bank pumping pattern from 1964 to 1968 by which the pumping was carried out at various bench levels which were closer to lignite extraction. By this, the pumping was reduced to about 50,000 GPM. The lignite bench pumping grids were introduced in 1971, pumping on the lignite bench on both side, the pumping from this grid pattern was further reduced the pumping quantum to 36,000 GPM.

Bund wells (From 1986 To 1995): Bund was formed with overburden materials on the mine floor after the excavation of lignite. By this, the quantum of pumping has been reduced to about 30,000 GPM. However there was problem in drilling and establishing the wells in the dumped soil. Present pattern of pump wells (From 1995 onwards): Fig: 5 To cope up with fast advancement of mine cut and increased lignite production, a decision was taken to establish pump wells in the advancing side of the mine cut on the top / middle bench level (Lower Overburden bench) and stage by stage brought down to lignite floor level and operating the wells in the de-coaled area after completion of lignite mining. It was decided to operate two rows of pumping (160 to 200 m. between rows) on the de-coaled area. By this pumping was drastically reduced to 20,000 to 25,000 GPM in Mine-I. The similar technology was adopted in all the mines. Currently about 60,000 GPM of Ground Water alone is pumped out in all the three mines put together to excavate 24 MT / Annum. Where as the same quantity of water was pumped for mining 3.5 MT/Annum in early days.

10

Fif.5

ADVANCING SIDE

A1 A2 A3

Fig.5

WELLA1- DRILLED AT MIDDLE BENCH ON THE ADVANCING SIDE AND BEING CONVERTED TO (BY CUTTING THE CASING PIPES AS A2 BOTTOM BENCH WELL(A3) LIGNITE BENCH WELLS IN STAGES AS THE MINE PROGRESS. PRESENT PUMPING IS IN THE RATE OF 20,000 TO 25,000 GPM.

8. PRESENT PLANS: By various improvements / modification, and technological developments made in mining technology, NLCs confidence level has increased and opened new mine cuts. Presently, NLC is operating 3 mines at Neyveli and one Bucket Wheel Excavators at NLC: CAPACI EQUIPMENT TY Total (Litres) Bucket Wheel Excavator 1400 6 (Bridge type) Bucket Wheel 1400 8 Excavator (Normal type) BWE with deep cut 700 6 MOBILE TRANSFER CONVEYOR: MOBILE TRANSFER CONVEYOR CAPACITY 11,000 TPH MTC 6,400 TPH MTC 4,700 TPH MTC 4,050 TPH MTC Total Total 11 7 3 2 23 mine at Rajasthan totally producing 26.1 MT/Annum of lignite. GMDC at Gujarat also adopted this technology of mining and produced 7.0 MT of lignite during 2006-07.

facility BWE without deep cut facility Bucket Wheel Excavator Bucket Wheel Excavator Bucket Chain Excavator Grand Total = 34 Spreaders at NLC:

700 500 350 500

9 2 2 1 34

Spreading Equipments capacity 20,000 TPH Spreader 11,000 TPH Spreader 8,000 TPH Spreader 6,000 TPH Spreader 4700 TPH Spreader Total

Total 4 5 1 4 1 15

11

Length of Conveyors at NLC Mines in KM as on 1st April 2008: Width 2400 mm 2000 mm 1800 mm 1600 mm 1500 mm Type of Belt Steel cord Steel cord Steel cord Steel cord Steel cord Fabric Total = 148.17 Kilometer 42.62 71.64 5.39 15.85 6.17 6.5

There are plans to open new mine at Jayamkondan in TamilNadu, Bithnok and Hadla in Rajasthan & Valia in Gujarat and additional projects at Neyveli to achieve the Table .7 Projected Production schedule upto end of XV plan (2031-32) End of Year State Tamil Nadu Gujarat Rajasthan Total % Annual growth for plan period New Initiatives Presently, the following are the improved technology implemented at NLC. Wireless Based Centralized Monitoring Operation and Control System in Mine-IA Top Bench: Wireless based automation control in MineIA consisting of one 700 L. BWE, one 4420 cubic meter/hour of MTC, five 1600 mm. Conveyor of total length 5000 meters (approximately) and one 4420 cubic meter/hour spreader including networking of existing programmable logical control stations for centralized monitoring, operation and control. This would be very helpful for operation as well as maintenance without much wastage of productive time. PLC Based Automation System for Lignite Bunker Mine-I: PLC based automation control for Mine-I lignite bunker conveyors and machines including retrofitting of relay logic with PLC in conveyors and Bunkering machines, networking, centralized control, operation, monitoring two way industrial paging system and CCTV system was implemented during XI PLAN 2011-12 24.516 23.730 7.680 55.926 12.51 XII PLAN 2016-17 38.096 37.830 12.008 87.934 11.5

goal of reaching 55 MT/annum of lignite in 2011-12 and 88 MT/Annum. in 2016-17 and to touch 150 MT/annum. during 2031-32.

XIII PLAN 2021-22 55.096 39.904 13.000 108.00 4.51

XIV PLAN 2026-27 64.000 44.000 22.000 130.00 4.01

XV PLAN 2031-32 75.000 48.000 27.000 150.00 3.10

2006 in Mine-I. This has enabled in evolving an automated system in operating lignite bunker for smooth dispatch of lignite to various downstream units. The SMEs procured for Mine-IA and Mine-I Expansion are of with PLC and other advance controls. Hence, the working hours of these equipments are touching more than 6000 hours per year. The equipments ordered for Mine-II expansion are all incorporated with latest art of technology like VVVF, PLC etc. Mining equipment maintenance management system (MEMMS) (SAP based): This system is to reduce the Breakdown, plan preventive maintenance, reduces the stoppage duration and also to reduce the inventory. Equipment details, maintenance task details, manpower, spare parts are computerized. For the work either planned or Breakdown, Work order will be generated with all the required information and tools to complete the work. Based on the feedback from the maintenance division equipment history, failure analysis, job cost will be carried out.

12

Drilling Development: In Neyveli drilling is carried out for catering to blast hole drilling, ground water control wells and exploratory wells. Ground water control wells are drilled in various diameters, namely 4, 12, 24, 36 and 42. The technique used to drill the large dia. hole > 24 is reverse circulatory method, were as smaller diameter are drilled by straight circulated method. The pipes used are usually MS pipes for large dia. and GI pipes for small dia Seepage Control Technique in Lignite Mines: In the year 2003, Mine-II faced acute seepage problem in overburden benches (surface and top) hampering the movement of machinery and equipments. Several pumping / yield tests were conducted in the large, small and medium size bore wells with various capacity pumps and after studying the potentiality of the combined aquifer (semi confined and water table) zones the strategy of dewatering were finalized. Dewatering of the combined aquifer zones through various capacity of pumps say 50, 100, 200 & 500 GPM has been found effective method and has been successfully implemented to start within the surface bench and subsequently shifted to the ground level about 150 to 200 m. away from the mine edge. The above dewatering is being done as a pre-mine dewatering strategy, wherein about 40 wells (4000 GPM) are pumping intermittently (different capacities) as and when the water levels fluctuate and saturate the aquifer zone. 9. ENVIRONMENTAL CHALLENGES AND ITS MANAGEMENT: NLC handles the challenges posed by different environmental factors sagaciously. The details relating to the challenges posed by individual environmental factors viz. air, water, land, humans etc and the environmental management measures adopted by NLC to handle these challenges are described in the following pages. Air pollution Control Measures: NLC has been able to maintain these good air quality standards by adopting proper control measures for preventing air pollution, which are enumerated below.

a) Deploying machineries with Electrical power: Most of the machineries used in mines are electrically operated and hence the emission of noxious gases, which is usual with diesel-operated machines, has been substantially reduced. b) Dilution of gaseous emissions: The Neyveli lignite mines are spread over a large area and have a normal width to depth ratio, which develops adequate natural ventilation and dilution of gaseous emissions through wind sweeping and vertical mixing of air. c) Green belt development: NLC had raised 171 lakh trees in the region over a period of time. Dense foliage has been created in the township, which has yielded multiple benefits to the community. Besides being a barrier against dust penetration into the township, the dense foliage has reduced the mean temperature by about 2 degree Celsius, attenuated the noise generated from the adjoining mines and thermal poser plants and reduced the levels of sulphur dioxide in air. It is found that a tree-belt of 10 metres has the capability to bring down the noise level by 10 decibels and a cluster of trees in an acre of land has the potential to absorb six tones of sulphur dioxide. d) Sharp teeth for Bucket Wheel Excavator (BWE): Adequate precautions are taken in using sharp tooth for bucket wheel excavators to reduce dust production. e) Chutes at transfer points: Necessary chutes are provided in all the conveyor transfer points. Wipers/ cleaning devices are provided underneath the conveyor belt. f) Water spraying at BWE excavation face: High-pressure jet of water is sprayed at active face where lignite is extracted by BWE, which prevents generation of dust at source. g) Water spraying on haul roads by mobile and fixed sprinklers: The lignite transport road and access roads of overburden benches are regularly sprayed with water with the help of mobile and static water sprinklers. h) Dust extractors and wet drilling: All blast hole drills have been equipped with dust extractors. Wet drilling is practiced for drilling Ground Water Control (GWC) wells.

13

i)

Black topping of service roads: The arterial service road connecting all benches is black topped. The lignite transportation roads have been Laterite topped. Besides the truck operators engaged in lignite transportation have been cautioned not to overload the truck, which may cause spillage, generating dust due to crushing by running trucks. Dust masks: The BWE operators and persons working in the vicinity of the BWE have been issued with dust masks. Electro Static Precipitators (ESP): High efficiency ESP (100%) is installed in the Flue gas exhaust of Thermal power plants. Tall chimneys upto a height of 220 metres are constructed for wide dispersion of flue gases.

operated simultaneously to obtain a synergistic net draw down and a calculated risk is taken by planning the pumping operations for keeping a positive pressure head of 5 to 7 meters above the Lignite bottom. b) Rainwater harvesting & Artificial recharging: Rainwater harvesting system has been introduced in the mines, power plants and township. Artificial recharging of ground water in the catch-ment areas has been taken up by constructing check dams, percolation wells and recharge wells in Nadiyapattu and Maligampattu villages near Neyveli and has proved very successful. The geological plan of Neyveli region showing the recharge area and the location of the villages is shown in Figure-II. The photos of check dams and the consequent effects in post-monsoon period is shown in Figures-III & IV Storm water treatment: 8000 GPM of storm water pumped from Mine-I has been diverted to treatment plant at surface. The treated water is sent to township for domestic use with consequent reduction in groundwater drawl from township bore wells. Utilization of storm water for TPS: NLC is taking steps for diverting 15,000 GPM of storm water from Mine-II to Thermal Power Station-II (TPS-II) and Thermal Power StationII Expansion after treatment in treatment plant.

j)

k)

WATER ENVIRONMENT: Lignite mining and its associated activities not only uses a lot of water but also affects the hydrological regime of the area and often affects the water quality. Large and deep opencast mine usually have great impact on the hydrological regime of the region. Moreover the surface runoff water through nallahs and canals get polluted due to the waste generated in mining and power generation operations. Water Conservation and Pollution control measures: The measures taken by NLC for water conservation and pollution control measures are enumerated below. a) Optimisation of ground water pumping: Over the years NLC has evolved the GWC pumping in mines by taking concerted efforts towards optimizing the pumping operations. Pumping is done close to the location of lignite extraction and a localized draw down effect is obtained which is just required to extract lignite safely. A number of pumps are c)

d)

e)

Sewage treatment plant: A modern sewage treatment plant has been established for treating sewage water from township and the treated water is let out for irrigation purpose. The plant is operating effectively as per the standards set by Tamil Nadu Pollution Control Board (TNPCB).

14

79 15' 1150'

20'

25'

30'

35'

40'

PO NN AIY AR RIV ER

45' BAHUR BLOCK

TO

79 50' 1150'

TO CH ENNA I

CH EN NA I

N

W E S

PANRUTI 45'

1 2

GADILAM RIVER

CUDDALORE

45'

(Maligampattu Village)

40'

(Nadiyapattu Village)

KADAMPULIYUR

Y AR ND OU EB NIT LIG

40'

CH RE

35'

AR

E G

AR

EA

NEYVELI TOWNSHIP

BAY OF BENGAL

1A M 120.0 INE

ER I

mt

BAY OF BENGAL

MINED OUT

191.28 mt

BO UN DA RY

LIGNITE BOUN DARY

Figure-II: Geological plan showing villages where artificial recharging is experimented

MINE I

17 3.72 mt

MINE I EXPAN.

BLOCK-B

VADALUR

MIN ING LE AS E

375.0 mt

VRIDHACHALAM 30'

MAN IMUK TA NADH I

MINED OUT

MINE II 98.41 mt

MINE II

438.20 mt

WALAJA TANK

PE RUP E MR ALU M ER AL I

35'

30'

MINE II EXPAN. MINE III

PORTONOVA

VE LL AR

RIV ER

7 .8 75

329.0 mt

VELLAR RIVER

25'

Kiramangalam Block

SETHIATHOPPU

SRIMUSHNAM

329.0 mt

KUMB AKON AM

South of Vellar Block

TO

t m

11 25

LEGEND

ALLUVIUM TERTIARY CRETACEOUS ARCHAEAN NEY E I LGNIT CORPOR TON LD NEY E I VL I E AI T ., VL

GE OGICA E PL A ION DIV I OL L X OR T ISON

NE V L LGNI E FE D - GE OGI LM P Y EI I T IL OL CA A

0

VEERANAM ERI ERI 11 20' 79 15' 20' 25' 30' 35' 79 40

Signa ture :

Sc a le : Pla te No.:

1 : 1.75 K s. m

A 4

Figure-III: Check dam in Nadiyapattu village (Before Monsoon)

Figure-IV: Water storage in upstream side (After Monsoon)

15

f) Dry ash disposal: NLCs Two Thermal Power Stations ( TPS-I & I Expn.) are provided with dry fly ash collection system and the 80% of the fly ash generated in these plants are utilized by cement and other industries. Installation of modern dry ash collection system in TPS-II is under progress and will be completed during 2008. Efforts are taken to utilize 100% of the generated fly ash. Land degradation Control Measures: NLC takes necessary measures for minimizing these damages on land by properly maintaining external dumps, adhering to a systematically planned reclamation programme, stabilisation of slopes, adopting innovative methods and growing soil specific trees for reclamation of the land. These measures are discussed below. To counter changes in temperature and other atmospheric conditions extensive afforestation within the mine lease area has been done. So far around 171 Lakhs trees have been planted since the inception of project. The details of Afforestation done in Neyveli region is given in Table-VI a) Integrated Farming System: NLC has embarked on a project for transforming the mine dump spoils into productive agricultural lands through an eco-friendly Integrated Farming System in collaboration with Tamilnadu Agricultural University (TNAU) at an estimated cost of Rs.450 Lakhs. The system envisages integration of various enterprises viz. agricultural crops, horticultural crops, forestry, animal husbandry, fishery, mushroom, biogas etc., which have greater potentialities. These enterprises not only supplement the income but also help sustain the productivity of the dump spoils and thereby restore the ecosystem. The project is being implemented with the following objectives. Standardization of crop husbandry and allied enterprises for generating profitable agricultural production system. Evaluation of seed hardening and seed pelleting technologies for various tree and crop species for the successful establishments in mine spoil.

Monitoring soil physical and bio-chemical properties in rehabilitated mine spoil ecosystem. Physiological manipulation to improve the growth and productivity of crops through chemicals and growth regulators. Conducting green house and pot culture experiments and planting forest and fruit trees. Exploitation of microbial systems for improving the mine spoil to sustain crop production. Assessing the carrying capacity of pasture, growth rate, production performance and economic traits of animals. Monitoring the restoration potential of biodiversity in the restored mine spoil. b) Top soil Reclamation: The topsoil contains all nutrients and micro-organisms to raise agricultural crops. But the topsoil gets mixed into a heterogeneous soil, since the BWE can cut the soil to a minimum height of 4 metres. In areas where topsoil is found to be highly fertile it is identified and stored separately for later topping in dumps or refilled areas. c) Bio-reclamation using Bio-fertilizer: A pilot plant facility was setup to produce various strains of baterial bio-fertilizer using lignite as carrier and applied to mine spoil in order to improve the microbial activity and fertility of the soil. Field experiments were carried out with various microbes viz. nitrogen fixing and phosphate solublizing microbes in crops viz. green manure, maize and ragi. Application of bio-fertilizer increased the soil fertility, crop productivity by 15 40% on using a dosage of 8kg/ha each of 4 baterial strains viz. Rhizobium, Azospirilum, Azotobacter and phosphobacteria. The total microbial activity achieved was to the tune of 0.6 1.1 million/ gm of soil. d) Utilisation of Fly ash in Reclamation: Lignite fly ash is highly alkaline in nature, texturally suitable for improving certain important physical parameters of both mine spoil and the lateritic soils of Neyveli and rich in available plant nutrients viz., Ca, Mg, K, P, S, Cu, Zn, Mn, Fe, B, Mo etc. Field experiments were conducted with different doses of fly ash in Neyveli

16

lateritic soil and back filled mine spoil over a period of 4 years. Crops like paddy, groundnut and maize were tested and found that 20T/ha of fly ash increased the yield of paddy by 20-40%. Application of fly ash @ 200T/ha in lateritic soil increased the yield of groundnut and maize by 30-60%. e) Reclamation using Lignite based Humic acid: Humic acid is the dark humus found in soil and made up of organic matter derived from plant breakdown by microbial action. NLC has successfully developed a process for extracting humic acid in the form of Potassium humate from lignite. Humic acid helps to retain the nutrients and soil moisture, supports microbial activity, and nitrogen fixation, and increases the yield from 20-30% in mine spoil. f) Formation of water fowl refuge, ponds and picnic spots: An artificial lake of 10 acres has been developed in the backfilled area and mines seepage water is pumped into the lake. Fishes have been introduced and the lake has been developed and maintained such that it acts as a refuge for migratory birds and hundreds of species visit it during different seasons. Figure-V shows the water fowl refuge created in Mine-I afforestation area. A picnic spot was also created with boating facilities, along with a mini zoo with rabbit, peacock, dove, spotted deer, duck etc. g) Satellite imagery studies: Satellite imagery studies are conducted using Remote Sensing data once in every two years, to studying the changes in land use pattern and levels of improvement in the environment of the mining area. h) Ash Pond Reclamation: Abandoned ash pond in thermal power stations causes air pollution in windy season. To arrest the menace, a trial was taken up in collaboration with TNAU and Lime, Farmyard manure, Red earth, Press mud, Bio-fertilizer were applied in the excavated pits in recommended dosage. Plant species like Neem, Casurina, Cashew, Teak, White babul and Tamarind were planted and the plants were found to have better growth which helped to arrest soil erosion and dust generation completely.

9. ALTERNATIVE TECHNOLOGY FOR FUTURE: To gain fully, utilized vast potential of lignite deposits, which are uneconomical for conventional mining, the following nonconventional alternative technology is considered by NLC in future. Underground Coal Gasification (UCG) Coal Bed Methane (CBM) Coal Bed Methane: o CBM is a natural gas produced by biothermogenic degradation of buried plant material during the process of coal formation. o Methane is associated with all coals including lignite. o Coal and lignite beds are both source and reservoirs. o There is a vast lignite resource at Mannargudi block of Tamil Nadu. There is totally 23.2 BT of lignite at Mannargudi in an area of 750 Km2 to a depth of 150m to 600m with a lignite thickness up to 100m. This deposit is of greater potential for development as CBM Field. o At the instance of NLC, the Mannargudi lignite deposit has been proposed for undertaking CBM exploration under the promotional exploration program. Underground Coal Gasification (UCG): NLC in its effort to diversity its resource base for power generation intends to develop and use the technology of UCG in lignite resources. A technical delegation from NLC and Ministry of Coal, Government of India (GOI) visited UCG site at Chinchilla, Australia and it is of the view that UCG can provide commercial quantities of industrial gas which can be used for power generation and supply at competitive rate. In view of the successful demonstration of UCG development recently in Chinchilla, Australia there is a possibility in India also for tapping the energy from uneconomical lignite block by advantageously utilizing UGC for possible power generation. Due to the in-situ specific nature of the UCG project, a pilot scale UCG testing evaluation and economic assessment of development and utilization are essential for implementation of full scale UCG project in Indian condition. A project titled Underground Coal Gasification (UCG) and its utilization for power generation studies in lignite deposits in Rajasthan has been undertaken by NLC under coal S&T grant of Ministry of Coal, Department of Science and Technology (DST).

17

Concluding Remarks: NLC is successful in adopting the continuous mining technology and also contributing in the development of continuous mining technology by constant modification and development of the technology to suit hard abrasive strata condition. The lignite production was only 2.5 MT/Annum in mid of 60s and there was a

quantum jump in production of lignite after 80s and reached the level of 31 MT/Annum presently. There is a scope for further development in lignite production due to enormous demand of power. Already plans are on anvil to start various lignite mines and linked power projects to achieve the goal of production of 150 MT/Annum of lignite in 2031-32.

Abbreviation: NLC Neyveli Lignite Corporation Limited. BWE Bucket Wheel Excavator. MT/A Million Tons Per annum. GOI Government Of India TPS Thermal Power Station 350L 350 Litre etc.

S&T - Science and Technology Mm3/ MM3 Millions cubic meter MT- Million Tons BT Billion Tons SME- Specialized mining Equipment GPM Gallons per minute

18

Você também pode gostar

- Neyveli Lignite Corporation Limited: Corporate Office: P & A DepartmentDocumento1 páginaNeyveli Lignite Corporation Limited: Corporate Office: P & A DepartmentRavi KrishnanAinda não há avaliações

- Environmental Impact Assessment of Mining Projects: Dr. Gurdeep Singh 1.0 ScreeningDocumento10 páginasEnvironmental Impact Assessment of Mining Projects: Dr. Gurdeep Singh 1.0 ScreeningRavi KrishnanAinda não há avaliações

- Heavy Media SeparationDocumento4 páginasHeavy Media SeparationRavi KrishnanAinda não há avaliações

- Ciueila (K Ehlfkk : B.A./B.Sc./B.Music/B.Dance Degree Examination, May 2015 (Part-I - Tamil)Documento1 páginaCiueila (K Ehlfkk : B.A./B.Sc./B.Music/B.Dance Degree Examination, May 2015 (Part-I - Tamil)Ravi KrishnanAinda não há avaliações

- ,y, Y, Y, Yf F F F F F F Fpak Pak Pak Pak - : B.Lit. Degree Examination, May 2015Documento2 páginas,y, Y, Y, Yf F F F F F F Fpak Pak Pak Pak - : B.Lit. Degree Examination, May 2015Ravi KrishnanAinda não há avaliações

- M.Sc. Degree Examination, 2013: SECTION - B (3 × 20 60)Documento1 páginaM.Sc. Degree Examination, 2013: SECTION - B (3 × 20 60)Ravi KrishnanAinda não há avaliações

- JKPH, Yf Fpa Tuyhw: B.A./B.Sc./B.Music/B.Dance Degree Examination, May 2015 (Part-I - Tamil)Documento1 páginaJKPH, Yf Fpa Tuyhw: B.A./B.Sc./B.Music/B.Dance Degree Examination, May 2015 (Part-I - Tamil)Ravi KrishnanAinda não há avaliações

- B.A. DEGREE EXAMINATION December 2014: (Economics)Documento2 páginasB.A. DEGREE EXAMINATION December 2014: (Economics)Ravi KrishnanAinda não há avaliações

- M. B.A. Degree Examination - 2013: 270. E. Business Common With M.B.A. Marketing Management & M.B.A Financial ManagementDocumento1 páginaM. B.A. Degree Examination - 2013: 270. E. Business Common With M.B.A. Marketing Management & M.B.A Financial ManagementRavi KrishnanAinda não há avaliações

- B.Lit. Degree Examination, May 2015:, Yf Fpak - IIIDocumento2 páginasB.Lit. Degree Examination, May 2015:, Yf Fpak - IIIRavi KrishnanAinda não há avaliações

- M.B.A. DEGREE EXAMINATION December 2014: (Human Resource Management)Documento1 páginaM.B.A. DEGREE EXAMINATION December 2014: (Human Resource Management)Ravi KrishnanAinda não há avaliações

- M.SC .Degree Examination - 2013: 530. Aerial Photography and PhotogrammetryDocumento2 páginasM.SC .Degree Examination - 2013: 530. Aerial Photography and PhotogrammetryRavi KrishnanAinda não há avaliações

- M.B.A. Degree Examination, May 2015: (Human Resource Management)Documento1 páginaM.B.A. Degree Examination, May 2015: (Human Resource Management)Ravi KrishnanAinda não há avaliações

- M.B.A. (Financial Management) DEGREE EXAMINATION - 2013: 230. Financial Analysis and Industrial FinancingDocumento2 páginasM.B.A. (Financial Management) DEGREE EXAMINATION - 2013: 230. Financial Analysis and Industrial FinancingRavi KrishnanAinda não há avaliações

- Answer Any ONE Question.: Section - CDocumento2 páginasAnswer Any ONE Question.: Section - CRavi KrishnanAinda não há avaliações

- M.B.A. Degree Examination - 2011: 230. Financial Analysis and Industrial FinanciingDocumento2 páginasM.B.A. Degree Examination - 2011: 230. Financial Analysis and Industrial FinanciingRavi KrishnanAinda não há avaliações

- M.B.A. Degree Examination, May 2015 (Financial Management) : 220: International FinanceDocumento1 páginaM.B.A. Degree Examination, May 2015 (Financial Management) : 220: International FinanceRavi KrishnanAinda não há avaliações

- M.B.A. Degree Examination - 2011: 220. International FinanceDocumento1 páginaM.B.A. Degree Examination - 2011: 220. International FinanceRavi KrishnanAinda não há avaliações

- B.A. Degree Examination, 2010: 710. History of TamilnaduDocumento2 páginasB.A. Degree Examination, 2010: 710. History of TamilnaduRavi KrishnanAinda não há avaliações

- Register Number: Name of The Candidate: 2: Total No. of PagesDocumento2 páginasRegister Number: Name of The Candidate: 2: Total No. of PagesRavi KrishnanAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- TakeawaysDocumento2 páginasTakeawaysapi-509552154Ainda não há avaliações

- Shot Blasting Machine ApplicationsDocumento7 páginasShot Blasting Machine ApplicationsBhavin DesaiAinda não há avaliações

- Introduction To Templates in C++Documento16 páginasIntroduction To Templates in C++hammarbytpAinda não há avaliações

- Day 2 - Evident's Official ComplaintDocumento18 páginasDay 2 - Evident's Official ComplaintChronicle Herald100% (1)

- Re BuyerDocumento20 páginasRe BuyerElias OjuokAinda não há avaliações

- Tripura 04092012Documento48 páginasTripura 04092012ARTHARSHI GARGAinda não há avaliações

- Read The Dialogue Below and Answer The Following QuestionDocumento5 páginasRead The Dialogue Below and Answer The Following QuestionDavid GainesAinda não há avaliações

- Regression Week 2: Multiple Linear Regression Assignment 1: If You Are Using Graphlab CreateDocumento1 páginaRegression Week 2: Multiple Linear Regression Assignment 1: If You Are Using Graphlab CreateSamAinda não há avaliações

- 1207 - RTC-8065 II InglesDocumento224 páginas1207 - RTC-8065 II InglesGUILHERME SANTOSAinda não há avaliações

- DocsDocumento4 páginasDocsSwastika SharmaAinda não há avaliações

- Cryptography Lab DA-1Documento19 páginasCryptography Lab DA-1Gautam Thothathri 19MIC0092Ainda não há avaliações

- ParaphrasingDocumento11 páginasParaphrasingAntiiSukmaAinda não há avaliações

- WKS 8 & 9 - Industrial Dryer 2T 2020-2021Documento26 páginasWKS 8 & 9 - Industrial Dryer 2T 2020-2021Mei Lamfao100% (1)

- Digital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniqueDocumento6 páginasDigital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniquevendiAinda não há avaliações

- AM-FM Reception TipsDocumento3 páginasAM-FM Reception TipsKrishna Ghimire100% (1)

- Indian Pharmaceutical IndustryDocumento25 páginasIndian Pharmaceutical IndustryVijaya enterprisesAinda não há avaliações

- Clevite Bearing Book EB-40-07Documento104 páginasClevite Bearing Book EB-40-07lowelowelAinda não há avaliações

- Prof Ed 3 Module 1Documento9 páginasProf Ed 3 Module 1alexa dawatAinda não há avaliações

- EdM 101 - Joan Marie PeliasDocumento9 páginasEdM 101 - Joan Marie Peliasjoan marie Pelias100% (1)

- Inqlusive Newsrooms LGBTQIA Media Reference Guide English 2023 E1Documento98 páginasInqlusive Newsrooms LGBTQIA Media Reference Guide English 2023 E1Disability Rights AllianceAinda não há avaliações

- Practical Organic ChemistryDocumento598 páginasPractical Organic ChemistryGerardo Estrada99% (127)

- Top249 1 PDFDocumento52 páginasTop249 1 PDFCarlos Henrique Dos SantosAinda não há avaliações

- Busbusilak - ResearchPlan 3Documento4 páginasBusbusilak - ResearchPlan 3zkcsswddh6Ainda não há avaliações

- BS EN 50483-6-2009 EnglishDocumento27 páginasBS EN 50483-6-2009 EnglishДмитро Денис100% (2)

- Organic Logo-Faq enDocumento6 páginasOrganic Logo-Faq enjcnavarro_Ainda não há avaliações

- Ebook Computer Forensics Principles and Practices 1St Edition Volonino Test Bank Full Chapter PDFDocumento29 páginasEbook Computer Forensics Principles and Practices 1St Edition Volonino Test Bank Full Chapter PDFmundifycoucheefnhgl100% (10)

- Bomba Manual Hidraulica - P 19 LDocumento2 páginasBomba Manual Hidraulica - P 19 LBruno PachecoAinda não há avaliações

- Ccie R&s Expanded-BlueprintDocumento12 páginasCcie R&s Expanded-BlueprintAftab AlamAinda não há avaliações

- Laser Mig - Hybrid - WeldinggDocumento26 páginasLaser Mig - Hybrid - WeldinggFeratAinda não há avaliações

- Parts List 38 254 13 95: Helical-Bevel Gear Unit KA47, KH47, KV47, KT47, KA47B, KH47B, KV47BDocumento4 páginasParts List 38 254 13 95: Helical-Bevel Gear Unit KA47, KH47, KV47, KT47, KA47B, KH47B, KV47BEdmundo JavierAinda não há avaliações