Escolar Documentos

Profissional Documentos

Cultura Documentos

Design of Elastic Garments For Sports in Circular Knitting

Enviado por

TJPRC PublicationsTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Design of Elastic Garments For Sports in Circular Knitting

Enviado por

TJPRC PublicationsDireitos autorais:

Formatos disponíveis

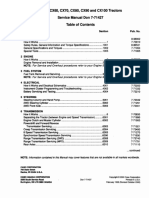

International Journal of Textile and Fashion Technology (IJTFT) ISSN 2250-2378 Vol.

3, Issue 1, Mar 2013, 39-48 TJPRC Pvt. Ltd.

DESIGN OF ELASTIC GARMENTS FOR SPORTS IN CIRCULAR KNITTING

FERNANDO BARROS DE VASCONCELOS1,2, FABIANO CASACA1, FERNANDA GOMES DE VASCONCELOS2, JOAO PAULO PEREIRA MARCICANO1 & REGINA APARECIDA SANCHES1

1

School of Arts, Sciences and Humanities of USP, Sao Paulo, Brazil

2

University Center of FEI, Sao Bernardo do campo, Brazil

ABSTRACT

The movements involved in most active sports require a certain level of stretch to compensate the difference between skin's elasticity and the lack of elasticity in conventional fabrics. Elastic textiles can improve the ease of movement of clothing and enhances the ergonomic wear comfort. The use of elastane (spandex) in circular knitting allows the production of fabrics that are molded to the body as a second skin and maintain their modeling without deformation during the product life. There are only few studies on knits behavior and especially about the possibilities of circular machine setup and their consequences in the final product. This study aims to show how, through the use of design of experiments (DOE), it is possible to optimize these adjustments in order to obtain certain characteristics in the final product. Using a 2 factorial design, were analyzed and defined the best adjustments of polyamides LFA (loop length) and elastanes tension to achieve the required level of weight per area, thickness and elongation, with the smallest percentage of elastane.

KEYWORDS: Knitting, Sport Garments, Polyamide, Elastane(Spandex), Design of Experiments INTRODUCTION

The growth in textiles consumption reflects, among others, a significant increase in the interest of the population for sporting goods, especially due to lifestyle. According Shishoo (2005), sportswear and sporting goods have not only contributed to the diversity of the market, but also for the growth of science and textile technology. The various aspects of performance require different material properties and at the same time, must meet the needs of the consumer. The development of new technologies, fragmented niche markets and the increasing demand of consumer expectations are the factors driving the industry. To be inserted in this context industries are implementing practices to develop new products and in order to expand the market, are improving their strategic positions, productivity, value-added niches and their arrangements. Voyce, Dafniotis and Towlson (2005) says that optimizing athlete's performance by providing freedom of movement, maximizing comfort, minimizingthe risk of injury or muscle fatigue is an important role play by stretch garments for sports. The major applications are: Garments where comfort and fit are most important Compression garments where stretch garments play an important part inimproving several aspects of an athlete's performance (speed, stamina andstrength).Moreover, all sports involve the build-up of lactic acid in the muscles, which causes soreness/fatigue. As muscles get tired they become less disciplined, increasing the risk of injury.The compression helps keep muscles in line and in right position to reduce the risk of injury during exercise. This study aims to show how it can be determined, through the design of experiments, the settings of the circular machine to obtain certain characteristics of comfort and performance in elastic knitswith elastane, which will be used for sports.

40

Fernando Barros De Vasconcelos, Fabiano Casaca, Fernanda Gomes De Vasconcelos, Joao Paulo Pereira Marcican & Regina Aparecida Sanches

LITERATURE REVIEW

According McCann (2005), the design of sportswear products can be classified according the diagram in figure 1. This study focused on the "functionality" axis, i.e., in the manufacture of an article that features mesh protection and athletic performance.

Design do Sports Apparels Sports apparels Vesturio Esportivo design Design

Funcionalidade Funcionality

Esttica Aesthetics

Proteo Protection

Performance Atltica

Performance

Novas Opes Style De Estilo

Figure 1: Sportswear Design Source: Adapted from McCann (2005) Bartels (2005), says that textile comfort rests on three pillars: elasticity, thermal regulation and touch. Vasconcelos (2006) placed as important properties of textile connected to the comfort: regain, liquid retention, thermal conductivity, type of yarn, fiber fineness, fiber cross-section, type of tissue, tissue thickness, number and proximity to the body layer. The combination of the factors cited by Vasconcelos (2006) determines the behavior of each of the Bartess axes. This study focuses elasticity axis. The difference between skin elasticity and the low elasticity of conventional tissue results in restriction of movement and loss of comfort (VOYCE, DAFNIOTIS and TOWLSON, 2005). Stretch fabrics can be manufactured using the following methods: Fiber with elongation characteristics, such as rubber and synthetic elastomers due to the geometry of the molecular chain of these fibers. Processing the crimp yarn by thermal or chemical means, as well as the texturing method (or false twist method). Fabric structure, such as the circular knitting fabric. Finish the fabric by fabric compression, addition of silicone rubber or elastic laminate application. Figure 2 shows elasticity requirements to be minimally assisted by the textile article to accompany certain body movements.

Figure 2: Body Movements. Source: Voyce, Dafniotis and Towlson (2005)

Design of Elastic Garments for Sports in Circular Knitting

41

According to Voyce, Dafniotis and Towlson (2005), simple body movements, like bending your elbows or knees cause the skin to stretch up to 50%. Movements involved in strenuous sports requirestretching further. The dramatic difference between the elasticity of the skin and the lack of tissue elasticity results in conventional restrictions of movement for the athlete and the consequent performance loss. Elastane (spandex), even when applied in small quantities, provides the necessary elasticity so that a piece of sports clothing can respond to each body movement and return to its original size and shape. However, Umbach (2001) show that the use of elastic yarns should consider that elastane is non-hygroscopic (cannot absorb moisture within their structure) and hydrophobic (cannot be wettable by liquid sweat) which reduces the thermo physiological wear comfort. In addition, elastane yarns are very smooth, which worsens the skin sensorial wear comfort. The use of spandex in circular knitting has enabled the production of fabrics that are shaped to the body as a second skin and maintain their modeling without deformation during the product life. There is a currently increasing in the number of products containing elastane in the collections of male and female fashion, sportswear and lingerie because of the aforementioned attributes and also due to decrease of elastane prices, mainly caused by increasing of the number of competing manufacturers, particularly in Asia. Regardless of the fabric fabrication process, the spandex is always used together with another fiber and not individually (Abdessalem et al, 2009). According Marmarali (2003) there are two different ways of use of the spandex in circular machines: bare or covered. When covered, spandex is surrounded by other yarn in coating process. This kind of yarn is not widely used in large-diameter circular machines, limited primarily to those which do not allow the use of an adequate positive feed system (Araujo e Castro, 1986), because its price is high in comparison to bare elastane, which results in a cost / benefit unrewarding. Thus, the prevailing system in the majority of circular knitwear is the use of bare elastane with another yarn (called rigid yarn) in order to establish a plated loop (Spencer, 2001), where the two yarns form parallel loops and the rigid yarn covers the spandex which is only visible in the underside of the fabric as shown in figure 3. According Lyer et al (1997), to attend this training, the yarns should be fed at different levels in the same feeder, as shown in Figure 4 with different working tensions.

Figure 3: Plated Elastane. Source: Spencer, 2001

Figure 4: Plated Elastane. Source: Lyer et al., 1997

42

Fernando Barros De Vasconcelos, Fabiano Casaca, Fernanda Gomes De Vasconcelos, Joao Paulo Pereira Marcican & Regina Aparecida Sanches

PRODUCT DEFINITION

The article to be produced should have the following characteristics: The article should present high rate of elongation in both directions but not too high to maintain a certain level of compression (VOYCE, DAFNIOTIS AND TOWLSON, 2005); Processing will be made in circular knitting to obtain greater stretch (TEZEL and KAVUSTURAN, 2008); It should be use synthetic yarn instead of cotton because in sport textiles, a short drying time is one of the main prerequisites for a good wear comfort (BARTELS, 2005); Use of polyamide microfiber yarn textured to meet the requirements for thermal regulation and touch (GASI, BITENCOURT AND VASCONCELOS, 2010); It must use an elastomeric yarn (to provide greater elastic recovery) in the lowest percentage possible for lower cost and do not affect the others characteristics like touch and comfort (UMBACH, 2001).

MATERIALS AND METHODS

This study aims to determine the optimal setup of the circular machine to get some comfort / performance features in mesh Polyamide / elastane, which will be used for sports, using the method of experimental design, as proposed by Sanches (2006) at flow shown in figure 5.

Seleo das matrias-primas Selection of raw materials

Determinao Determination of dos control parmetros de controle parameters

Escolha processo de Choice ofdo manufacturing fabricao process

Physical texting Ensaios fsicos

Fabricaoproduction dos tecidos Samples da significncia dos Anlise Factors significance fatores de controle e interao analysis Verificao da curvatura

Curvature verification

Regulagem da mquina Machine setup definition

5

Confeco dos tecidos

Tissue production

Anlise dos analysis resultados Results

Figure 5: Product Development Flow Source: Sanches (2006) The following yarns were used: Rigid yarn of polyamide 6.6: 80dtexf68 x 2 textured. Elastane yarn: 44 dtex (40 den).

Samples were produced in a circular machine with the following specifications: Brand / model: Mayer Relanit jauge (needles/inch): 28 Diameter (inch): 30 Needles: 2640 Feeders: 96

Design of Elastic Garments for Sports in Circular Knitting

43

The study was conducted using a factorial design 2 . Concepts of experimental design as replication and randomization of the samples were used. (MONTGOMERY, 1991). In this study the variation factors are: polyamide LFA (A) elastane tension (B)

The response variables are: weight per area (g/m) thickness (mm) elastane % elongation % in both directions of the fabric. For definition of the tests a 2 factorial design were used, considering that the relationship between the variables studied are linear (Abdessalem et al, 2009). The variation factors and their levels are shown in Table 1 while the LFA values in cm / revolution are shown in Table 2. Table 1: Factors and Levels Factors Polyamide LFA(cm/machine tour) Elastane tension (cN) Level Min. Max. 830 970 3,000 7,000

Table 2: Design of the Experiments Amostra 1 4 2 3 1A 4A 2A 3A StdOrder 1 2 3 4 5 6 7 8 RunOrder 2 4 6 10 8 5 1 7 CenterPt 1 1 1 1 1 1 1 1 Blocks 1 1 1 1 1 1 1 1 LFA PA 830 970 830 970 830 970 830 970 Tensao EL 3 3 7 7 3 3 7 7

Note: LFA PA in cm/machine tour; EL Tension in cN The design shown in Table 2 was carried out with Minitab software with factors and levels of Table 1 and a total of eight runs. In accordance with the planning in Table 2 were produced samples with the settings in Table 3. Two samples of each setup were produced as a result (run order) in Table 2. Table 3: Setup of Circular Machine Samples 1 2 3 4 1A 2A 3A 4A LFA PA 830 830 970 970 EL Tension 3 7 7 3 RQ PA(mm) 173 173 203 203 Stich cam 11 11 15 15 RQ EL(mm) 237 156 188 264

RQ = quality wheel diameter

44

Fernando Barros De Vasconcelos, Fabiano Casaca, Fernanda Gomes De Vasconcelos, Joao Paulo Pereira Marcican & Regina Aparecida Sanches

After production, the raw samples were resting for a week and then were washed, centrifuged and dried to allow a relaxation of internal stress as specified in the following Table 4. Table 4: Relaxation Process Relaxation Process 1-Rest 2-Wash 3-Centrifugation 4-Dry 5-Conditioning Apparatus Table Washing Machine Centrifuge Oven Table Time 1 week 45min 1min 60 min 48h Temperature room room room 60 C room

Then the samples were subjected to tests to determine the weight per area, thickness, elongation and elastane percentage. The weight per area and thickness were determined according res respectively ABNT - NBR 10591 and ABNT NBR 13383. The elongation values were determined using JIS - L 1018. To meet the requirements of the knit considered, the loads have changed in relation to the original standard, using the following values: L = measured with pre-load of 30 gf L0 = measured after 1 min with a load of 600 gf L1 = measured after 3 min pre-load of 30 gf The percentage of spandex in the samples was determined according to ABNT - NBR 11914.

RESULTS AND DISCUSSIONS

The data obtained from tests conducted on sample are shown in Table 5. Table 5: Results

Std Order Run Order LFA PA(cm/re volution) EL Tension (cN) Weight per area (g/m2) Thickness (mm) Elongation (%) Elongation Courses(%) % Elastano

Amostra

1 2 3 1A 4A 2A 3A

1 3 4 5 6 7 8

2 6 10 8 5 1 7

830 830 970 830 970 830 970

3 7 7 3 3 7 7

326,6 337,0 361,4 321,9 335,0 334,1 355,2

0,634 0,664 0,808 0,624 0,776 0,648 0,802

73,8 66,9 111,5 76,0 111,5 69,2 113,9

51,4 46,7 81,7 50,3 81,7 48,5 89,5

10,6 8,7 9,3 10,1 10,6 8,4 9,0

The values obtained were then analyzed with the aid of the program Minitab. Table 6 shows the p values for the influence and interaction of the factors among the five effects studied. P values less than 0,05 are noted in red.

Design of Elastic Garments for Sports in Circular Knitting

45

Table 6: ANOVA P Value ANOVA Weight Per Area LFAPA (cm/revolution) ELtension (cN) Interaction 0,002 0,004 0,127 Thickness 0,000 0,007 0,928 Elong.Wales 0,000 0,047 0,069 Elong.Courses 0,000 0,567 0,650 % Elastano 0,052 0,001 0,716

It can be observed, at 95% confidence level, that the factors of influence on the response variables which are statistically significant (p <0.05) are: weight per area: polyamide LFA and elastane tension thickness: polyamide LFA and elastane tension Elongation at wales (length sense): only polyamide LFA Elongation at courses (width sense): only polyamide LFA Elastane percentage: only elastane tension The graphs of Figure 6, show relations of weight per area, thickness, elongation in width and length and the percentage of spandex to both factors, polyamide LFA and elastane tension. With the above modeling it is possible to define conditions for setting the machine for certain properties in the final fabric. If we consider, for example, produce a fabric having the following characteristics: weight per area between 325 and 335 g/m thickness at most 0,7 mm elongation in width between 50 and 80% elongation in length between 50 and 80% elastane percentage at most 10.0% The Minitab tool overlaid contour plot, gives the graph of Figure 7, where the white area is the response surface that meets the conditions proposed. In this graph, the response with less elastane tension and less polyamide LFA elastane that caters to the conditions originally proposed is marked.

46

Fernando Barros De Vasconcelos, Fabiano Casaca, Fernanda Gomes De Vasconcelos, Joao Paulo Pereira Marcican & Regina Aparecida Sanches

Weight per area = 0,132 LFAPA + 3,90 TEL + 201,4

Thickness = 0,001 LFAPA + 0,007 TEL 0,275

Elongation wales = 0,30 LFAPA 173,7

Elongation courses = 0,26 LFAPA 167,1

% Elastane = - 0,43 TEL + 11,9

Figure 6: Surface Graphs

overlaid contour plot

7

LFA PA (cm/v olta) = 849,502 Tenso EL (cN) = 4,38575 gram. (g/m) = 330,076 esp. (mm) = 0,659256 along. C omp. (%) = 77,8216 along. Larg. (%) = 54,5937 % Elastano = 9,78803 gram. (g/m) 330 335 esp. (mm) 0 0,66 along. Comp. (%) 50 80 along. Larg. (%) 50 80 % Elastano 9 10

6 Tenso EL (cN)

3 850 875 900 925 LFA PA (cm/volta) 950

Figure 7: Response Surfaces Overlaid Thus, using in the machine setup: polyamide LFA of 849 cm/ revolution and elastane tension of 4.4 cN,

Design of Elastic Garments for Sports in Circular Knitting

47

It will be obtained a jersey with the following characteristics in relaxed state: 330,0 g/m of weight per area, 0,659 mm of thickness 54,5 % elongation in width, 77,8 % elongation in length 9,8 % of elastane.

CONCLUSIONS

This paper sought to show how to use the procedure for knit development to obtain certain characteristics in the final product. It was applied the Design of Experiments methodology to show the impact of each process variable, both individually and their interaction and to determine de relationship between the machine setup and tissue properties. It was verified that weight per area and thickness are influenced by rigid yarn LFA and elastane tension. On the other hand, the rigid yarn LFA (polyamide) is the main responsible by the elongation of the knit. The tension of the spandex has its importance mainly inspandex percentage and elastic recovery. The machine adjustments were optimized and defined to meet previously specified performance properties and cost of the fabric. It is proposed for future works, applying the same procedure considering a broader set of fabric properties.

REFERENCES

1. ABDESSALEM, S.B., ABDELKADER, Y.B., MOKHTAR, S., ELMARZOUGUI, S. (2009). Influence of Elastane Consumption on Plated Plain Knitted Fabric Characteristics, Journal of Engineered Fibers and Fabrics, Volume 4, Issue 4, p. 30 35 2. 3. 4. 5. ARAJO, M., Castro, M.M. (1987). Manual de engenharia txtil. v 1 Fundao Calouste Gulbenkian, Lisboa. BARTELS, V. T. (2005). Physiological comfort of sportswear, In: SHISHOO, R. Textile in sport, Woodhead Publishing in Textiles, Cambridge. DENTON, M. J. (1987). Texturing of Continuous Filament. The Journal (Bradford Textile Society) 1987 GASI, F., BITENCOURT, E., VASCONCELOS, F.B. (2010).Estudo Comparativo Das Propriedades De Permeabilidade Ao Vapor Transporte De Umidade E Proteo Ultravioleta Em Malhas De Poliamida 6.6 E Polister Com Elastano, Qumica Txtil, ano XXXIII, n 98. 6. 7. 8. 9. HEARLE, J. W. S.; HOLLICK, L.; WILSON, D. K. (2001), Yarn Texturing Techonology. CRC Press. Inglaterra. IYER, S., MAMMEL, B., SCHCH, W. (1997), Maquinas Circulares: Teoria e Prctica de la tecnologia del punto, Meisenbach Bamberg. LAUNSBY, R. G., WEESE, D. L. (2003), Straight Talk on Designing Experiments, Launsby Consulting, 1993 MARMARALI, A.B., Dimensional and physical properties of cotton/spandex single jersey fabrics, Textile Research Journal, vol. 73, p. 11-14 10. MCCANN, J. (2005), Material requirements for the design of performance sportswear , In: SHISHOO, R. Textile in sport, Woodhead Publishing in Textiles, Cambridge. 11. MONTGOMERY, D.C. (1991), Design and analysis of experiments. John Wiley & Sons. New York, 3edio. 12. SANCHES, R.A. (2001), Otimizao dos parmetros de regulagem das mquinas circulares de malharia, utilizando a Metodologia Taguchi. Campinas, Faculdade de Engenharia Mecnica, Universidade Estadual de Campinas. MSC Dissertation.

48

Fernando Barros De Vasconcelos, Fabiano Casaca, Fernanda Gomes De Vasconcelos, Joao Paulo Pereira Marcican & Regina Aparecida Sanches

13. SANCHES, R.A. (2006), Procedimento para o desenvolvimento de tecidos de malha a partir de planejamento de experimentos. Campinas, Faculdade de Engenharia Mecnica, Universidade Estadual de Campinas.Doctoral Thesis. 14. SHISHOO, R. (2005), Textiles in Sports, Woodhead Publishing in Textiles, Cambridge. 15. SPENCER, D. (2001), Knitting technology, Pergamon Press, 3ed, London. 16. TEZEL, S., KAVUSTURAN, Y. (2008), Experimental Investigation of Effects of Spandex Brand and Tightness Factor on Dimensional and Physical Properties of Cotton/Spandex Single Jersey Fabrics.Textile Research Journal, Vol. 78 Issue 11. 17. UMBACH, K. H. (2001), Optimization of the wear comfort by suitable fibre, yarn and textile construction, 40thInternational Man-Made Fibres Congress, Dornbirn, Austria, 2001 18. VASCONCELOS, F. B. (2006), Parmetros para o desenvolvimento de artigos esportivos, Congresso de Moda Esportiva, Rhodia Poliamida, So Paulo. 19. VOYCE, J., DAFNIOTIS, P. and TOWLSON, S. Elastic textiles, In: SHISHOO, R. Textile in sport, Woodhead Publishing in Textiles, Cambridge, 2005

Você também pode gostar

- Sustainable Design in Textiles and FashionNo EverandSustainable Design in Textiles and FashionAinda não há avaliações

- Sustainable Innovations in Recycled TextilesNo EverandSustainable Innovations in Recycled TextilesAinda não há avaliações

- Helical Auxetic YarnDocumento16 páginasHelical Auxetic YarnTehseen MarwatAinda não há avaliações

- A Novel Design Approach andDocumento12 páginasA Novel Design Approach andnourAinda não há avaliações

- Performanceanalysisofspandex Incorporatedsinglejerseyfabricsfor Sportswear-MinDocumento12 páginasPerformanceanalysisofspandex Incorporatedsinglejerseyfabricsfor Sportswear-MinNasrin AkterAinda não há avaliações

- Sport - TechDocumento34 páginasSport - TechnmjklAinda não há avaliações

- Fabric Physical Properties and Clothing ComfortDocumento7 páginasFabric Physical Properties and Clothing Comfortdr beshoy awadAinda não há avaliações

- Sport TechDocumento34 páginasSport Techaqsa imranAinda não há avaliações

- Investigation of Air Permeability of Cotton & Modal Knitted FabricsDocumento6 páginasInvestigation of Air Permeability of Cotton & Modal Knitted FabricsAhmad SamerAinda não há avaliações

- Evaluation of Clothing FitDocumento7 páginasEvaluation of Clothing Fitzinabu girmaAinda não há avaliações

- Effects of Different Count and Stitch Length On Spirality, Shrinkage and GSM of Knit FabricsDocumento7 páginasEffects of Different Count and Stitch Length On Spirality, Shrinkage and GSM of Knit FabricsPUGAZHENDHI SAinda não há avaliações

- J Eml 2019 01 007Documento20 páginasJ Eml 2019 01 007eduar yecid duarte gomezAinda não há avaliações

- TextilDocumento16 páginasTextilSalim Akhtar KhanAinda não há avaliações

- The Future of The Textile Processing Geotextile Structures andDocumento7 páginasThe Future of The Textile Processing Geotextile Structures andProf.dr Vojislav GligorijevicAinda não há avaliações

- Fabric Science: Submitted By: Indranil Saha (7) Surbhi Goyal (18) B.Ftech Semester IvDocumento32 páginasFabric Science: Submitted By: Indranil Saha (7) Surbhi Goyal (18) B.Ftech Semester IvIndranil SahaAinda não há avaliações

- Textiles in SportsDocumento5 páginasTextiles in SportsRagini MukherjeeAinda não há avaliações

- From 3D Scan To Body Pressure of Compression Garments: Liz, Malengier B, Vasile S, Cools J, Van Langenhove LDocumento6 páginasFrom 3D Scan To Body Pressure of Compression Garments: Liz, Malengier B, Vasile S, Cools J, Van Langenhove LTsehaytu AberaAinda não há avaliações

- A Pilot Study: Evaluating The Influence of Knitting Patterns and Densities On Fabric Properties For Sports ApplicationsDocumento5 páginasA Pilot Study: Evaluating The Influence of Knitting Patterns and Densities On Fabric Properties For Sports Applicationsmihret henokAinda não há avaliações

- (GAM) Uso Sistemático de Superficies Elasticas en El Proceso de EntrenamientoDocumento10 páginas(GAM) Uso Sistemático de Superficies Elasticas en El Proceso de EntrenamientoNassim asenAinda não há avaliações

- Analysis of The Performance Properties of Knitted Fabrics Containing ElastaneDocumento18 páginasAnalysis of The Performance Properties of Knitted Fabrics Containing ElastaneSudipto BeheraAinda não há avaliações

- Breakage of SpandexDocumento20 páginasBreakage of SpandexEhsaas RifatAinda não há avaliações

- Selected Medical and Automotive Products Produced On Weft and Warp Knitting EquipmentDocumento17 páginasSelected Medical and Automotive Products Produced On Weft and Warp Knitting EquipmentAyşe Feyza YılmazAinda não há avaliações

- Customization of A Lightweight Ballistic Vest: November 2008Documento8 páginasCustomization of A Lightweight Ballistic Vest: November 2008LatwPIATAinda não há avaliações

- Fabric Weight For KnitDocumento36 páginasFabric Weight For KnitMohammad Zahirul IslamAinda não há avaliações

- Riginal Rticles A Study of The Effects of Machine Gauge and Some Knit Structures On The Physical Properties of Weft Knitted FabricsDocumento7 páginasRiginal Rticles A Study of The Effects of Machine Gauge and Some Knit Structures On The Physical Properties of Weft Knitted Fabricserica_burton8232Ainda não há avaliações

- 10.1080 00405000.2018.1470451Documento8 páginas10.1080 00405000.2018.1470451mohammadi.m1324Ainda não há avaliações

- Dynamic Elastic Behavior of Cotton and Cotton / Spandex Knitted FabricsDocumento8 páginasDynamic Elastic Behavior of Cotton and Cotton / Spandex Knitted Fabricsyogesh123789Ainda não há avaliações

- Prakash 2013Documento9 páginasPrakash 2013haremboraAinda não há avaliações

- Analysis of Mechanical and Dimensional Properties of The Denim Fabrics Produced With Double-Core and Core-Spun Weft Yarns With Different Weft DensitiesDocumento9 páginasAnalysis of Mechanical and Dimensional Properties of The Denim Fabrics Produced With Double-Core and Core-Spun Weft Yarns With Different Weft DensitiesTahir NizamAinda não há avaliações

- Ijftr 33 (3) 239-245Documento0 páginaIjftr 33 (3) 239-245Sivakumar KAinda não há avaliações

- Effect of Yarn CountDocumento12 páginasEffect of Yarn CountSyed Salahuddin MunnaAinda não há avaliações

- Effect of Elastane Plating On Physical Thermal Comfort Properties of Lyocell Single Jersey Knit Fabric With Different Loop LengthDocumento9 páginasEffect of Elastane Plating On Physical Thermal Comfort Properties of Lyocell Single Jersey Knit Fabric With Different Loop LengthMuhammad Bilal QadirAinda não há avaliações

- Moussa Et Al 2015 Development and Optimisation of Waterproof Breathable Double Sided Knitting Using A FactorialDocumento30 páginasMoussa Et Al 2015 Development and Optimisation of Waterproof Breathable Double Sided Knitting Using A FactorialHatice HaticeAinda não há avaliações

- Curtains Fringe and Passementerie Strips of Lace Design Elements in Current Height Fashion in Mahalet MarhoumDocumento18 páginasCurtains Fringe and Passementerie Strips of Lace Design Elements in Current Height Fashion in Mahalet Marhoumayanogemechu58Ainda não há avaliações

- Ijftr 36 (3) 300-307 PDFDocumento8 páginasIjftr 36 (3) 300-307 PDFTheTaftabitaAinda não há avaliações

- Parative FullDocumento10 páginasParative FullTJPRC PublicationsAinda não há avaliações

- Methodology For The Selection of Chemical Textile Products: Oscar F. Toro, Alexia Pardo Figueroa & Brigitte M. LaricoDocumento8 páginasMethodology For The Selection of Chemical Textile Products: Oscar F. Toro, Alexia Pardo Figueroa & Brigitte M. LaricoTJPRC PublicationsAinda não há avaliações

- StretchDocumento7 páginasStretchDaniel Ramos VaraAinda não há avaliações

- Biomimetics: Finite Element Analysis of Orthopedic Hip Implant With Functionally Graded Bioinspired Lattice StructuresDocumento16 páginasBiomimetics: Finite Element Analysis of Orthopedic Hip Implant With Functionally Graded Bioinspired Lattice StructuresAli Cem GöçerAinda não há avaliações

- A Study of Waterproof SeamsDocumento2 páginasA Study of Waterproof SeamsAbhishek KumarAinda não há avaliações

- In - Search - of - The - Right - Trouser - Pattern - Body ShapesDocumento6 páginasIn - Search - of - The - Right - Trouser - Pattern - Body ShapesX sitmgAinda não há avaliações

- Overlock-Stitched Stretch Sensors: Characterization and Effect of Fabric PropertyDocumento14 páginasOverlock-Stitched Stretch Sensors: Characterization and Effect of Fabric PropertyDÃljït SīñghAinda não há avaliações

- Thermo Comfort of Single JerseyDocumento22 páginasThermo Comfort of Single Jerseyamaury cosmeAinda não há avaliações

- 1 PBDocumento6 páginas1 PBmohitAinda não há avaliações

- Finite Element Analysis of Contact Pressures Between Seat Cushion and Human Buttock-Thigh TissueDocumento7 páginasFinite Element Analysis of Contact Pressures Between Seat Cushion and Human Buttock-Thigh TissuePuneet BahriAinda não há avaliações

- S NgcoboDocumento15 páginasS Ngcoboselulekongcobo123Ainda não há avaliações

- Knitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Documento5 páginasKnitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Pradeep AhireAinda não há avaliações

- Active Sports Wear FabricDocumento7 páginasActive Sports Wear Fabricsagaranju100% (1)

- FEI1020Documento5 páginasFEI1020priyaAinda não há avaliações

- Elastane FabricDocumento8 páginasElastane FabricMaria MirandaAinda não há avaliações

- Clothing Pressure Modeling 2019Documento14 páginasClothing Pressure Modeling 2019Yehualaw AyresamAinda não há avaliações

- Dynamic Impact Surface Damage Analysis of 3D Woven para Aramid Armour Panels Using NDI TechniqueDocumento22 páginasDynamic Impact Surface Damage Analysis of 3D Woven para Aramid Armour Panels Using NDI TechniqueMaialen Espinal ViguriAinda não há avaliações

- Comfort Properties of Bi-Layer Knitted Fabrics - Knitting & Hosiery - Features - The ITJ PDFDocumento12 páginasComfort Properties of Bi-Layer Knitted Fabrics - Knitting & Hosiery - Features - The ITJ PDFAhmad SamerAinda não há avaliações

- Spacer FabricDocumento6 páginasSpacer FabricAnonymous 1pZlqV100% (1)

- Ballistic Impact Mechanisms - A Review On Textiles and Fibre-Reinforced Composites Impact ResponsesDocumento63 páginasBallistic Impact Mechanisms - A Review On Textiles and Fibre-Reinforced Composites Impact ResponsesKhurram ShehzadAinda não há avaliações

- Factors Influencing Comfort Properties of TextilesDocumento6 páginasFactors Influencing Comfort Properties of TextilesMohammed Atiqul Hoque Chowdhury100% (1)

- ATY Fabric PropertiesDocumento5 páginasATY Fabric PropertiesHitesh ShahAinda não há avaliações

- Design Methods Report OutlineDocumento7 páginasDesign Methods Report OutlineHATICE BEYZA YILMAZAinda não há avaliações

- IMPLIMENTING ERGONOMICS IN IT MEN FORMAL APPAREL - Pavataarini - PriyankaDocumento15 páginasIMPLIMENTING ERGONOMICS IN IT MEN FORMAL APPAREL - Pavataarini - PriyankaPAVATAARINI PAVATAARINIAinda não há avaliações

- Applied Ergonomics: Y.J. Wang, P.Y. Mok, Y. Li, Y.L. KwokDocumento13 páginasApplied Ergonomics: Y.J. Wang, P.Y. Mok, Y. Li, Y.L. KwokDairy.PandaartAinda não há avaliações

- 2 29 1645708157 2ijtftjun20222Documento8 páginas2 29 1645708157 2ijtftjun20222TJPRC PublicationsAinda não há avaliações

- Comparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanDocumento8 páginasComparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanTJPRC PublicationsAinda não há avaliações

- Flame Retardant Textiles For Electric Arc Flash Hazards: A ReviewDocumento18 páginasFlame Retardant Textiles For Electric Arc Flash Hazards: A ReviewTJPRC PublicationsAinda não há avaliações

- Baluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaDocumento14 páginasBaluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaTJPRC PublicationsAinda não há avaliações

- 2 33 1641272961 1ijsmmrdjun20221Documento16 páginas2 33 1641272961 1ijsmmrdjun20221TJPRC PublicationsAinda não há avaliações

- 2 4 1644229496 Ijrrdjun20221Documento10 páginas2 4 1644229496 Ijrrdjun20221TJPRC PublicationsAinda não há avaliações

- Development and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateDocumento10 páginasDevelopment and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateTJPRC PublicationsAinda não há avaliações

- 2 51 1656420123 1ijmpsdec20221Documento4 páginas2 51 1656420123 1ijmpsdec20221TJPRC PublicationsAinda não há avaliações

- Effectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewDocumento14 páginasEffectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewTJPRC PublicationsAinda não há avaliações

- 2 52 1649841354 2ijpslirjun20222Documento12 páginas2 52 1649841354 2ijpslirjun20222TJPRC PublicationsAinda não há avaliações

- 2 31 1648794068 1ijpptjun20221Documento8 páginas2 31 1648794068 1ijpptjun20221TJPRC PublicationsAinda não há avaliações

- 2 52 1642055366 1ijpslirjun20221Documento4 páginas2 52 1642055366 1ijpslirjun20221TJPRC PublicationsAinda não há avaliações

- The Conundrum of India-China Relationship During Modi - Xi Jinping EraDocumento8 páginasThe Conundrum of India-China Relationship During Modi - Xi Jinping EraTJPRC PublicationsAinda não há avaliações

- Using Nanoclay To Manufacture Engineered Wood Products-A ReviewDocumento14 páginasUsing Nanoclay To Manufacture Engineered Wood Products-A ReviewTJPRC PublicationsAinda não há avaliações

- 2 44 1653632649 1ijprjun20221Documento20 páginas2 44 1653632649 1ijprjun20221TJPRC PublicationsAinda não há avaliações

- Covid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangDocumento8 páginasCovid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangTJPRC PublicationsAinda não há avaliações

- 2 51 1651909513 9ijmpsjun202209Documento8 páginas2 51 1651909513 9ijmpsjun202209TJPRC PublicationsAinda não há avaliações

- 2 51 1647598330 5ijmpsjun202205Documento10 páginas2 51 1647598330 5ijmpsjun202205TJPRC PublicationsAinda não há avaliações

- Dr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahDocumento12 páginasDr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahTJPRC PublicationsAinda não há avaliações

- Vitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019Documento16 páginasVitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019TJPRC PublicationsAinda não há avaliações

- Self-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsDocumento8 páginasSelf-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsTJPRC PublicationsAinda não há avaliações

- An Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaDocumento10 páginasAn Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaTJPRC PublicationsAinda não há avaliações

- A Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)Documento8 páginasA Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)TJPRC PublicationsAinda não há avaliações

- 2 67 1645871199 9ijmperdfeb202209Documento8 páginas2 67 1645871199 9ijmperdfeb202209TJPRC PublicationsAinda não há avaliações

- 2 67 1645017386 8ijmperdfeb202208Documento6 páginas2 67 1645017386 8ijmperdfeb202208TJPRC PublicationsAinda não há avaliações

- Analysis of Bolted-Flange Joint Using Finite Element MethodDocumento12 páginasAnalysis of Bolted-Flange Joint Using Finite Element MethodTJPRC PublicationsAinda não há avaliações

- Effect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementDocumento8 páginasEffect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementTJPRC PublicationsAinda não há avaliações

- 2 67 1653022679 1ijmperdjun202201Documento12 páginas2 67 1653022679 1ijmperdjun202201TJPRC PublicationsAinda não há avaliações

- 2 67 1648211383 1ijmperdapr202201Documento8 páginas2 67 1648211383 1ijmperdapr202201TJPRC PublicationsAinda não há avaliações

- Numerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingDocumento18 páginasNumerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingTJPRC PublicationsAinda não há avaliações

- Denver Equipment Company Handbook - IndexDocumento6 páginasDenver Equipment Company Handbook - IndexCristiam MercadoAinda não há avaliações

- 카달로그 - Metal Plug ValveDocumento22 páginas카달로그 - Metal Plug Valvetazghat beghdadiAinda não há avaliações

- Wire DrawingDocumento4 páginasWire DrawingSolomon NgussieAinda não há avaliações

- Mori Seiki ZT 1000 y enDocumento16 páginasMori Seiki ZT 1000 y enOswald muñoz100% (1)

- THK Paint Defects GB PDFDocumento24 páginasTHK Paint Defects GB PDFmaddyAinda não há avaliações

- Cement 12Documento24 páginasCement 12prashannapandit832Ainda não há avaliações

- LG 38LV - 20210324Documento97 páginasLG 38LV - 20210324sybreed88Ainda não há avaliações

- Reverse Osmosis DETAILSDocumento38 páginasReverse Osmosis DETAILSgkdora574100% (1)

- 0.drying Heat Pumps-Part IDocumento17 páginas0.drying Heat Pumps-Part IDr-Abhijit SinhaAinda não há avaliações

- What Really Happens To The Plastic You Throw Away?: Emma Bryce - TED-EdDocumento1 páginaWhat Really Happens To The Plastic You Throw Away?: Emma Bryce - TED-EdJennefer Gudao AranillaAinda não há avaliações

- Lot - 1 Weekly Progress ReportDocumento14 páginasLot - 1 Weekly Progress ReportMesfin DerbewAinda não há avaliações

- Sonalika Training ReportDocumento64 páginasSonalika Training Report3drohit100% (4)

- CASE 7 71427 PreviewDocumento51 páginasCASE 7 71427 PreviewOneplayerAinda não há avaliações

- Breathing-Air-Purifiers Atlas CapcoDocumento6 páginasBreathing-Air-Purifiers Atlas CapcoVara PrasadAinda não há avaliações

- Science 5 Q1 WK7Documento12 páginasScience 5 Q1 WK7ivy loraine enriquezAinda não há avaliações

- Dikin VRVDocumento52 páginasDikin VRVahmedomar_953724702Ainda não há avaliações

- Deaeration Technique DT199505 - A01Documento3 páginasDeaeration Technique DT199505 - A01smallik3Ainda não há avaliações

- Material EquilentDocumento16 páginasMaterial EquilentShoaib JadoonAinda não há avaliações

- IQP Final Report 2Documento81 páginasIQP Final Report 2Mohamed NasrAinda não há avaliações

- Psych Exercise02 SolutionsDocumento9 páginasPsych Exercise02 Solutionsjasson ponce100% (3)

- Natural Fibers Plastics and Composites 2004 PDFDocumento368 páginasNatural Fibers Plastics and Composites 2004 PDFMaria Inês Vasconcellos FurtadoAinda não há avaliações

- Iso 8179-1-2017Documento16 páginasIso 8179-1-2017Ahmed AliAinda não há avaliações

- ZJP Roots Vacuum Pump - Manual - 1ED.20200422.ENDocumento17 páginasZJP Roots Vacuum Pump - Manual - 1ED.20200422.ENLuisAngelChavezAinda não há avaliações

- 1sbc100122c0202 ch04Documento47 páginas1sbc100122c0202 ch04mathankumar1980Ainda não há avaliações

- Safe Furnace and Boiler Firing (2012) PDFDocumento96 páginasSafe Furnace and Boiler Firing (2012) PDFFrank Seipel6100% (1)

- Saybrook: Pull-Down Filtered Kitchen FaucetDocumento2 páginasSaybrook: Pull-Down Filtered Kitchen FaucetCasper John Nanas MuñozAinda não há avaliações

- The Effect of ShearDocumento11 páginasThe Effect of Shearanakren296Ainda não há avaliações

- PV 1303Documento10 páginasPV 1303tufantasma100% (2)

- Karl Fisher TitrimeterDocumento5 páginasKarl Fisher TitrimeterKhalid ZghearAinda não há avaliações

- CX1Documento7 páginasCX1acceleron8Ainda não há avaliações