Escolar Documentos

Profissional Documentos

Cultura Documentos

Cooling PDF

Enviado por

jokishTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cooling PDF

Enviado por

jokishDireitos autorais:

Formatos disponíveis

ENERGY CONSERVATION TIPS TOTAL FOR ENERGY COOLING TOWER CONSULTANT

Control cooling tower fans based on leaving water temperatures. Control to the optimum water temperature as determined from cooling tower and chiller performance data. Use two-speed or variable-speed drives for cooling tower fan control if the fans are few. Stage the cooling tower fans with on-off control if there are many. Turn off unnecessary cooling tower fans when loads are reduced. Cover hot water basins (to minimize algae growth that contributes to fouling). Balance flow to cooling tower hot water basins. Periodically clean plugged cooling tower water distribution nozzles. Install new nozzles to obtain a more-uniform water pattern. Replace splash bars with self-extinguishing PVC cellular-film fill. On old counter flow cooling towers, replace old spray-type nozzles with new square-spray ABS practically-non-clogging nozzles. Replace slat-type drift eliminators with high-efficiency, low-pressuredrop, self-extinguishing, PVC cellular units. If possible, follow manufacturer's recommended clearances around cooling towers and relocate or modify structures, signs, fences, dumpsters, etc. that interfere with air intake or exhaust. Optimize cooling tower fan blade angle on a seasonal and/or load basis. Correct excessive and/or uneven fan blade tip clearance and poor fan balance. Use a velocity pressure recovery fan ring. Divert clean air-conditioned building exhaust to the cooling tower during hot weather. Re-line leaking cooling tower cold water basins. Check water overflow pipes for proper operating level. Optimize chemical use. Consider side stream water treatment. Restrict flows through large loads to design values. Shut off loads that are not in service. Take blow down water from the return water header. Optimize blow down flow rate. Automate blow down to minimize it.

ELECTRICAL UTILITY www.totalenergyconsultant.com

ENERGY CONSERVATION TIPS TOTAL FOR ENERGY COOLING TOWER CONSULTANT

Send blow down to other uses (Remember, the blow down does not have to be removed at the cooling tower. It can be removed anywhere in the piping system.) Implement a cooling tower winterization plan to minimize ice build-up. Install interlocks to prevent fan operation when there is no water flow. Establish a cooling tower efficiency-maintenance program. Start with an energy audit and follow-up, then make a cooling tower efficiencymaintenance program a part of your continuous energy management program.

ELECTRICAL UTILITY

www.totalenergyconsultant.com

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Notes On Plant Layout Part 1Documento1 páginaNotes On Plant Layout Part 1jokishAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Objectives Boiler Water TreatmentDocumento1 páginaObjectives Boiler Water TreatmentjokishAinda não há avaliações

- How A Steam Jet EjectorDocumento1 páginaHow A Steam Jet EjectorjokishAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Bound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatDocumento1 páginaBound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatjokishAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- DryingDocumento1 páginaDryingjokishAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- What Is CommissioningDocumento1 páginaWhat Is CommissioningjokishAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Bound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatDocumento1 páginaBound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatjokishAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- DryingDocumento1 páginaDryingjokishAinda não há avaliações

- Pressure Relief DeviceDocumento1 páginaPressure Relief DevicejokishAinda não há avaliações

- Wire RopeDocumento1 páginaWire RopejokishAinda não há avaliações

- Applications of Liquid Ejectors and Jet PumpsDocumento1 páginaApplications of Liquid Ejectors and Jet PumpsjokishAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Jet PumpsDocumento3 páginasJet PumpsjokishAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Calculation of The LFL and UFL of MixturesDocumento1 páginaCalculation of The LFL and UFL of MixturesjokishAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- ConductanceDocumento1 páginaConductancejokishAinda não há avaliações

- Humid PDFDocumento4 páginasHumid PDFFrank MtetwaAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- How To Do Sundarkand Path & BenifitsDocumento1 páginaHow To Do Sundarkand Path & BenifitsjokishAinda não há avaliações

- BafflesDocumento1 páginaBafflesjokishAinda não há avaliações

- Chemical Engineering ReferenceDocumento2 páginasChemical Engineering Referencejokish0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Impeller TypesDocumento1 páginaImpeller TypesjokishAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Mixing and AgitationDocumento1 páginaMixing and AgitationjokishAinda não há avaliações

- EjectorsDocumento1 páginaEjectorsjokishAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Typical Overall Heat-Transfer CoefficientsDocumento2 páginasTypical Overall Heat-Transfer CoefficientsjokishAinda não há avaliações

- Preliminary Heat Exchanger Design ExampleDocumento4 páginasPreliminary Heat Exchanger Design ExamplejokishAinda não há avaliações

- Stress AnalysisDocumento1 páginaStress AnalysisjokishAinda não há avaliações

- Natural Draft Cooling TowersDocumento2 páginasNatural Draft Cooling TowersjokishAinda não há avaliações

- Fundamentals of Heat Exchanger Theory and DesignDocumento3 páginasFundamentals of Heat Exchanger Theory and DesignSakthikumar ChandrasekaranAinda não há avaliações

- Intro To Mechanical Draft CoolersDocumento1 páginaIntro To Mechanical Draft CoolersjokishAinda não há avaliações

- Systems Review: Systems Are Defined As A Set of Interacting or Interdependent Equipment and ProcessDocumento2 páginasSystems Review: Systems Are Defined As A Set of Interacting or Interdependent Equipment and ProcessjokishAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- FansDocumento1 páginaFansjokishAinda não há avaliações

- PumpsDocumento1 páginaPumpsjokishAinda não há avaliações

- Mineral Wool Compressive PropertiesDocumento10 páginasMineral Wool Compressive Propertiespturner890Ainda não há avaliações

- "Monorail" - Monorail Beam Analysis: Program DescriptionDocumento14 páginas"Monorail" - Monorail Beam Analysis: Program DescriptionYash SutharAinda não há avaliações

- M04 Read and Interpret PlansDocumento113 páginasM04 Read and Interpret Plansmustied mohammed100% (1)

- Construction Guidelines - SM LucenaDocumento30 páginasConstruction Guidelines - SM Lucenaconeyqu0% (1)

- Atal Mission For Rejuvenation and Urban TransformationDocumento3 páginasAtal Mission For Rejuvenation and Urban TransformationAshutosh MasgondeAinda não há avaliações

- Florida Heat PumpDocumento12 páginasFlorida Heat PumpGhiban ConstantinAinda não há avaliações

- MS-CVL-009 Erection of Hollowcore Slabs 1Documento12 páginasMS-CVL-009 Erection of Hollowcore Slabs 1Suju RajanAinda não há avaliações

- Tension MembersDocumento48 páginasTension MembersNIBEDITA DEYAinda não há avaliações

- Fire Sprinkler Systems#Documento8 páginasFire Sprinkler Systems#aimiza50% (2)

- Glass Powder PropertiesDocumento7 páginasGlass Powder PropertiesMR. ESHAN GHARPUREAinda não há avaliações

- UM-min PDFDocumento44 páginasUM-min PDFIsidro Ochotorena BeunzaAinda não há avaliações

- Through Hardening ProcessesDocumento3 páginasThrough Hardening ProcessesPurushothama Nanje Gowda100% (2)

- Standard Cement LiningDocumento3 páginasStandard Cement Liningjungzki100% (1)

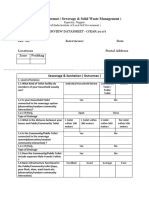

- Field Survey Format (Sewerage & Solid Waste Management) : Equicity, NagpurDocumento3 páginasField Survey Format (Sewerage & Solid Waste Management) : Equicity, Nagpurritesh MishraAinda não há avaliações

- CET 513 Lecturer NoteDocumento13 páginasCET 513 Lecturer NoteAminu AbdullahiAinda não há avaliações

- Comp - Statement of Lab EquipmentsDocumento8 páginasComp - Statement of Lab EquipmentsKumar gsAinda não há avaliações

- Sugarcane Bagasse BricksDocumento8 páginasSugarcane Bagasse BricksganeshAinda não há avaliações

- DD 210714Documento132 páginasDD 210714Ajay SinghAinda não há avaliações

- Perkins 1104C-44TA Parts Manual 161182Documento140 páginasPerkins 1104C-44TA Parts Manual 161182Vlad Ptashnichenko100% (5)

- CBX SeriesDocumento22 páginasCBX SeriesAtika AnjumAinda não há avaliações

- Classified 20230730 1Documento4 páginasClassified 20230730 1Qamar SikandarAinda não há avaliações

- Landscape Irrigation Products Catalog: The Intelligent Use of WaterDocumento196 páginasLandscape Irrigation Products Catalog: The Intelligent Use of WaterCosmin BonghezAinda não há avaliações

- Cement Manufacturing ProcessDocumento15 páginasCement Manufacturing ProcessJHON LHOYD CORPUZAinda não há avaliações

- Polypropylene: Sub-Group Description ApplicationsDocumento1 páginaPolypropylene: Sub-Group Description ApplicationsJulio GarcíaAinda não há avaliações

- HRCA SteelDocumento30 páginasHRCA SteelShankar PranavAinda não há avaliações

- Structural Engineer CVDocumento2 páginasStructural Engineer CVkarthikAinda não há avaliações

- Monotop 412 NFG PdsDocumento4 páginasMonotop 412 NFG PdsJames MizziAinda não há avaliações

- Production RateDocumento50 páginasProduction RateFührer Magdi Badran100% (2)

- 9999999999999999FAQs About Mechanical Splices - ETN-M-4-14 PDFDocumento8 páginas9999999999999999FAQs About Mechanical Splices - ETN-M-4-14 PDFSeahorseAinda não há avaliações

- WO Mechanical Car ParkDocumento27 páginasWO Mechanical Car ParkrohanbagadiyaAinda não há avaliações

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationNo EverandPractical Reservoir Engineering and CharacterizationNota: 4.5 de 5 estrelas4.5/5 (3)

- Abrasive Water Jet Perforation and Multi-Stage FracturingNo EverandAbrasive Water Jet Perforation and Multi-Stage FracturingAinda não há avaliações